A subfloor is required for laying “small-piece” or “soft” floor coverings. The article describes the features of arranging wooden floors, which are often used in houses, and the choice of materials, which is determined by the type of foundation and the type of finishing floor covering. Schemes and stages of work on arranging the subfloor are described. After reading the article, you will learn how to make a reliable, durable subfloor with a flat surface.

The subfloor is the top part of the floor pie Source belinastroy.ru

Kinds

The most common option for a subfloor in a frame or wooden house (or “black”) is to create a durable flooring supported by beams. But for the first floor it is also possible when the logs are installed on a reinforced concrete slab floor on a strip foundation, on a shallow foundation slab or on a concrete floor on the ground. The last three options are not fundamentally different from each other, although in all cases the methods of fastening and leveling the logs horizontally are different.

Since the concrete base itself is strong and reliable, it can be considered as the “underlying” part of the floor of the lower floor (according to the regulatory terminology SNiP 2.03.13-88). In this case, it remains to equip only the “leveling” part (wet, dry or prefabricated screed) and the “intermediate” part (heat, vapor and waterproofing). And lay the finishing coating over the leveling part.

Concrete floors laid on the ground are another common option Source remontik.org

The subfloor is only part of the wooden floor. It is made from edged boards and sheets of moisture-resistant wood materials. The thickness of the flooring (board or sheet) and the layout of the logs have a “direct” relationship: less thickness means less interval between runs.

Important! If we are talking about boards, then when laying diagonally (for example, in rooms with complex geometry), the pitch of the lag should be even smaller. Moreover, the angle between the board and the purlin must be greater than 45°.

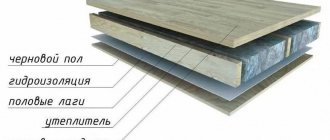

Wood flooring is the top layer of the cake. Layer by layer the entire structure looks like this:

- Lining . It does not affect the load-bearing properties of the ceiling, but acts as a support for insulating materials.

The thickness of the lining must be sufficient to support the weight of the insulation Source doma-na-veka.ru

- Waterproofing . Membrane type materials are used. They do not allow water to pass through, but allow water vapor to erode from the insulation, which then exits through the vents in the basement (plinth) of the foundation.

- Thermal insulation . Usually these are mineral wool mats, which, unlike polystyrene foam, are non-flammable materials.

- Vapor barrier . There are three types in total. Films with limited vapor permeability that maintain a “balance” between moisture transfer from the room into the insulation and from the insulation to the outside. Vapor-tight films are a vapor barrier that almost completely excludes the penetration of warm air with water vapor into the insulation. Foil materials (reflex films) are a vapor barrier that returns some of the heat back into the room. All three types, as befits a vapor barrier, have waterproof properties that protect the insulation from above, from the side of the room, from water ingress.

- Flooring.

A multilayer sheet of plywood for the subfloor will withstand heavy loads Source yug-energo.ru

See also: Catalog of companies that specialize in the design and construction of turnkey country houses.

Design Features

At the base of the floor on wooden logs are beams (joists). These are beams made of wood or polymer materials, laid parallel to each other, which serve as support for the sheet material. This is one of the most common options for creating a subfloor.

It is distinguished by:

- sufficient ease of installation;

- low cost of material;

- significant increase in floor strength;

- uniform load distribution;

- ease of installation of thermal insulation and noise protection.

It is impossible not to note the versatility of this type of subfloor. Logs can be laid on the ground, wooden or concrete surfaces; of course, in all cases it is important to ensure maximum protection of the wood from moisture. The result of work done correctly will be a dry, ventilated subfloor, which will have a positive effect on the characteristics of the floor and the structure as a whole.

Device options

There are two main filing options:

- Under the beams . The disadvantage of this method is that in the subfloor of the house there is often not enough “space” to carry out the fastening procedure. The advantage is that almost the entire volume between the beams can be used for insulation. Only when reflective vapor barrier materials are laid should a small gap be left between the film and the flooring.

Fastening to each beam, on both sides of the “opening”, cranial bars - a lining is mounted to them. The most common and easy to implement method. The disadvantage is that the insulation layer will be less than the thickness of the skull block plus the lining.

