The problem of preserving a wooden home, wooden furniture and other wood products has always existed. Especially where the humid climate contributes to the active prosperity of mold, fungi, putrefactive bacteria and other destructive biological factors. Various methods are used to protect wood. In this article you can read about one of them - simple, but very effective and popular among home and professional craftsmen - oiling wood. After spending about 14 minutes viewing the material, you will learn about the advantages and disadvantages of the method, how to use it, what types of oils you can buy and which manufacturers to pay attention to.

What is wood oil and why is it used?

Let's start answering this question from the second part. The motivation for using oil on porous wood surfaces was the obvious physical characteristics of oily liquids:

- water repulsion - up to complete non-wetting of oil-impregnated materials;

- good penetration into capillary volumes, accompanied by displacement of air.

Oil impregnation applied to wood penetrates deeper into the wood structure, the lower the density of its species. Gradually the oil polymerizes, giving hardness to the coating. Since the access to moisture and oxygen is greatly limited, it is easy to guess that for the vast majority of microorganisms, oil-coated wood will not be a favorable habitat.

What is wood oil? First of all, it is worth saying that this is a liquid product that is used for the protection and decorative finishing of wooden structures and products. All types of oil are easy to use and, when chosen correctly, provide good results.

Applying oil to wood The composition of oil used to coat wood can vary. It can be just oil: vegetable, mineral, combined. Or modified oil, that is, with additives that enhance certain properties. Recently, complex oil-based formulations containing solvents and solid particles have been increasingly used.

For example, it is worth adding wax to the oil mixture, and the wood will receive, in addition to protective impregnation, a fairly thick and durable coating. If stabilization of wood with oils should not lead to the formation of a noticeable surface coating, solvents are added to the composition. They allow you to saturate the wood to the maximum possible depth.

Wood finishing oils

What is

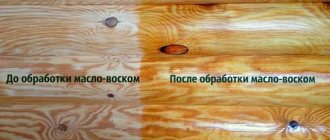

Oil-wax for wooden furniture is a material used for polishing interior items.

As a result of its use, a protective coating with good performance characteristics appears on the surface.

The main components of the material, as the name implies, are oil and wax. The first agent penetrates even into the lower layers of wood, protecting it from external negative influences, preventing the destruction of the solid structure. Wax forms a hard coating on the surface. It also protects the wood from external negative influences, and also increases the attractiveness of the furniture.

Where are wood oils used?

The short answer to this question is that any type of wood in any space can be treated with oil-based compounds. That is, the treatment of wooden surfaces with oil can be carried out indoors for various purposes, as well as outside buildings and other objects located in the open air. As a rule, different types of oil are used for work in different conditions. However, there are also universal formulations.

Use wood oils

Wood oil for interior work

The wooden surfaces to be treated with oil compositions indoors can include: walls, floors, ceilings, furniture, window frames, doors and other structural elements.

Wood oil for interior work The main requirement that applies to all types of oils for interior work is safety for health. Therefore, they are all made on a natural plant basis. Safe compounds are also used as solvents:

- completely natural - for example, gum turpentine;

- synthetic, containing a large amount of ether compounds, which completely volatilize as they polymerize and harden.

The next requirement for oil depends on how heavy the load the surface will bear. For example, if the cabinet walls have almost no such walls, then the countertop wears out quite quickly, and the parquet floor requires special reinforced protection. But wood is most at risk in rooms with high humidity - in the kitchen and even more so in the bathhouse.

Wood oil for interior work Here, in order to prevent destructive rotting under the influence of mold, both a high rate of polymerization, leading to hardening of the oil, and a protective film are necessary. Therefore, for example, the composition of the oil for protecting shelves in bathhouses and saunas includes driers that accelerate polymerization, as well as various types of wax involved in creating a protective film. At the same time, taking into account the inevitable contact of the wooden surface with the body, only natural ingredients that do not cause irritation and allergies were selected.

Wood oil Finally, weighing all the pros and

disadvantages of oil for wood of one type or another, it is necessary to take into account that it is not only protection, but also a decorative finish for a wooden surface. There are oils on the market with different shades and different tinting densities:

- absolutely colorless, completely preserving the natural texture of wood;

- containing pigments with varying degrees of intensity of natural shades: from weak yellowish to fairly dark gray-brown;

- compositions with different color pigments and varying degrees of matting.

