When, during the construction of a house, it comes time to install the roof, a reasonable question arises: how to fasten the rafters? The answer to this depends on many factors: the design of the roof and the design load on it, the steepness of the slopes, the material and load-bearing capacity of the walls, the expected shrinkage of the building, etc. Each of these factors influences the choice of fastening method and rafter fasteners. In addition, the rafters are also attached to the walls and to each other in different ways.

Rafter system - bottom view Source krepezhinfo.ru

General information

To better navigate this topic, you need to know what rafters are, what they are, what they are attached to, and in what cases one or another type of rafter system is chosen.

Rafters are the load-bearing structures of pitched roofs, which take on the entire load from the roof and the snow cover on it, transferring it to the walls of the building. In private housing construction, they are most often made of timber or large-section boards placed on edge. Much less often, metal structures are used in the form of prefabricated elements or ready-made trusses. What and how to make the rafters from is decided based on the calculated load on them and the customer’s preferences.

Metal rafter system Source dawaihati.com

Structurally, rafters are divided into hanging and layered:

- Hanging rafters are installed on small houses, garages and other outbuildings, in which the span between the walls is no more than 5-6 meters. Their upper ends are connected to each other without additional support, and the lower ends, resting on the walls, are tightened with horizontal elements - ties. Tightenings reduce the bursting loads from the rafters on the walls, taking them upon themselves.

Additional tightening increases the span to 8 meters, and struts resting on the tightening - up to 10 meters Source obustroeno.com

- Layered rafters are installed on buildings with large spans over 10-12 meters with an average load-bearing wall or supporting columns. Their upper ends rest on the ridge girder, which in turn is supported by racks resting on the bench - a horizontal beam lying on columns or an internal wall. If the problem of how to install rafters on a pitched roof is being solved, then a layered structure is also chosen, since in it the role of a ridge girder is played by a higher wall.

In this case, tightening is not necessary due to the absence of tensile loads Source remoskop.ru

Designing a gable roof structure for a house

The first and fundamental stage in the construction of a gable roof is its design. We have already said that the choice of roof angle will determine the load taken by the roof, and, as a consequence, the choice of roofing material that can withstand precipitation and the loads from this precipitation and wind.

At this stage, design drawings of the future roof are created and all necessary calculations are carried out. This is necessary, first of all, to have an idea of the general appearance of the roof and its dimensions, as well as to take into account all the expected maximum loads.

After the design, you will have in your hands the entire package of documents, which will indicate all the dimensions of the future roof, its area for the purchase of roofing materials, and the full range of lumber used in the construction. Having a list with the nomenclature of lumber will allow you not to spend extra money on its purchase, since lumber is the main expense item when building a roof.

After all design work has been completed, they proceed directly to construction work. When doing the work yourself, half the budget is saved, which could have gone to paying builders

In this case, it is important to remember to comply with all norms and rules so that the final result meets expectations.

Fastening the rafters at the bottom

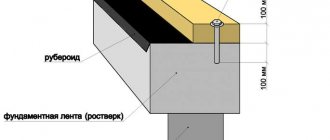

At the bottom, the rafters can rest directly on the wall if it is made of logs or timber. They cannot be supported on walls made of piece materials (brick, concrete, aerated concrete blocks, etc.), since rafters can only be placed on solid foundations that do not transmit moisture.

But this is not the only reason. The roof should be supported by a structure that evenly distributes the load across the walls. Therefore, on their upper part along the entire perimeter, a mauerlat is mounted - a thick wooden beam, eliminating point loads on the masonry elements. Waterproofing must be laid between it and the wall material.

The roofing system can also be attached to floor beams. This is done in the case of frame buildings or mansard roofs. Often floor beams are used as ties for hanging rafters. They must protrude beyond the outer plane of the walls by at least half a meter to form a cornice overhang. And the rafter leg is installed on the edge of the beam.

Frame structure with rafters attached to the floor beams Source krovlyakryshi.ru

It is important. You can do without a Mauerlat or top trim only if the walls have sufficient strength and can withstand a point load. Therefore, on frame buildings, the rafters are installed exactly above the vertical load-bearing posts.

