Sawing with band saws is carried out with a specialized woodworking tool in the form of an endless (ring) belt. Band sawing has a number of advantages, for example, a very small thickness of the band, and therefore the cut, the equipment can work with logs of large diameters, etc.

A band saw is a special type of multi-cutting cutting tool for wood, which is a closed flexible steel strip (ring) with teeth cut on one side, serving as cutters.

The design features of a band saw determine the scope and features of its use for sawing wood. To cut with a band saw, it must be installed with its flat side on two pulleys, with a diameter sufficient for normal, kinking-free bending of the metal strip along the pulley. Sawing is carried out on a straight section of a tensioned saw band between the pulleys, and the movement is carried out during their rotation.

Equipment equipped with similar pulleys, as well as pulley drive mechanisms and mechanisms or devices for feeding a tool or workpiece into the cutting zone is generally called a band saw or band saw machine.

Sawing with band saws, having a number of significant positive features, is nevertheless a very complex process. The sawing process is significantly influenced by the size of the band saw, the drive power of the pulleys, the tension of the band during sawing, and much more.

First, about the advantages of band sawing:

How does a band saw work?

A hand-held wood band saw consists of several blocks fastened together, the number of which can be increased or decreased, depending on the desired functionality of the tool. The main components of the band saw design are:

- frames with guides that help the movement of the tape;

- drive mechanism for belt tension;

- a device that holds the tape for cutting;

- lifting mechanism;

- belt drive with wedges;

- electric motor with a power level of 15 kW, or gasoline engine;

- latches of wooden parts on the frame;

- tap and container with water for wetting the product when sawing;

- rails for moving the mechanism.

Some models have special protective covers and mechanisms for a more stable position of the tool - these elements will make working with the device safer and more convenient. The essence of the principle of operation of a band saw is to fix a log between two guides and divide it using a cutting blade.

How to make such a tool yourself?

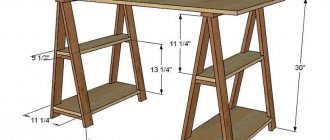

Before you start assembling the saw structure, prepare at least a simple drawing to clearly understand the dimensions and main components of the device. Most of the parts will be made of wood.

The frame is made of polished sheet glued with overlap. The minimum thickness of the mechanism parts is 2.5 cm. It is not recommended to use furniture boards or wooden slabs, as they are not strong enough.

The frame is made in the shape of the letter C. To make the body rigid and durable, overlays are attached to a wooden surface glued together from six layers. Make sure that the fragments are located only at right angles to each other.

Next, we assemble the moving part of the saw. We mount the profile to simplify the creation of the guide groove. With this profile, the sawing blade will be tensioned to the desired degree.

To strengthen the corner joints, we install additional fasteners. Next, the design is modified so that the frame moves freely in the grooves.

To create the spinning rollers, several pieces of wood are glued together and round pieces are cut out. Additional parts are installed on the wheels, which will make working with the device less noisy and more productive. After fixing the wheels, the saw blade is tensioned to ensure a stable position on the pulleys. A sufficiently tensioned blade will make precise and neat cuts.

What is useful to know to successfully work with the tool?

To make the work process easier, illuminate the work area using an ordinary lamp. It is better to install protective frames on the device, which will help remove chips and serve as guide elements. The optimal material for them is an MDF board with a thickness of at least 8 mm.

After installation of the device is completed, disinfect all wooden parts with an antiseptic solution so that rot and mold do not begin to appear soon after you start working with the device. A video with instructions will tell you in detail how to work correctly on a band saw on wood.

Band Saws: Brief Description and Guide

Band saws: brief description and instructions for use.

In this article, we will begin to consider issues related to the technology of sawing with band saws, consider the types of band saws, talk about the problems that arise during the operation of band saws and consider ways to solve these problems. It must be said that this technology has already shown itself to be an effective way to make money, but not all owners of this business know all the intricacies of this area.

Perhaps one of the most common tasks facing business management is choosing band saws. Here you need to maintain a balance between the quality and cost of the canvas. The cost of band saws depends not only on the manufacturer, but also on the type of steel from which these saws are made. All band saws that are used on band sawmills can be divided into two classes. The first ones are made of high-quality carbon steel, its designation is C75. The second band saws are made of alloy steel, its designation is D6A. It is believed that blades made from alloy steel are more wear-resistant.

Next, we will consider the types of band saws made from different classes of steel.

Band saws with constant hardness.

