Moisture-resistant plywood is a composite construction and finishing material consisting of several sheets of veneer bonded together with formaldehyde glue. Water-repellent properties are achieved by impregnating wood with special compounds made on the basis of synthetic resins.

Waterproof plywood sheets are one of the most popular finishing materials today due to their high performance and technical characteristics. The main distinguishing feature of plywood is its high mechanical strength with sufficient flexibility. This is achieved due to the mutually perpendicular arrangement of veneer layers.

Among other positive qualities of moisture-resistant types of plywood sheets, the following should be noted:

- Resistance to high humidity. Some types can be used for finishing rooms with air humidity up to 80%. At the same time, the sheets do not deform from dampness, do not come apart, and are not affected by fungus and mold.

- Easy to use and handle. Moisture-resistant plywood, despite its high strength, is lightweight and easy to process. Its cutting, sanding, painting and fastening do not cause any difficulties.

- Resistance to external influences. It is characterized by resistance to mechanical loads, changes in humidity and ambient temperature.

- High decorative and aesthetic qualities. The original wood pattern of natural veneer gives the interior a special, “eco-friendly” flavor.

- Affordable cost compared to other finishing materials made from natural wood.

- Versatility of use. Moisture-resistant varieties of plywood are successfully used both for finishing interiors and for cladding exterior surfaces of buildings.

The only limitation to the use of this material is due to the presence of adhesive containing formaldehyde in its composition. If there are people in the family who are allergic to it, then it is better to choose a different material for interior decoration.

Divisions and nuances

FC plywood is divided into grades:

Table of plywood grades.

- 1st grade. Plywood with this grade marking has an ideal surface on which to apply varnish. At the same time, defects in the top veneer along the length should not exceed 20 cm, and such defects as chipped edges, lack of veneer on one side of the sheet should not be more than 3 in number. And if they are present, the dimensions should be minimal.

- 2 varieties. This FC plywood has a slightly larger number of defects and possible production damage. Cracks no larger than 20 cm in size and the presence of inserts from other wood are allowed. Defects in the outer veneer layer, such as scratches and dents, should be no more than 5% of the total area of the plywood sheet. At the same time, the wood itself, from which veneer for grade 2 plywood is produced, may have knots of different colors and holes associated with their loss as a result of processing in production.

- 3 varieties. On such plywood, defects in the amount of 9 pieces are allowed, such as knots (fused, healthy), wormholes with a diameter of 6 mm. During production, glue can leak onto the edges or joints of veneer sheets by 5% of the total sheet area. The width of the edge defect associated with the lack of veneer should not exceed 20 cm, as well as the overlap.

- 4 varieties. This is plywood of the lowest quality production. The number of knots, both fallen and present, is not limited. In addition, the standards do not impose restrictions on wormholes whose diameter does not exceed 40 mm. Due to such low quality of grade 4 plywood, it is used for the production of containers and other rough construction work.

Table of properties of FC plywood.

In addition to dividing into grades, FC plywood can be divided according to the degree of treatment of the outer surface into unsanded, sanded on one side, sanded on both sides. This division is indicated in the sheet marking with the designations НШ, Ш1, Ш2, respectively. A description of all the characteristics of plywood must be included in the documentation available from the seller of this product. The buyer has the right to demand it.

The thickness of the plywood sheet ranges from 3 mm to 30 mm. This characteristic is determined by the number of glued layers of veneer. When producing plywood, an odd number of veneer sheets are glued together. That is, if the sheet thickness is 3 mm, then 3 layers of veneer were glued together to make it. 30 mm plywood consists of 21 layers and is the most durable.

Dependence of durability on stress during transverse bending for FK plywood of various laminations.

The wood species of the central layer of plywood, onto which the veneer is subsequently glued, may differ from each other. But this does not in any way affect the characteristics of the plywood as a whole. If more than 2 sheets are used in the production of plywood, and their wood fibers are at right angles to each other, then the result will be facing plywood.

Most often, birch wood is used as a starting material for the production of FC plywood.

However, the use of coniferous species is acceptable. Plywood made from birch or pine can be distinguished by eye by the texture and color of the outer veneer.

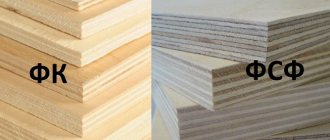

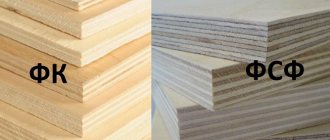

FK grade plywood

FK brand plywood is moisture resistant, made from veneer treated with a composition based on urea resins, which are easily soluble in water (photo). Therefore, this type of plywood is not particularly moisture resistant, although it is declared as moisture resistant.

