Parameters such as density, in some cases resistance to moisture penetration, as well as the weight of one sheet of plywood and its thickness are extremely necessary to know in advance when carrying out loading work, when calculating the amount of building materials needed to complete the assigned tasks for finishing buildings. Modern technologies have made sheets of coniferous or birch plywood a very popular and often used material, depending on specific plans.

Birch plywood

Density

It is the most important and determining factor in the selection of this building material. This characteristic directly depends on the raw materials that are used in the sheet production processes. The base is wood veneers. Therefore, plywood made from coniferous pulp has a density of 550-650 kg/m3. When used in the production of hardwood, the density of plywood is up to 700-750 kg/m3. Due to this, this building material made of hardwood veneer has a higher density, and this structure of the material can be considered the best for carrying out many design projects. Most carriers and construction organizations use a simplified scheme for calculations:

- Coniferous – 550 kg/m3;

- Birch - 700, respectively.

Vegetable garden-365

- home

- SUMMER CALENDAR

- _CALENDARS

- HOUSEKEEPING AFFAIRS

- _PLANTING AND PLANTING MATERIAL

- _

- _

- _HEALTHY RECIPES

- _HELPFUL TIPS

- _ACTIVITIES AND EVENTS

- _

- _DISEASES AND PESTS

- _

- _COUNTRY DESIGN

- _LANDSCAPE DESIGN

- _

- _

- _

- _HOME CONSTRUCTION

- __Foundation

- FLOWERS AND PLANTS

- _FLORAL

- _

- _

- _

- GARDEN

- _BERRIES

- _PUMPKIN

- _TOMATO

- _SPICY

- _NIGHTLANDS

- _VEGETABLES

- _BULB

- _

- _LEAF

- _ROOTS

- _TUBE FRUIT

- _CABBAGE

- _CEREALS

- _

- _TREES AND SHRUBS

- _

- _CHERRY AND CHERRY

- _LEGUMES

- Mega Menu

Despite the fact that the construction market is overflowing with various materials, there are still some that remain in demand to this day. These include plywood. This material has a wide range of applications and has excellent physical and technical parameters. One of the most important parameters of plywood, which determines its grade and quality, is the density indicator. It is this parameter that will be discussed in this article.

Peculiarities

Plywood is a composite building material made from various types of wood. It consists of several layers of veneer, which are connected with a special adhesive composition. Like any other building material, plywood has certain properties. It is characterized by:

- strength;

- environmental friendliness;

- flammability;

- moisture resistance;

- excellent insulating properties, among which it is worth noting thermal conductivity and moisture permeability.

But the most basic parameter that consumers pay attention to when purchasing and using this material is its density. The specific density of plywood is the ratio of the weight of the material to its volume. It depends on what kind of wood veneer the material was made from. The production process of sheets is controlled by regulatory documentation: GOSTs 3916.1-96, 3916.2-96, 11539-83. They indicate the permissible density of the material - from 300 kg per m³ to 700 kg per m³.

Density of different types of plywood

Based on the type of wood, plywood is classified into types, each of which is characterized by a certain density. Let's look at each type in detail.

Berezovaya

This tree has high strength, so plywood made from it has excellent physical and technical parameters and is of a high grade. The surface of the product is smooth and beautiful. The specific density of birch veneer products varies from 640 kg/m³ to 700 kg/m³. The scope of application of this type of material is wide and varied. It is used:

- for the manufacture of monolithic structures, for example, formwork;

- in the process of arranging the floor covering;

- for covering walls and ceilings.

Birch plywood is ideal for making structures with a high level of strength.

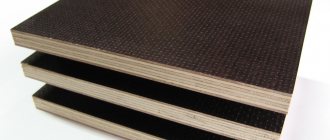

Laminated

This is one of the most popular and frequently used types. The thing is that the sheet consists not only of veneer, but also of protective layers of laminate. The material has excellent characteristics and properties. It is characterized by high mechanical strength and density, which ranges from 640 kg/m³ to 700 kg/m³.

Laminated plywood can be used:

- for the manufacture of formwork at construction sites;

- in the process of decorative finishing indoors;

- for the arrangement of children's and sports grounds;

- for installation of fences and billboards;

- for the production of packaging products;

- for covering car vans.

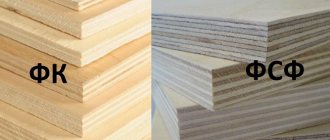

Plywood weight

This characteristic can sometimes play a leading role, since in the construction of various structures it is necessary to calculate the load placed on the foundation of the structure. Knowing the information about the weight of one sheet of plywood, you can easily calculate the total load of the building material used. Like density, weight depends on the original veneer used as the base of the sheet (coniferous is lighter than deciduous). But the type of adhesive composition, according to experts, has virtually no effect on the density of plywood. Thus, the FSF brand has the same density as FK.

