Any adult who is more or less familiar with the basics of frame construction and has at least a little experience working with tools can assemble or make a change house with their own hands. Arrangement of a compact, light and well-insulated residential building on 15-20 m2 of area will require at least a week for the box, and 3-4 days for finishing the trailer, connecting light, sewerage and water.

Does it make sense to build a change house with your own hands?

There are several ways to get a residential trailer for the temporary residence of a small team of construction workers. The situation is usually complicated by the fact that you will have to live in a change house in the winter in a suburban area, when the dacha or house itself, as such, does not yet exist, or is just being built.

The problem of changing houses for workers is solved in several ways:

- Rent a residential trailer from friends, neighbors, a construction or specialized company. The worst option. They will give you a good cabin for a maximum of a week, but for an old and broken trailer, the owners usually require repairs;

- Build a change house using hired workers. They will do it quickly and at the same time for little money. The quality of the constructed residential unit is low, and most often, after a month, another will need to be repaired or even re-equipped;

- Buy a ready-made change house or order it from a construction company according to pre-agreed conditions and drawings. It turns out to be quite expensive and not always correct.

Most construction companies prefer to sell their standard trailers, heated trailers, and living boxes, which are produced on the market. Therefore, there is no hope at all that a company will agree to make or build a good quality change house according to an individual project and an acceptable price.

In terms of price, a typical 6x3 m residential trailer costs $1100-1200, plus delivery and installation will require another 10% of the cost. If you add the costs of making a foundation and sewerage, it turns out that it is easier and cheaper to build a change house with your own hands. High-quality, solid, according to your taste and layout.

Floor

First, boards (or OSB-3) of the subfloor are attached between the joists. The protruding edge of the bottom trim beam (150×100 mm) is used as a support.

Do-it-yourself change house floor installation.

Then the surface of the subfloor is covered with waterproofing film. For this purpose, dense polyethylene is often used, but roll materials with bitumen or polymer-bitumen impregnation Gidroizol are considered more reliable. The film is laid with an overlap between the strips of at least 20 cm, with the seams taped with construction tape. The edges of the strips should extend onto the walls (the same 20 cm).

Insulation is placed between the joists. It is better to choose mineral wool, for example URSA. Unlike polystyrene foam, it is not flammable and does not harbor rodents. Its only drawback is its hygroscopicity and the property of losing its insulating properties when saturated with moisture (the same condensate). Therefore, you need a gap between the finished floor covering and a vapor-permeable membrane or use Izospan, which does not allow water to pass through - this will protect the mineral wool from direct contact with water and allow water vapor to erode from it.

The best choice for a finished floor is a tongue and groove board. The tongue-and-groove connection principle of the coating makes it possible to further protect the insulation from water getting into it.

But you can lay the same OSB, and linoleum on top.

What can you build a cabin from?

Before planning construction, it would be right to think and select a variant of the cabin design so that, after completing construction work on a suburban site, you can turn the trailer into a useful room for the household. For example, refurbish a bathhouse or build a summer kitchen, or even a small garage for a vehicle.

More often, country houses are built according to several standard schemes:

- Frame building made of boards, wooden beams and lumber;

- A change house with a metal frame and a subfloor base;

- Construction from OSB boards and panel materials;

- Panel board or temporary housing made of plywood;

- A warm version of a cabin made from sandwich panels.

Any of the listed schemes is quite accessible to even a novice carpenter or carpenter to build a residential block with his own hands. If you have no construction experience at all, then you can find step-by-step instructions that will help you make a change house with your own hands without making gross mistakes, and the quality of workmanship depends entirely on your attitude to the work. It’s clear that for your needs, you don’t need to force anyone to make a residential trailer efficiently and efficiently.

Layout and drawings

Standard sizes of cabins and openings:

- length - 6-9 m;

- width - 2.5 m;

- height - 2.5 m;

- doors - 0.9x2.1 m;

- windows - 0.9x0.9 m.

Since you are building a shed to suit your needs, you can move away from standard solutions and make it larger or smaller.