The depth and expressiveness of the tone of oiled wood depends not only on the initial color of the oil, but also on the number of layers applied.

Wood oil

Wood oil for exterior use

The oil used to protect wood exposed to the open air does not have to be natural. Mineral oils are quite suitable for technical structures - warehouses, sheds, fences, etc. They are based on refined petroleum products. Combination formulations consisting of a mixture of vegetable and mineral oils are also often used.

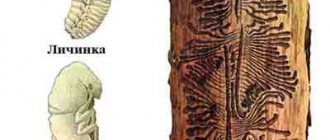

Wood oil Special mineral and combined oil-based compositions, as well as some technical oils that are not intended but used for application to wood, are not environmentally friendly and are not intended for residential premises. But with them, the tree is reliably protected not only from rotting in unfavorable conditions, but also from insects and rodents.

Oil for wood In the case when the facade of a wooden building in which there are people is to be finished, the pros and cons of different types of oil coatings must be weighed especially carefully. Since human health always remains the main selection criterion, natural oil is predominantly chosen. However, it makes sense to apply a mineral or combined composition to certain areas, especially those located close to damp soil.

Oil for facade GOODHIM If mineral oil does not have high decorative properties, then natural oil gives the wood a very dignified appearance. Many modern compositions make it possible to apply a coating tinted in a variety of shades to its surface. For example, completely natural facade oil has 15 such shades.

Varieties

There are several ways to classify material.

Depending on the type of wax:

On hard wax

This category includes products based on Caranuba and Candelilla wax. They add shine to the surface and have water- and dirt-repellent properties. Protects the base shade from fading. The materials are safe to use. Suitable for processing any surfaces.

On beeswax

This product acts in the same way as previous materials, but it has a lower melting point, so it does not increase the fire safety of wooden furniture.

Depending on the shade, the following products are distinguished:

- Colorless. There are no dyes in the composition of such materials. Thanks to this, the furniture retains its original shade.

- Colored. Materials containing dyes. They tint the surface, giving it the desired shade.

Depending on the type of wood, products are allocated for oak, pine, etc.

Both colorless and colored products have the same properties. The only difference is that the latter tint the furniture, while the former do not.

What types of wood oils are there?

Let's start answering this question with what natural vegetable oil can be. The first most popular is flaxseed oil. More often, this definition refers to linseed oil, a modification of linseed oil that is more convenient for practical use. The advantages of this oil: excellent absorption and good polymerization ability. Disadvantage: polymerization is slow. However, the process is accelerated by exposure to UV rays. In this case, the coating darkens, which some also consider to be a disadvantage.

OSMO Azure

The best in all respects relative to flaxseed oil is the oil that is obtained from tung tree nuts or walnuts, as well as camelina and teak oil. However, due to their high cost, they are used much less frequently. Sunflower oil, hemp oil, soybean oil and others are significantly inferior to flaxseed oil and are used extremely rarely in their pure form. More often they are used as raw materials for the production of drying oil.

Terrace Tikkurila Valtti

An oil-based wood finish may contain oil, wax, natural resins, solvents, pigments, and more. Solid components such as wax and pigments are suspended. They are often called dry residue, because when the coating dries, they form a more or less noticeable protective and decorative layer. Oil containing a high percentage of solids is thick. It is more suitable for wood with large, visible grains. For hard wood species, in which the fibers are almost invisible and impregnation is difficult, liquid oils with a very low percentage of dry residue are used.

Facade oil GOODHIM

Important. For very hard wood species, oil with a high solids content is not used, because it is poorly absorbed and may subsequently peel off.

TIKKURILA SUPI for floors

Also, a big problem with absorption is typical for coniferous wood. As long as the essential oils of wood are felt, resin is released, which can penetrate through any coating. There is only one way out of the situation - degumming using solvent treatment.

BELINKA façade

All types of natural oils can be produced with different percentages of solids. Modern technologies now make it possible to obtain even solid oil with a solids content of 100%. As for mineral oils, the process of polymerization, that is, hardening, is especially difficult for them.