FK grade plywood, manufactured in accordance with GOST, does not emit harmful compounds of phenol and formaldehyde, therefore it can be used indoors.

Several types of FK plywood are produced:

- Coniferous – made of coniferous veneer;

- Birch – made of hardwood veneer;

They produce several varieties, the most expensive of which is elite. To reduce the cost of the material, manufacturers often produce sheets with one side of a higher grade. The so-called front side of a sheet of plywood can be of one grade, and the back side of another.

Application of FC plywood

Moisture-resistant plywood of the FK brand is used:

- in construction, for internal wall cladding;

- to create inexpensive furniture;

- as a basis for laying laminate or laminate boards; floor base;

- for creating various types of temporary architectural structures.

Which plywood to choose?

Coniferous and hardwood plywood have their own advantages and disadvantages. Coniferous compared to birch is much cheaper and lighter in weight. There are fewer layers of veneer in a sheet of softwood plywood than in a sheet of birch plywood. Because of this, the strength, elasticity and wear resistance of the material are inferior to sheet wood plywood.

Coniferous veneer is impregnated with natural resins, so it is less susceptible to various molds. The appearance of birch veneer is less textured, light, coniferous veneer is darker and has an interesting pattern (photo).

Definitely, if you need a more durable structure, it is better to use brands of hardwood plywood, in this case birch, if you need a relatively inexpensive and environmentally friendly material - softwood veneer plywood. Birch and coniferous plywood are practical and convenient building materials.

Conclusion

Now you know what properties different brands of moisture-resistant plywood have and you can choose the right material for certain purposes. Additionally, watch the video in this article. If you have any questions, please contact me in the comments, and I will try to answer as soon as possible.

Did you like the article? Subscribe to our Yandex.Zen channel

October 3, 2022

Finishing timber

If you want to express gratitude, add a clarification or objection, or ask the author something, add a comment or say thank you!

Plywood: sheet dimensions, thickness

For different jobs, sheet material of different sizes may be more convenient. And plywood is no exception. It is available in different sizes, which are usually divided into standard and non-standard. Standard ones are prescribed in GOST standards (GOST 3916.1-96), non-standard ones are produced to order - for large companies or those formats that are more in demand in retail. Usually a sheet of plywood has the shape of a rectangle, but it can also be in the shape of a square.

There are rectangular and square plywood sheets

Standard plywood sizes

In general, different types of plywood are described by different GOSTs (GOST 2707, GOST 20907, GOST 102-75, GOST 3916.1-96) and they contain different size grids.

Standard sizes may vary depending on regulations

The most popular small-format plywood sheets have the following standard sizes:

- 1220*1220 mm;

- 1525*1220 mm;

- 1525*1525 mm.

Small sheets of plywood are good because you can work with them without helpers. But a large number of seams is not good.

According to GOST 3916.1-96, it is allowed to produce plywood of non-standard length by agreement between the manufacturer and the consumer.

Plywood dimensions according to GOST 3916.1-96

In theory, combinations from the above list can be any. In practice there are much fewer of them.

Large format

In some cases, it is more convenient to use large sheets of plywood - there are significantly fewer joints. The most commonly used large format plywood is the following sizes:

- 1830*1525 mm;

- 3050*1525 mm

- 3000*1500 mm;

- 2500*1250 mm;

- 2440*1220 mm.

Plywood: dimensions and thickness are standardized by a large number of standards

No one has brought order to the standards, so theoretically you can find almost any size that fits into one of them. So, for example, according to GOST 102-75:

- The length of the plywood sheet can be from 1000 mm to 1525 mm. The length change step is 25 mm.

- The width can be from 800 mm to 1525 mm with the same gradation pitch - 25 mm.

Moreover, the maximum deviation in length and width is 4 mm. The thickness of the plywood can be from 1 mm, but this is a rare “aviation” grade. The usual one is available in thicknesses from 3 mm to 30 mm, but you can find up to 40 mm. The permissible error in thickness dimensions is 0.5 mm.

There are standards regulating the sizes of coniferous and hardwood plywood

If you look at the later standard 3916.1-96, it specifies a different grid of plywood sizes with a specific listing of possible values (see table above).

Thickness

The picture with the thickness of plywood is approximately the same: if desired, you can find from 1 mm to 40 mm thick. It is possible that there are thicker options. But most often there are slabs with a thickness from 6 mm to 27 mm.

