Wooden buildings retain heat well. But if in warm climates the natural properties of wood are sufficient to maintain comfortable conditions in the house, then in regions with low winter temperatures the house must be additionally insulated. The heat insulator is installed on the walls, floor, ceiling - if any surface is left uncoated, the insulation of a wooden house from the inside will be less effective. It would be best to do the insulation during construction - it is much more difficult to carry out work in a habitable room

Insulation of a wooden house Source www.remontnik.ru

When installing insulation, a gap must be left between it and the finish for air circulation. This helps prevent the accumulation of moisture in the rooms, the appearance of mold and mildew.

How are wooden houses insulated inside?

Most often, houses made of timber are insulated inside with various types of construction wool - basalt (mineral), fiberglass and others. These are lightweight and affordable materials, environmentally friendly. The industry produces rolled and block types of wool.

Basalt wool retains heat well, but allows air to pass through. Thanks to this quality, fungus and mold do not appear in the rooms.

Rolled basalt wool Source fasad.guru

Glass wool absorbs a lot of moisture, so in order to avoid condensation, an additional layer of waterproofing is made for it. The big disadvantage of glass wool is its complex structure. The material is saturated with a large number of glass microparticles (hence the name). When working with cotton wool, they get into the respiratory organs and onto clothing. To work safely with glass wool, you need special clothing and a respirator.

All types of wool are easy to install. To install a heat insulator made of such material, high qualifications are not required. Rolled types of wool have high plasticity, but they are less dense compared to block types. When working with rolled materials, you can cut off the required amount of insulator. The tiles are made of the same size, so during installation of the sheathing, the sizes of the pieces are taken into account.

Cotton wool in slabs Source building.lv

Insulation of wooden walls is also carried out with polystyrene foam or polystyrene foam.

Expanded polystyrene is popular because of its low cost. In addition, it is easy to work with and retains heat well. It is a good sound insulator. The disadvantage is the release of toxic substances by the material during combustion.

What kind of insulation can be used?

Before you decide to insulate a wooden house or bathhouse from the inside, you need to choose a suitable thermal insulation material. In this case, it all depends on the available budget. you can use both inexpensive and time-tested materials and modern expensive insulation materials. The only strict limitation is that when insulating residential premises you cannot use:

- expanded polystyrene and polystyrene;

- various types of large-sized insulating materials.

Acrylic sealant closes cracks well and sets quickly.

After a certain time, they begin to release toxic substances that lead to the development of various kinds of diseases. These materials reduce to zero all the environmental friendliness and safety of timber buildings. So the insulation of a log house can be done exclusively with the help of environmentally friendly and modern materials recommended for such use. When insulating a house, bathhouse or any other log structure, follow the manufacturer's instructions for installing thermal insulation material.

In addition to being environmentally friendly, the insulation must be fireproof and have all the necessary certificates confirming its quality. In most cases, the insulation of a log house is carried out using mineral wool.

How to insulate a floor in a wooden house? Features of wood processing. Table of cubic capacity of round timber. Read more>>

Preparatory work

How to properly insulate the walls of a wooden house from the inside largely depends on the correctly selected materials. If this issue is resolved, then you can move on to preparatory work, which consists of preparing the surface and making the sheathing.

For reference! When preparing the surface, it is necessary to seal the gaps that may have appeared between the beams or logs. To do this, you will need additional materials: tow, felt or polyurethane foam.

Wooden bars are most often used as lathing. Metal sheathing is rarely installed. The metal for the sheathing must be coated with an anti-corrosion compound.

Vertical wood lathing Source uk.aviarydecor.com

Preparation of wooden surfaces

To ensure high-quality application of the insulator, prepare the surface for coating with insulation. Tow/felt/foam is placed in the cracks. After the gap is completely closed, the foam has dried and its excess has been removed, putty is applied to the wall. The putty layer is carefully leveled. The wood is coated with a special compound that protects against mold and mildew. All wooden surfaces are treated with a fire-retardant compound before installing insulation.

See also: Catalog of wooden house projects presented at the Low-Rise Country exhibition.

Possible errors and difficulties

You cannot use a large layer of material - otherwise the dew point may move into membranes, slabs, or mineral wool. Thermal insulation characteristics will sharply decrease, the insulation will not last long.

Attention! Some cottage owners install the material from the inside and outside, but this does not allow the wall to dry, which leads to the formation of rot, mold, mildew and shortens the life of the house.

