All builders know that reinforcement of a strip foundation is a necessary stage in the construction of buildings, thanks to which it is possible to achieve the necessary characteristics of strength, reliability, resistance to external influences, and significantly extend the service life. The tandem of concrete and metal guarantees the best properties that neither of these materials can provide separately.

Strip foundations are most popular in individual construction of residential buildings, as they are relatively inexpensive, involve low consumption of materials, and quick and simple construction. But without strengthening the foundation, a structure of this type will not have the necessary properties and will not last long. Therefore, hardening must be done; all work can be done with your own hands.

Requirements for fittings

To understand what reinforcement is needed for a strip foundation, it is necessary to perform calculations and consider the main types of material. To perform the work, mechanically strengthened, hot-rolled, heat-treated construction reinforcement is used. The class is selected according to maximum loads, taking into account tensile characteristics, ductility, weldability, corrosion resistance, ability to withstand temperature changes, etc.

The main brands of rods: hot-rolled rod (A), cold-deformed wire (BP), very strong rope (K). For the foundation frames, rods of the A400 (AIII) yield strength class with a crescent-shaped herringbone pattern are selected.

Proper reinforcement involves the use of the following types of rods:

- Workers - for laying around the perimeter

- Transverse vertical

- Transverse horizontal (clamps)

- Additional - usually a binding wire is used instead

To understand which fittings are best to use, you need to remember some rules. To strengthen the base of one- and two-story buildings and light structures, rods with a diameter of 10-24 millimeters are suitable. The strength characteristics of thicker (and much more expensive) reinforcement are unlikely to be used.

The rods must be corrugated, as they provide excellent adhesion to the concrete mortar; their thickness must clearly correspond to the values specified in the documents. Smooth rods are cheaper, but they will not allow you to create a reliable and durable reinforced frame. They can only be used in transverse connections where the load is not very large.

When creating a strip foundation frame on homogeneous soil, you can choose a material with a diameter of 10-14 millimeters; on heterogeneous soil, 16-24 is better. If the side of the building is more than 3 meters, the working reinforcement of the monolithic foundation is made from rods of at least 12 millimeters, but not more than 40.

The technology requires that horizontal clamps in diameter should not be less than a quarter of the working rods - usually 6 millimeters. Vertical rods for low-damage foundations of 80 centimeters or less should be at least 6 millimeters in cross-section. Having thought everything through, you can determine what diameter of rods is needed for different types of work.

Shallow tape reinforcement

The question of the need to reinforce a shallow strip foundation (MSLF) is often asked. To dot all the i's, let's explain some points that are indicated in SNiPs.

- If a one-story building with a height of no more than 10 m is being constructed with a reduced degree of responsibility on any soil. There is no need to reinforce the foundation.

- When constructing buildings higher than 10 m at the normal second level of responsibility. And these are residential and public buildings with several apartments. Reinforcement must be carried out. In this case, the spacing of the reinforcing rows is at least 20 cm.

In design projects for lightweight buildings, the reinforcement method is often specified in the form of laying a single grid similar to a slab foundation. This is fundamentally wrong, because in the center of a strip foundation (even a shallow one) the loads are insignificant. They are located along the edges of the tape.

That is why working reinforcement is the main thing in terms of load-bearing capacity. That is why the rods are located from the edges of the concrete structure at a distance of 5 - 10 cm, and not 30 or 40. They have the largest diameter compared to the vertical and transverse elements.

Reinforcement requirements

Before reinforcing, you need to decide what size the frame will be, make a drawing, draw a diagram of all the work and structures. The geometric dimensions of the foundation must be such that the location of the reinforcement is free. The concrete layer completely covers the frame, protecting it from external influences and corrosion.

The minimum distances between the rods must be sufficient for effective joining and compliance with all technology rules. Only high-quality fittings are used in the work, in accordance with SNiP 3.03.01. Bending of rods is performed using special devices. The bending radius corresponds to the diameter and physical parameters of the rods.

Video of manual machine for bending reinforcement

And another useful video:

Video on how to bend reinforcement using a homemade machine

Calculation of size, quantity and diameter of reinforcement

It is important to immediately know how much reinforcement is needed to make the reinforcement cage reliable and durable. Knowing the dimensions of the building, you can carefully calculate everything.

Standard frame configuration for small houses:

- Bottom and top row of belt

- 3-4 rods for each row

- The current distance between the rods is about 10 centimeters. The distance from the rods to the edges of the base should be at least 5 centimeters.

- The belts are connected with clamps or sections of rods in increments of 5-30 centimeters.