The area of the cabin depends on the purpose:

- to change clothes and store equipment, 8-10 m² is enough;

- if you plan to relax or live there temporarily, it is better to make the room more spacious - up to 25-30 m².

Planning is decided according to the same principle:

- for a warehouse - a room without partitions;

- for temporary accommodation - a vestibule and a room.

The doorway can be located at the end or in the middle of the cabin. In both cases, the room is conveniently divided into several parts that can be used for different needs. In the walk-through vestibule, equipment is stored or a locker room is organized; other rooms are equipped with a kitchen, storage room, and rest area.

Here are some options for drawings with different locations of internal partitions and communication designations:

Change house with two separate rooms and a vestibule

Two separate rooms with vestibule, bathroom or storage room

Smaller vestibule, but larger rooms

Change house with shower and toilet

To heat water, an electric boiler or instantaneous water heater is used, but provided that the cabin has running water. For the summer period, you can install a storage tank on the roof of the cabin. On hot sunny days, warm water will be enough to freshen up after work.

With separate entrance to shower and toilet

For the toilet, you can make a separate cesspool, dig a plastic septic tank, or install a dry closet with peat or liquid filler. The latter option is convenient because it does not require sewerage or plumbing, and there are no odors or other unpleasant phenomena associated with a cesspool.

Wooden cabin

Most often, prudent owners plan to build a trailer or temporary living block with further plans to use the room as a bathhouse or summer kitchen. In this case, it is best to build a shed from timber 70-90 mm thick.

The box is installed on a permanent foundation made of concrete or bored piles. The walls of the cabin are assembled using the traditional technology of laying wooden beams.

Customers prefer to build the roof, window and door openings, and the floor of the cabin according to a temporary plan, for shrinkage. A residential block without any insulation with mineral wool or penoplex provides comfortable living conditions from May to October, during the period of the most intensive work at the dacha. It is at this time that most construction has to be done on a suburban site.

For your information! It is more expensive to build a change house from timber than to buy a ready-made standard version of a residential block or trailer.

The benefits of such a solution are calculated for the future. In just a year or a year and a half, when the dacha box has been built, rough cladding has been completed and electricity has been connected, the log cabin, which has completely completed the shrinkage processes, can be converted into a bathhouse or summer kitchen with a clear conscience.

Panel change house

The vast majority of inexpensive standard trailers or residential blocks are manufactured using a panel design. Most of the wall, floor, roof and interior trim parts are cut on woodworking machines and sold as a kit. All that remains is to transport the purchased change house to the site and build it according to the attached assembly diagram.

Features of panel residential premises include:

- Simplicity and high speed of assembly. In order to build a panel shed, you will need a screwdriver with a double set of batteries, a saw and several hundred wood screws;

- Low price for the building. On average, a panel structure costs 20% less than classic frame and metal trailers - cabins;

- A minimal amount, and sometimes a complete absence of insulation.

The walls of the residential block are made of sheet plywood, with virtually no frame; only the corners, ceiling and floor are sewn from timber. The rigidity and stability of the shed room is ensured only by the strength of the plywood sheets. Often, strong storm winds can easily deform and sometimes even break the structure.

For your information! Panel structures of cabins are often used by unscrupulous shabatniks in order to build living quarters and blocks for urgent orders in the shortest possible time.

The box assembled from plywood is insulated with mineral wool and lined with clapboard or sheet metal profiles. The result is a beautiful building, but absolutely weak and practically uninhabitable.

Change house made of OSB boards

Approximately 60% of all summer cottages are built in the form of frame structures covered with OSB boards. The material, similar in properties to plywood, but at the same time much cheaper, perfectly withstands atmospheric moisture, has better heat and sound insulation. The strength of OSB boards is lower, so it will not be possible to build a panel shed from them; the walls of the residential block will simply delaminate and fall apart under load.

