Beech furniture

In the production of various furniture, beech is used in different forms, that is, as ordinary wood, and also in the form of plywood or veneer. Beech wood, due to its high strength, is most often used for the manufacture of furniture surfaces that require high resistance to mechanical stress.

Therefore, beech wood is used for the production of office and public furniture. Most chairs are made from this wood. You can often find beds, desks, sofas, interior doors, wardrobes, armchairs, and kitchens made from solid beech. Beech wood is also used in furniture production for the manufacture of frames for various types of upholstered furniture.

The beautiful texture of beech trees and its light shades allow you to create furniture that is distinguished by elegance and restraint. Thanks to these qualities, beech furniture is widely used both in residential apartments and to create an appropriate environment in various public institutions.

Interior doors of various textures are also made from beech wood. The price of ordinary beech furniture is rated at five points. That is, the cost fully meets several criteria - appearance, strength and practicality.

In addition, beech wood is excellent for making children's furniture, in particular for cribs. They are particularly durable, environmentally friendly, practical and beautiful in appearance.

Photo of beech wood furniture

Bed

Furniture set

Cushioned furniture

Bedroom furniture set

Sofa bed

Tree species

I am often asked which wood is better to carve from - soft or hard? I answer: each breed is good in its place. Any log, board, or piece of wood (dried, without cracks and not rotten) is a valuable material, each of them has its own merits and beauty. Soft woods are good for learning carving: linden, aspen, poplar, alder, chestnut, cedar. They are easy to process with a cutting tool, it is easier to achieve the required shape, plasticity, relief, and it is not difficult to perform final processing. Hard textured rocks with clearly defined growth rings, despite the difficulty of processing, have their advantages; products made from them are beautiful without tinting, polished to a shine, strong and durable.

It is necessary to remember: wood as a material is an integral part of the future work; the artistic level of the product largely depends on the correct choice of species. You can do the same work using different rocks, but in the end we will get completely different quality results. The ability to use material correctly comes with practice.

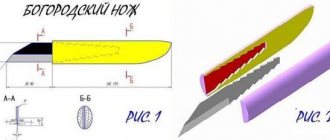

So, a tree. I think it’s easy to distinguish coniferous trees from deciduous ones by their crown, leaves, bark, fruits, and textured ones from plain ones on the cut. The carver needs to know which ones are soft and which ones are hard, which ones have texture and which ones don’t. On a cut of the trunk you can distinguish annual rings; a living tree has one more of them every year. By counting the number of rings, you can find out how many years the tree has been growing. On a cross section of the trunk of many species, the core, core, sapwood, and bark are distinguished (Fig. 1.1). Brightly colored rocks with clearly defined layers are called textured.

Rice. 1.1. End structure of wood (a); types of sections (b): 1 – growth rings; 2 – core; 3 – core; 4 – sapwood; 5 – bark, cork layer; 6 – cross section (end); 7 – radial cut (core); 8 – tangential cut

I propose to carefully examine the table, which gives the characteristics of the most used wood species for carving, as well as some rare, but well-proven wood species in artistic processing.

Basic beech lumber

Beech is used to produce edged and unedged boards, veneer, furniture panels, and plywood.

All these lumber are used for specific purposes:

- During manufacturing, edged boards This affects the color constancy and durability of the material. Edged boards are used as flooring, platbands, staircase elements, various massive cabinet furniture options, countertops and baseboards.

- Unedged boards cost less and are used for various cladding.

- In the production of furniture, special furniture panels . The pattern of the furniture board is weakly expressed; over time, the pinkish tint may darken.

Beech flooring is installed mainly from edged boards. This material is smooth, there are no splinters in it, and it can easily be polished and, if necessary, covered with paints and varnish. Beech flooring is warm, and special treatment prevents it from deteriorating under the influence of high humidity.

Photos of kitchens made of solid beech

Kitchen No. 1

Kitchen No. 2

Kitchen No. 3

Dry edged and unedged boards

The production of beech boards must be carried out in compliance with certain standards. Since this tree easily absorbs moisture, its processing after cutting should be carried out in a short time. Otherwise, the wood will warp and it will be difficult for it to give the desired shape. Edged beech board is easy to sand, it is durable and attractive in appearance.

These characteristics allow you to create interior interiors of apartments and your own houses. After proper processing, a beech board becomes somewhat stronger than an oak board and, thanks to this hardness, easily holds nails and screws in its fibers.

Experts do not recommend using beech boards for external cladding of houses or for arranging baths. Such wood does not change for the better under the influence of weather conditions and humidity; beech is not used as a material for insulating a house.

Plywood

Beech plywood is quite widespread, so it will not be difficult to purchase it in construction stores if necessary. Plywood is made by gluing a certain amount of veneer.

The main, sought-after qualities of beech plywood include:

- Flexibility. Beech plywood bends easily and does not crack. Due to this, plywood products can be given any shape if necessary.

- Plywood is easy to cut and saw, it can be sanded and polished.

- The color of beech plywood varies from light to dark shades. Heat treatment easily changes the shade of the material.

- Beech plywood is easily and firmly fixed to various surfaces.

Beech plywood of classes 2 and 4 is especially valued. The ease of processing such material at home and, accordingly, practicality is rated five points. Wall coverings and some elements of different types of furniture are made from plywood. Plywood is also used for making all kinds of crafts.

Pros and cons of beech wood

Beech is valued for its strength and attractive appearance. The special structure of the fibers and careful processing of the wood surface make it possible to obtain amazingly smooth products. Processing beech wood is considered a labor-intensive process.

Deviation in one direction or another from drying standards leads to the appearance of cracks in the products. The disadvantages of beech include its high hygroscopicity. This often leads to rotting of beech products used in humid environments.

The advantages of beech include its wide availability. Proper processing puts this tree in quality along with oak. Beech can be easily sanded and tinted, and is moderately expensive compared to other tree species.

Chapter 1 ABOUT THE TREE

Since ancient times, the forest has been a faithful assistant to man. For centuries, it fed and warmed, sheltered from enemies, gave clean air and pleased the eye. The diversity of the flora and fauna of the forest allows it to be used today in a wide variety of areas of human activity.

In the vast world of the forest, a tree that is familiar to all of us from childhood deserves special attention: a tall, slender trunk directed into the sky, a beautiful spreading crown... This amazing material in itself attracts attention, you can admire it ad infinitum. When a person, with the touch of his skillful hands, gives it a second life, the world gains a new masterpiece of art. Wood and the artist's hands, the eternal union of goodness and labor.

Beech carving

Carving beech yourself requires a certain skill and sufficient experience. Due to its high strength, chisels are required to create the ornament. In production conditions, it is incomparably easier to create drawings on beech boards.

Three-dimensional milling of a bas-relief with a gnome on a special machine for beech wood:

Reviews of working with similar products

A wide variety of products are made from beech. Their quality depends on compliance with the manufacturing technology of wooden blanks. Beech needs to be properly dried and treated with resins, which reduce its sensitivity to moisture. Independent production of crafts, wall coverings, and stairs is a rather labor-intensive process.

“I purchased a beech board with the intention of using it for flooring in the living room. The process of laying and adjusting the material went quite quickly, and there was no need to even resort to the help of relatives. But I wasn’t able to cut a beautiful handle for the front door; in some places there were unnecessary chips on the workpiece” - Andrey, 45 years old