This is what the floor plan with filing to the cranial block looks like Source derevyannyydom.com

- On top of the beams . Disadvantage - the height of the logs is chosen greater than the thickness of the insulation. As an option, it is possible to lay an additional counter-lattice on top of the logs for another layer of thermal insulation.

In principle, such a complex ceiling device is only necessary for a heated residential building. In a garden or country house for seasonal use, you can limit yourself to only wooden flooring without filing and insulation, although waterproofing in this case must also be laid to protect the wood from moisture.

Important! All wooden elements, from the sheathing to the flooring, must be impregnated with antiseptics and fire retardants. And after sawing and drilling, the ends must be treated again with these compounds using a brush.

Fire and bioprotection is a mandatory stage in the processing of wood working in extreme conditions Source derevovdom.ru

Insulation technology

It is best to consider the insulation of the floor along the joists visually, with options for installing various types of heat insulators. But first, a series of preparatory work should be carried out with the wooden structure.

Advice

If the thermal insulation layer will be installed in an old structure, a thorough inspection of the wooden floor should be carried out.

During long-term use, wooden elements could be exposed to moisture or mold, which leads to a deterioration in their performance properties. Therefore, they are carefully checked and, as necessary, restoration work or complete replacement is carried out. This procedure is not required when laying new floors.

After this, you can begin installing the insulation. Regardless of its type, the subfloor is waterproofed first. Often it is also made of wooden boards; it is much less common to find a soil base. In the latter case, the beams are attached to the walls of the building and to the ground using special supporting structures.

After checking the condition, you can begin installing the thermal insulation layer. The general scheme is the following design.

The order of work is as follows:

- Formation of the internal waterproofing layer. To do this, you need to use special mixtures. It is best to treat the base before its installation - in this way you can ensure maximum impregnation with the waterproofing compound. Most often, bitumen mastic with the addition of polymer components is used for this. It is necessary to treat both the outer and inner surfaces of the flooring.

The use of rolled materials is not recommended. During operation, a condensation film may form between the boards and the film, which will be absorbed by the wood. The reason for this phenomenon is the temperature difference between the foundation plane and the inner surface of the board. Often the dew point is located right here, which leads to condensation in winter.

- Installation of lag. If load-bearing wooden structures have not yet been installed, they must also be treated with protective waterproofing material. During their installation, the optimal distance between the lags should be taken into account. It depends on the width of the span and the size of the installed beams.

If the installation takes place on a brick or concrete wall, you need to arrange the place where the beams and load-bearing structures of the building are connected. For this, it is best to use rolled waterproofing material, such as roofing felt. Once installation is complete, you can proceed directly to insulation.

- Installation of thermal insulation. The choice of insulation installation technology directly depends on its type. For rolled materials (basalt wool), it is enough to spread the material on the surface of the subfloor. During work, it is important to minimize the size of the gaps between the layers. Due to the fact that the height of the logs is often 250 mm, several layers can be installed. It is recommended to develop the scheme in such a way that the joints of each subsequent one do not coincide with the previous one. This is required to prevent the appearance of so-called cold bridges - zones where the temperature will be significantly lower than in the main thermal insulation layer.

Advice

For sheet material (foam plastic, extruded polystyrene foam), it is not recommended to fasten it using mounting dowels. Since individual thermal insulation elements will be located between the beams, it is important to correctly draw up a plan for cutting them. When closely connected to each other, an optimal energy saving factor will be ensured. The absence of mechanical load helps to preserve the primary arrangement of insulating sheets.

If bulk heat-insulating materials - expanded clay - are used, the composition must first be prepared. To do this, mix components of different fractions (from 10 to 20 mm), and then evenly fill the space between the logs.

- Ventilation gap. Before installing the main covering (boards or solid ceiling), an air gap is created between it and the thermal insulation. It is best to install wooden slats on the surface of the beams for this. With their help, you can create ventilation voids necessary to remove moisture and level the finishing surface.

Material requirements

The following materials are usually chosen for flooring :

- edged board;

- waterproof plywood;

- Fiberboard or chipboard with waterproof treatment;

- OSB plate;

- cement particle board (CSB) or GVL.