Thickness of hardwood and softwood plywood, ply layers and permissible deviations for sanded and unsanded boards

By the way, it’s interesting that any of the standards states the maximum permissible deviation is 0.5 mm

Which, considering the number is not always large, is not so little. And this deviation can significantly complicate the installation of the material on the floor.

The difference has to be corrected with thin pads, or, if it is small, sanded off at the joints with a sanding machine.

Introduction

Plywood is a multi-layer material made from veneer.

The number of veneer layers is always odd, that is, there are three-layer, five-layer and multi-layer. There is plywood that can have 23 layers. To maximize strength, the layers are always arranged perpendicularly, although, of course, there may be options with a parallel arrangement, but this is a very rare case and should not be taken into account. Plywood differs in its strength from other wood panels, such as chipboard

Plywood is processed and sawed without the use of any special industrial tools; you can even use an ordinary household jigsaw and simple wood saws.

Main dimensions

The veneer layers from which plywood is made are connected with various adhesives and kept under pressure until they fully adhere. These layers are laid on top of each other so that the direction of the wood fibers in the previous layer does not coincide with the direction of the next layer. This method improves the strength of the material to bending and other mechanical damage. The minimum number of veneer layers in a plywood sheet is made at least 3 - in this case, the size of the sheet thickness is marked as 3 mm. The largest number of them is 21 sheets, but the thickness of the finished material can be in the range of 30-40 mm.

Plywood dimensions may vary in width and length; each parameter is measured in millimeters. According to their size range, plywood sheets can be large, for example, 2000x3000 or 2000x3500 mm, and small, for example, squares 1220x1220 mm. The standard size of the thickness of the material directly depends on the number of veneer sheets glued together. The greater the thickness of the slab or sheet, the stronger the material.

Standard

Small errors in the dimensional parameters of a plywood sheet are also regulated by the state standard. GOST, adopted in our country, allows the production of these woodworking products in any size, according to the consumer’s order.

The most common width dimensions for plywood are 1220 and 1525 mm. The length of the product can be limited to 1525 or 2440 mm. Such parameters are in demand among consumers, since they are easier to use during work, and they can be transported by light-duty vehicles. Plywood materials with large format or non-standard parameters have a length of 3500 or 3660 mm and a width of 1500 or 1525 mm. Sheet materials with similar cutting are often used for finishing work when finishing large areas or for production needs.

Non-standard

Small-format wood-based sheet materials are also popular. On sale you can see products with the following dimensions: 1220 by 1220, 1220 by 1525 or 1525 by 1525 mm. Such minimal cutting is convenient because one person can handle a sheet of plywood without the involvement of third-party assistants. On the other hand, when facing with such sheets, there are too many joining seams, which sometimes is not a good solution.

With large formats, sheets are most often in demand, the dimensions of which are: 1525x1830, 1220x2440, 2500x1250, 1500x3000 or 1525x3050 mm. Such product parameters are not found by every manufacturer - some produce only part of the listed formats or are guided by their own dimensional standards.

Based on the GOST standards adopted in 1975, the dimensions of the sheet material are as follows:

- The length of the sheet is made from 1000 to 1525 mm, the interval for increasing the dimension is 25 mm;

- The width of the sheet is made from 800 to 1525 mm, the interval for increasing the dimension is also 25 mm.

Due to the fact that plywood is not subject to particularly precise requirements for compliance with dimensions, typical values can deviate from the standard requirements by up to 0.5-4 mm in length and width, and by 0.5 mm in thickness.

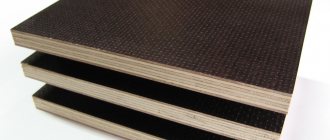

Criteria for choosing plywood for formwork

Which plywood is best to use for formwork? The building materials market offers a huge selection of different types of plywood, differing in composition and processing options. In addition, the product line is represented by numerous manufacturers.

And if you are still in doubt which formwork material is best, pay attention to certain criteria:

thickness of plywood for foundation formwork. The final price of plywood depends on this indicator, and it is quite understandable that the desire to save money immediately appears. But you should act wisely. If the plywood turns out to be too thin, you will not achieve a good result - the formwork panels will bend from the pressure created by the concrete solution, and their destruction may occur. The optimal solution is considered to be a plywood thickness of 1 - 1.2 cm, and if concrete is to be poured in a thick layer, experts recommend using more reliable laminated plywood 18 - 20 mm; variety. Plywood material comes in different classes, the most expensive of which is considered “extra”. Samples of classes I – IV are considered cheaper. The material should be selected taking into account its intended use, and most often it is plywood of classes I and II, which has a good margin of safety; feedstock

When purchasing plywood, you need to pay attention not only to the glue used in production, but also to the veneer material. Preference is most often given to coniferous wood or birch.

