Articles

All photos from the article

Wood jigsaws come in many varieties. They differ in width, length, tooth, material and even tail. In this article we will look at the subtleties of the right choice, which determines the quality of the cut and the speed of your work.

Assorted jigsaw files for wood

What it is?

A jigsaw file is a blade equipped with teeth of one type or another, fixed at one end to the movable rod of the tool. Since all materials have their own properties and characteristics, a large number of varieties are produced. They are designed to solve various problems, cutting certain materials. As a rule, craftsmen purchase sets of several types of cutting tools.

Selection criteria may be:

- The most popular and common types of cutting.

- Purpose for a particular material.

- Creation of a universal set that allows you to perform most types of processing.

Separate, specialized samples are also available for sale. They are purchased to perform specific work according to previously known parameters of the material and cutting conditions.

The choice of file type is determined by the user’s level of training, experience and knowledge. In order to avoid mistakes and choose the best option, you should study the features and characteristics of the cutting tool.

By width, thickness and pitch of teeth

The width is selected taking into account the requirements for the work results. Wide products are more stable, so they can be cut at high speed without deviations. If you need a high-quality sawn curve, narrower files that are easy to make turns are also suitable. The teeth should be located on the drive axis - this makes the tool more controllable.

The thickness determines how strong the deviation of the file from the vertical will be. Thick blades best provide a perpendicular, even cut, but are unlikely to be suitable for jigsaws with a quick-release mechanism.

The pitch of the teeth is the distance between their tips. Most countries use the designation TPI (“teeth per inch”). Measured by the number of teeth per inch of length. If the TPI is 5, for example, that means there are five teeth per inch of blade. For cross-cutting wood, it is more advisable to use a saw with TPI 7−4. For regular work, 7-9 is enough. A file with TPI13−10 will help you make an extremely accurate cut.

It is necessary to take into account the thickness of the workpiece - 6-8 teeth must work simultaneously, otherwise the blade will vibrate and the cut will come out torn.

Types of files, technical characteristics

All files are produced for specific types of cutting.

They can solve specific problems:

- Clean cut

- High-speed sawing of material.

- Sawing out openwork patterns, precise figures.

- Cutting hard materials, steel or aluminum.

- Working with certain materials.

All these operations require the use of fabrics that have the appropriate characteristics.

Let's look at them in order:

Tooth shape, cutting edge geometry

The type and shape of the teeth are the main factors determining the performance and quality of the cut.

There are different types of saws that can be divided according to certain characteristics.

Based on the geometry of the cutting edge, the following types are distinguished:

- Separated canvases.

- Flat files with no streaks.

According to the method of cutting teeth:

- Milled

- Sanded

Depending on the combination of these parameters, the following options are distinguished:

- Milled, with wiring . The teeth are created using a milling machine. Externally, they are distinguished by the rounded shape of the cavity between two adjacent teeth. They can have a classic type of setting (alternately inclined to the sides), or a wavy type of setting (several teeth inclined in different directions with a variable amount of deviation from the axis). The former are used for quick and rough cutting on soft materials (wood), the latter - for cleaner cutting of wood, chipboard, plywood, etc.;

- Polished with routing . They have triangular teeth with a classic set. Capable of cutting wood, chipboard, plywood, MDF, etc. relatively cleanly;

- Polished without routing . Canvases with a flat surface. There is no set of teeth, which allows you to get a thin and accurate cut of clean materials - laminate, finished wood, plastic, etc.

In addition to the shape, the size and pitch between the tips of the teeth plays a significant role. The smaller they are, the cleaner the cut will be. At the same time, as the size decreases, the productivity and speed of sawing materials decreases. Typically, saw blades with fine cuts are used when laying floor coverings, fitting additional elements of door or window blocks, and other precise and clean work.

In addition, there are blades with different directions of the tooth tips. They usually point upward (toward the shank), which provides a cleaner edge on the underside. However, there are samples in which the notch is directed away from the shank. These blades are used for cutting laminate or other materials that require a neat and clean edge.

Types of jigsaw blade shanks

One of the main criteria for choosing a canvas. The fact is that if you purchase a saw with a shank that is different from the type used in your jigsaw model, then you will not be able to install it. After all, the saw blade is attached precisely with the help of a shank. Today you can find four types of blades on sale, which differ in shanks. Two of them are universal and fit models from different companies, two are produced for a specific manufacturer.

