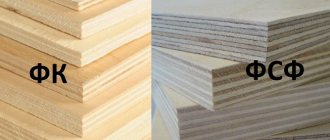

Both of these types of plywood are widely used, affordable and easy to use. The scope of application of FC and FSF plywood is industrial production, packaging, construction, car and machine building. The versatility of the material has been proven over years of use for finishing walls, floors, ceilings, partitions, construction, and design. Let's try to figure out the differences between FK plywood and FSF plywood, and how they can be distinguished visually.

What is the fundamental difference?

The first is not at all resistant to a humid environment, but is quite durable and versatile. Designed for dry conditions only. Much cheaper than the second option, therefore it is widely used for the production of furniture, wall cladding, packaging containers, as a substrate for laminate, parquet and other coatings.

Made from peeled wood of birch, alder and some other hardwoods (a combination of these is also possible). After penetration of moisture, it usually delaminates and curls, which is a serious difference between FK and FSF plywood. The thickness of such sheets can reach 40 mm. They are divided into varieties based on the presence of knots.

Pack of FC plywood sheets

The second is characterized by increased resistance to moisture, which it resists very successfully. Thanks to this property, it is in demand in roofing processes and can be used not only inside, but also outside of buildings. It has good wear resistance and mechanical strength.

It is made mainly from birch and coniferous veneer. It can be impregnated with compounds not only against moisture, but also against fire (FSF TV), which is why it has an expanded range of applications: construction, industry, mechanical engineering and aircraft construction.

Marking

For a complete qualitative assessment, a marking is applied to the plywood sheet or tag, by which you can find out its main characteristics.

For example, the inscription “pine plywood FSF 1/2 E1 Sh2 1500x1500x9 GOST 3916.2-96” means that the plywood is made of pine veneer glued with formaldehyde resin, with surfaces of the 1st and 2nd grade (front and back sides), first class phenol emissions, with double-sided grinding, thickness 9 mm, size 1500x1500 mm, produced according to the specified GOST.

If you notice an error, a non-working video or link, please select a piece of text and press Ctrl+Enter .

0

How to distinguish FC plywood from FSF externally?

Without experience in this matter, you can get confused, since they are hardly distinguishable by external signs, which sometimes causes misunderstanding. The only factor that clearly shows the difference between them is the shades of the layers.

FC is lighter, as it is connected with glue without the presence of phenol, which is why the cut sheets are as close as possible to the natural color of the veneer. While FSF with increased moisture impregnation has a darker color with the presence of a reddish undertone.

| Data Comparison | FC | FSF |

| Veneer type | Deciduous trees (birch, alder, aspen) | Deciduous-coniferous species (birch, pine, larch) |

| Gluing | Urea-formaldehyde composition | Phenol-formaldehyde composition |

| Moisture resistance | Average (for non-residential and residential premises) | Maximum (for interior and exterior work) |

| Presence of phenol | No | Eat |

| Treatment | Lamination, sanding | Lamination, sanding |

Differences in physical and mechanical parameters

Application area

Here's where FC plywood is used:

- laying/leveling the floor;

- furniture manufacturing;

- finishing of walls/ceilings;

- construction of partitions.

Here's where FSF plywood is used:

- construction of formwork;

- roofing;

- construction of street structures;

- finishing of transport (applicable only to FSF-TV sheets).

FC and FSF plywood are different materials intended for different needs. Therefore, it is impossible to choose which is better. When purchasing, be guided only by the purpose for which the material is purchased. For finishing residential premises, use FK brand products, and for exterior work, give preference to FSF sheets.

Which plywood is less harmful - FC or FSF?

For the manufacture of wood-laminated boards of the FK type, a silicate adhesive is used, which is non-toxic to humans and animals. This equates plywood to safe building materials, suitable for interior decoration and installation of partitions in dry conditions.

Packaging of FSF plywood sheets

FSF is more resistant to moisture because it has a special impregnation based on potentially harmless resins. The glue also contains 8 mg/100 g of phenol, which negatively affects the health of others.

general characteristics

Wooden plywood is a common material used:

- during construction and finishing works of interiors, roofs, facades and others;

- in experimental and design modeling;

- in packaging production;

- for the needs of various industries, including aviation, mechanical engineering, and railway transport.