Terrace oil GOODHIM

As mentioned earlier, mineral oils for wood are refined derivatives of petroleum products. Cleaning is sometimes so good that a safe and odorless substance is obtained - for example, petroleum jelly. It is good for everyone, but it does not polymerize and, accordingly, does not harden.

BELINKA for sauna

However, even in non-polymerized form, petroleum mineral-based protective oil does not wash off and works well in many extreme conditions. Railway sleepers and utility poles are impregnated with mineral oil. Mineral-based oil is very cheap, and in some cases even free - if you use already used oil.

AQUATEX BALM (“Rogneda”)

For example, engine oil from a car can be spread on piles that are dug into the shore, or they can also be treated with transformer oil. However, the use of these wood preservatives is limited for environmental and safety reasons. In addition, they have a strong and unpleasant smell. While natural oils have a pleasant natural aroma and are absolutely safe and environmentally friendly.

Terrace oil Healthy Home

And another disadvantage of wood treated with mineral oil is its unfavorable appearance: the natural color is lost and rapid or slow, but inevitable darkening occurs.

Impregnations for treating wooden surfaces of walls and floors.

OIL WAX, oil and wax impregnation, oil and wax for the floor, hard wax or regular VARNISH?

There are consumers who, apparently out of ignorance, out of habit, or out of saving money, buy the first beautifully and brightly designed jars with finishing moisture-proof or varnish impregnations that they like in the nearest or convenient stores or markets.

At the same time, many do not even think that each protective composition, impregnation or varnish, in order for it to work well, must be selected according to many parameters, and not just by price and your liking, for example, the gloss or color of the treated surface obtained after applying this finishing impregnation. If you follow an unprofessional approach to choosing a finishing protective coating for your own home or bathhouse, then after a very short time, instead of a beautiful wooden frame from a log or timber, you can end up with log walls with a PEELING and peeling surface on which the incorrectly chosen varnish or other protective finishing agent is peeling off, and the burnt, darkened wood underneath has a gray-black color. Surely many have seen houses and baths with an incorrectly selected final protective coating. The negative effect of cracking and peeling of the surface most often occurs due to the fact that incorrectly selected finishing impregnations can form a HARD, low-plasticity, NON-BREATHABLE, vapor-proof film. This film superficially protects the wood from external influences and has a certain adhesion (degree of adhesion) to a log or beam, but due to the fact that the wood of a wooden house is constantly in a barely noticeable movement, expanding or contracting depending on temperature conditions and relative humidity of the surrounding air, The surface film-like glass-like low-deformation coating begins to PEEL AWAY, BURST and sag. If these shortcomings are not eliminated in time, then from the resulting “untreated wounds” on the wood, fungus, mold and darkening will quickly begin to appear over the entire surface of the log house, which leads to EXPENSIVE GRINDING of the log or timber. The practice of building wooden houses and bathhouses and the centuries-old history of treating wood with various impregnations to protect log houses, wooden floors, roof slopes made of boards or shingles suggest that varnish is a relatively new impregnation or means of protecting wood. Suffice it to remember that when varnishes had not yet been invented, in Rus' log houses were treated with linseed oil, and a protective layer of beeswax was applied on top of the oil-treated wood. Such impregnation was applied once after the frame was assembled and served for many years. No work was carried out to scrape the initially applied wood oil and wax from the wood, and to improve the quality of protection and enhance the protective properties of wooden houses and baths treated in this way, periodic renewal of the oil-wax coating was carried out, i.e. the layer of oil and wax was renewed. Proof that the wood in a wooden house, previously treated with oil and wax, was not mechanically cleaned of oil and wax before it was renewed and a new layer was applied; wooden walls and floor boards previously treated with oil and wood wax in houses and baths were not subjected to scraping, as is the case It is now recommended to do this for many varnishes before renewing them or reapplying varnishes; this is what we can see NOW in ancient estates that have survived to this day, where a wooden floor made from old boards is most often present in its original form, or log houses treated with oil and wax have been preserved hand-cut and a LOG that is over 450 years old ! If they were sanded or scraped every year with each renewal and application of a new layer of wax, then there would be nothing left of them.