T-shaped version

T-shank. This type of blade was developed by Bosch for new models of jigsaws, which recently appeared in the manufacturer’s lineup. However, given the weight of the Bosch concern in the market of hand-held power tools, other manufacturers of electric jigsaws began to switch to this standard, which led to an increase in files with a T-shaped shank. Today, such files have become the most popular on the market; they are suitable for the vast majority of jigsaws Makita, Metabo, Hitachi, Skil, AEG, DeWalt, Sparky, Interskol, and many other models.

The popularity of T-shank files is due to their reliability, simplicity and high speed of blade replacement.

U-shank

Files with a U -shank. Often blades with such a shank are called American. Indeed, such files were first used by American manufacturers of jigsaws; their chuck was designed for this type of fastening. Today, files with a U-shaped shank are the second most popular; they fit jigsaws from Skil, DeWalt, Wolf, Ryobi, Stayer, Black & Decker. In addition, this file is suitable for all models of jigsaws with block and screw chucks.

Jigsaw DeWALT DW349

Currently, blades with a U-shaped shank are gradually losing their relevance. Today, even most American manufacturers are switching to T-shank chucks. Be careful when purchasing saw blades for new models of jigsaws Skil, DeWalt, Wolf, Ryobi, Stayer, Black&Decker.

Bosch shank. Blades with such a shank are similar in design to files with a T-shaped shank. The only difference is the presence of a second stop. Today saws of this design are practically out of use. They can only be installed on outdated models of Bosch jigsaws; such files are almost never found on sale.

Makita shank . Today, blades with such a shank are rarely found on sale. These files are only suitable for older models of jigsaws from this Japanese manufacturer.

Saw blade sizes

Saw accessories for jigsaws are characterized by three sizes: length, width and thickness. When choosing a nail file, you should understand what tasks you are buying it for. At the same time, it is necessary to take into account the capabilities of the tool itself; carefully read the technical characteristics of the jigsaw, look at the maximum dimensions of the blades with which this or that model can be used.

File length. According to this parameter, files vary in a fairly wide range: from 40 to 250 millimeters. However, most models of household and semi-professional jigsaws are equipped with saw blades up to 150 millimeters long. In fact, the depth of the cut depends not so much on the length of the file, but on the capabilities of the jigsaw itself. At the same time, for sawing thin parts, we recommend using short blades, this way you can avoid the blade moving away from the markings and guarantee high cutting accuracy.

The process of setting up a jigsaw for the correct cut

It is important not only to choose the right equipment, but also to know how to set up a jigsaw for work. The first thing to check is the loft in the actuator stem. It must be in accordance with the limits specified in the instructions. And also check the reliability of the sole. And if there are gaps, the fastening points should be tightened.

Checking the installation of the sole relative to the file

The installation angle may not be correct initially. And to fix this, you should configure the tool yourself. To do this, you need to loosen the fasteners, move the sole to disengage the teeth, install the sole correctly, and securely fix it.

Flatness of the sole over the entire surface

If this condition is not met, it is necessary to remove the sole from the jigsaw and straighten it with precise blows with a bronze hammer on an anvil. And then sand the surface with sandpaper.

Offset of the groove for securing the saw to the end of the drive rod

In this case, it is necessary to turn the shank of the nail file with the same offset as the groove, but only in the opposite direction. This will make it possible to install the saw blade exactly along the axis of the sole.

To prevent the file from breaking during the procedure, it is necessary to heat the transition of the shank into the blade red-hot on a gas stove and, using pliers, turn it to the required offset angle. When finished, you need to straighten the file with a hammer on an anvil.

Type of material to be processed

Initially, a jigsaw was created for cutting wood. Accordingly, replacement equipment was made for this material. However, it quickly became clear that the tool’s capabilities are much wider; almost any material can be cut. The only condition is the use of appropriate fabric. Currently, different groups of paintings have been created:

Saw blades for wood processing

As we have already mentioned, for each type of material it is necessary to select a file with certain characteristics. Cloths for wood processing are divided into three types:

For fast cutting. Quite often, a jigsaw is used for work where the accuracy of the cut is not particularly important, and the speed of the process comes first. The manufacturer took into account such user needs and designed special files. They have a number of characteristics that distinguish them from other canvases:

- Length – from 60 mm;

- Presence of a large tooth (4.5 – 6 mm);

- Wide tooth spread (up to 1 mm).