You can make a wonderful frame shed from OSB boards. It is somewhat more expensive to build a room box from panels, since the wooden frame made of timber is insulated with polystyrene foam boards and sheathed with OSB on the outer and inner surfaces of the sides. Of course, using frame technology, it is possible to make a residential block based on plywood, sandwich panels or SIP materials.

If the cabin trailer is going to be made mobile, then it is best to use a metal frame made of a square pipe. But in this case, after the completion of the construction of the dacha or cottage, the change house will be suitable for a maximum of building a utility block or garage.

Change house made of metal profiles

As a rule, sheet metal and rolled metal are not used for temporary summer cottages. The change room turns out to be cold in winter and hot in the summer heat. Considerable expenses will be required to make effective thermal insulation of increased thickness.

In addition, the cost of purchasing metal will be approximately twice the cost of building a frame wooden structure. Metal profiles and profiled sheets are used for the construction of capital premises with a high level of comfort at the dacha.

In this case, it is easier to buy an old sea container; its price will not exceed $400-450. About the same amount will be required to finish the inside of the box, install windows, insulate the walls, build a sewer system, and install water and electricity.

With an estimate of $800, spending a week of vacation, you can build not just an excellent shed, but a full-fledged guest house in which you can live in the winter, store materials and tools, like in a safe, and not worry about your country property.

Change house made of sandwich panels

Of all the existing temporary housing schemes, trailers and residential blocks made of SIP panels are considered the warmest and most comfortable. It is unlikely that you will be able to make a change house with your own hands from industrial-type metal sandwich panels, since the dimensions of the slabs may exceed the required dimensions of 6x3 m. Full-fledged hangars and garages on a metal frame are built from sandwiches; such structures are not used as living quarters.

The process of building a cabin from SIP panels is in many ways similar to the technology of panel houses. Finished foam blocks cut to size, covered with OSB boards on both sides, are laid on a rough timber frame and secured with polyurethane foam.

If you first make a high-quality pile foundation and cut out the blocks, it will take a maximum of two to three days to build the trailer box with one assistant.

How to choose a foundation for a cabin

Whatever type of cabin is chosen, there is no need to build a permanent foundation using monolithic concrete or reinforced concrete piles. In this case, you just need to protect the cabin from moisture from the ground. It is advisable to use asbestos pipes, used railroad sleepers, cinder blocks and other standard building materials to build a foundation for a cabin.

Instructions for laying the foundation for a cabin:

- The site selected for the construction of the type of structure in question is cleared of debris and grass.

- In the corners of the site and in the places where supports are supposed to be placed (usually 6-8 of them are enough), the top layer of soil is removed.

- In areas cleared of the top layer of soil, a mixture of crushed stone, sand and screenings is laid, then carefully compacted with a special device (the “pie” must first be thoroughly spilled with water).

- If asbestos-cement glasses are used as foundation pillars, then paving slabs can be laid under them - this move allows you to slightly increase the area of the supporting base.

- Sleepers or cinder blocks (depending on what material was chosen for the construction of the foundation) are laid on the pad, all these parts must be checked by the building level for a perfectly horizontal position.

- Roofing material is laid in 1-2 layers on the laid sleepers or cinder blocks - this will provide additional protection of the main structure from moisture.

The described type of foundation is very easy to implement - even an absolute beginner in construction can handle this work. In addition, if necessary, transfer/transport the shed to another location, such a foundation will only simplify the task.

Types of frame cabins

If we proceed from the criterion “price – quality – comfort”, then the best option is temporary housing built using a frame scheme. The popularity of cabins on a supporting frame is explained by two factors:

- Flexibility of the construction scheme. You can choose materials for insulation, room decoration and exterior cladding to your taste, without being tied to a specific type of wall construction;

- High comfort and relatively simple construction technology that forgives mistakes even for inexperienced workers.

If you make a defect or make a mistake in calculations during the work, you can always correct the defect, although this will require additional costs and resources.

Change house with wooden frame

A residential trailer with a frame made of timber and boards can be built on almost any soil. According to the technology for constructing a trailer cabin, it is usually necessary to make a small foundation of brick, concrete blocks or piles, on which, like on a pedestal, the following are successively built up and installed:

- The base of the floor of the future living space;

- Wall frame posts and horizontal ceiling beams;

- Insulation is laid and wall cladding is made of wooden lining, siding or corrugated sheets.

