In any, even the most modern kitchen, you can find utensils made of wood. They are distinguished by their unique beauty, grace, and look original and stylish. They give special home comfort and decorate the interior. Wood products attract not only their appearance, but also their practicality. In some respects, natural wood is far superior to modern materials used in the production of kitchen utensils.

Eco-friendly wooden food utensils meet the strictest hygienic requirements due to their organic origin. And accordingly, it has natural disinfecting properties. In addition, modern products have excellent resistance and durability. Wooden products do not break when dropped, are not afraid of temperature changes, and it is absolutely impossible to get burned on them. You can store various foods in such containers for a long time. Due to its porous structure, it can absorb excess moisture. In wooden dishes, products such as salt, sugar, cereals do not become damp, pickles and preserves do not become moldy, and the prepared food remains fresh for a long time.

What kind of wood are utensils made from?

Each tree, like any living organism, has unique properties. Taking into account the varieties of the breed when choosing dishes, you can get a product that is not only beautiful and durable, but also healing.

Most often, the following are used to make tableware:

- Oak is a long-living tree with a special strength. Oak dishes are famous for their resistance to high humidity and do not crack during sudden temperature fluctuations. Wood has astringent and anti-inflammatory properties. Especially recommended for people suffering from frequent intestinal disorders.

- Acacia is a tree that has natural pain-relieving properties. In addition, the plant has a very beautiful texture and color. Dishes made from this breed will look amazing and have a very pleasant aroma.

- Bamboo is an antiseptic wood, insensitive to moisture. The cookware is very durable and especially lightweight. Suitable even for the smallest children, as it does not break or crack when dropped, and is comfortable for the smallest hands.

- Ash is a tree with heavy and expensive wood. It has pronounced antiseptic properties, eliminates fungi, parasites and even Koch bacilli. The devices have a natural, very beautiful dark color, strength and durability.

- Linden – has anti-inflammatory, antipyretic, antispasmodic properties. Dishes made from it are especially recommended for people with stomach diseases and frequent colds. Food made from it has a unique taste and aroma.

Range of possible products that can be produced

When organizing the production of wooden utensils, you can focus on different types of main consumers - the greatest demand is for ordinary kitchen utensils used in everyday life when preparing and eating food. Painted wooden dishes are also popular and have their own buyer, but their sales are somewhat lower due to the higher selling price.

One of the profitable areas of your business activity can be wooden tableware for restaurants and cafes - currently, a large number of such establishments are stylized in the Russian style and use traditional Russian folk costumes, paintings, customs and household items in their decoration.

What equipment is used to make dishes?

Wood is a material that can be easily processed by hand, but high-quality manufacturing requires the craftsman to have certain knowledge, working skills, special tools and the necessary equipment. For mass production, you need an entire carpentry workshop with drilling and turning machines that perform various preparation operations, electric planes, and angle grinding mechanisms.

For small home production, you may need a relatively small set of tools:

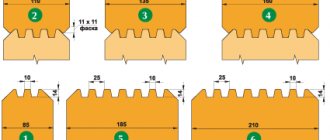

- Hacksaws of different sizes with large and small teeth.

- A set of chisels - with different working surfaces (flat, figured). There are twelve types of chisels in total.

- Several incisors - large and small, differing in the shape of the cutting blade.

- Planers and jigsaws - for quality work you need to have several tools.

- Special oils, paints, food varnish.

In addition, the craftsman may need chases, rasps, various brushes, scrapers with different profiles, knives for cutting spoons, and various staples.

Financial calculations

The cost of a unit of goods on the market on average ranges from 400 rubles for a small item to 1,500 rubles for a large one: it depends on the material, type of dishes and complexity of the work.

The profitability of a business depends on well-configured sales channels.

If you constantly expand your activities, regularly advertise your products and carry out related events, your annual profit can be more than 1,000,000 rubles.

Start-up capital

When taking into account initial costs, which include:

- purchase of equipment and wood for processing;

- rental of premises for production and sales points;

- initial advertising campaign;

- registration of individual entrepreneurs and other related activities.