When choosing a blade for quick wood cutting, you should consider what type of sawing you are going to do: longitudinal or transverse. For sawing along the grain, a saw with an oblique tooth is better; for cross-cutting, it is better to use blades with straight teeth.

For figured cutting. It is unlikely that anyone will be surprised by the statement that it will not be possible to cut a circle, oval or other shaped part in wood, plywood or chipboard using a wide saw. For these purposes, narrow blades are used, which, due to their size and some specific features, accurately maintain the cut line in rounded areas.

- Length – up to 40 mm;

- Tooth height – up to 2 mm;

- File width – up to 4 mm;

- Beveled back of the saw.

Accessories for clean cuts. Some operations require clean and careful cutting. We are talking, first of all, about the production of furniture, musical instruments, cutting parquet boards and other specific operations. In this case, the craftsman is interested not so much in the speed of wood processing, but in quality. The best quality is achieved when using a saw blade with a reverse tooth. True, to work with such a blade requires certain qualifications and experience: the operator has to overcome the resistance of the jigsaw. For sawing laminated parts, saws with two rows of teeth are used.

- Teeth size – up to 3 mm;

- Minimal divorce.

For metal work

Modern jigsaws are capable of sawing various metals, including black steel. However, the productivity of the tool when working with such materials drops sharply, the depth and speed of the cut decreases, and at the same time the wear rate of saw blades sharply increases.

Files for metal processing are made from high-quality high-strength steel and are distinguished by fine teeth (up to 1 millimeter) with a wavy sharpening. If you often have to work with metal parts, we recommend buying several files: separately for steel, for aluminum, for bronze and other non-ferrous metals.

For sawing other materials, such as plastic, polymers, plexiglass, plasterboard, manufacturers develop unique types of blades that are suitable specifically for a particular material. When processing particularly hard surfaces, we recommend purchasing tungsten-coated files.

For polymer materials

For cutting pipes and other PVC products, blades with large teeth designed for cutting wood or metal are suitable.

Fine-toothed saw blades will also cope with the task, but you will have to cut at a minimum speed, otherwise the plastic sawdust softened by the high temperature will clog the saw teeth. For thin sheets of plastic and plexiglass, metal blades with fine teeth are excellent. And to cut thick plastic, you can take a wood saw and cut at low speed.

For specific tasks

Files intended for glass and ceramics are made of particularly strong alloys and have a diamond coating on their cutting edge or, more often, a tungsten carbide coating. Using a jigsaw to cut ceramic tiles or glass only makes sense if you need to cut out shaped elements; There are other, more suitable tools for direct cutting of these materials.

Drywall and other building materials containing abrasive particles of gypsum, cement or sand quickly dull any saws. The exception is saw blades designed specifically for these materials with carbide tips on the cutting edge.

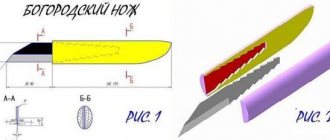

A file designed for cutting cardboard, rubber and other soft materials is more like a knife. It is “toothless”, and its cutting edge is made in the form of polished waves.

Universal

Universal files, usually made of high-speed steel, are used to work with various materials - wood, plastic, metal. You should not expect high quality cuts when using them.

What affects cutting accuracy

Several factors influence the accuracy of the cut. Therefore, you should pay attention to them and take them into account when working.

The cutting accuracy depends on:

- tool power;

- speed, speed;

- equipment lengths;

- blade thickness and width;

- tooth pitch.

Important! Regardless of the characteristics of the tool, poor quality assembly of the device can reduce its capabilities.

How accurate the cut will be depends on the accuracy of the cut.

Jigsaw blades: marking to help

For a non-professional person, purchasing the right saw consumables can be confusing. You can always ask the question: “What are the types of consumables? Which company's products are better? Many brands produce specialized types for wood, iron, plexiglass, and plastic. It is important for a carpenter or home craftsman to understand the purpose of purchasing products and the selection criteria that will help determine the desired functionality.

Alphanumeric markings on the canvas and tail dyeing will help you make the right choice. Each symbol indicates performance and application based on the material being processed.

The first letter is the shank type:

- The T-shape model is the most common among many manufacturers;

- U-shape for older models of screw or block type power tools;

- M - special model with two holes, only for Makita;

- F - standard rectangular shape with one hole Fein.