Steel class C75. Band saws with uniform hardness over the entire width of the blade. Hardness 40-45 HRC. Examples of such band saws include Wood-Mizer Timbery and Wood-Mizer Silver.

On average, such saws can withstand 20 sharpenings, have sufficient elasticity, the interval between sharpenings is 0.8-1.0 m3 of saw logs. The teeth of such a saw become dull faster and are more suitable for soft wood. Feed 6-10 m/min.

Steel class D6A. They have the same elasticity, the interval between sharpening is 1.0-1.5 m3 of saw logs, and can withstand up to 25 sharpening stages. Feed 8-12 m/min. These saws include Wood-Mizer Double Hard and Banso WinterSteiger.

All of the above saws are supplied completely ready for use, the teeth are hardened, sharpened, and set.

Band saws "soft back - hard tooth"

Rice.

1. a. Bimetallic saw: 1 - quick cutter, 2 - saw body; Rice. 1. b. Saw with a hardened tooth: 3 - weak fixation of the tooth; 4 - average tooth fixation; 5 - strong tooth fixation - Steel class C75. The body of such band saw blades is with good flexibility and elasticity. The teeth are hardened, hardness 60-65 HRC. Back hardness 35-45 HRC. The teeth are hardened by 1.5-2.5mm. In practice, you can find 3 types of tooth hardening: strong fixation, medium fixation, weak fixation. The more the teeth are hardened, the better it holds sharpening and setting, but the downside is its fragility. The volume of sawlogs between sharpenings is 1–2 m3. Feed – 8–15 m/min.

From the general list, two manufacturers can be distinguished whose band saws have some specific properties: Banholzer Baumamaster.

Basic requirements for the parameters of band saws, which are the key to successful and long-term operation.

1) thickness

2) width

3) saw tooth pitch 4) cavity depth - tooth height;

5) rear corner 6) front corner

7) divorce

tooth set line

- Class D6A. D6A alloy steel band saw blades perform 10-20% more than C75 grade steel bandsaw blades. The number of regrinding cycles is approximately 10-15 times and is limited by the height of the hardened part of the teeth, however, in the case of high-quality preparation, it can reach 25 cycles. Such blades show fairly stable operation and stability in the cut.

Manufacturer: Wood-Mizer DoubleHard.

Bimetallic wood strip blades for sawmills

These types of band saws include blades consisting of two types of steel. The body of such a band saw is made of D6A steel with a hardness of 40-45 HRC. At the tip of the teeth, a quick cutter is laser welded, the height of which ranges from 1.5-2 mm, with a hardness of 65 HRC. M42 grade steel is mainly used for the manufacture of high-speed cutters.

Bimetallic band saws are characterized by increased durability and service life, an increased interval between sharpening cycles, the ability to work at high feed rates, and a large volume of sawn logs.

Manufacturer: BAHCO, Wood-Mizer Bimetal

Carbide-tipped band saws (stellited band saws).

Stellite

(eng. Stellite) - a super-hard alloy based on cobalt and chromium with tungsten and/or molybdenum additives for spraying and surfacing of machine parts, machine tools and tools in order to increase wear resistance.

Stellited band saws are used in large woodworking plants. Such blades have an excellent tooth profile, pitch and structure.

The cost of a stellited band saw is much higher than all of the above, usually the price difference ranges from 300 to 500%. However, this cost is justified by the quality of work, durability and performance.

Manufacturer: Wood-Mizer RazorTip

What affects the working life of band saws

It is known that the parameters of band saws greatly affect its service life. Let's look at the options and try to analyze which type of band saw is suitable for your tasks.

Saw thickness: • minimum thickness 0.9 mm for blade width 32-60mm. The advantage of this saw is its very good elasticity and flexibility, i.e. achieves its versatility in relation to the diameter of the saw pulleys. Such band saws are often used on band dividing machines. However, due to the low rigidity of the blade, maintenance should be carried out much more often. Limitations are also the diameter of the saw log and the time of year: it is not recommended to use it for sawing saw logs with a diameter of more than 400 mm, and also to use it in winter at negative temperatures. • thickness 1.0-1.07 mm is the most common and optimal option for band saws with a width of 32 to 100 mm. Sawing occurs at medium feed. Can be used year-round, but at the same time choosing the right tooth profile. The limitation is working on saw pulleys with a diameter of less than 450mm. • thickness more than 1.07 mm - more common on band saws with a width of more than 100 mm. Works great on pulleys of at least 800mm, suitable for large diameter sawlogs. The production of band saws with stellite, as well as band saws working with flattened teeth, is used. Can be used year-round, at high flow rates. The limitation is the use of band saws on pulleys less than 800mm.