Recommended ratio between board thickness and joist layout Source semanticscholar.org

Plywood is stronger due to its multi-layer structure, and it is much thinner for a subfloor.

Necessary tools and building materials

Tools for screeding

There are several different technologies for laying subfloors. This requires different materials, but the same tools. The main list includes:

- devices for removing the old floor if repairs are being made;

- construction or laser level, tape measure, corner;

- shovels, trowels, wood hacksaws, jigsaws;

- screwdriver, drill, grinder;

- beacons and rules for leveling the screed;

- concrete mixer for preparing concrete;

- thermal insulation materials – the latter are recommended to be kept indoors for about a day before installation;

- waterproofing – roofing felt, films, membranes, coating compounds;

- vapor barrier - not always required;

- materials for dry screed - chipboard, waterproof plywood, GPV sheet.

Other tools may be required to install the subfloor.

Classic scheme

A feature of the classic scheme is the significant distance between the beams.

Typically, the layout step is 0.8-1 m, and this is “reflected” in the choice of board thickness.

This is what a “powerful” log house floor looks like Source ukrasheniyedoma.com

A typical subfloor structure looks like this:

- timber with a section of 15x15 or 15x20 cm;

- cranial block with a cross section of 4x4 cm;

- hemming with a board 2.0 cm thick (can be unedged, but cleared of wane) or plywood 1.5 cm thick;

- waterproofing (glassine, polymer membrane);

- insulation (stone wool) no more than 10 cm thick - this is all that the remaining volume between the beams allows after installing the cranial block with filing;

- vapor barrier;

- board 4.5-5.0 cm thick.

And now this design is used, but it no longer meets modern requirements for thermal protection. Therefore, a counter-lattice is mounted on top of the beams, between which another layer of thermal insulation is laid.

Another advantage of this method is that the layout of the logs can be reduced to 30-40 cm, and subfloor boards can be chosen with a thickness of 20-24 mm.

Scheme of complex insulation of a frame house with a double thermal insulation contour of the floor and mesh as a backing Source obustroeno.com

The modern scheme for laying a subfloor for a wooden house is more advanced and allows you to insulate the floor without additional “superstructures” in the form of a counter-lattice:

- Boards placed on edge . Fixed to the beam, and, if necessary, supported by intermediate supports, they act as logs. The thickness of the board is 5 cm, and the width is at least 20 cm. The layout step can be made 60 cm (to match the width of the stone wool rolls), and in terms of wood consumption for purlins, this option is more economical than the classic scheme.

- Polymer (wire mesh) for supporting waterproofing and insulation.

- wind and waterproofing film . Allows excess moisture to evaporate, protects the insulation from water ingress and weathering of fibers.

- Stone wool in the form of semi-rigid mats 20 cm thick.

- Vapor barrier.

- Flooring made of boards 36 mm thick.

The only drawback of the modern scheme is the poor stability of the lag. This is due to the large difference between the width (the supporting part) and the height. To ensure the stability of the structure, additional transverse braces are used that “connect” the logs to each other and to the frame (grillage).

Typical ceiling of the first floor of a frame house made of boards on the “edge” Source stranapap.ru

The advantages of the scheme are obvious - savings on lumber (in “volume” equivalent) and a simple one-layer insulation scheme.

Subfloor of the second floor (attic) or cold attic

There are no living rooms under the wooden floor of the first floor, so “simple” materials can be used for lining without finishing or decorative surface treatment. The interfloor ceiling is hemmed from below with planed boards or clapboard.

And although insulation of the floor between heated floors is not required, mineral wool is placed between the joists. In this flooring pie it acts as sound insulation. Ideally, you should use acoustic wool. It differs from the usual one in its “chaotic” fibrous structure. But heat-insulating modifications can also be laid - with the same thickness and density, their sound absorption coefficient is only 10-15% lower than that of acoustic ones.

The ceiling of a cold attic must be insulated.

Installation of a cold attic ceiling begins with attaching a vapor barrier Source legkovmeste.ru

And since in a low-rise building even an “uninhabited” attic is used, the insulation must be covered with a subfloor (but without further finishing).