The second number is the canvas size:

- 1 - short, up to 7.5 cm;

- 2 - average, 7.5 - 9 cm;

- 3 - long, 9 - 15 cm;

- 7 - maximum, from 15 cm.

The penultimate letter is the size of the teeth in ascending order of size:

- A - small;

- B - average;

- C, D - large.

The last letter indicates the special properties of the cutting blade:

- X - progressive pitch of teeth;

- R - reverse or reverse teeth;

- O - a particularly thin edge of the back of the canvas;

- P - ensuring the most accurate cut;

- F - made of double alloy, providing special strength.

Marking of Bosch files

Bosch labels its files with an alphanumeric code. The code looks like this:

Nozzle sizes

Canvas length. The length of the file can be varied over a wide range - from 4 to 25 cm. Please note that the longer the file, the thicker the workpiece it can cut. It is worth noting that the actual depth of cut that can be achieved will depend not only on the length of the saw blade alone, but also on the capabilities of the tool. To saw thin material, it is worth using short files, because their use will guarantee a clean and neat cut, because the process will not be hampered by the deformation of a very long blade.

Width of saw blade. The marking of files for an electric jigsaw also includes data such as width. It is selected depending on the type of work that needs to be done with an electric jigsaw. Wide saw blades are ideal for straight cuts - it will be easier to guide them in the required direction, and it turns out that the sawing line will be perfectly straight. But for figured cutting you will need a blade with a narrow back, which is easier to perform various maneuvers and “draw” smooth curved lines.

Thickness of the canvas. And now we come to the most important thing. The thicker the file, the less it will deviate from the vertical position when working, which means that the cut along its entire length will be perpendicular to the surface of the material. But when trying to get a perfect, even cut, you should not forget that too thick files may not fit an electric jigsaw with a quick clamping mechanism.

Additional markings on the blade: what is important to pay attention to

Jigsaw equipment is supplied individually and in the form of universal sets of several blades: for soft and hard wood, for metal, and plastic. Responsible manufacturers add supporting information to consumables to avoid mistakes when choosing.

Material letters

- HM – especially strong alloys;

- .HCS (CV) - carbon composites;

- HSS - high speed metal;

- CV - chrome vanadium steel alloy;

- BM (BiM) is a bimetallic structure of strong alloys and high-speed metal, the most durable and wear-resistant.

Decoding the quality characteristics of the cutting edge

- Wood - work on soft wood;

- Hardwood - hard wood and PVC plastic;

- Metall - cutting of steel alloys and metalworking is possible;

- Inox - work with stainless material;

- Plaster, Fiber - fiberglass blanks;

- Alu - for processing aluminum;

- Soft-material - soft rubber and carpeting;

- Acrylic - acrylate and polycarbonate composites.

The purpose of a jigsaw consumable can be determined by the color of the tail section:

- gray color - work with wood materials;

- blue color - metal alloys;

- red - plastic surfaces;

- white - on wood and metal;

- black color - ceramic, steel, soft and fibrous materials.

Difference in tooth shape

In addition to the material, the files differ in the shape of the tooth . The possibility of use also depends on this. The teeth are as follows:

- Set apart milled. Through one they are bent in different directions. The normal wiring width is considered to be 1.5 times the thickness of the web. The wiring provides cooling and easy removal of sawdust. Used for quick cutting of not particularly hard wood, plastic structures and non-ferrous metals.

- Wave-shaped milled. A group of teeth that alternately deviate left and right. The angle of deflection of each subsequent group differs from the angle of inclination of the previous one, a wave is formed. These files are used for finishing cutting of aluminum and plastic products, non-ferrous metals.

- Ground teeth. Used for finishing cuts of plastic and wood blanks, laminate and polymer materials.

- Set apart, polished. Used for accelerated cutting with rough cuts of soft wood, fiberboard and chipboard.

Most popular models

All power tool manufacturers make jigsaw files. It is difficult to name the highest quality and most convenient models, since the technologies are practically the same from each other.

Let's look at the most popular and sought-after types:

Makita A-85715

- The products of this company are known to all users and do not need additional recommendations.

- The blades are durable and provide a clean, straight cut without chipping.

Makita A-86898

- This is a set of 5 blades for wood, plastic, steel and non-ferrous metal.

- They are distinguished by high quality and durability.

Dewalt DT 2168

- Strong and durable fabrics that practically do not lose quality even after prolonged use.