Each of these varieties is distinguished by its affordable prices. More expensive materials include plywood sheets made from fir, larch and teak. If difficult operating conditions are expected, it is recommended to purchase reliable and expensive material that can withstand a greater number of operating cycles.

GOST defines several options:

- standard - square sheets, the length of the sides is 122 and 152.5 cm. There are rectangular sheets, the length and width of which are 152.5 and 122 cm, respectively. The main advantage of such material is its reasonable cost;

- large format. On sale you will find laminated plywood, the parameters of which are 3000 x 1500 x 18 mm. It is more convenient to use such sheets of material when constructing plywood formwork for walls. Their cost is slightly higher than standard ones, but the shields are made without joining seams. In addition, for pouring 2-meter walls, the formwork panels will be solid;

- non-standard. It is possible to produce plywood material according to individual customer requests. This creates certain advantages, but the cost of such an order increases significantly.

An important criterion that you should pay attention to when choosing plywood is the quality with which the surface of the material is processed. The ideal solution would be even and smooth sheets

Their use will allow:

- speed up dismantling work, because plywood sheets are separated from hardened concrete much easier;

- The monolithic surface is smooth, plywood is better suited for subsequent processing.

An important feature of choosing laminated plywood for formwork is the country in which the product was produced. Today, material from domestic and Chinese manufacturers is in demand, while plywood from China is less expensive

It is used as an economical option when construction is underway on a low-rise building or structure with small architectural forms. As a rule, such black plywood used for formwork can withstand a limited number of cycles, but is well worth the expense.

For large working volumes, it is recommended to purchase domestic material and, to ensure the reliability of its use, install plywood formwork on metal racks. To increase the turnover rate of laminated plywood for formwork, experienced experts advise using special lubricants - barrier or chemically active. In the first case, you create additional protection, and in the second, you increase the plywood’s resistance to moisture.

Veneer for making plywood

Veneer is the main element of plywood, which is thin sheets of wood with a thickness of 0.1 mm to 8 mm. To understand the features of plywood, you need to talk in more detail about the veneer from which it is made.

Normative base

Veneer production is regulated by the following regulations:

- GOST 99-96 “Rolled veneer”

- GOST 2977-82. "Sliced veneer"

- GOST 99-89. “Rolled veneer” (obsolete)

There are three main methods for producing veneer:

- Peeling;

- Planing;

- Sawing.

Peeled veneer

For the peeling operation, special peeling machines are used. The principle is as follows: a log (a sawn tree trunk, cleared of bark) rotates around its own axis, and a special knife of a peeling machine, located parallel to the log, cuts off a thin layer of wood of a given thickness. As the block rotates, the knife moves towards its center, thereby ensuring an even thickness of the veneer. Both coniferous and deciduous wood species can be used for peeling:

- pine;

- birch;

- Linden;

- beech;

- oak;

- maple;

- ash;

- fir;

- cedar;

- alder;

- aspen;

- spruce

etc.

Sliced veneer

To obtain sliced veneer, the surface of the wood is cut (planed) on special machines. In this case, the width of the resulting veneer does not exceed the width of the planed timber.

By varying different angles of the knife relative to the longitudinal axis of the timber, you can get different patterns and textures. Both coniferous and deciduous wood species can be used for planing:

- pine;

- birch

- beech;

- oak;

- pear;

- elm;

- chestnut;

- Red tree;

- Linden;

- ash;

- alder;

- maple;

- velvet tree;

- nut

etc.

Sawn veneer

This is the simplest and oldest method, in which a plate 0.5 - 5 mm thick is simply sawed off from the workpiece. For the production of sawn veneer, both coniferous and deciduous wood species are mainly used:

- pine;

- birch

- beech;

- oak;

- Linden

etc.

"Fine-line" veneer

If the result of the types of veneer production discussed above is a thin sheet of wood, then “fine-line” veneer is an artificial veneer. It is based on wood, but also contains glue and dyes (about 8%). To make it, natural veneer is taken from soft wood, soaked in special solutions and dye, after which it is glued and pressed under high pressure into special bundles. These pressed bundles are then cut into ultra-thin sheets called “fine-line” veneer.

The resulting veneer has a number of advantages:

- like natural veneer, it is environmentally friendly;

- has no defects on the surface, unlike traditional 100% veneer;

- it can have any pattern, texture or just a solid color applied on it;

- high – elasticity and flexibility;

- Inexpensive types of wood are used for its manufacture, which makes it less expensive than traditional 100% veneer;

- moisture resistant, that is, can be used in rooms with high humidity.