These products are layered panels or slabs of varying thicknesses made from wood veneer, pressed and glued together.

Main differences

To more clearly distinguish between these two types of plywood, we offer a brief comparison of them.

So, FC is absolutely safe for health, is not resistant to moisture, is suitable for interior work and furniture production, is fragile and does not withstand mechanical stress, easily breaks and delaminates.

While FSF has low environmental friendliness, which is why it can harm humans and animals, it has excellent moisture resistance, is applicable for interior, facade, and any other external work, and has increased fracture strength and pressure.

Kinds

When choosing a material, you need to pay attention not only to its brand, but also to other differences, such as:

- the type of wood from which the veneer is made;

- variety, which determines quality;

- type of surface treatment.

Below we will take a closer look at all types of this material.

Wood type

FK plywood and FSF plywood can be divided into two types:

- from hardwood - as a rule, hardwood means birch. Slabs made from this veneer are most valued due to their high strength and other positive qualities;

- from coniferous species - has higher water resistance qualities due to the high content of resins in the structure. In addition, the advantage of softwood slabs is their lower cost. However, this wood is less hard and durable.

Example of the surface of different types of plywood

Variety

As mentioned above, the grade determines the quality of the slabs. According to existing GOSTs, plywood is divided into the following grades:

| Variety | Peculiarities |

| E | Slabs of this grade do not contain defects. |

| I | A small number of small knots and cracks up to 2 cm long are allowed on the surface. |

| II | On a square meter of sheet, up to 10 knots with a diameter of no more than 2.5 cm are allowed, as well as a small number of wormholes. |

| III | Slabs of this grade can have an unlimited number of fixed knots and a small number of fallen ones. Up to 10 wormholes per square meter are also allowed. |

| IV | Slabs can contain an unlimited number of wormholes, knots and other defects. The only requirement is that the veneer sheets should not delaminate. |

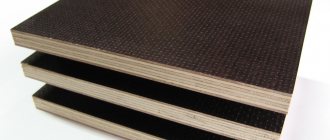

The photo shows laminated plywood sheets

Types of processing

Depending on the type of treatment of the outer surface, the material in question differs into the following types:

- NS – has an untreated surface, therefore it is most often used for rough work. However, if necessary, such plywood can be sanded with your own hands for subsequent opening with varnish;

- Ш2 – the slab is polished on both sides, therefore the cost of such material is the highest;

- Ш1 – only one side of the slab is sanded;

- FOF - the surface of the board is laminated on both sides. This treatment improves its moisture resistance. As a rule, FOF is made on the basis of the FSF brand.

Here, perhaps, are all the main varieties of plywood of the FK and FSF brands. The instructions for choosing a material are extremely simple - you need to decide on the scope of its application and the conditions in which it will be used, and then select the most suitable brand, grade, etc.

Geometry and stuff

Thickness. The biggest dilemma here is what to take on the floor. In general, there is a rule that at least 3/4 of the thickness of the subsequent floor covering. From experience, they don’t take less than 10mm on the floor. For residential premises with light loads, this is usually a thickness of 12-15mm. What is more important here is not the thickness, but the quality with which the sheets will be laid. Even 18mm plywood can creak and sag beautifully.

There is nothing to recommend regarding the format - it is chosen based on their design needs. The most popular format of the FC brand is square sheets 1525x1525mm.

There is also such a factor as the manufacturer: the price may differ by 20% or more. For example, laminated plywood is successfully produced by both China and the Russian Federation. Guess which is cheaper :) There are actually a lot of plywood manufacturers with the same markings - it’s better to inquire about the differences at the supplier’s place. Touching the product is also a significant factor in choosing..

Very often in construction, renovation, exterior and interior decoration, a material is required that is equally strong and lightweight, inexpensive and resistant to environmental conditions. Plywood meets all these requirements. In this article we will take a detailed look at the types of plywood, its characteristics and the purpose of each type.