To start a business you will need an amount of 500,000 rubles.

Monthly expenses

- rental of production premises – 25,000 rubles;

- wood - about 50,000 rubles;

- wages for workers (when hiring 2 employees by trade) – 50,000 rubles;

- remuneration for other personnel - from 50,000 rubles;

- advertising – from 20,000 rubles.

How much can you earn

On average, with the right approach and proper promotion, a business can bring in from 1,000,000 rubles a year.

Payback period

Depending on the correctly selected sales channels, means of sale, the level of competition in the city, well-planned marketing, and the right business niche, the business can recoup costs and begin to make a profit in 6 months. With smoother development, the payback period can last up to two years.

Tableware production technology

The process of manufacturing wooden tableware and kitchen utensils is carried out in several stages.

In specialized workshops:

- Obtaining unpainted products (linen) - from prepared wooden blocks, the master uses a lathe to shape future products - plates, salad bowls, boards and stands. After production, the dishes are dried in dryers at a temperature of about 27-30o C, from several days to a month.

- Putty - products are coated with special purified clay (wapa), left to soak, and the process is repeated several times.

- Primer – leather swabs are used to manually cover the product with boiled linseed oil (linseed oil). Leave and dry in the unit at a temperature of 40-50o C. Repeat the procedure 3-4 times. Light sanding is carried out.

- Tinning – preparation for subsequent painting. Powdered materials are rubbed in to give a gold or silver color. They are impregnated with different compounds and fired in an oven.

To create wooden utensils with your own hands:

- It is necessary to cut the workpiece to the required size. For a spoon or fork, a 300x50x50 mm block is suitable; for a plate, you can choose a saw cut with a suitable diameter.

- It is recommended to clamp the workpiece tightly in a vice so that it does not slip off, as well as for ease of use.

- The bar is given its original shape using flat or shaped chisels. Make the necessary indentations.

- Fine eyeliner is applied using various shaped cutters and the final outlines are given to the products.

- Polishing dishes. For the inner surface or curved parts, use sandpaper. Flat surfaces are smoothed with an emery stone.

- If desired, carving with a cutter, as well as processing with oils or varnish.

Video: how to make dishes from wood.

Is it worth looking for masters?

What is better: to hire several master carpenters who have solid experience working with wooden products, or to comprehend all the intricacies of the work yourself, using various manuals, or taking special courses? It is impossible to answer this question unequivocally. Each option has its advantages and disadvantages. Working with a team, you undertake to pay wages, regardless of how many products you sell in a month. You need to look for a room with a larger area; you will have to purchase tools in larger quantities.

Working alone, without an experienced mentor who would suggest a way out of a difficult situation, is quite difficult. Production volumes from one person compared to a team are trifles. In addition, in addition to production, you also need to deal with the procurement of raw materials, sales of finished products, and other administrative and organizational issues. In general, each of you must resolve this issue with the greatest benefit for yourself.

Coating and decoration of finished dishes

In order for wooden tableware to serve for a long time and retain its beauty and health benefits, it must be properly processed. This especially applies to plates and spoons for everyday use. The main rule is not to make impregnating compositions with chemicals that are harmful to the body. They will add beauty to the products, but they can only be used for interior decoration.

Impregnation

The best thing is to treat the dishes with vegetable oil or food grade varnish for color and durability. They do not harm the body, prevent moisture from penetrating into the product, and add attractiveness. You can choose any oil for impregnation - sunflower, olive, sea buckthorn, pumpkin, and so on. Since ancient times, professional craftsmen have used linseed oil for this purpose. The best choice is bleached linseed oil, which can be purchased at art stores.

Impregnation of wooden objects is sometimes called painting, since after it the wood acquires an even honey or amber color. It is prepared on the basis of vegetable oil or a mixture with beeswax (mastic).

For impregnation, the product is immersed in a container with oil placed in a water bath. The mixture should be hot to better penetrate the wood, but not boil. The dishes are turned several times for better processing. The beginning of the process is the appearance of air bubbles coming from the wood, and the end is their cessation. The product is then blotted several times with a paper towel and then left to dry in the sun for 3-4 days.