Product types

The most important property for construction, after strength indicators, is, of course, moisture resistance. For example, for the same formwork it is necessary to choose a material with high water resistance, otherwise the formwork will absorb water from the concrete, which will lead to a violation of the performance characteristics of the latter.

The most common types include FSF and FC. They differ in the method of production.

- In the first case, the veneer is impregnated with formaldehyde resins before gluing.

- In the second case, gluing is done using glue based on formaldehyde and urea. As a result, the first material is more often recommended for external work, and FC - for internal work.

In fact, both types are produced in both E1 and E2 classes. At the same time, the moisture resistance of FSF is much higher. Strength, weight, and resistance to aggressive environments are approximately the same.

Thickness

The most important characteristic is the thickness of the plywood sheet. For interior decoration, panels with a thickness of 2-10 mm are taken. They are used, for example, as wall coverings. Plywood is also used for flooring. And when making a waterproof floor, a sheet thickness of 8-10 mm is used. With unevenness, the thickness increases, as a rule, to 12.

Below are approximate tables of volume, weight, dimensions

| Birch plywood sheet thickness (mm) | birch sheet , weight of cube and square meter | |||||||

| 1220 x 2440 mm | 1525 x 1525 mm | |||||||

| Number of sheets in 1m3 | Weight of 1 sheet (kg) | Weight 1 m3 (kg) | Weight 1 m2 (kg) | Number of sheets in 1m3 | Weight of 1 sheet (kg) | Weight 1 m3 (kg) | Weight 1 m2 (kg) | |

| 3 | 112 | 5,8 | 650 | 1,9 | 143,3 | 4,5 | 645 | 1,9 |

| 4 | 84 | 7,7 | 647 | 2,6 | 107,5 | 6,1 | 656 | 2,6 |

| 5 | 67,2 | 9,7 | 652 | 3,3 | 86 | 7,6 | 654 | 3,3 |

| 6 | 56 | 11,6 | 650 | 3,9 | 71,7 | 9,1 | 652 | 3,9 |

| 6,5 | 51,7 | 12,6 | 651 | 4,2 | 66,2 | 9,8 | 649 | 4,2 |

| 7 | 48 | 13,5 | 648 | 4,5 | 61,4 | 10,6 | 651 | 4,5 |

| 8 | 42 | 15,5 | 651 | 5,2 | 53,8 | 12,1 | 651 | 5,2 |

| 9 | 37,3 | 17,4 | 649 | 5,8 | 47,8 | 13,6 | 650 | 5,2 |

| 10 | 33,6 | 19,4 | 652 | 6,5 | 43 | 15,1 | 649 | 6,5 |

| 12 | 28 | 23,2 | 650 | 7,8 | 35,8 | 18,1 | 648 | 7,8 |

| 15 | 22,4 | 29 | 651 | 9,7 | 28,7 | 22,7 | 651 | 9,8 |

| 18 | 18,7 | 34,8 | 650 | 11,7 | 23,9 | 27,2 | 650 | 11,7 |

| 20 | 16,8 | 38,7 | 650 | 13 | 21,5 | 30,2 | 649 | 13 |

| 21 | 16 | 40,6 | 650 | 14,6 | 20,5 | 31,7 | 650 | 13,6 |

| 24 | 14 | 46,4 | 650 | 15,6 | 17,9 | 36,3 | 650 | 15,6 |

| 27 | 12,4 | 52,3 | 649 | 17,6 | 15,9 | 4,8 | 649 | 17,5 |

| 30 | 11,2 | 58 | 650 | 19,5 | 14,3 | 45,4 | 649 | 19,5 |

| thickness, mm | Parameters of a sheet of coniferous plywood, weight of a cube and square meter | |||||||

| 2500x1250 mm | 2440x1220mm | |||||||

| PC. in m³ | sheet weight, kg | weight m³, kg | weight m², kg | sheets m³ | sheet weight, kg | weight m³, kg | weight m², kg | |