Familiar plywood

Plywood is a wood-laminated material with at least 3 layers. The layers are veneer or tree bark. During manufacturing, veneer is placed in each layer perpendicular to the previous one, therefore density and strength increase, and the composition used for gluing the layers increases moisture resistance.

Types of plywood and its classification

Plywood is a long-known and popular sheet building material. It has high bending strength, both in the longitudinal and transverse directions. In private households it is used for cladding frames and flooring. Cheap varieties are also used in some construction processes.

Plywood is made from several layers of veneer glued together.

Fiber layers located in different directions. This increases the flexural strength of the material in all directions.

Plywood is one of the most famous and popular sheet materials in construction.

Plywood is made from coniferous trees and birch. Birch is more expensive and is more often used as furniture. Coniferous is made from wood of all coniferous species. Cheaper options - from larch, pine and spruce - can be used both for the manufacture of furniture and for construction needs (for example, for cladding a frame or for removable formwork in the manufacture of concrete products). Siberian cedar veneer can be used. This type is usually used as a finishing material.

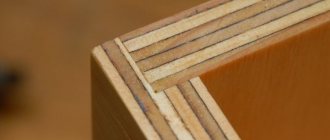

Layers and their number

There are at least three layers in plywood, but there may be more. The layers are arranged so that the veneer fibers are directed in different directions - alternately along the long side of the sheet, then across. An odd number of veneer layers is more common. In private housing construction, three and five-layer plywood are most often used. In this case, the orientation of the layers is selected relative to the central layer.

The location of the layers is perpendicular to each other

If the veneer fibers on the outer layer are directed along the long side, the plywood is called longitudinal. It has great flexibility. If the veneer grains are located along the short side of the sheet, the plywood is called cross-section plywood and is used where high bending rigidity is required.

Moisture resistance

Since glue is used in manufacturing, the entire material has a fairly high degree of water resistance. There are several popular brands of plywood:

- Moisture resistant is marked with FC. For gluing it, glue based on urea-formaldehyde resin is used. That is, there is the emission of formaldehyde. With emission class E1 and lower, it can be used indoors or for making furniture.

- Plywood with increased moisture resistance - FSF. The same glue is used only with water-repellent additives. Can be used for outdoor work.

- FSF-TV. The same water-repellent plywood but with fire-resistant additives.

- Laminated - practically insensitive to moisture.

If you need a material for indoor use and don't want to worry about formaldehyde in the air, look for the FBA brand. It is environmentally safe, but is only suitable for rooms with normal humidity. The FB brand does not swell even under water; there is also BS aircraft plywood. It does not react to chemical environments yet. Used in the construction of ships and airliners.

Surface treatment degree

The outer layers of plywood can be sanded during production. There are these types:

- Unpolished. There is no surface treatment. Marked with NS.

- Only one side is sanded smooth. Ш1 is added to the marking.

- Both sides are sanded - Ш2.

Plywood sanded on both sides is used to make furniture. For construction, both smooth sides are rarely needed. Usually, if polished is used, then Ш1. And only if this material is used for decorative cladding. More often on construction sites you need unsanded one - it provides better adhesion to other materials.

Selection rules

The selection parameters are the water resistance of the material and the emission class - the main difference between the materials.

- For cladding facades or during the construction of outbuildings, only FSF is used. FC is not resistant to water and will quickly become unusable. For external work, you can use material with a high emission class.

- Children's swings, sports facilities, and structures for street advertising are also made from FSF.

- For garden furniture, they use FSF, but with a low emission class, since these items come into contact with human skin.

- For covering the internal walls of residential premises, FC is used. But for the bathroom and kitchen , as it cannot withstand high dampness. For these rooms, FSF with a low emission class is used.

- as the underlay for the floor .

- as a roof lining . There is a high risk of leakage here.

- Furniture for home, office, and shop is made from FC . Containers for transportation are also made from it .

FC is often used for making decor and home crafts, since plywood is easy to saw, cut, and bend.

Which plywood is better to choose for the floor?

Finish floor made of FC plywood, varnished.