To process with mastic, pieces of natural beeswax are added to vegetable oil and heated in a water bath. It turns out to make a mixture of different consistencies. It is better to impregnate dishes made of hard wood with a soft liquid, and hard mastic will work well on soft types of wood.

Giving medicinal properties

Some artists use various herbs and oils for beautiful color and healing qualities. Treatment with sea buckthorn or pumpkin oil will give your dishes orange tones. Adding tincture of chamomile, burdock, dandelion or mint will fill it with a pleasant smell and protect the tree.

Craftsmen often use epoxy resin to decorate wooden utensils, which emphasizes the natural beauty of wood. Products with resin handles look great in any interior. They are not suitable for hot dishes. You can serve them with cookies, nuts, various fruits or candies.

How to advertise a business

Distribution channels are the basis of business on handmade products. It is important to establish connections with the outside world through social networks, the Internet, forums - any places where your audience lives. Develop accounts on different platforms, hire a photographer and take beautiful photos of products that you can use in all resources.

Also try selling through fairs, participation in city and outdoor events, and festivals. Make acquaintances with interior design studios: let them offer your products to customers with suitable apartment design.

The creative business is interesting, challenging and profitable. The markup on wooden products reaches 200%, so you won’t be left without money. The main thing is to work on yourself, quality, range and service. In the future, consider creating your own retail store or online store.

High competition in business is not always a bad thing. A point selling hot corn is a popular type of business that is always relevant. Pay attention to offers for ready-made businesses. Maybe you will find your ideal option. A ready-made business helps you save time on the first steps of development, on paperwork and establishing relationships with suppliers. Decide on the type of launch of your business and get started!

Features of care

Wooden products can only be washed by hand, with soft sponges under running warm water. Do not soak in water for a long time, and after washing you should immediately wipe and leave to dry. Wood products must be stored away from sources of moisture.

Periodically (once a month) products should be disinfected with vodka or alcohol. To destroy germs and also to prevent unpleasant odors. If a smell appears, you can wipe the surface with a weak solution of vinegar or lemon. To maintain the beautiful color of the dishes, once every few months you need to prepare a decoction of onion peels with lemon juice and wipe the utensils.

To avoid cracking of products, they are soaked in vegetable oil and then dried in the sun or at room temperature.

Do not place wooden products in the oven, microwave, or on the stove.

Selecting a room

At first, all the work takes place in the business owner’s apartment. Subsequently, when expanding and increasing turnover, a small workshop is rented.

Organize your workspace effectively at home. It is advisable to allocate a separate room for a workshop. You will need a lot of tools and it should always be at hand. Divide the space into several functional zones: in one you cut and process the product, dry it and paint it if necessary. Take care of high-quality ventilation in the room.

If space at home does not allow, which is often the case in our modern apartments, and the budget is small for renting a workshop, ask for square meters in a local art house. There is one like this in every, even small, city in Russia. In addition to this, pottery workshops, handicraft centers and similar organizations are suitable. For a small rent, they will let you under their roof and provide you with a place.

Beer mugs

A traditional feature of the dishes is considered to be an expanded bottom, but often craftsmen imitate the shape of a barrel. Norwegians produce cylindrical containers, covered with openwork carvings on the outside. Durable mugs are made from solid oak and acacia. The wood can be cut and does not crack.

Wooden beer mugs are popular among the male half of humanity.

Important! For production, dried, dense wood is used. After turning, the surface is ground and impregnated with varnish that hardens in air.

A wooden beer mug does not overheat, and the drink in it remains at a certain temperature for a long time.

Tea cups

A fishing cup is a small bowl without a handle. They are painted under Khokhloma. Chinese ones resemble small bowls; they have a small rim that makes it easy to hold the container. Modern cups are made in the shape of porcelain ones. Tea pairs made from dense breeds differ in appearance only in color.

This mug has good thermal conductivity, which means the cup will remain cold for a long time, and the tea in it will cool down for a long time.

Important! For stylish designer dishes, instead of a saucer, a wooden round stand is made - a ring-shaped processed cut.