Thanks to the separation of processes, a frame change house can be built simultaneously by a team of two or ten people, everyone will find a task to do. The shed can be done in one go or assembled gradually over several weeks or summer months.

The only problem with the frame structure is the protection of insulation and wood from rain and ground moisture. Therefore, they either try to build residential blocks with a wooden frame and put a roof on them in the shortest possible time, or use special expensive oil-varnish impregnations for protection.

Change houses with a metal frame

In addition to wood, you can use a metal corner or a square pipe of any profile to assemble the frame base. Most often, cabins on a steel frame are built for mobile trailers with a base on metal supports.

If a suburban area is located in swampy areas or on soils with a high groundwater level, the use of a metal frame avoids deformation of the building body due to frost heaving.

The most popular option is to use a frame from a steel railway container. In order to build a change house, sheets of walls and ceiling are cut out, leaving only the frame. The floor and ceiling are reinforced with a 60x60 mm square pipe, and boxes made of steel angle are welded in places where windows and doorways are installed.

After laying the insulation, the walls are sheathed with profiled sheeting.

Portable cabins

Construction on a suburban site does not always require the arrangement of a full-fledged, albeit temporary, living space; a team of workers can come to the site on a separate schedule. But even in such a situation, you will need to make a temporary trailer to organize the simplest living conditions, where you can shower, wash, and go to the toilet.

The version of the change house shown in the diagram can be made from wooden lining, or built from galvanized steel profile. Plastic panels are best suited for bathroom cladding; the material is not afraid of moisture and does not absorb odors.

Change house from a construction trailer

The scheme for making a temporary shed from a mobile construction box is no different from using a wheeled version of the shed. Most owners of suburban areas do not even try to remodel or refurbish the premises.

The box is simply delivered and installed on a prepared, planned site on concrete blocks. Construction sheds and wagons are usually used as temporary housing mainly in the autumn-winter season, since the cabin box lined with corrugated sheets or plastic does not get wet and does not lose its thermal insulation even in heavy rain and wind.

DIY cabin projects

The most popular are frame cabin cars made from the hulls of sea containers or assembled using timber technology.

The change room is divided into two sections - sleeping and living. The dimensions of the container allow you to make a small kitchen.

A container shed, in fact, remains the only option when you can build an entire house to accommodate 7-10 people without any problems.

If necessary, you can build a non-residential change house, make a shower stall and install wardrobes or hangers for clothes.

Wooden shift cabins are considered more comfortable when it comes to staying for several weeks or months. It is clear that the perception of a metal box and a wooden house is different; a room made of wood is still more convenient and pleasant.

In this case, you will need to make a comfortable bathroom inside the room, build a small steam room and a covered terrace at the entrance to the room. All these are little things, but it is thanks to them that you can maintain the proper level of comfort.

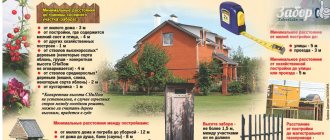

Where to place a change house (best ideas)

An important criterion for independent work is the choice of the optimal location. Any residential building should not be located in close proximity to latrines or unstable soil.

A number of safety rules are also important:

- If groundwater is close to the groundwater level, the cabin should be raised onto a small base or podium.

- If the condition of the underlying soil is poor, due attention should be given to pouring the foundation.

- If the room has a shower, it is important to properly supply water and sewer pipes to the future building.

- For this reason, a place on the site is chosen that is closest to the water source. The same parameters take into account the location of the source of electricity and heat.

Also, you should not locate the new premises near the roadway, because noise and exhaust fumes will regularly disturb your vacation outside the city.

How to build a 6x3 shed with your own hands: step-by-step instructions

If you want to make a simple, inexpensive and at the same time convenient shed-trailer, then it is best to try to build with your own hands an ordinary frame room from timber and clapboard.