Mounting to a wooden wall

Before installing rafters on log or beam walls, you do not need to do any strapping on them - installation is carried out directly on the supporting structures. In this case, the method of fastening depends on the expected shrinkage of the structure:

- If the house has already shrunk or in the case of reconstruction and replacement of the roof on an old wooden house, the fastening is made rigid by cutting grooves in the upper log for the rafters and rigidly securing them with brackets or metal corners on both sides.

Rigid fastening with notches and metal corners Source filartbel.by

When installing roofs on new wooden houses, sliding fastenings are used. When a building shrinks, its geometry can change, causing excess stress in places of rigid fastening and deformation of the roof structure. To prevent this from happening, the rafters are allowed to move in the transverse direction, adjusting to the shrinkage. To do this, they use special fasteners that allow them to do this. This could be a steel angle with a long slot on one shelf instead of mounting holes. Or a sliding support, as in the next photo.

Mounting on a sliding support Source stroika-1.ru

See also: Catalog of projects of houses with a gable roof

Attaching to the Mauerlat

You need to think about how to attach the rafters to the Mauerlat of a gable roof even at the stage of installing the Mauerlat itself. If it is fixed to the side of the wall using staples driven into wooden plugs, then it is not able to normally absorb thrust loads. Therefore, the fastening of the rafter system must be rigid, preventing shifts or rotations of the elements relative to the Mauerlat and each other.

For reference. A non-thrust Mauerlat is simpler and cheaper to install, but the entire roofing structure is not very resistant to wind loads. Therefore, it is installed only on small buildings - garden houses, garages, bathhouses.

Possible options are shown in the diagram:

Rigid fastening to the Mauerlat Source mercabadom.ru

- At the end of the rafter, a “saddle” is cut out, with which it is put on the mauerlat, after which the connection is strengthened with two steel angles installed on both sides, or with three nails, two of which are driven in from the side at an angle and crossed in the body of the mauerlat, and one is driven vertically into the rafter .

- Instead of making a cut, a support block is sewn to the rafter leg, its end resting on the mauerlat. This is what they do if there are difficulties with how to cut the rafters at the right angle and the right size. Further fastening is also carried out on crossed nails or corners.

- A notch or support block restricts the freedom of movement of the rafter, preventing it from sliding along the supporting plane. And additional fasteners do not allow it to move horizontally. If you increase the degree of freedom of this unit without making a “saddle” or using a bracket as a fastener, then you will have to make the connection of the rafters in the upper part as rigid as possible.

Calculation of a gable roof

Often, novice builders, before designing and calculating the purchase of material, have questions about how to find out the length of the rafters of a gable roof

To do this, it is important to know at the design stage what the width of the building will be in order to select rafters of a standard size, so that you do not have to splice them together, sacrificing their load-bearing capacity. At the same time, you need to remember about the angle of the roof.

All of these factors will ultimately influence the length calculation.

So, to calculate the length of the rafters of such a roof, you need to divide the triangle formed by the rafter system into two right triangles. Further, knowing the width of the building and the angle of inclination of the roof, you can determine the height of the ridge of the gable roof. Knowing the two legs of a right triangle and using the Pythagorean theorem, we can calculate the hypotenuse of each right triangle, which is the required length of the rafters of our roof.

As a result, to determine the final length, another 30-50 cm must be added to the obtained value to ensure roof overhangs.

All calculations carried out to determine the height of the ridge (also known as the height of the pediment) and the length of the rafters are clearly shown in the image:

From all of the above, we can conclude that a gable roof is the cheapest and most versatile type of roofing for a private home. There are examples when, using improvised means, people erected a gable roof on their own alone. But we still advise you to use the help of specialists in such matters, because a well-made roof over your head means comfort and coziness in the house.