Impregnation for wood. Impregnation for wood. Impregnation for wooden surfaces.

Modern knowledge and technologies have made it possible to expand the range of impregnations that improve the protection of wood, preserve its qualities, and introduce additional properties that meet the requirements and desires of customers. The advent of varnishes and azures for the treatment and protection of wood makes it possible to impart properties to a wooden surface that oil-wax impregnations could not previously provide. But with many positive qualities inherent in varnishes and enamels, wood oil, wax oil for wood, as an impregnation for wood or an impregnation for a wooden surface, may be a priority or more suitable when processing wooden houses and carrying out finishing work in a wooden house.

Interesting: Danish butter is not from Denmark

Wood oil is a very interesting topic for manufacturers and DIYers. There are many recipes, widely known and secret. There are also a kind of folk-historical brands, the essence of which is difficult to explain. For example, teak oil, which is not made from teak, but is mixed from different oils with an indefinite number of additives. The historical homeland and authors of this good complex oil, which ideally should also include a part of tung, are unknown. And even eminent foreign manufacturers do not bother with having at least a minimal additive in the form of tung oil.

Danish oil is even more popular. On the Internet you can find recipes made by leading companies, as well as recipes for making them yourself in your home kitchen. This oil's affiliation with the country of Denmark is very relative: Denmark produced furniture from expensive wood, and post-war Americans really liked this furniture. Either there was not enough furniture for everyone, or it was necessary to bring respectable wardrobes and sideboards into line with the salary - one way or another, interested people from the company Rusting Ltd came up with an oil that turned widely consumed wood into noble wood. Needless to say, it was a very good oil. It gave the desired color and, although it did not form any visible coating, it was stable and durable. Even with effort, it was not easy to get to the essence of the wood. The principle and purpose of this excellent composition has been preserved to this day and has even been developed.

The Danish butter recipes available are full of variety - everyone can bring their best skills under this name. As with teak oil, the presence of a product called tung oil is extremely rare, but in both cases there is linseed oil.

Application

To treat wooden furniture with oil-wax, you don’t have to turn to professionals. You can do the work yourself if you follow the following instructions:

Prepare the surface

All fasteners are carefully screwed or driven in so that the caps are as deep as possible into the surface. After this, the holes are sealed with wood putty. This material also masks defects - cracks, etc. if any. After this, take a break until the putty has completely hardened.

The base is sanded

To do this, use a grinding machine or sandpaper.

The surface is dedusted

The easiest way is to wipe the furniture with a damp cloth and wait until it dries.

Perform the first surface treatment with oil-wax

For this, it is best to use a brush with natural bristles. The product is applied along the wood fibers.

Take a break to let the material dry

This usually takes 8-10 hours.

Re-treat the surface

Stop work again to allow the product to harden.

The coating is polished by machine

This enhances its appeal by adding a glossy shine.

How should wood oil be applied?

On an industrial scale, methods such as immersion in special baths are used to treat wood with oil. Sometimes under pressure and at elevated temperatures.

For home work everything is much simpler. You can successfully use your usual brushes and rollers. Some people use a spray gun. Treating a horizontal surface is especially simple: pour oil little by little and rub it in with a sponge, cloth or napkin. Useful application rules:

- When preparing the surface, grinding with 120-180 abrasives is used. To achieve a good result, be sure to vacuum the treated surface and not wipe it, as this will clog the pores. Shake the oil thoroughly before use.

- Oil is applied to wood in layers. The wood is coated as evenly as possible. Immediately or after 5 minutes, unabsorbed oil must be removed, preferably with a piece of cotton cloth.

- The first layer is dried especially carefully. For loose wood species, lint appears after the application of liquid oils. In this case, the surface is treated with sanding mats.

- Oil is preferentially applied to a horizontal surface with an upward motion, since it flows down on its own. When processing any surface, the final movements are along the fibers.

- Important. Do not apply different oils sequentially to a wooden surface during one cycle, as they may contain conflicting ingredients.

- When the oil dries, ensure good ventilation.