Premises made from timber, boards and OSB boards are inferior to those made from containers or car boxes, but this is an invaluable experience for novice builders and an opportunity to avoid mistakes when building a cottage or bathhouse.

Foundation installation

As a basis for a wooden cabin measuring 6x3 m, you can use supports made of concrete blocks or build brick supports to a height of at least 20 cm. First, the turf and fertile layer of soil are removed from the area of the base of the foundation, the soil is leveled in a horizontal plane, compacted, covered with geotextiles and dumped layer of sand with crushed stone screenings.

In total, for a change house measuring 6x3 m, you will need to make 12 pillars, three rows of four supports. The tops are carefully leveled and adjusted in the same plane along the horizon so that the trailer does not turn out crooked or sway. Roofing felt is glued onto the supports using mastic insulation.

Next, on top of the foundation you need to make a frame box from timber. If the change house is planned to be built in winter, then the base will additionally need to be insulated. For example, after filing the subfloor boards, lay film waterproofing and cover it with expanded clay.

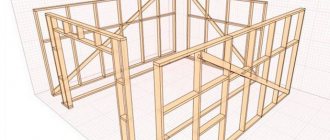

Frame installation

The supporting structure of the cabin can be welded from a square pipe; on top of the wooden frame, you will need to make and secure a metal frame, to which the vertical frame posts will be welded.

The frame of the metal trailer is assembled by welding from a square profile pipe 20x40 mm.

For an ordinary wooden cabin, the frame system can be built from pine beams with a cross-section of 90 mm. Each rack must be aligned vertically and temporary side braces must be made. The racks are attached to the frame with steel angles, which you can make yourself from the remnants of rolled stock.

The heads of the wooden racks must be trimmed to the level, making sure that the ends of the vertical beams of each row are located in the same horizontal plane. To strengthen the frame, two struts need to be made under each rack.

Construction materials

For a wooden change house you will need a board and timber to install the frame.

To create the base you will need a 10x5 cm beam for strapping beams or racks. To insulate the rack - timber up to 15 cm.

For rafters and joists you will need a 50x100 mm edged board. For lintels - timber with a section of 50x50 mm. For sheathing under the roof, boards of 25x100 mm are used.

OSB is used as sheathing, and insulation is used under the sheathing.

You will also need mineral wool for insulation and a wind barrier for protection from the outside. Exterior finishing is often done with corrugated board, clapboard or block house. Inside they use plastic panels or other options to taste. For the roof, you can choose ondulin, slate, corrugated board and other materials.

The amount of materials depends on the construction scheme.

Installation of windows and doors

Installing door and window units is not particularly difficult. First you will need to make markings on the racks where exactly you plan to build the windows. Based on the marks, you will need to build supporting horizontal jumpers on which the boxes will directly rest.

The final installation of windows and doors in the cabin can be done after laying insulation and installing film insulation, the edges of which will need to be tucked under the edges of the window frames. After finishing the walls with OSB boards, you need to make and install platbands on the windows and doors, otherwise the wall insulation will quickly become damp.

Traditionally, plank and slab floors are used in cabins. After laying the mineral fiber layer, the surface is covered with a vapor barrier film and hammered with a tongue and groove board.

The second option for arranging the floor instead of boards involves laying sheets of bakelite waterproof plywood. If you have to enter the change house in very dirty shoes, then it is better to supplement the plywood with linoleum.

Advice! Before building a plywood floor, markings of the location of the joist beams are transferred to the sheets. In this case, the risk of the self-tapping screw missing the support beam is practically zero.

Roof installation

For wooden trailers, pitched roofs are used. The row of vertical posts on the front side of the building needs to be made longer, about 40 cm higher than the supports on the back side of the frame.

The rafter system rests on two parallel beams. A sheathing is sewn onto the rafters, followed by a film vapor barrier, a layer of mineral wool, waterproofing and plywood padding for laying the roofing.