However, there are also disadvantages, namely:

- Low strength (fragility). Due to the use of soft wood, it is susceptible to deformation under mechanical stress;

- Possible appearance of cracks. To increase strength, the material is coated with varnish, which under certain influences can form cracks.

- The presence of artificial components (8% glue and dyes) does not allow this material to be classified as 100% environmentally friendly.

Fine-line veneer has a wide range of applications. For example, it is widely used in the production of furniture, doors, flooring, as well as various decorative materials to create interior design solutions.

Varieties and labeling

FSF plywood is made from soft or hard trees; they can be either deciduous or coniferous. It can be longitudinal or transverse, have 3, 5 or more layers (three, five and multi-layer, respectively). These gradations can be combined by manufacturers in various proportions.

Building materials can have different grades:

- Grade I is characterized by the greatest damage - the total length of defects on 1 sheet should not exceed 20 cm;

- Grade II - the length of the cracks is up to 15 cm, the presence of an adhesive composition on the surface of the products is permissible (no more than 2% of the area of the plank);

- Grade III – holes from knots, falling knots, and wormholes are acceptable for it;

- Grade IV implies the presence of various manufacturing defects (an unlimited number of wormholes with a diameter of up to 4 cm, fused and unfused knots), such products are considered the lowest quality.

They are characterized by minimal deviations in the structure of the wood. Wormholes, knots and holes from them, veins and other defects are not allowed.

To determine the main parameters of plywood boards, manufacturers attach markings to the building material. Let's give an example: “pine plywood FSF 2/2 E2 Sh2 1500x3000 x 10 GOST 3916.2-96”. The marking says that the presented plywood sheet is made of pine veneer using FSF technology, with front and back surfaces of grade 2, class 2 phenolic emission, double-sided sanding, thickness 10 mm and dimensions 1500x3000 mm, manufactured in accordance with GOST 3916.2-96 standards.

Advantages of the material and its disadvantages

The production method makes plywood durable and resistant to deformation. This is achieved through the presence of several layers and special adhesive compositions. Therefore, the following advantages of such plates can be highlighted:

- Moisture resistant. Waterproof plywood is not subject to destruction when exposed to moisture. It does not peel off into layers and is not deformed.

- Easy to use. The high strength of the material does not interfere with the processing process. Plywood is easy to process using a variety of tools. It is easy to install.

- Compatibility with other building materials. Most often, waterproof plywood is used as an additional material. It easily combines with natural and polymer building materials.

- Wear resistance. Plywood can withstand mechanical stress without compromising its integrity.

- Resistant to temperature changes.

- Wide scope of use.

- Aesthetics. Plywood has an original wood pattern and color in appearance.

- Affordable price. Plywood boards are cheaper than solid wood. And you can always save money by choosing a lower grade material.

The only drawback of the material is the presence of harmful substances included in the glue. We are talking about formaldehyde. Therefore, it is not recommended to use plywood in residential areas and where there are children or people with allergies.

Characteristics of moisture-resistant plywood produced by the Sveza holding.

Hardness with low weight.

Products manufactured by Sveza Holding have excellent strength characteristics and are light in weight.

Furniture made from it will undoubtedly be strong, light, comfortable and will last a very long time. Moisture-resistant plywood board has an undeniable advantage over simple wood in terms of stability of geometric dimensions, since knots on natural wood can lead to deformation of the finished product. At the same time, thin sheets are successfully used for the production of bent and glued figures. Environmental friendliness

The fact that birch veneer sheets are glued together with urea glue makes the material absolutely environmentally friendly.

This plywood can be safely used even for the manufacture of children's furniture. Resistant to temperature changes.

Wood heats up the more, the higher its humidity.

FC plywood, made on , is moisture resistant and, due to this, resistant to temperature changes. Beautiful appearance.

The veneer for the slabs is cut from northern birch, which is distinguished by its uniform density and beautiful texture.

High, so-called furniture grades, are distinguished by an ideal veneer surface without knots or defects, perfectly polished. The use of transparent color films in combination with the beautiful texture of wood allows you to implement many design ideas. Good sound absorption.

Plywood sheets have good acoustic properties.

With a sheet thickness of 21 mm, the sound absorption coefficient is about 27 dB. Acoustic characteristics can be improved using special soundproofing layers. Water resistance.

According to GOST 3916.96, in terms of the degree of water resistance of the adhesive joint, FK plywood is water resistant.

Thus, when exposed to moisture, it will not swell, will not deform, and will not crack when drying. Resistance to aggressive environments.