Attention! Cloths, sponges, brushes, napkins soaked in oil are prone to spontaneous combustion and therefore require proper disposal. They can be immersed in water or sealed in a tin without oxygen.

Selection rules

When choosing wax oil, consider the following points:

- Composition of the material . Experts recommend giving preference to products containing hard waxes, since they are refractory and have increased strength, which means a longer service life of the coating. In addition, when choosing a material, you should pay attention to the presence of allergens, which include orange oil, etc. It is not recommended to purchase such products, as they can provoke negative reactions in the body.

- Type of wood. The wax oil must be suitable for processing the specific wood from which the interior items are made. The appropriate markings are indicated on the material label.

- Furniture shade. Colorless products are suitable for all interior items. Colored materials are chosen depending on the shade of the product.

Expert opinion

Doshin Roman Valentinovich

Cabinetmaker, work experience - more than 15 years

Wood is the best material for making furniture. This is an environmentally friendly product, which indicates its safety for people. In addition, wood is easy to process, looks attractive and, with proper care, lasts for decades. The only “weak point” of the material is the lack of resistance to the harmful effects of moisture. However, this problem is easily solved by oil-wax. It creates a coating on the surface that protects furniture from moisture. The main thing is to choose a quality product. I recommend using hard wax based products. They are easy to apply, create a durable coating and have a melting point of +72-910C.

Where to buy high-quality oil for wood processing?

The best way to answer this question is by contradiction. That is, this means that you should not buy wood oil from an unstable trading organization without decent storage facilities - where no one is responsible for the quality of the goods offered and cannot present certificates of quality compliance. Obviously, the best oil is guaranteed to be bought in a store that sells products from well-known manufacturers. If you do not neglect the opportunities to get some benefit from the purchase, then there is another reliable option - purchasing the product directly from the manufacturer.

As practice has shown, it is in stores and online stores that have a direct connection with production that the most favorable price-quality ratios are observed.

For example, you can order, with delivery, wood oil through the GOODHIM sales department. You can order a small quantity or a batch. Wholesale, of course, will be cheaper. You can find out what variety of assortment is available today from the table.

Wood oils WOOD OIL from GOODHIM

| Oil type | Retail price for 0.75 l, rub. | Wholesale price for 0.75 l, rub. |

| Facade oil | 1144 | 915,20 |

| Terrace oil | 888 | 710 |

| Interior oil | 1723 | 1378,40 |

| Wood oil under normal conditions | 641 | 512 |

| Natural linseed oil | 662 | 529 |

| Oil for protecting shelves in bathhouses and saunas | 809 | 647,20 |

All wood oils WOOD OIL GOODHIM have a 100% natural composition, do not contain harmful additives and provide reliable protection of wood from mold, rot, and insects. Each product has a detailed description, including instructions for use.

How long does oak oil take to dry?

According to experts and manufacturers, oils intended for interior work on oak dry within 12 hours. This statement is true for comfortable room conditions: air temperature – 23 °C, humidity – no more than 50%.

The oil gains maximum strength only 2 weeks after application. During this time, the composition penetrates into the deep layers of wood, fills its pores and capillaries, is absorbed and polymerized. It is not recommended to wash oiled oak floors with water during these 14 days.

When conditions change, the polymerization time of the oil also changes. The lower the temperature and higher the humidity, the longer the coating takes to dry. Outdoors, despite higher humidity, as well as daily temperature fluctuations, oil on oak dries faster than indoors. Natural air movement, regular airflow and exposure to ultraviolet radiation have an effect. The latter accelerates polymerization, but at the same time gradually destroys the color. Additives with UV filters allow you to avoid this unpleasant effect.

The presence of colored pigments in oils does not in any way affect the drying speed of the coating. However, if the color of the surface changes significantly, the oil must be applied in several layers to achieve the desired color density. Multilayer coatings take longer to dry.

What brands of oils are there on the Russian market?

It is impossible to answer this question absolutely accurately within the framework of one article - the range of wood oils on the Russian market is so rich and varied. Products from both foreign and domestic manufacturers are presented. Selectively, you can name such popular brands as:

- Belinka, whose wood oil is represented by a solid line and includes: sauna oil with paraffin, facade oil, oil with wax, yacht type oil - for harsh climatic conditions, multi-colored oil for decorative coating, as well as Belinka oil, safe for contact with food. .