Wall cladding and insulation

The easiest way is to make a warm layer of the walls of the cabin based on polystyrene foam or mineral slabs. It is best to use PPS insulation in a metal trailer; basalt fiber mats are laid in the walls and secured with sheathing slats.

The next step is to lay a vapor barrier on the floor of the cabin to make the canvas durable and airtight; the joints between the individual tapes are taped. Windproofing needs to be done on the outer surface of the walls; it is also fixed with slats and tape.

Ceiling and roof

A change house is a small structure that can be rationally covered with a pitched roof. It is easy to manufacture and economical in terms of material consumption.

To create a slope, one of the long walls needs to be made higher to provide a slope for water drainage. This is usually the front façade. To create the required drop, you can immediately make the front pillars longer when installing the frame, or attach a wooden panel of the required height to a ready-made box.

The elevation angle is determined by the type of roofing material and must be no less than:

- 3-5° - for rolled roofing, folded metal sheets;

- 7° - fiber-cement sheets, corrugated sheets;

- 12° - metal, ceramic or bitumen tiles.

The footpiles are laid on the mauerlat - the supporting beam of the strapping, secured with corners, overlays, and staples.

A sheathing of 25 mm thick boards is mounted on top of the rafters or a continuous flooring of OSB boards is laid on which a soft roof can be laid.

Arrangement of a change house

The outer walls of the cabin trailer are sheathed with clapboard or OSB boards if finishing is planned for painting. In this case, the overhangs along the perimeter of the roof are not large enough, or the building itself is located in an open area, it is best to cover the outer walls with profiled roofing sheets. Ventilation windows are cut out along the upper and lower edges of the sheet, or it is better to build independent vents for water vapor.

Interior decoration of the cabin

If the building is planned to be built with subsequent repurposing as a bathhouse or guest house, then the best finishing option is considered to be cladding the walls and ceiling with ordinary clapboard.

After two or three years of operation of the cabin, the material darkens, a dark coating of dampness and even mold may appear along the lower edge, so anything else is rarely used for the walls.

The exception is the bathroom and shower block of the change house. In this case, it is best to make the walls and ceiling based on plastic panels.

Lighting in the cabin

According to fire safety rules, the exit from the room and the installation location of the heating device, stove, air heater must be illuminated. The rest of the room is equipped with lighting at your own discretion. Typically, a change house is divided into two parts in which ceiling lamps need to be made - a bathroom and a recreation area.

All electrical wiring of the cabin is mounted in metal corrugations. All lines must be located on top of the wall cladding. The place for the box with the circuit breaker and the bags is chosen so that the working panel is illuminated by a ceiling lamp.

Water supply and sewerage in the cabin

The supply of water and drainage communications into the premises is carried out through the subfloor of the trailer. To prevent the pipes from freezing in the winter, a caisson or collector is built in the ground under the sewer and water supply system, insulated with polystyrene foam and covered with a plastic box.

For mobile and summer versions of the trailer, you can build a connection to water and drainage using flexible and corrugated pipes.

Rules for choosing a site for construction

The construction of a cabin on a site begins with choosing a location. This is an important point, because if the structure is planned to be permanent, its location should be convenient for further use. Several factors are taken into account when choosing.

- A temporary building is placed near the entrance to the yard. Here it will not interfere with construction work; it will be easier to assemble and subsequently disassemble.

- A stationary structure, which is planned for conversion into a summer kitchen or guest house, is placed close to the place where the house will be built. It is desirable that there is the possibility of connecting utilities.

- The building, which will later become a bathhouse, is being built in compliance with fire safety requirements. It is best to build it at some distance from the house, but with the obligatory supply of sewerage and water.

It’s good if the place is level, so that you have to spend less effort preparing the site.

Instagram bytovki1

Instagram bytovki_moskva

- Country cottage area

How to choose the right plot of land: 6 tips

Heating in a change house

To heat the room, you can use two options:

- Make heating with a wood stove with a cast iron body;

- Build a heating system for a cabin using several electric convectors.