Natural wood itself has anti-corrosion resistance, and in combination with the use of moisture-resistant urea glue, this characteristic reaches high values.

Classification of plywood by purpose

The scope of application of plywood (laminated, sanded, moisture-resistant and other types) is not limited to construction; due to its properties, the material is extremely in demand in various fields.

Ship's. For the finishing of shipping vessels, only the highest quality types and grades of moisture-resistant FB plywood (on bakelite glue) are used, which work well in conditions of high humidity and aggressive environments.

Furniture. The types of plywood used for furniture must be environmentally friendly, wear-resistant and durable. As a rule, combined FC plywood is used for furniture.

Construction In the construction industry, as a rule, grades 3/4 and 4/4 birch plywood are used. These types of plywood can be used for floors, walls and other structures as a rough finish.

Aviation. For these purposes, FSF grades of plywood are used. This plywood has excellent technical characteristics and is ideal for such complex and critical areas of activity as aircraft, ship, railcar and automotive industries.

Formwork. To create the formwork, laminated FB plywood is used, which has excellent characteristics in terms of moisture and wear resistance, strength and exposure to aggressive environments.

Decorative. FC plywood is used for finishing the premises. This type of plywood must have excellent characteristics of the outer layer (flat surface with a textured pattern). This type of plywood is usually made from valuable wood or premium wood.

Automotive. For cars, as a rule, FSF type plywood with a laminated or mesh-ribbed surface is used. Plywood has high strength, moisture resistance and durability. It is used for covering all elements of a truck body (walls, floor, doors, ceiling).

Additional points

FSF plywood, made from softwood, is much more suitable for construction than the same birch plywood. It is used as a frame in the construction of buildings; it is an alternative to OSB. FSF plywood is mainly coniferous and is considered a direct competitor to OSB. Builders, when it is necessary to lay subfloors, mainly use FSF coniferous plywood. Fasteners can be easily screwed into this material. It has high elasticity and is not subject to deformation. The properties listed above are the main advantages of coniferous plywood in comparison with birch grade.

Another positive property of coniferous plywood is its excellent wear resistance and enormous strength when chipped.

https://youtube.com/watch?v=oBKo4GSU9mg

When such coniferous plywood is made, due to the high porosity of the pine needles, the glue is immersed much deeper into the veneer layers, resulting in increased flexibility and increased strength of the material. This type of plywood is endowed with excellent thermal insulation properties. Builders use coniferous slabs for especially critical structures.

The difference between laminated plywood and regular plywood

Below are some characteristics that were defined by GOST of 2010:

- For the production of laminated plywood boards, plywood of the 1st and 2nd grades of the phenol emission class of level E1 is used, and at the same time everything meets strict requirements for the presence of defects on the veneer, the gluing method and the final density of the material.

- The covering for plywood can be made of thermoset plastic or high-strength polymer film. According to the test conditions, the coating should remain unchanged even after 6 hours of boiling, as well as upon contact with liquid concrete and an alkaline environment.

A sheet of laminated plywood, unlike the bakelite variety, is impregnated using the hot method, and it contains less phenol. As a result, we obtain an elastic and at the same time quite durable material, which has a varnished protective layer of polymer. Laminated plywood with a water-resistant effect is more plastic than bakelite board, which has better water resistance characteristics than the laminated sample, but has increased sensitivity to abrasive wear and impacts.

To create the coating of a laminated pitchfork, in addition to textured paper and phenol-formaldehyde resin, polyvinyl chloride films and melamine varnishes are used. Although the technical characteristics of melamine and PVC coatings are slightly worse than FFS, they are indispensable when creating colored plywood sheets. If standard samples have a phenol emission class of E1 according to GOST, then a painted PVC sample emit several times less toxic substances.

According to the technical characteristics of laminated plywood and the method of using GOST, the laminated board is used for exterior finishing and in the manufacture of concrete casting molds. If the same sheet of plywood is painted, then it can be used for interior finishing work, as well as for covering walls in a frame house and as a sublayer for leveling the floor.

It is easy to distinguish standard laminated plywood from painted one - it all comes down to color, since the standard version is dark brown, and colored boards are tinted in shades that are lighter than the original.

Moisture-resistant laminated plywood

It can be made by alternating birch and coniferous veneers. Moisture resistance is the ability not to be affected by moisture from the environment. Brands of such products vary depending on the brand of glue used:

- The elements are glued together with urea-formaldehyde, marked with FC, it can even be used inside apartments;

- The veneer is glued with phenol-formaldehyde resin, marked FSF, it is better to keep it in the fresh air;

- Using bakelite adhesive, it is marked with FBS. The most waterproof, this building material is allowed to be used even in the ship, aircraft and automotive industries.