- OSMO oil of the famous German brand represents the universal oil Azure, oils with hard wax: with quick drying, with a non-slip effect for the floor, as well as OSMO oil for countertops.

- Among the wood oils from the well-known company TIKKURILA, VALTTI oils are very popular: terrace - oil with white spirit thinner, oil for external use in harsh conditions, as well as universal oil.

- Products from domestic manufacturers are increasingly conquering the market, which not only develop unique compositions in their own scientific laboratories, but also launch a full cycle of their production.

The following wood oils are in great demand:

- Healthy House oil for terraces and floors produced by Lakra Sintez LLC;

- oil Aquatex Balsam “Rogneda”;

- natural GOODHIM oils: for baths and saunas, for facades, for terraces, for interiors, as well as universal linseed oil.

Price level for oils from foreign and domestic producers

| Oil name | Price in rubles per 1 liter |

| OSMO Azure | 4325 |

| TERRACE TIKKURILA VALTTI with organic thinner | 810 |

| TIKKURILA SUPI for floors | 1032 |

| BELINKA façade | 1290 |

| BELINKA for sauna | 1070 |

| Natural facade GOODHIM | 1525 |

| Terrace GOODHIM | 1184 |

| AQUATEX BALM (“Rogneda”) | 620 |

| Terraced Healthy Home | 460 |

The price of wood oil depends on many factors: the composition and quality of the components, and the covering ability. It should be borne in mind that wood oil is a very economical material and 1 liter is a fairly large amount.

Compound

Vegetable oils are used to make the material:

skeleton

linen

soy

sunflower

As for wax, one of three types of this material is used to produce the product:

Carnauba

Extracted from the leaves of the Brazilian wax palm. Refractory material of increased hardness. It is safe to use because it does not emit toxic substances and does not cause allergic reactions. For this reason, oil with the addition of this type of wax can be used to treat wooden furniture even in children's rooms.

Candelilla

Extracted from the Canelilla bush. Refractory material, safe to use. Does not provoke the appearance of negative reactions in the body, does not emit toxic fumes. This, just like with the previous option, allows you to use oil and wax to treat furniture in children's rooms.

Bee

This wax, unlike the two previous materials, is not refractory. Its melting point is only +350C. However, its manufacturers also use it to make furniture polishes. This is not surprising, because the product helps level the surface, gives it an attractive shine, and creates reliable protection from external negative influences.

In addition to the main components, the material usually contains the following components:

- paraffin;

- solvents;

- driers - elements that reduce the drying time of the product;

- dyes - these elements are absent in colorless compositions;

- additives – protect the base from the negative effects of ultraviolet radiation, which prevents the surface from fading.

How to choose the right wood impregnation?

When choosing a wood impregnation (be it oil or any other product), it is important to understand exactly where it will be used and under what conditions it will be used.

First of all, you need to decide for what work the material is intended.

- for internal or external. The choice of composition of the product depends on this, because toxic products can be used on the street (although it is advisable, if possible, to use safe protective equipment). In addition, for outdoor use you need to choose an impregnation with weather-resistant properties.

Secondly, you should pay attention to the nature of the operation of the surface being treated

. For flooring and all horizontal surfaces that people walk on (steps, terraces), it is better to choose materials with increased wear resistance. For most vertical surfaces this criterion is less significant.

It is difficult to make a mistake in choosing, because manufacturers, as a rule, indicate the purpose and scope of application of the product. All you have to do is follow their recommendations.

Additional factors for choosing impregnation:

- Decorative properties

- many products slightly change the shade of wood, and some contain a coloring pigment. - Durability of protection

- while water-based impregnations last only a short time, Decken oils protect wood for 3-4 years. - Cost

– Price is important when comparing different products with the same features. - Product consumption

- you should always compare the cost and consumption of products, which vary significantly. - Method of application

- you need to select a product that can be applied without significant effort and expense.

Is it better to coat wood with wax or oil?