The electrical option is simpler; you only need to lay power copper wiring from the entry point of the switchboard and circuit breaker. In this case, for each heater you will need to make your own wiring and grounding branch, and build a suspension. To heat a room with an area of 15-20 m2, you will need to make two points of 1 kW each.

For a wood-burning stove, you will need to build a niche or set aside a corner of the room for it. The walls and floor are lined with thick metal with vermiculite thermal insulation. It is clear that if they plan to build a bathhouse on the basis of a change house, then it is better to choose a place for the stove in the warmest corner of the room without windows.

We carry out external cladding

We cover the frame with film. Attaching the outer skin.

The trailer cabin can be left without cladding, but a structure made of wood or metal will require mandatory external finishing. We won’t just leave the “bare” frame, will we? We cover the frame with waterproofing film. Carefully seal the joints of the waterproofing strips with tape. Many different materials are suitable for external wall cladding:

- wooden boards;

- composite panels;

- siding, etc.

Choose at your own discretion. The cabins covered with a block house also look very nice.

External cladding of a change house with siding External finishing of a metal change house Insulation of a metal change house Sheathing of a metal change house with corrugated sheets

Preparation and construction

The preparation stage for the construction of a change house from corrugated sheets begins with the creation of a level area for the building. First, the area is cleared of debris, bushes and weeds. Next, the site is leveled and a dense film is spread on the ground, the dimensions of which should be one meter larger on each side of the parameters of the floor area in the building.

The main stages of construction of a shed made of metal profiles include:

Construction of a columnar foundation

It is better to use cinder blocks, which can be easily disassembled when the shed is no longer needed. For a constant, i.e. capital structure, a stronger foundation is being built:

- The completely fertile layer is removed from the selected area.

- The space is covered with geotextiles.

- A ball of sand, 5 cm thick, is poured onto it.

- Holes are dug in the corners, up to 50 cm deep. The same holes should be made every 1.5 meters around the perimeter of the hole.

- Geotextiles are also placed in the post holes and sand is poured, which is carefully compacted.

- The foundation is built from bricks, which form a base 30 cm high (can be higher).

- Reinforcement is placed in the center of the foundation, the height of which should be 1 m or more. It is necessary to fix the logs later.

- There should be an empty area around the reinforcement, which is filled with concrete.

- The pillars are insulated with roofing felt or other material.

A metal frame is being constructed. You will need a beam measuring 100 by 150 mm, from which the support posts are made. They are installed in the corners of the floor. The logs are placed around the perimeter and fixed. Transverse and longitudinal logs are mounted to them. All beams are connected in places where they fell out using self-tapping screws. It is worth additionally checking each element to ensure that the structure is durable.

Floor installation

Logs are installed along the short wall, which are mounted along the bottom trim. Lumber is used with a cross-section of 100 by 50 mm, in which grooves must be cut. Their depth is 25 mm. Grooves are created in the same way on the end supports. Spacer logs are placed in the lower frame, which are fixed with screws and corners. Next, boards or sheet material made of chipboard and fiberboard are laid. Install joists along and across the walls. The step between the floor supports should not be less than 50 cm; insulating material is placed in the space. The flooring is being laid.

Related article: Decor and design of window and door openings

Roof installation

The type of covering should be simple and pitched. The roof is erected after the walls are built, so that the material is placed and secured correctly at the very top of the cabin. The roof is made mainly of galvanized iron sheet.

Sheathing the outside of the cabin

You will need corrugated sheeting that is reliable and durable, practical and has an attractive appearance. If the owner of a change house wants to sell it when the structure is no longer needed at the dacha, then corrugated sheeting will speed up the selling process. The material has excellent characteristics and is easy to install and process.

Sheets of corrugated sheets for external cladding must meet the following characteristics:

- Uniformity of zinc coating.

- High level of material density.

- Availability of protective polymer coating.

The corrugated sheeting is reinforced on the outside with steel corners and end (or cornice) strips, which are used to complete the roofing.

Internal lining

The interior of the cabin is decorated using different materials, of which priority should be given:

- Plywood.

- Chipboard.