- Suitable for clean sawing of floor coverings, openwork kerf threads, etc.

Set “Gross”78295

Average price: 738 rubles.

German quality has been repeatedly confirmed by numerous customers. The company produces tools for professional processing of all types of wood, fiberboard, chipboard, PVC up to 60 mm, laminate boards and high-quality blades for it. Durable steel cutting surfaces made of chrome and vanadium have a long service life. Wear-resistant, with increased hardness.

"Gross"78295Advantages:

- perform basic types of cuts: rough, fast, clean;

- for metal and wooden surfaces;

- T-shaped European shank;

- 10 pieces per pack.

Flaws:

- high price.

PEBARO set

Average price: 149 rubles.

Since 2000, the German company has been one of the best in the production of tools and components for hobbies and children's creativity. The company's products are highly reliable, durable and safe to use.

PEBARO setAdvantage:

- Made from high quality steel composite;

- for plastic and wood;

- 12 pieces per pack;

- low cost.

Flaws:

- No.

Set “Makita” А-86899

Average price: 350 rubles.

A Japanese brand that produces power tools and high-quality equipment for work in professional fields and private use. Durable steel compounds make the files resistant to mechanical wear, bending and creases.

Set “Makita” A-86899Advantages:

- for wood, metal, plastic;

- T-shank;

- type of cut: rough, clean, fast;

- 5 pieces per pack.

Flaws:

- unclear markings;

- high price.

Set “Bosch” Mixed Wood and Metall 2609256746

Average price: 599 rubles.

occupies a strong place among the leaders in manufacturers of consumables for power tools. The widest range allows you to select both a single item and a specific set. Modern alloys extend the service life of the product.

The company has introduced its own labeling, which is also used by other manufacturers. Components are produced in Switzerland or the UK, the T-shank is compatible with power tools from Makita, Hitachi, AEG, Metabo, etc.

Set “Bosch” Mixed Wood and Metall 2609256746Advantages:

- various files for metal, aluminum, several types of wood;

- information packaging;

- 10 pieces per set, 2 of each type;

- universal shank;

- average price category.

Flaws:

- one type of cut is fast.

"DeWALT"DT 2294

Average price: 739 rubles.

The company's 90-year history is an example of the reliability of the designed equipment. Powerful, durable and precise power tools are complemented by high-performance accessories. Carbon and bimetallic types of steel are used for it. The recognizable yellow and black colors have become a symbol of Swiss quality.

"DeWALT"DT 2294Advantages:

- for wood and metal blanks;

- 3 types of cuts: clean, fast, figured;

- universal tail section;

- 10 pieces included.

Flaws:

- high price;

- confusing markings.

Stayer Station wagon 159488-Н5

Average price: 132 rubles.

The manufacturer produces a wide range of hand and power tools. In Russia since 1999. Many buyers recognize the quality and reliability of the product and vote for it with increasing demand.

Saw consumables are made from resistant carbon steel, which ensures flexibility and long service life; a special protective coating on the cutting edge allows you to maintain the sharpness of the blade.

Stayer Station wagon 159488-Н5Advantages:

- main types of cutting: clean, fast, figured;

- processes chipboard, metal, wood, plywood, fiberboard;

- 5 pieces included;

- T-shank;

- budget brand.

Flaws:

- not found.

BOSCH Robust Line

- Set of 10 saw blades made from high carbon steel.

- It demonstrates high cutting quality and durability, but the price of the kit somewhat limits demand.

Types of saw holders

There are 2 types of fastening of a file in a jigsaw: automatic and mechanical.

Automatic quick clamping system

With an automatic system, the blade is placed in the gripper with a shank and secured with grooves.

To replace the blade, a special lever is provided, thanks to which there is no need to remove the protective casing. Using the adjusting screw, the required position of the file is achieved.

The advantages of this method are the speed and ease of replacement, which do not require special skills.

The disadvantage is the wear of parts, leading to a decrease in the quality of the cut, and the difficulty of repair due to the lack of spare parts (especially for Chinese equipment).

Mechanical (manual) fastening method

With the mechanical fastening method, replacing the file and adjusting its position is carried out manually. This fastening is reliable, durable, and has good cutting quality. In the event of a breakdown, repairs are cheap. Parts are easy to find (bearings, Interskol jigsaw rollers, etc.). The disadvantage is the complexity of the process and the skill to correctly insert the file into the jigsaw.