The ceiling diagram of a cold attic looks like this (from bottom to top):

- false ceiling of the underlying heated floor;

- vapor barrier laid in a continuous and continuous layer with sealing tape along the entire perimeter of the ceiling;

- insulation between beams (lag);

- membrane-type waterproofing laid on the surface of stone wool;

- spacer bar stuffed onto the beams, providing a ventilation gap;

- attic subfloor.

Important! The layer-by-layer structure does not reflect the installation sequence. At the first stage, a vapor barrier film is attached to the bottom of the floor beams. And on top of it, a block is mounted on the beams, to which the sheathing for the false ceiling is attached. If you first hem the boards, the film will have to be laid on top of the beams. In this case, water vapor will penetrate into the wood, but there will be nowhere for it to erode, which will lead to wetness of the floor beams and create conditions for their rotting.

Wood selection

Repairing the foundation along beams involves using only high-quality and durable wood that can withstand large static and dynamic loads over a long period. That is why in the process of choosing logs you need to take into account the following parameters:

- Section. The minimum cross-section of logs for floors in private houses is 15 by 15 cm;

- Dimensions. In the process of laying beams into “sockets”, it is desirable that the distance between them and the wall is at least 10-15 mm;

- Tree species. For installation of floors, larch of the 2nd or 3rd grade is suitable;

- Humidity. The maximum moisture content of materials can only be 12-15%. Since wood absorbs moisture, additional treatment of the logs with antiseptics will be required when laying the floor.

Subfloor under tiles

The technology of how to properly make the subfloor of a wooden house for laying tiles has its own characteristics if a board is chosen for the flooring.

Tiles in a wooden house in some rooms are simply necessary due to the nature of their use Source et.aviarydecor.com

Unlike wood, ceramic tiles do not change their linear dimensions with changes in humidity levels. Moreover, wood reacts differently to such differences in the directions along and across the fibers. And to compensate for these changes, a “damper” layer must be laid on top of the boards.

Plywood or moisture-resistant plasterboard is chosen as the top layer of the leveling part of the subfloor. Although plywood is made of wood, it does not change its linear dimensions due to its multi-layer structure with multi-directional arrangement of fibers in each layer. But we must take into account that both materials are subject to deformation during prolonged contact with water or when used in a room with a “wet” regime. And in such areas, before laying the tiles, you need to make another waterproofing layer.

Plate

If a wooden house stands on a slab (foundation or ceiling on a brick plinth), then the floor of the first floor is equipped with a screed. In this case, the same technologies are used as in stone houses.

On a solid base, logs can even be installed on point adjustable supports Source pinterest.it

Even for installing a wooden subfloor, there is a choice among a wider list of methods:

- installing joists on supports on a concrete base without fixing them to the base and load-bearing walls (floating floor);

- installation of logs on adjustable supports;

- installation of adjustable plywood.

TOP 3 mineral wool manufacturers

| Photo | Name | Rating | Price | |

| #1 | Rockwoll | ⭐ 98 / 100 | More details | |

| #2 | Knauf | ⭐ 97 / 100 | More details | |

| #3 | Isover | ⭐ 96 / 100 | More details |

Rockwoll

The company is considered a market leader in the production of mineral wool. The manufacturer has a wide selection of products.

Rockwoll

pros

- environmental friendliness;

- fire safety;

- soundproofing;

- price-quality ratio;

- long service life;

- no shrinkage or shedding;

- Wide selection of sizes and packaging options.

Minuses

- Personal protective equipment is required when working.

Rockwoll mineral wool

Knauf

Knauf insulation products are safe materials produced using innovative technology and from natural ingredients.

Knauf

pros

- excellent heat and sound insulating properties;

- simple installation;

- non-flammable material;

- without smell;

- resistant to insects and rodents.

Minuses

- high price.

mineral wool Knauf

Isover

The material is supplied in rolls and slabs. The products are manufactured using special technology, which allows them to cope with the assigned tasks perfectly.

Roll insulation ISOVER

pros

- simple installation;

- affordable price;

- a wide range of;

- environmentally friendly material;

Minuses

- low resistance to moisture.

Isover mineral wool