When insulating internal walls, you need to take into account a number of nuances :

- It is better to carry out work in the warm season, when the wood is dry;

- if the facade is finished with material, you need to check the presence of vents between the wall and the cladding, which allow the surface to dry;

- before insulation, the wood should be well treated with impregnation;

- when installing drywall, the sheathing is constructed taking into account the fastenings for gypsum boards;

- Foam cannot be used for interior lining.

The technology and methods of insulating a house differ from the options for finishing an apartment, and if the cottage is made of wood, some recommendations of specialists should be followed. To do the job correctly you need to be well prepared.

Basalt wool insulation technology

After the walls (ceiling) have dried after treatment, begin installing the insulation.

Stages of work when insulating walls with basalt wool:

- The outermost elements are determined . They are carefully checked using a level and plumb line, since further installation work depends on their position.

- Fix the first vertical block with screws and dowels.

- At a distance of 1 m, the next vertical strips and so on until the entire surface is covered with lathing. For the installation of rolled wool, the installation of the sheathing ends at this stage.

- If there are windows or doorways , separate bars are installed along their perimeter.

Lathing near windows Source 51unlim.ru

- To install a piece of heat insulation, a sheathing grid with horizontal elements is made. Horizontal strips are placed on the resulting vertical mesh at equal distances. The distances between the bars must correspond to the dimensions of the insulation. The result was a mesh for installing thermal insulation.

- Cotton wool is placed in the cavity between the fixed slats . When installing the heat insulator on the walls, do not use glue or other means for fastening. If the lathing is done correctly, the wool will fit tightly to the surface, but you must remember about the ventilation gap. If the ceiling is insulated, the insulation will have to be fixed.

Any cotton wool has a porous structure, so it accumulates moisture. Therefore, when insulating a wooden house with cotton wool, you should definitely cover it with a vapor barrier. When installing the roll material, cut off the required length and attach it to the wall. Before starting work, you should calculate how much material is needed to insulate a wooden house. Add 10% to the resulting number.

See also: Catalog of companies that specialize in home insulation.

Video description

For some thoughts on the use of polystyrene foam and expanded polystyrene, see the video:

In particular, there are many complaints about the release of toxins during combustion, plus it is believed that foam plastic evaporates harmful substances into the air even at normal temperatures.

The material does not allow steam to pass through well, and in a room without good ventilation, moisture will constantly accumulate.

The advantages of the material include relatively easy installation, which means that workers will not be required to have high qualifications, and the cost of the work will be lower.

Polystyrene foam is available in slabs of various sizes and thicknesses Source on-woman.com

Stages of foam installation work:

- A lathing is installed on the pre-prepared surface with a pitch of planks equal to the size of the foam boards. Installation begins with load-bearing walls.

- Foam plastic is laid between the bars while maintaining a ventilation gap.

- A membrane film is fixed on top of the insulation . If it is possible to use other materials for other insulators, a special film with membranes is chosen for foam plastic. It will allow you to maintain a normal microclimate in the room.

- The installation of insulation is completed with finishing work .

What does the cost depend on?

The average price of work in the Russian Federation is from 200 rubles per square meter . The work includes several successive stages. Insulation is carried out separately:

- ceiling;

- walls;

- attic;

- gender;

- attics.

The cost of installing thermal insulation depends on the materials, technology, and location of the work . Insulation of the ceiling, interfloor ceilings, and floors in the presence of an unheated basement is carried out from below. This option is the most labor-intensive, installation of the material is carried out at a height, prices per m2 are calculated taking into account the increased coefficient.

Floor insulation

Concrete floors must be insulated. Wooden ones are covered with a heat insulator if desired, but after insulation, the room will be much warmer.

Floor and wall insulation scheme Source daewoocenter.ru

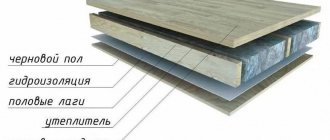

In wooden houses, the insulation is laid on a subfloor and the finished floor is installed on top.

A film with a membrane, polyethylene, is used as a vapor barrier. Insulation using roofing felt is popular among people. This material has been known for a long time, it is cheap, protects well from moisture, and is durable.

Mineral wool is used as floor insulation. It is cheap, easy to install, durable, and has good heat and sound insulation properties. In addition, a relatively new material is increasingly being used - expanded polystyrene, which is gradually displacing cotton wool from the building materials market.

The sequence of actions when installing insulation on the floor of a wooden house.

- is leveled .

- A waterproofing is laid , the task of which is to prevent moisture coming from outside from reaching the insulation. In regions with wet soil, special attention should be paid to this stage.

- Install logs . The thickness of the logs must be at least 5 cm. The distance from the wall is 30 cm. The distance between the beams is 50 cm.

- Insulation is laid between the joists . The presence of voids between individual pieces of heat insulation is not allowed.