What exactly should I cover the floor with? Choosing “clothes” for the floor is both easy and difficult at the same time - each type of coating has its own advantages and nuances. Matte, glossy, colored, clear, high-tech or old-fashioned?

There are different ways to protect a solid wood floor: choose your coating wisely.

A beautiful natural wood floor has a thousand advantages and only one drawback - it needs to be looked after. Therefore, the laid floor board (floor slats) is covered with one of the types of decorative coatings - varnish (varnishes), paint, oil or wax. The materials are different, and sometimes give the opposite effect, but they are equivalent only in one thing - all coatings for real solid wood floors will require regular updating.

SO, HOW AND WHAT TO COVER A NEW FLOOR?

You can choose the old Scandinavian method - it is two hundred percent environmentally friendly. Ready? Scandinavians do not cover anything after finishing sanding, but begin to wash with household, ordinary “gray-brown” soap.

What is the secret of Scandinavian soap impregnation? Over time, the wood becomes covered with a thin but dense layer of soapy substance, which means it is practically not contaminated.

More traditional methods include covering a wooden floor with varnish, paint, oil and wax. True, they are now trying to use paint less and less, and previously rare oil is being used more and more often (you can get to know this valuable material better in our article WHY DOES WOOD NEED OIL?).

Wood oil is not a convenient way to apply a topcoat, but in the end it will serve your floor well - the wear resistance of a floor coated with oil is maximum. Any damage is sanded and impregnated with oil - and no trace remains! The floor is covered with oil in several stages, but it is completely saturated only after a couple of years of regular applications. How to coat wood after oiling?

Which is better: heated floors or radiators?

Warm floorBatteries

After the first application of oil, the floor becomes somewhat impractical (it is troublesome to clean from dust and dirt), but then the oil floor even acquires dirt-repellent properties. The oil, being an environmentally impeccable composition, impregnates the wood, protecting it both inside and outside.

Parquet wax (another environmentally impeccable coating) does not impregnate wood, but it protects it perfectly! Parquet wax (made from beeswax) is usually used as an additional layer after oil impregnation, but sometimes waxing is done as a separate coating. Applying wax is very simple, for example, with a roller.

After which you need to wait until it dries and you can polish it with a cotton cloth. The wax coating, like the oil impregnation, is renewed 2 times a year - in spring and autumn

Varnishes for wood. If previously a wooden floor was always painted, now paint can only be found in design projects - and everywhere floors are coated with varnish. This coating does not hide, but emphasizes the fashionable and desirable texture of natural wood.

The varnish has good protective properties, is quite practical, and the wood “gets” an excellent emphasized (or changed towards greater saturation) shade and a spectacular gloss.

Varnishing begins with an inspection of the freshly laid and freshly sanded floor. The screw heads recessed into the floor are covered with sealant or putty (for wood), and the floor itself is covered with a starting varnish - craftsmen recommend applying it immediately after sanding. How long does this varnish take to dry? If you bought floor boards that are absolutely dry and of high quality (such as those from AvangardLes), then a couple of weeks will be enough.

An insufficiently high-quality floor board (floor board) with a moisture content of more than 12% is dried with the first layer of varnish for about three months - and it is not advisable to apply the next layer of varnish before this period expires. But there will be time to choose the type of finishing varnish.

So, varnishes come in three main types:

Water-soluble wood varnishes are odorless, dry fairly quickly and are perfectly absorbed. Water-soluble varnishes can be one-component (service life up to three years) and two-component (service life up to 10 years), they differ in wear resistance and price.

Alkyd varnish for wood emphasizes the structure of wood better than others and is suitable for “moving” bases, wear-resistant, but very finicky - it takes a long time to dry, does not tolerate uneven drying (sun, heating radiators) and “generous” application, which can “wrinkle” the surface. Requires special care!

Waterless polyurethane varnish for wood is better suited than others for high-traffic areas - it is wear-resistant and resistant to household chemicals and water. However, it does not apply to environmentally friendly coatings for bedrooms and children's rooms, since acidic hardeners are used during the application process (work with a respirator!).