So, if you need to build a building with an area of 150 square meters, the perimeter of the external walls is 50 meters. To calculate the amount of reinforcement, you need to take everything into account: 2 belts of a longitudinal row of 3 rods each equals 6 rods, multiplied by 50 meters, that gives 300 meters of main rods. If the lintels are laid in increments of 30 centimeters, the result is 167 pieces per 50 meters. The length of the transverse lintels is 30 centimeters (167x0.3=100.2 meters), vertical - 60 (167x0.6=200.4 meters).

It turns out that to the question of how much reinforcement is needed to strengthen a house with an area of 150 square meters with a wall perimeter of 50 meters, the answer is: 300 meters of thick corrugated rods and 300.6 thinner rods. Plus 10-15% for stock and docking.

How much rod do you need?

Having developed a strip foundation reinforcement scheme, you know how many longitudinal elements you need. They are laid around the entire perimeter and under the walls. The length of the tape will be the length of one reinforcement rod. By multiplying it by the number of threads, you get the required length of the working reinforcement. Then add 20% to the resulting figure - a margin for joints and overlaps. This is how much in meters you will need working reinforcement.

You count how many longitudinal threads according to the diagram, then calculate how many structural rods are needed

Now you need to calculate the amount of structural reinforcement. Calculate how many crossbars there should be: divide the length of the tape by the installation pitch (300 mm or 0.3 m, if you follow the recommendations of SNiP). Then you calculate how much it takes to make one lintel (add the width of the reinforcement cage with the height and double it). Multiply the resulting figure by the number of jumpers. You also add 20% to the result (for connections). This will be the amount of structural reinforcement to reinforce the strip foundation.

Using a similar principle, you calculate the amount needed to reinforce the sole. Putting everything together, you will find out how much reinforcement is needed for the foundation.

You can read about choosing the brand of concrete for the foundation here.

Rules for reinforcing strip foundations

- Working rods must comply with at least class A400.

- Welding is not used to connect rods due to the likelihood of weakening the cross-section of the element.

- The frame is tied at the corners, not welded.

- It is better not to use smooth reinforcement even for clamps.

- The layer of external protective concrete should be at least 4 centimeters, which will guarantee effective protection against rust.

- In the longitudinal direction, the rods in the frame are connected with an overlap equal to at least 25 centimeters and at least 20 diameters of the rods.

- The standards require that when metal rods are frequently placed, the aggregate in the concrete solution is not very large and does not get stuck between the rods.

- How to properly lay reinforcement in a trench - this can be done in two ways: create a frame outside the foundation or directly in the trench. The reinforcement methods are almost equivalent, but you will have to hire someone to work in the trench, while constructing the frame separately on site can be done independently.

- Knitting is carried out with a special crochet hook or knitting machine.

- Many people wonder what kind of wire is used for knitting - the answer is simple: soft thin wire of not a very high level of strength. It needs to be pulled well; a strong knot is obtained in 2-3 turns of the hook.

- The overlap (the distance from the edge of the rod to the knitting point) should be at least 5 centimeters.

- All wire connections should be as tight as possible, with no free space between the clamps and the frame, and no element should move.

About the need for strengthening

To what extent is it necessary to strengthen a concrete mass with steel wire? After all, concrete has fairly high strength characteristics. Indeed, concrete has increased resistance to compressive loads, but requires reinforcement against the destructive effects of tensile forces.

The greatest likelihood of stretching is on the surface of the base, this is where the reinforcement should be placed

How to knit reinforcement mesh yourself

The following step-by-step instructions will give you the opportunity to learn how to properly make a frame and provide the foundation with the necessary properties. The easiest way is to knit ready-made reinforcement for a strip foundation on the ground. Straight sections of the mesh are created outside the structure, but the corners are knitted after the frame is lowered into the trench.

- First you need to cut pieces of rods. It is better to start knitting with the shortest section of the foundation in order to gain a little experience. You need to cut to a minimum, trying to use the entire length of the working rods. If we take as an example a strip foundation 40 centimeters wide and 120 centimeters high, then the indicators are as follows.

- The metal is poured on all sides with a layer of concrete at least 5 centimeters thick. The net dimensions of the frame in height are a maximum of 110 centimeters, width – 30. For knitting, add 2 centimeters on both sides for an overlap. It turns out that the blanks for horizontal jumpers should be about 34 centimeters long, and vertical ones - about 144 centimeters. This is for high foundations, but usually a base with a height of about 80 centimeters is used.

- 2 rods are placed on a flat surface, horizontal spacers are knitted at a distance of 20 cm from the ends on both extreme sides: the wire is folded in half, pushed under the fastening point and tightened by twisting the hook.