- A vapor barrier film is laid on top of the insulation .

- After all layers have been formed, the finishing floor .

Is thermal insulation required on both sides?

Experts advise installing thermal protection only on the outside of the walls; if the wall thickness is over 200 mm, the mineral wool should be at least 100 mm thick.

When, for some compelling reason, the owner cannot install an external protection system, it is allowed to install it inside, but very serious restrictions will apply here.

First of all, not only the walls, but also the floor and ceiling of the rooms will require thermal protection , since these structures will transmit cold from external uninsulated walls.

The internal insulation will block the path of warm air to the outer wall, which will cool even more; the dew point will move to the inside of the wall under the heat-protective layer, which will cause damage to the wood due to high humidity. Therefore, if an internal thermal protection system is nevertheless chosen, the owner must choose such a scheme to minimize negative processes.

In addition, the internal protection system will invariably take up free living space, which is essential for small houses and will block access to electrical wiring and other life support systems.

When installing insulation inside the house, you will have to think through everything down to the smallest detail. With internal insulation, the microclimate in the room will be disrupted and humidity will increase due to the fact that the tree will no longer be able to perform these functions. Such a house will require a powerful ventilation system, which will also take away some of the heat from the general house balance.

As a result of installing a vapor barrier layer, which is mandatory for such buildings, a thermos effect appears. The walls will not “breathe”, humidity rises, the wood will begin to become damp, mold and mildew will form, which will adversely affect the health of the residents of the house.

A heat-protective layer is installed on both sides when summer houses with a wall thickness of less than 150 mm are transferred to houses with permanent residence. In this case, one layer of external insulation of 100 mm will not be enough, so install a second internal one of 50 mm and above.

Vapor barrier

If there is a need to install a vapor barrier, it is better to use a special film with a membrane.

It will allow the walls to pass air normally, and after installation, condensation will not accumulate inside the “pie”. To install a vapor barrier, film or polyethylene is applied to the insulation. An allowance is made along the edges.

Film with membranes for vapor barrier Source kedrovdom.ru

How to save money while maintaining quality?

the most economical and effective of them was determined . This technology has been successfully used in Russia for more than 15 years, and in EU countries even longer.

If you strictly follow the installation technology of this type of insulation, the building will be very warm. You should not save on cheap building materials; the insulation must have a quality certificate, then the thermal protection in the house will last for several decades.

In this process, you can save on the labor of hired workers - the process is quite simple and can be performed by a home craftsman independently.

Elimination of heat loss

The weakest points from the point of view of cold penetration are the joints. There should be no gaps between individual pieces of insulation. The insulating material is laid tightly to the sheathing. For floor insulation, an important point is the connection to the walls. In these places, the insulation is laid with a slight overlap on the walls and is fixed.

When applying a vapor barrier, make sure that each layer of material overlaps the previous one with a slight overlap.

The insulating material is applied directly between the wooden beams before insulating the walls of a wooden house from the inside. For this, long-known materials are used - tow, linen rope, flax wool. You can fill the joints of the beams with modern sealants - latex, acrylic, rubber.

Also, to reduce heat loss in a wooden house, the “warm seam” method is used.

Applying a warm seam

Materials

Thermal insulation of log walls has its own characteristics, unlike stone houses. This design will require a material with certain characteristics :

- high vapor permeability is not lower than that of logs, and better yet higher, especially with external thermal protection;

- the insulation must be moisture resistant so as not to accumulate moisture on the surface of the logs, otherwise this will lead to their rotting;

- have high protection against fire and biological contamination;

- be breathable;

- have a loose structure to fit the logs tightly if a ventilation frame is not installed.

Rounded logs are an extraordinary building material; they not only “breathe”, but also act as a natural air recuperator. Penetrating into the body of the wood, air is dispersed along the fibers and removed through the end, that is, in fact, the tree “breathes” through the ends.

By closing the natural air channels in the log with vapor-tight building materials, the wood will begin to rot.

Therefore, it is strictly forbidden to use:

- extruded polystyrene foam;

- all types of foam;

- construction foam.

The most preferred building materials for these buildings are:

- Ecowool, a natural safe building material with high protective characteristics.

- Mineral wool with a density of 50 kg/m3 must come with a superdiffusion membrane to protect against air blowing.

- Sawdust granules for backfilling.

- Expanded clay as backfill material.

- Foam insulation - polyurethane foam.

- Caulk for heat protection of inter-crown seams.

- “Warm seam” technology using modern acrylic sealants.

A detailed article about means for thermal insulation of a log house is here, and a review of sealants for sealing cracks is here.