Video description

More about this in the video:

Houses built from gas silicate blocks, foam blocks and other relatively fragile materials are necessarily reinforced along the upper perimeter of the walls with a monolithic concrete belt. Without it, reliable fastening of the Mauerlat is impossible, since such materials do not hold the fasteners well. As a rule, even while pouring the concrete belt, studs are installed vertically into it, onto which the Mauerlat is subsequently “attached” and secured with nuts.

In this case, the wooden lining of the walls is more reliable and can withstand thrust loads well. In addition to the methods already described on how to attach rafters to the Mauerlat, you can use others. For example, using an overhead perforated plate with or without a rafter cut. Or on a staple or three crossed nails without sawing. It is only important to cut off the supporting part of the rafter so that it exactly coincides with the plane of the Mauerlat.

Fastening with a plate without cutting Source krysha-expert.ru

See also: Catalog of companies that specialize in roofing work

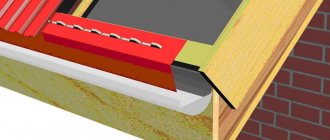

Please note that when installing without cutting, the rafter legs will have to be lengthened by extending them with fillets to form an outlet for the eaves overhang.

To reduce the bursting load on the Mauerlat of a gable roof, sliding (hinge) joints are used. These can be special fasteners, one vertically driven nail, or fastening to a bracket with multi-directional teeth.

Hinged joints of the lower part of the rafter legs are most often used when it is necessary to decide how to fasten the rafters on a pitched roof. But in this case, the upper part is firmly fixed to the ridge beam or the wall of the pitched roof, which performs its functions.

Rafter pitch size and length

As a rule, the pitch of rafters for residential buildings ranges from 60-100 cm. The type of roofing material and the total mass of the roof are important here. The number of rafters per slope is calculated by dividing its length by the step size plus one. For the entire roof the value is doubled.

It is also necessary to calculate the length of the gable roof rafters. The length of the rafter leg is calculated using the Pythagorean theorem. If the maximum beam length of 6 meters is not enough, it can be increased with other sections.

Video description

Video about the construction of a rafter system for a pitched roof:

Modern steel rafter fasteners greatly facilitate the work of creating a roof frame. When using them, you should use the following tips and recommendations:

- all fastened wooden elements must have a thickness of at least 50 mm;

- The shaped fasteners should be fixed with galvanized screws or nails. Moreover, the nails should not be ordinary, but rough - with notches on the trunk, at least 40 mm long;

- symmetrically located fasteners can be additionally tightened with studs, tightening the nuts on both sides of the rafters.

Fastening with M12 studs Source mercabadom.ru

How to attach rafters for a bathhouse

It is enough to lay the beams on top of the logs and fix them with metal corners.

You can make cuts in the logs. To do this, you first need to accurately mark the future holes, then take a chainsaw with a sharp chain and make cuts with a depth equal to half the cross-section of the log.

The height of the grooves should be 3 centimeters greater than the height of the beams in order to align them if necessary.

When the cuts are made, armed with a chisel and a hammer, you need to finish the job, giving the holes the desired shape.

Be sure to check the level of the beams.

Before laying the beams, their ends must be wrapped with pieces of Europen (insulation) soaked in an antiseptic solution, then the beams must be additionally secured with metal squares.

Mounting at the top

In the upper part, the structural elements are also fastened differently depending on its type and the need to create a rigid or movable connection.

Hanging rafters can be attached end-to-end or overlapped. The butt joint is quite rigid, as they rest against each other. To do this, the upper ends are cut at such an angle that when installed, the sections take a strictly vertical position and fit tightly together.

Butt connection Source srub-banya.by

Functions

The rafter system is a set of supporting elements that support the geometry of the roof, the frame of the roof structure, giving it rigidity and the required slope. The composition, section thickness, and location of the parts of the “backbone” of the roof are determined using calculations that take into account permanent and temporary loads. The rafter frame performs the following functions that determine the functionality of the roof:

- Sets the geometry, slope. The rafter legs of the frame give the roof the necessary angle of inclination and shape, facilitating easier removal of snow or precipitation from the surface. It is the frame that determines how many gables or slopes the roof will have, which means it is this structural element that determines its appearance.