How to apply varnishes to wooden floors? Varnishing requires skill, and if this procedure is new to you, it is better to first “practice” on waste from laying the floor. What is the best way to degrease metal before painting with solvent or white spirit? For example, quick-drying water-soluble varnishes are applied with a high-quality roller using strictly forward movements “from yourself”. Some varnishes can be applied with a spatula - with quick movements along a smooth path of the letter S, others are applied in a cross-shaped motion, others - across the floorboard and immediately leveled lengthwise.

Before working with varnish, be sure to read the instruction manual so as not to make mistakes!

Where can I buy everything needed to lay a new natural wood floor?

Call the AvangardLes company, we always have in stock not only absolutely dry and high-quality floor boards (floor slats, floor boards) made of Angarsk larch of all common sizes, but also hidden fasteners for laying floor boards and paint and varnish products for finishing work!

Additional Information:

- For intensive use and use of the product in aggressive environments, it is better to give preference to varnish. It should be borne in mind that varnish, unlike oil, is not repairable in domestic conditions. If the varnish surface is damaged (scratches, abrasions appear), you will have to sand off and re-varnish the entire surface . This is not done at home. Professional factory repairs will be required.

Acrylic varnish does not initially cause allergies. I experience this myself. Unlike other varnishes that I have used for a long time, it saturates the wood, as if merging with it, and hardens on the surface with a very, very thin film. Hardens.

Chemists said that this is called polymerization and that in this state the varnish is completely inert and absolutely safe.

Unlike varnish, oil deeply saturates the wood without changing, but only emphasizing its natural texture. The treated surface remains textured and acquires a slight matte tint. Is it better to level a wall with plasterboard or putty?

Wood oil imparts water-repellent properties to the surface, protects it from dirt and does not close the pores, that is, the surface remains “breathable”.

Oil coating of floors gives you the opportunity to make minor repairs yourself, for example, get rid of stains and scratches, which are less visible on oil than on varnished floors. The easiest way to remove scratches is to sand them with sandpaper and soak them in wax or oil. After applying the solution, the floor will swell slightly (temporarily) and the scratch will heal.

Oil permeates the wood after application, while wax forms a thin film on the surface of the product. But unlike a solid polymer varnish film, wax allows the wood to “breathe,” albeit not as intensely as when coated with oil. Therefore, wax provides less protection from abrasion and mechanical damage, but it is much better at protecting the wood from drying out and rotting processes inside the fibers.

Wood is a material that is in great demand. This demand is due to a large list of advantages. But it is worth noting that wood is quite capricious - it cannot withstand humidity, temperature changes, bugs and fungal infections. However, all this is not a reason to abandon the tree. To appreciate its advantages and not encounter disadvantages, you need to carry out protective treatment with oil-wax.

Let's look at the features of this impregnation and talk about how to choose it correctly.

Despite a lot of aesthetic and functional advantages, wood can hardly be called an absolutely ideal material. The thing is that it is very afraid of such negative factors as humidity, temperature changes, fungi, bugs, etc. Is this a reason to abandon the tree?

Not at all! But this is a reason to properly protect the material. Experts recommend using oil-wax for interior work. What's good about this type of protection? How to choose a composition and how to work with it?

We suggest you learn about this further, and at the same time read reviews about oils in order to accurately determine the most suitable impregnation.

How to treat the surface → Room decoration → How to choose the right paint → Surface treatment technologies → Leveling and finishing the walls → Selecting and applying a primer → Removal from the surface → Stretch ceilings and technologies → Reviews and testimonials

Types of impregnations by purpose

In terms of functionality, there are impregnations:

- Antiseptic - prevent the development of microorganisms (fungi, mold, bacteria). It is antiseptics that protect wood from blue stains, rot and damage by insects.

- Water-repellent - do not allow moisture to penetrate deep into the material and, thereby, prevent its deformation. Most often they also have an antiseptic effect.

- Fire-resistant - for a long time prevent the ignition of wood under the influence of fire. The effect is achieved due to the presence of fire retardants in the composition.

- Frost-resistant - increases the resistance of wood to sub-zero temperatures.

- Decorative - emphasize the unique wood texture, and also give the wood the desired shade.

The best Decken impregnations combine antiseptic, water-repellent and decorative functions.