The mechanical fastening method is divided into block and screw.

In the first case, the jigsaw blade holder is made in the form of a block with a slot, which is clamped with 2 front screws.

This clamp is suitable for various files. However, uneven tightening of the screws leads to skew of the blade, which affects the quality and speed of the cut.

With a screw clamp, the file is secured and adjusted using 1 screw. This ensures correct installation and high-quality operation of the equipment.

How to choose the best and most reliable jigsaw blades?

A review of popular brand models allows you to find the best option for your wallet and the amount of work to be done.

Simple recommendations and convenient markings will help you make the right choice. Retail stores and many specialized online construction sites will help you decide where to buy cutting consumables. Study reviews from real customers, compare products by price and order jigsaw accessories online from the online store.

Very often, abandoning cheap counterfeit products in favor of branded products pays off. Additional costs when purchasing consumables will be paid off by the high quality of the cut, the absence of additional processing, the speed of the process and the absence of injuries during the work.

How to clean the surfaces of a hand jigsaw

At the end of the work, it is necessary to clean the jigsaw from sawdust with a brush and, if possible, blow it with air. Apply lubricant to the file and store it in a dry place. If you do not clean the surfaces after work, the service life of the tool will be significantly reduced.

Knowing the differences between jigsaw files, you can make the right choice of equipment, which will allow you to carry out the work efficiently and quickly. An incorrectly selected blade can cause not only breakage, but also damage to the instrument. Also, do not forget that the tool must be cleaned of dust after each use so that the file can last a long time.

Cutting edge geometry

The files differ not only in size, but also in the setting (configuration) of the teeth. The wider the setting and the larger the teeth, the more productive the tool is and the lower the quality of the cut.

Wiring also affects the efficiency of working with certain materials. Its incorrect selection will complicate the work of the master and lead to a decrease in the quality of the cut.

Milled blades with classic layout

The teeth of the files with a classic layout are directed in different directions. This increases labor productivity when working with wood and chipboard, and eliminates excessive heating of the canvas during intensive use.

Experts recommend choosing this file if there are no strict requirements for the quality of processing. Products with a classic layout can be designated as “rough cut” jigsaw files.

The products work with wood, fiberboard, chipboard and all types of plastic. It is not intended for interaction with workpieces made of metals and alloys.

Rice. 7 Milled file with classic layout

Rice. 7 Milled file with classic layout

Milled blades with wavy layout

Files with a large number of teeth, the direction of which changes in groups. The deviation of the teeth from the main plane of the file is insignificant. The working surface is made in the shape of a wave.

All jigsaw files with a clean cut have a wavy layout. These products are ideal for working with wood, plywood and chipboard.

Rice. 8 Milled file with wavy layout

Sanded blades with classic layout

Analogues of milled saw blades with classic layout, differing in blade width and processing method. The presence of grinding ensures smooth operation of the tool and simplifies cutting operations. The product is optimal for working with wood and wood-based materials.

Rice. 9 Sanded file with classic setting

Rice. 9 Sanded file with classic setting

Sanded blades without routing

Products whose teeth are arranged sequentially. The products can act as saws for curved cuts. It forms smooth and neat openings and is designed to work with materials of small and medium thickness.

Rice. 10 File with conical grinding without setting

Models without routing are used as saws for finishing cuts on wood, plywood and laminate. They are indispensable when carrying out finishing activities.

Marking

There is no unified labeling system, and each manufacturer is free to create their own version of presenting information.

All the necessary information about this blade is applied to its side surfaces and allows you to understand the purpose, features and other parameters of the file. There is a prevailing way of designating the parameters of canvases, developed by Bosh specialists.

It consists of letters and numbers that represent the following characteristics:

- The first letter is the type of shank (T - T-shaped, U - respectively, M - Makita, etc.).

- A number indicating the length of the file (1 - up to 75 mm, 2 - from 75 to 90 mm, 3 - from 90 to 135 mm, 7 - over 150 mm).

- A letter indicating the size of the teeth (A - small, B - medium, C and D - large).

- The last letter carries additional information (F - blade made of a bimetallic alloy of special strength, P - clean cut, O - narrow rear part of the blade, making it easier to cut curved shapes, X - progressive notch pitch, R - reverse teeth).

On the neck of the canvas there is information about the metal from which it is made, and on the side surface there is a material that can be processed with it.