Saw width: • width 32-35 mm, such band saws are used in woodworking enterprises of small and medium volumes of finished products. The work is carried out at low and medium feed. • width 38-40 mm. Band saws of the correct width have greater rigidity. Accordingly, due to their slightly larger width and greater rigidity, they behave more stable in the cut. Work occurs at medium feed. • width 50 - 75 mm, such belts have proven themselves to be excellent for working with saw logs with a diameter of more than 600 mm. Work at medium and high feed.

Saw tooth pitch: • pitch 19 mm - used extremely rarely. Sawing occurs at low feed rates, sawing speed is extremely low. However, the advantage of this step is the more stable behavior of the saw in the cut due to the participation of a larger number of teeth in sawing. • pitch 22 mm - universal pitch, most often found on the market. Works well at medium feed. • pitch 25 mm - more often found on band saws with a width of 100 mm, works well at high feed rates. The advantage is the sawing speed.

• 35 mm pitch - more common on flattened band saws, as well as stellited band saws.

• pitch 45 mm - used on stellited band saws.

Advantages and disadvantages of a band saw

This type of saw is successfully used in various types of work with wood and other materials and has a number of advantages:

- It is economical to use the tape model, as it makes very narrow cuts;

- high productivity of the device due to fast sawing speed;

- the moderate cost of the device is available due to its specific structure;

- does not create much noise during operation, which makes the work process more comfortable.

Along with numerous advantages, band saws also have some limitations and disadvantages:

- the complex process of setting up the device’s operating parameters, which can be a problem for a beginner;

- Due to the nuances of the mechanism’s design, it can only perform longitudinal cutting of wood.

What you need to know about the band saw

How the wood will be cut depends on the shape of the equipment tooth. It is the tooth of the band saw that indicates the type of cut. What should you give preference to? A narrow band saw is inexpensive and very easy to use. The point is that the tooth cannot be no more than 20% of the width of the blade, otherwise the steel will tear under heavy load, like a sheet of paper. The pitch and height of the teeth determines the area of the cavity. Because if the sawdust is not removed, but accumulates in the cut, the saw will jam and become clogged with sawdust. In practice, there is a definition of tooth height, and it is no less than 5 mm. And, accordingly, the width of the canvas should be less than 25 millimeters. A narrow saw that has broken is common. Wide saws rarely break. Cracks may appear on such saws, and this is due to incorrectly selected dimensions and adjustments. But to break such a saw, you still have to work hard. Cracks can be:

- in the cavities of the teeth;

- in the central part of the saw;

- on the edge at the back.

The most common defects occur in the tooth cavities of belt equipment. Defects occur during the operation of the saw. Due to defects, such a saw makes an uneven cut in the wood. How to prevent the formation of defects? On narrow saws, the teeth are bent. The layout is carried out like this: 1st tooth to the left, 2nd to the right, 3rd straight and again: left, right, straight. In this case, the saws are carried out by the left and right teeth, and the straight one is engaged in removing sawdust.

It is considered best to work with a saw that removes sawdust by 100%, and a narrow saw removes by 30%, because the height of the teeth of this type of saw is low. From the above we can conclude that the operating speed of a narrow saw is lower, since the sawdust removal is low and slows down the saw. In addition, a narrow saw does not have a stabilizing body and therefore gets stuck and loosens in the cut, causing a break. And here again you will need to repair and cook. The conclusion is clear: a wide band saw for wood is still the best option. The only thing that can be done is to increase the width of the steel sheet. The ratio should not exceed 20 to 80. The teeth can be flattened at the tip, thereby creating a widening in the cut. You can also fuse stellite. After this, the teeth are guaranteed to work at their best. If stellite is made, then wiring is not necessary.

It should also be said that the quality of the wood also affects the type of saw. The tree must be clean, with a minimum number of knots. A wide saw works great with any width of log. High speeds are not a problem for her. In wide band saws, the teeth can be adjusted more finely. The width, angle, and thickness of the cut can also change. Thanks to this, product yield can be increased by up to 25%. A narrow band saw is made with cheaper equipment and is easier to assemble. This is a kind of relative plus in the treasury of narrow saws.

Hand saw

A narrow saw heats up completely during operation, while a wide saw only heats up the part of the blade that cuts, which can sometimes cause a wave to appear at the cut site.