- Serves as a basis for attaching waterproofing material. The rafter frame sheathing is used to secure the finishing roof covering.

- Evenly distributes the weight of the roof. The interconnected elements of the rafter system evenly distribute and then redirect the load from the finishing coating and the weight of the snow mass between the load-bearing walls of the structure, preventing distortion or deformation of the structure.

- Ensures the functioning of the roof. The structure of the frame, taking into account the characteristics of the roof and roof covering, provides support, aeration and protection from condensation.

Please note that a well-designed rafter system is the key to the durability, reliability and mechanical strength of the roof, so its design and installation is trusted to professional architects. Experienced craftsmen believe that a high-quality frame is much more important than the final roofing covering, so you should not skimp on it.

Functions of rafter systems

Summary

It’s not enough to know how to install rafters and secure them to the walls of the house. First you need to calculate the loads and choose the optimal fastening method, taking into account the length of the spans, the possibility of shrinkage and other factors affecting the stability and durability of the structure being created. And most importantly, you need to have experience working with wood and be a perfectionist in order to achieve the perfect identity of each pair of rafters and install them in the same plane.

You can take on such work yourself if you have a detailed project in hand and an experienced assistant nearby. Otherwise, it makes sense to turn to professionals.

What problems does the rafter system solve?

The main function of the roof is protection from precipitation, wind, and external influences. Most regions of Russia are characterized by pitched roofs, which ensure the drainage of rain or melt water and the independent removal of excess snow. Flat roofing types are found only in the southern regions, so there is no point in talking about them.

The composition of the roof includes two main elements:

- roof;

- rafters

The roof acts as a sealed covering, laid at a certain angle on the supporting structure - the rafters. Their tasks include:

- maintaining the roofing sheet;

- creation of a stable and reliable system that takes on snow and wind loads;

- attic ventilation;

- protection of the upper ceiling from temperature changes, sunlight, moisture and other influences.

A rafter system insulated with liquid polyurethane foam allows you to create a residential attic. Source combo-izol.ru

In addition, the rafters ensure uniform distribution of the load on the walls and foundation of the house. For regions with snowy winters, the task of the system is to form a certain angle of inclination of the slopes, ensuring an optimal balance between snow and wind loads. All these functions have to be performed simultaneously, so calculation and installation of the system are important and critical stages of building a house.

Material

Rafter structures are made of wood. There are quite strict standards for the quality and size of the material. Basic requirements for wood:

- edged boards of coniferous or hardwood are used for assembly;

- the moisture content of the material should not exceed 18%;

- Each linear meter of board may contain 3 knots (no more), the maximum diameter of which does not exceed 3 cm;

- through cracks are not allowed;

- the length of non-through cracks should not exceed half the length of the board.

High-quality lumber Source specdispetcher.ru

What does it consist of?

At the heart of any interfloor ceiling, be it a basement or an attic, are large-caliber beams, on which a so-called pie of flooring, insulation and external finishing is placed. The difference between the structure of the attic and the basement is only in the cross-section of the beams . The attic requires stronger beams, especially if we are talking about a warm room where furniture will stand and people will walk around.

For cold floors, the standard is timber or other versions of beams with a section of 100x150. It is impractical and unsafe to use a smaller thickness. For a stronger floor, you can use 100x200 beams. They are heavier, but you will need less of them, since the step can be increased from the standard 60 cm to 1.5 m.

Next, a vapor barrier is laid on the side of the lower room, filling it with a rough ceiling, for example from OSB boards. On the attic side, insulation and waterproofing are laid and a rough attic floor is created .

In another option, you can use metal beams, for example, I-beams. They are more durable, but when used, the thermal conductivity of the entire cake suffers. Metal has high thermal conductivity, which increases the cost of insulation.

Another option for attic flooring is concrete slabs, which are laid ready-made on the load-bearing walls of the house. The advantage of a reinforced concrete floor is its high strength and the absence of the need to install a vapor barrier. The downside is that it is cold and heavy, as well as expensive and labor-intensive from an installation point of view.