- At a distance of about 50 centimeters, all the horizontal struts are fastened in turn, the structure is put aside, another one of the same is made - these are the lower and upper frames that need to be tied together: adapt stops for both meshes between the rods and 2 struts vertically at the ends, attach the remaining pieces. The same should be done with all straight sections of the structure.

- Then, pads with a height of at least 5 centimeters are laid at the bottom of the trench, side supports and a mesh are installed correctly. Now you need to knit every corner and joint, creating a single frame. The overlap of the ends of the rods must be equal to at least 50 times the diameter of the rods.

- Next, the lower turn is tied, the vertical posts are attached, and the upper frame is attached to them. Then, on all surfaces of the formwork, you need to check the distances, indentations, and overlaps at the joints so that everything is done correctly and clearly.

- Connecting rods along the length usually does not cause problems, but fastening the frame parts in the corners must be done in accordance with established standards. There are two ways: between two perpendicular structures or at the point where a wall adjoins another.

Corner knitting technologies:

1) Rigid with a foot - at the end of each rod, knit a foot at a right angle with a length of at least 35 diameters of the rod, connect the bent part to the perpendicular section. This is how the outer rods of the wall frame are attached to the outer rods of the other, while the inner ones are also welded to the outer ones.

2) G-clamps - instead of a clamp, take a clamp with a length of at least 50 reinforcement diameters, one side is attached to the frame of one wall, the other is attached perpendicular. The outer rods are connected to the inner ones, the pitch of the clamps is ¾ of the height of the wall.

3) U-clamps - for one corner you need to install two U-shaped clamps with a length of at least 50 reinforcement diameters, each welded to one perpendicular rod and two parallel ones.

Junctions are created using similar fastening methods.

Subtleties of working with crochet

From the moment you begin to reinforce the foundation, it is necessary to clarify the rules for using tying tools. The gun is used on a large scale by professional builders, but for private construction, a crochet hook will be quite a suitable device.

If you prepare the appropriate templates in advance, the use of the hook is greatly simplified. To prepare the templates, you need wooden blocks 30 cm wide and 50 cm wide; their length can reach no more than three meters, otherwise it will be inconvenient for you to work on such a workbench.

We drill grooves and holes in the block that follow the outlines of the steel rods in the frame base. Knitting wire, cut to a length of 20 cm, is placed in advance in the places prepared in this way, after which the reinforcing rods are fixed.

To understand how to properly reinforce the foundation, or rather, to study the intricacies of tying the frame, it is proposed to consider one example. For construction you will need a couple of options: for crosshairs (the arrangement of elements is perpendicular) and for overlapping joints. For a strip base, the second method is mainly used, and the first is more suitable for pouring a monolithic slab.

Step-by-step instructions to form a frame using overlapping crochet joints are as follows:

- connect the reinforcement at several points along the entire length of the joining section, the wire is positioned so that it falls between the reinforcement corrugations;

- the knitting wire is folded in half and placed under the knitting area;

- hook the loop;

- the free end is brought to the hook and placed on top with a slight bend;

- the hook is rotated, at which the knitting wire begins to twist;

- the instrument is carefully removed.

To make one overlap connection, you will have to repeat the procedure three to five times - a one-time cross connection will not be enough. The knitting is reliable, since this method of fixation prevents possible shifts of the steel elements.

Knitting reinforcement using a special device - a knitting machine

To create this tool, you need to take several boards 20 millimeters thick, cut 4 boards along the length of the reinforcement, connect two at a distance equal to the pitch of the vertical posts, creating 2 identical templates. Next, two vertical supports are made with a height equal to the height of the reinforcement mesh. The supports are constructed with side corner stops; it is better to choose a flat area for work.

The device is used as follows: the legs of the stops are installed on two knocked down boards, the two upper boards are placed on the top shelf of the stops and fixed. That's it, the reinforcement mesh layout is ready, now you can quickly knit it. It is enough to place the vertical reinforcement struts in the marked places, fixing them with nails, install the rods on each steel lintel, doing this on all sides of the frame. Next, take a hook and wire - that’s it, you can knit. Such a device is relevant where it is planned to create many similar mesh sections.

Video on how to knit reinforcement using a device

How to knit reinforced mesh in a trench

Working in a trench is more difficult, so you need to plan everything ahead of time. Special devices or ordinary stones are placed at the bottom of the trench at a height of at least 5 centimeters in increments of the width of the mesh. The stones are laid out with longitudinal rods, and horizontal struts are tied. Until the rods are in the desired position, a second person holds their ends.

The reinforcement is knitted with a step between spacers of 50 cm wide. We install the pegs and begin to knit the monolithic structure. This is done on all straight sections. Parts of the frame should not touch the formwork; they should be at a distance of several centimeters from the formwork.