Therefore, a wide saw must be pulled much tighter than a narrow saw. The design of a wide saw is more complex, which naturally affects the cost. In addition, it is very difficult to work on a wide band saw; you need to have a number of specific skills and knowledge. A good, well-established machine with a wide band saw will give large output volumes.

In order for sawing to be productive it is required:

- machine equipment with a wide band saw;

- experienced operator;

- high quality prepared equipment;

- the person responsible for sharpening;

- sharpening mechanism;

- service staff.

Band saw machine

Band saws can be used to cut quickly and efficiently. However, a number of rules must be followed. Before use, familiarize yourself with the equipment, care for the equipment, clean and lubricate it, check and maintain it on time. If there is no finance, then you can make the machine yourself. Having the skills, parts and special equipment, following the diagram, you can try to assemble a band saw with your own hands. Of course, a self-assembled machine will not have super speed, but as they say: without haste, you can complete your sawing tasks very well and productively.

How to choose the right saw?

If you choose the right tool, you will not have to repair band saws on wood anytime soon. Since there are a lot of options for choosing the appropriate tool model, quite a few people know how to choose the right device for their needs. We invite you to familiarize yourself with the most important and essential criteria for assessing the quality and functions of different saws. First of all, pay attention to the technical parameters of the models.

The cutting accuracy depends on the cutting speed and material feed. There are optimal speed ranges to achieve the best performance results.

The higher the performance of the device, the less resistant the saw blade will be to damage, deformation and wear.

The reputation of the manufacturer is also of great importance - if the reviews about the manufacturer are good and the reputation is reliable, then the product will most likely be of high quality.

Examine the condition of the main components of the device - the moving structure, portal, guide parts, pulleys and rollers.

A portal made of square pipes with reinforcing profiles is suitable for sawing wood parts. Otherwise, the main body may soon become bent during the cutting process.

But working on small parts won't hurt it that way. The best material for guide elements is solid metal that is resistant to deformation from loads.

Tape cloth

A sharp and well-oiled blade will produce a quality cut. As the cutting edge of the gear blade becomes dull during operation, more heat is generated, and at some point this amount of heat produced may become greater than the ability of the coolant to remove this heat from the cutting zone, especially if the coolant is already old or has an incorrect ratio with water. Make sure the blade tooth pitch is correct for the material being cut. Using too small a tooth pitch may cause chips to become lodged in the small chip grooves of the blade and interfere with the cutting process, as well as create a rough cut surface on the workpiece.

For most applications, a coarser belt tooth pitch is more efficient and increases productivity. Inspect the resulting chips after cutting. It should be small and curled. If not, check the sliver and the sliver cleaning brush to make sure chips are not getting caught in the flutes. Blue chips are a sign of too much heat being generated. Make sure the band saw feed is set correctly for the workpiece. Even a small adjustment to this parameter can significantly improve the quality of the cut. You need to check this parameter in the tape manufacturer's catalog. Also check the guides of the band saw, including the placement and accuracy of the inserts and rollers. Make sure the guide rollers can rotate freely. A jammed or damaged roller can jam the belt.

How to determine the quality of the canvas?

The correct choice of saw blade determines the service life of this important part. Therefore, you need to choose a blade that is suitable for the type of work you want to do with your bandsaw. The best steel for cutting blades is alloyed or carbon.

But a saw made from an alloy of two high-strength metals, which is characterized by increased strength and excellent cutting qualities, has also become popular. The higher the number of teeth per inch, the more accurate the cut will be. The optimal quantity is usually taken to be 8 teeth per inch. The width of the edge is not very important, but the blade will last longer if it is five times the height of the teeth.

How to assemble a band saw for wood

First you need to assemble the table. The size of the table and frame are selected arbitrarily. A channel is used as a rod, which is prepared for assembling all elements. The bar is attached with a corner, the so-called forty. Next, the pulleys are attached.

The pulleys must be the same size, and the pulley located at the top must be covered with a protective cover.

A damper that absorbs vibrations; its transmission coefficient should be 1, since the pulleys are of the same size. A corner is used as a guide. Thanks to the cutouts and grooves, it becomes possible to adjust. The ribbon has a special meaning, and it is better, of course, to buy it in a store. However, if it is not possible to buy, then the tape can be cut from steel. The thickness of the blade depends on the wood that you plan to cut. Soft wood up to 0.4, dense wood 0.8. The steel blade should be cut into teeth and twisted into a ring. Next you need to cut and sharpen the teeth. Next is tensioning.

Band saw from drill