| 6 | 53,3 | 10,3 | 549 | 3.3 | 56 | 9,8 | 549 | 3.3 |

| 6,5 | 49,2 | 11,2 | 551 | 3.6 | 51,7 | 10,6 | 548 | 3.6 |

| 8 | 40 | 13,8 | 552 | 4.4 | 42 | 13,1 | 550 | 4.4 |

| 9 | 35,6 | 15,5 | 552 | 5 | 37,3 | 14,7 | 548 | 4.9 |

| 9,5 | 33,7 | 16,3 | 549 | 5.2 | 35,4 | 15,6 | 552 | 5.2 |

| 12 | 26,7 | 20,6 | 550 | 6.6 | 28 | 19,7 | 552 | 6.6 |

| 12,5 | 25,6 | 21,5 | 550 | 6.9 | 26,9 | 20,5 | 551 | 6.9 |

| 15 | 21,3 | 25,8 | 550 | 8.3 | 22,4 | 24,6 | 551 | 8.3 |

| 16 | 20 | 27,5 | 550 | 8.8 | 21 | 26,2 | 550 | 8.8 |

| 18 | 17,8 | 30,9 | 550 | 9.9 | 18,7 | 29,5 | 552 | 9.9 |

| 19 | 16,8 | 32,7 | 549 | 10.5 | 17,7 | 31,1 | 550 | 10.4 |

| 21 | 15,2 | 36,1 | 549 | 11.6 | 16 | 34,4 | 550 | 11.6 |

| 24 | 13,3 | 41,3 | 549 | 13.2 | 14 | 39,3 | 550 | 13.2 |

| 27 | 11,9 | 46,4 | 552 | 14.8 | 12,4 | 44,2 | 548 | 14.8 |

Production Features

Moisture-resistant plywood is used in various industries. It includes all brands that have varying degrees of moisture resistance. The composition of the adhesive mixtures includes low-soluble synthetic resins that actively resist moisture. Some brands may have a greater ability to withstand the damaging effects of moisture than others.

Moisture-resistant types are used to make furniture, sports equipment, and toys. In construction, plywood sheets are used as flooring, for leveling walls, and for roofing. It is actively used in areas where lightweight and durable materials are required. This material is in steady demand in shipbuilding, aircraft construction and the construction of elevators.

Types of plywood.

Using formaldehyde resin with the addition of urea to glue the plates, FC products are obtained. It belongs to moisture-resistant species with an average degree of resistance. It is made by gluing coniferous or mixed veneers with urea adhesives. It is actively used in construction, finishing rooms inside the building. Furniture production uses this material to make drawers and boxes.

By adding phenol, plywood is obtained under the name FSF, which is classified as a product with increased moisture resistance. This type is used for interior and exterior decoration.

Plywood, called FSF, can be covered with phenolic film. Then it gets the name laminated plywood FOF. Treatment with phenol film does not allow the use of plywood products for interior decoration. FOF is usually used for outdoor work. It is used to install advertising billboards that do not react to precipitation, use it as a base for roofing material, and make furniture.

The highest quality and lightest aircraft plywood. It has increased flexibility. It is made from the highest grade of finished veneer, the thickness of which does not exceed 2.5 mm, and is used in aircraft modeling.

Plywood products are made from birch or coniferous trees. Birch veneer is heavier than coniferous veneer, which is reflected in the total weight of the sheet.

Regardless of what kind of veneer was used, treating it with formaldehyde resin with additives makes the resulting products protected from moisture.

Weight

How to determine how much a sheet of plywood of known dimensions weighs?

One type of wood

The algorithm for calculating mass is also directly related to a school general education course forgotten by many.

From a geometric point of view, a plywood sheet is a rectangular parallelepiped. Its volume, as is known, is equal to the product of the lengths of all sides. Knowing the volume and average ρ, it is easy to calculate the mass - you just need to multiply these two parameters.

The volume of a rectangular parallelepiped is equal to the product of the lengths of its sides.

A nuance: to get the mass in kilograms, ρ must be converted into kg/m3, and the dimensions into meters.

As an example, let's calculate the weight of a sheet of plywood measuring 1525x1525 mm and 24 mm thick.

Raw materials – fir veneer.

- Let us take the value of ρ equal to 390 (specific gravity of fir) + 50 (mass of resin per cubic meter) = 440 kg/m3;

- The dimensions in SI units will be 1.525 x 1.525 x 0.024 meters. We multiply them and get 0.055815 m3;

- We multiply ρ by volume and get the mass of the sheet. 0.055815 x 440 = 24.5586 kg.

Two types of wood

For a sheet combined from two rocks with different densities, it is necessary to calculate the mass of each rock and add the results.

As a sample calculation, let's calculate the weight of the sheet from the previous example with one caveat: it has 21 layers of veneer, with 2 layers of pine and 19 of poplar.

A leaf can consist of different types of wood.

- We calculate the volume of pine layers. It is equal to 1.525 x 1.525 x 0.024 x 2 / 21 = 0.00532 m3;

- We calculate the mass of pine veneer and the resin that binds it: 0.00532 x (500 + 50) = 2.92 kg;

- We calculate the volume of poplar veneer: 1.525 x 1.525 x 0.024 x 19/21 = 0.05 m3;

- Find the weight of the poplar veneer in the sheet, taking into account the resin that binds the veneer layers: 0.05 x (550 + 50) = 30.3 kg;

- Add up the results: 30.3 + 2.92 = 33.22 kg.