Strength characteristics of laminated sheet

| Name of parameters | Value, MPa |

| Maximum chipping strength on the adhesive layer after soaking for 24 hours | 1,5 |

| Maximum tensile strength | 40 |

| Maximum static bending strength | 60 |

This is interesting: Garden furniture made of wood: we explain in detail

Moisture-resistant plywood: material features

This wood-based panel material consists of sheets of deciduous (most often birch) or coniferous veneer, peeled using a certain technology. Initially, the raw materials have natural resins, which determine the level of moisture resistance. Hardwoods are better protected from getting wet than conifers, so the former are used for exterior decoration, and the latter for indoor work.

The use of synthetic binders increases moisture resistance and makes it possible to obtain water-resistant plywood. The following types of glue are used for impregnation:

- Urea compounds – water resistance limit is 5–12%. Materials based on them do not withstand prolonged exposure to moisture, so the use of such waterproof plywood is limited to interior decoration of rooms with average humidity. Plywood sheets are produced under the FK brand.

- Phenol-formaldehyde compositions - impregnation resistance to moisture is 12–17% due to the use of synthetic resins. The substance has good astringent and water-resistant properties. It is used more often for exterior decoration, but it has also found application in interior decoration and the arrangement of moisture-resistant structures. Such material is produced under the FSF brand.

- Laminated plywood - the strength characteristics and moisture resistance of this material largely depend on the type of protective coating. Lamination technology gives products parameters that are not characteristic of wood, but at the same time preserves the natural structure of wood. This material has found wide application in monolithic construction and is used in the furniture industry and design field. Produced under the FOF brand.

Let's take a closer look at the types of laminated moisture-resistant plywood. The material is made on the basis of FSF boards, in which the veneer is glued together with phenol-formaldehyde resins. Thus, even without lamination, it is classified as a durable product. Further, the characteristics and properties of laminated moisture-resistant plywood depend on the type of protective film used:

- phenol-formaldehyde coating – the film is impregnated with phenol and formaldehyde resins, water-resistant substances. The scope of application of the slabs is limited to external work, formwork production, facade cladding, etc.;

- Melamine coating is a fairly waterproof substance. Types of moisture-resistant melamine-laminated plywood are used for interior decoration of rooms with high humidity.

In addition, the characteristics and properties of moisture-resistant laminated plywood depend on the type of texture of the protective coating: SP - for painting, F - smooth, W - mesh or embossed. The ends of the products are treated with acrylic waterproof paint.

Varieties

Types of plywood.

Based on the degree of moisture resistance, plywood is divided into the following grades:

- FBA;

- FC;

- FSF;

- FOF;

- FB.

The first group is sheet material glued with albumin casein natural glue. Among other groups, this plywood has the least resistance to high humidity, but at the same time it is an environmentally friendly product.

The second brand is made from birch veneer. It has an average moisture resistance, so it is usually used for interior finishing work. The main advantages include high environmental safety and non-toxicity. However, with high humidity, deformation, warping and swelling may occur. The most popular FC sheet format is 152x152 cm. This is a square, the thickness of which is 2.1 cm.

FSF brand plywood has increased moisture resistance, since moisture-resistant adhesive based on phenolic resins is used in its production. The use of moisture-resistant glue in combination with birch wood gives such plywood a great advantage over other lumber. Standard sizes of FSF are 122x244, 125x250, 152x305 and 152x152 cm, with a thickness from 4 to 30 mm. This type of plywood is widely used for external construction and finishing work.

Plywood design resistance table.

Laminated plywood (FOF) is produced on the basis of the FSF brand. The main purpose of lamination is to give the material increased performance characteristics, including moisture resistance, as well as improve the strength and wear resistance of the material, and create a decorative effect.

Laminated plywood has the following technical characteristics:

- sheet sizes: 122x244 and 125x250 cm;

- sheet thickness: from 9 to 40 mm;

- density: 680-700 kg/m3;

- humidity: less than 10%.

Due to its unique characteristics, laminated plywood is used in such areas as:

- construction and finishing works;

- structural work;

- automotive industry;

- carriage building, etc.

Required clearances for installing plywood.

Bakelized plywood (FB) is the most durable and moisture-resistant brand, which is made with the addition of phenol-formaldehyde resins, which give it these qualities.

The technology for gluing bakelized material involves the use of high pressure, which increases strength and gives it special dimensional stability.

Certain grades of FB plywood are successfully used in the aviation industry and shipbuilding.

Bakelized brands can be used even in aggressive environments, in water and in dry climates.