Then the corners are knitted using one of several existing methods. It is imperative to maintain the length of the overlaps, with the installation of vertical rods. Rods are often used here with a larger diameter, increasing the strength of the material. Upon completion of the binding, the concrete solution is poured in one go, covered with polyethylene, and during the drying process, it is periodically watered with water by spraying.

General recommendations

Having decided on the tool used for knitting, having prepared the necessary materials and performing the work, follow the following recommendations:

- ensure the same distance (4-5 cm) from the horizontally located elements of the reinforcement frame to the soil, using wooden pads or non-metallic supports. The rods should not touch the ground at the bottom of the trench;

- the immobility of perpendicularly located steel rods when fixed with wire can be ensured by using a simple device that clamps the ends of the rods with boards;

- Do not drive vertically located rods intended for fixing horizontal rods into the soil. Use non-metallic coasters, which will prevent contact of the rods with the ground and reliably protect it with concrete from corrosion processes;

- check the reliability of fixing the frame elements using wire. Errors in fixing the rods have a slight effect on the location of the reinforcement contour during manual filling. However, the use of a concrete pump that supplies the composition under pressure can affect the location of the elements, pushing them apart or displacing the structure;

- Additionally, check the reliability of the fastening of the rods in the corners of the frame, which are a vulnerable area of any foundation. The ends of the rods located at right angles, which must have bends, are not allowed;

- the criterion for correctly performed knitting work is the immobility of the spatial structure under the influence of human weight;

Ensuring the design of strengthening the assigned tasks is possible with the correct selection of the assortment of rods, determining the location and number of elements, according to preliminary calculations.

Welding fittings for reinforcement

In most joints, it is better to use knitting instead of welding - the finished structure will be more durable. Welding is possible only if you have a machine and extensive experience, exclusively on straight sections.

In order for the foundation to be truly reliable, it is also necessary to take care of the correct execution of the excavation work under the tape, arranging several layers of materials (not only for the base and top of the foundation, but also for filling).

Peculiarities

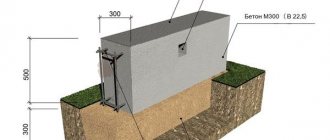

The strip foundation is a monolithic concrete strip without breaks at doorways, which becomes the basis for the construction of all walls and partitions of the structure. The basis of the strip structure is a concrete mortar, which is made from M250 cement, water, and sand mixture. To strengthen it, a reinforcement frame is used, made of metal rods of different diameters. The tape goes deep into the soil a certain distance, while at the same time protruding above the surface. But the strip foundation is subject to serious loads (groundwater movement, massive structure).

In any situation, you need to be prepared for the fact that various negative influences on structures can affect the condition of the foundation. Therefore, if the reinforcement is not done correctly, at the first slightest threat the foundation may collapse, which will lead to the destruction of the entire building.

Reinforcement has the following advantages:

- prevents soil subsidence under the building;

- has a positive effect on the soundproofing qualities of the foundation;

- increases the stability of the foundation to sudden changes in temperature conditions.

Practical advice

In places where there is no heavy load, you can select reinforcement in favor of bars of smaller diameter. If strength does not suffer from this, but it is possible to reduce the cost of work, this option is allowed. Deciding what diameter of reinforcement to use in your work should take into account two parameters: ensuring sufficient strength and the cost of work, choosing the optimal price-quality ratio. In some places, the use of thick reinforcement is simply not relevant, but purchasing more expensive material will significantly increase the cost of the entire construction.

The layout of the frame in the formwork must be level. Before laying the structure, it is necessary to carefully check all dimensions to exclude distortions, deformations, and non-compliance with parameters.

Video reinforcement of shallow monolithic strip foundations

And another video:

Rules for fastening rods

According to this scheme, you can tie the reinforcement:

- The wire is tied in half.

- A hook is inserted through the loop.

- On the reverse side, the end is wrapped around the intersection and also placed in the hook.

- The wire twists.

Recommended rules and methods of work when knitting:

- The rods are pulled up, twisted, the ends are bitten off with wire cutters;

- The wire twists several turns when it is tightly stretched;

- The rods and clamps are tied.

Using paper clips, staples, clamps

If necessary, speed up the knitting using the above-mentioned materials. In these situations, knitting is done by hand without using a tool. Rods with a small diameter can be tied with self-tightening plastic clamps. Universal devices suitable for any sections. They are light, installed by hand and do not smudge. Do not forget that they have low strength and can be damaged at low temperatures.

Advantages of staples and other fasteners of the same type:

- Productivity increases;

- The density of connected nodes increases;

- Easy to use.