- GKL.

- GVL,

- Hardboard.

- Profiled sheeting.

- Painted galvanized sheet.

Many builders use clapboards made of wood, plastic sheets, and boards made to look like imitation timber. A cut or tongue and groove board is perfect for the floor.

Walls and ceilings can be covered with corrugated sheeting, the thickness of which varies from 9 to 12.5 mm. The floors are lined with slabs with a thickness of 28 to 30 mm. The top flooring is covered with linoleum.

Openings

The change house will definitely have an external door and internal ones if there are several rooms or premises inside the building. It is recommended to install iron, wooden or plastic structures on doorways that are securely fastened vertically and horizontally. Window frames are made of plastic and wood, which are closed from the outside with metal shutters. They will protect the change house from thieves.

What type of raw materials to choose?

Wooden beams are the most important component in the construction of a wooden temporary dwelling. It is important to choose the right building material so that the structure lasts a long time.

GOST 18288-77 indicates that the height and width of the timber cannot be less than 100 mm. At the same time, the parameters of this material are regulated by GOST 24454-80.

According to it, softwood lumber can contain a different range of sizes :

- The nominal length of the timber is from 1 to 6.5 m, the gradation is 0.25 m. Practice shows that material with a length of 6 meters is in great demand; products of 7 meters are made to order.

In the production of laminated veneer lumber, beams up to 18 meters in length can be produced. Common sizes of beams: 100x100, 100x150 and 150x150 mm. For lintels, lumber with dimensions of 50x50 mm is suitable . - The width of the lumber varies from 100 to 250 mm, pitch 25 mm. The width of the product should be similar to or greater than the thickness. The demanded width of lumber in construction is 150 mm.

- The thickness of the timber varies from 100 to 200 mm, the pitch is 25 mm, the thickness of the product is 250 mm.

Construction of a frame made of metal or wood

To facilitate the installation of the cabin, detailed instructions are included with the structure. However, some points, for some reason, were not noted in the supplement, and everyone who decides to install the building with their own hands should familiarize themselves with them:

First of all, it is necessary to carefully level the site on which the house will be installed, because otherwise it will simply be impossible to use a building level to check the level of both the floors and the future roof. It is equally important to take care of purchasing blocks for the foundation, that is, to have additional funds available for the purchase of the product in question and its transportation. The piping for a prefabricated structure should be installed on the foundation blocks. Wall sandwich panels are installed vertically, since using another technology will not allow the collapsible wall elements to be accurately adjusted to each other and reliably connect the entire structure. After installing the panels, all connections are securely tightened together. To install window and door units, you must have certain skills. To summarize, you can come to the following conclusion - if you decide to buy a prefabricated structure, you should carefully weigh both the advantages and disadvantages of the structure in question and understand whether you have the experience for self-assembly chosen option for temporary housing

To summarize, we can come to the following conclusion - if you decide to buy a prefabricated structure, you should carefully weigh both the advantages and disadvantages of the structure in question and understand whether you have the experience to independently assemble the chosen option for temporary housing.

Advantages and disadvantages

The main advantages of timber cabins include:

- environmental friendliness of the material;

- affordable cost of the finished product;

- good sound insulation;

- the ability to build the structure yourself in a short time;

- good thermal insulation.

The main disadvantages are:

- fire hazard;

- short service life if you do not take care of the building;

- low resistance to temperature changes and other external factors.

Types of buildings

There are several types of log cabins:

- Standard .

The structure is a continuous room without partitions inside. Builders call such premises “empty spaces.” This building can accommodate several people; the room is also suitable for storing equipment. - Baby vest .

This is a room divided in the middle by partitions into two rooms and a corridor. In such a change house you can zone the space. One part can be made into a living area, the second room can be equipped with a bathroom, and the corridor can be turned into a warehouse. - With vestibule . This is a room separated from the general space by a small vestibule. It is better to use such cabins in the cold season, since the living area is separated by a closed corridor from the street. Such structures can be insulated, equipped with a stove inside and lived there in winter.