Main characteristics of bakelized plywood:

- leaf length: 150-770 cm;

- width: 120-155 cm;

- thickness: 5-18 mm;

- density: 1200 kg/m3;

- humidity: no more than 8%.

Peculiarities

There are many options for this material, they all differ in their width, coating and manufacturing features.

In order to choose the optimal product, you need to pay close attention to studying the characteristics. Plywood is a regular sheet that is created using wood

In turn, it goes through several stages of processing, which gives the product its unique properties.

The process of gluing the layers occurs through the use of special compounds, which are usually based on resins. The result is a lightweight material that can also boast of its resistance to temperature changes.

Among the main advantages of such a product are the following.

- Resistance to moisture, so the material can even be used for finishing a bathroom. This can be achieved due to the fact that when in contact with water, the plywood sheets do not delaminate and do not lose their shape.

- Ease of processing and installation. This material is famous for its strength, so you can use any processing tools without fear. Plywood can be cut, sawed or drilled without any problems, which makes it stand out from other materials.

- Possibility to combine with other materials. It should be noted that laminated plywood is very often used as an additional material, so it is perfect for finishing a ceiling, floor or roof. Most experts use this plywood in combination with natural wood.

- Huge scope of application. Laminated plywood can boast of its unique performance characteristics, which allows it to be used in the process of finishing work, in the production of furniture and decorations.

A distinctive feature of moisture-resistant laminated plywood is that during the manufacturing process it is processed much longer and is also covered with thicker paper. This paper is impregnated with a special composition, which makes the finished product durable and allows it not to lose its properties for a long time. In addition, it provides resistance to water.

Laminated plywood differs from other materials in that it is almost insensitive to temperature changes, so it can even be used in a bathhouse. The special layer also protects against the effects of cleaning agents, including aggressive abrasives. Another feature of this plywood is that it contains a minimal amount of phenol. This results in a more elastic and durable material, which also has a varnished protective layer of polymer.

Plywood marking

Plywood, like any other building material, has markings based on its various properties.

The following parameters used for marking are distinguished:

- by type of adhesive

- for processing the top layer

- by formaldehyde content

- decorative plywood marking

Let us examine these notations in more detail.

By type of adhesive

The moisture resistance of plywood is determined primarily by the composition of the adhesive. Depending on it, the following grades of plywood are distinguished.

| Designation | Adhesive composition | Moisture resistance | Application |

| FC | Urea adhesive with the addition of formaldehyde resins | Yes | It can be used both indoors and outdoors. belongs to a high class of environmental cleanliness. |

| FSF | Phenol-formaldehyde glue | Yes | It can only be used outdoors, as the binding components are hazardous to health. It is used for the manufacture of laminated plywood, which is used in the construction of external structures. |

| FBA | Albumocasein glue | No | It can be used indoors. |

| FB | Bakelite varnish | Yes | It can be used in any climatic conditions and at maximum humidity. Withstands exposure to sea water. |

| BS | Alcohol-containing bakelite glue | Yes | The characteristics are even better than those of FB. It is often used in aircraft and shipbuilding, which is why it is also called “aviation”. |

| BV | Bakelite composition | No | Since water-soluble bakelite is used in production, plywood is not moisture resistant. However, plywood is quite durable. |

By processing the top layer

An important parameter of plywood is the quality of the top layer of plywood and its processing. A special marking for this parameter has been defined.

| Designation | Description |

| Ш1 | The veneer is sanded on only one side of the plywood |

| Ш2 | The veneer is sanded on both sides of the plywood |

| NS | The veneer of the top layers of plywood is not sanded |

According to formaldehyde content

Since formaldehyde is very harmful to human health, the amount contained in plywood is important and affects the environmental friendliness of the material

| Designation | Formaldehyde content per 100 g of material |

| E1 | does not reach 10 mg |

| E2 | from 10 to 30 mg |

| E3 | from 30 to 60 mg |

Marking of decorative plywood

Decorative plywood (DP) can be covered with various film coatings and paper, which give it a unique appearance and additional enhanced characteristics. The following brands are distinguished.

| Designation | Facing coatings | Resins |

| DF-1 | Transparent, does not hide the texture of natural wood | Urea-melaminephore-maldehyde |

| DF-2 | Opaque with decorative paper to imitate the texture of precious wood. Any design is possible. | |

| DF-3 | Increased water resistance. Transparent, does not hide the texture of natural wood | Melaminephore-maldehyde |

| DF-4 | Increased water resistance. Opaque with decorative paper that imitates the texture of precious wood. Any design is possible. |