First of all, the choice is influenced by the purpose - finishing or rough flooring . The second requires durable and attractive plywood. The leveling substrate must be simple enough to provide stability to the structure.

The selection options are as follows.

- Brand – FC is suitable for dry residential premises. For bathrooms and kitchens, use FSF with an emission class no higher than E1.

- Grade - high grade is not needed for rough flooring, so grade 3 and even grade 4 sheets are used. For finishing flooring, grade 1 or 2 plywood is used.

- Humidity – the floor requires dry wood, with a moisture content of no more than 15%.

- The number of layers is or the thickness of the sheet. The subfloor serves as a stabilizer, so its minimum thickness is 12–18 mm. The finishing flooring can be thinner - 10–12 mm. If plywood is laid in 2 layers, the specified thickness is divided in half.

- Sheet sizes - for small rooms it is better to take the regular format, as it is easier to adjust manually.

On logs On concrete On old boards

It is worth paying attention to the manufacturer.

Ways to level a floor using plywood

The sheets are large in size, which makes it possible to reduce the number of joints when installing a covering of a large area. At the same time, the strength and service life of the structure increases. Sufficient thickness of the sheets also helps to increase the reliability of the coating. You can level the floor in different ways.

Installing plywood on a concrete floor

Method 1: installation on concrete screed

There are several options:

- Frame on joists. The structure is based on timber, which allows the floor to be insulated (thermal insulation is placed in the cells formed during the sheathing). This option is the most labor-intensive. Its disadvantage is the reduction in the height of the room.

- Anchor mounting. The fasteners secure the plywood sheets to the concrete base. By adjusting the anchor pins the floor can be leveled.

- Application of adhesive composition. Features of fixing sheets up to 12 mm thick: the concrete base is carefully leveled, leaving up to 4 mm of a gap around the perimeter of the room in case the material expands when operating conditions change.

INTERESTING: PVC tiles: types and installation of vinyl tiles (step-by-step instructions)

Method 2: installation on a wooden base

Installing plywood on a wooden floor

First, check the quality of the subfloor. Bars and boards should not “play” under load. Decaying wood is replaced. Only minor defects are acceptable. Wood is exposed to negative external factors, so it is necessary to follow a number of rules in order to increase the service life of the rough structure:

- structural elements are ground, which allows larger defects to be eliminated; a grinder can be used; for smaller errors, sandpaper is sufficient;

- large defects (cracks) cannot be removed with a grinder; in this case, use a special putty for woodworking;

- plywood sheets are fastened with fasteners, their heads must be recessed into the wood, these areas are subsequently masked with the same putty;

- When installing sheets, check the strength of the plywood; they should not “play” when pressed.

Important: To reduce the intensity of friction between the structural elements of the rough base and the plywood sheets, use a backing.

Advantages of using plywood for floor installation

The popularity of floor leveling material is due to its positive qualities:

- ease of floor installation, no complex leveling procedure required;

- environmental friendliness;

- compatibility with different materials of the rough base;

- low price;

- increasing the service life of the subfloor structure, since replacing it is more difficult than plywood sheets;

- additionally reduces heat loss from the room through the floor;

- simple preparation for basic work.

When installing, you should take into account the recommendations of experienced craftsmen:

Important: The thickness of the plywood sheets also depends on the distance between the joists. To ensure that the finishing coating does not sag under the influence of mechanical loads, you need to use a material with a thickness of 15 mm, provided that the logs are located at a distance of 60 cm from each other.

Recommendations from experts

To avoid deformation of plywood sheets during operation, to ensure protection of this material, and to strengthen the entire floor structure, you need to take into account the specifics of installation work:

- plywood is laid in a checkerboard pattern; in one area the corners of 4 sheets should not be allowed to come into contact at once;

- If possible, logs are placed in increments of 0.5 m;

- fasteners when working with a wooden base should be 2.5-3 times longer than the thickness of the plywood;

- It is recommended to additionally use waterproofing when laying the material;

- if laminate or parquet boards are used as the finishing material, the rough plywood base should be slightly less thick in thickness than the thickness of the front covering.