One of the important criteria that Customers rely on when considering chopped or rounded logs as a material is price. One important nuance arises here: the cost of building houses from logs is incorrect to compare directly.

The construction price for the project is calculated based on the cubic capacity of the structure and the complexity of the work. The total volume and number of crowns may differ, because the rounded log has its own working height and width of the connecting groove. When building a hand-cut house, the increase in diameter along the entire length is taken into account, so a log house has a cubic capacity that is 15-20% larger than a similar cottage made of rounded logs.

The diameter of a log processed on a machine is the same along its entire length and it is equal to a similar chopped log at the top. Therefore, a log house made of logs of the same standard diameter will in fact have thicker walls.

Features of residential buildings made of logs

Regardless of which option you choose, rounded or chopped logs, with proper construction and processing of wood, your home will be warm, reliable and comfortable. Natural wood, although it needs protection from fire and pests, remains one of the best building materials today. Log houses made from it look at the same time traditional, fashionable and:

- provide the correct microclimate - the tree “breathes”, is optimally ventilated (about 30% of oxygen is renewed per day), regulates the level of internal humidity, absorbing and releasing water;

- does not harm health and even helps to improve it - if you use conifers that secrete disinfecting phytoncides;

- helps save on heating due to the low thermal conductivity of the material.

Now let’s find out what is better, a rounded or chopped log, and what are their differences.

Average prices in the Russian Federation

Timber harvested in the northern regions has a higher price . For example, 1 cubic meter. Kirov pine costs on average from 7,000 to 8,000 rubles, depending on the diameter of the log, and Arkhangelsk pine costs from 10,000 to 13,000 rubles.

Chopped logs from the central part of the Russian Federation (Yaroslavl, Kaluga, Smolensk and Bryansk regions) can be purchased at an affordable price - from 6,000 rubles. for 1 cubic meter But when buying inexpensive timber, you should carefully check its quality, since you can purchase wood that is damaged by insects or infected with fungus.

Average cost of Arkhangelsk pine or spruce:

| Log diameter (mm) | Unit | Cost, rub.) |

| 220-260 | cubic meters | 12000-12500 |

| 260-300 | cubic meters | 12500-13000 |

| 300-400 | cubic meters | 13000-14000 |

Rounded houses

Rounded logs are logs from which the bark and surface layers are removed on special machines with a system of cutters. After processing, the shape becomes strictly cylindrical and the surface smooth. This simplifies the stacking of logs; thanks to the same dimensions, they fit more tightly to one another. Other advantages of the technology:

- no need for external finishing;

- high thermal insulation properties - due to dense laying there are fewer gaps;

- neat, albeit somewhat monotonous, appearance of the houses.

Lumber is produced faster and cheaper, but it cannot be said that the final cost of construction from different types of logs will be radically different. Although rounded elements are inexpensive, they must be additionally protected from biological and climatic hazards.

When processed on machines, the entire hard layer is removed from logs - sapwood, cambium, and they become vulnerable to rot, pests, and mold. To the total cost you will have to add the costs of fire retardants, antiseptics, special paints and varnishes, and the difference in price will be minimized. In addition, rounded elements shrink up to 12%.

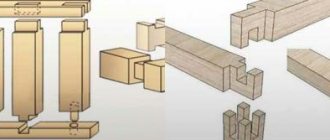

Purpose of the longitudinal cut

On logs with any lock, a longitudinal cut is often made; it is believed that this will allow the stresses arising in the material to be relieved

On logs with any lock, a longitudinal cut is often made. It is believed that it will relieve stress arising in the material. However, for this cut to be sufficiently effective, its depth must be at least 2/3 of the radius of the product. In fact, this cut is made much smaller. Thus, its presence for stress relief is a myth that arose due to the characteristics of broaching machines. On such a machine, a cut is made to prevent the log from turning during processing.

Air can easily pass through this gap in the log. If you carefully examine an established frame, you will notice that most of the cracks start not from the longitudinal cut, but from the profile groove cut into the element.

Important: in this regard, we can conclude that if the technological features of the machine do not require making a cut, it is better not to make it at all.

Houses made of chopped logs

The manual cutting method involves harvesting using axes, saws, and treating the surface of the wood with a scraper. This is an ancient method in which the bark is removed white, but the hard layer is completely preserved. The process is very labor-intensive, requiring knowledge of the matter, dexterity, and physical effort, which is why specialized craftsmen are involved in it. To eliminate unevenness that prevents a tight fit and to even out the diameter and dimensions of the material, debarkers and planes are used. A log treated in this way acquires many advantages. It:

- protected from moisture, climatic and mechanical influences, gives slightly less shrinkage (from 10%) due to the untouched hard layer;

- authenticity and uniqueness - houses made of logs with preserved natural texture are unique;

- improved thermal insulation compared to rounded logs - the energy efficiency of houses is higher;

- longer service life, no need for external finishing.

The disadvantages of such houses are directly related to the quality of the material. This is really complex and specific work, so the cost of building a house is higher. If you trust the construction and preparation to professionals, residents will not encounter common shortcomings - cracks, gaps, loose installation due to different diameters, cracking due to violation of technology, “cold bridges” due to loose fitting of the crowns.

COMPARATIVE CHARACTERISTICS

Characteristics: Rounded, Chopped

| Appearance | The surface is flat and smooth, the shape and width of each log is the same. | The width and shape differs in each log, the surface is rough and uneven. |

| Diameter | The entire length of the log is the same, not exceeding 320 mm. | Different. The choice of sizes is quite wide, up to 520 mm. |

| Assembly | Due to the identical diameters and smooth surface, it is quite fast and simple. | Complicating the process due to different-sized logs. Requires additional skills and professionalism |

| Thermal insulation | The tight fit ensures high insulating properties and minimal heat loss. | A large number of gaps reduces the insulation characteristics. To live in a log house on a permanent basis, additional insulation is required. |

| Production | Mechanical. High production speed at the expense of loss of some protective properties. | Manual. The protective layer remains intact, but the production time increases. |

| Protective layer | Gets lost. Treatment with additional protective agents is necessary. | Saved. A basic impregnation against moisture and insects is sufficient. |

| Shrinkage | From 0.5 to 1.5 years. The result is 7-12%. | From 0.5 to 1.5 years. The result is 7-12%. |

Which option is preferable for building a house?

If you look at the difference between a chopped log and a rounded one in terms of use for building a house, you need to proceed from your own goals. It is important for you to get housing quickly - choose processing on a machine, since “manual” log houses must withstand a shrinkage period of up to 8-12 months. You don’t have to figure out how to choose a rounded log - most manufacturers use standard machines, the building material is uniform.

Hand cutting is preferable if you want:

- get a house “for centuries”, built using traditional technology, impressive and monumental;

- immediately take care of the future - reduce upcoming energy costs, simplify home maintenance (logs will deteriorate much less);

- preserve the natural texture of wood and get the most environmentally friendly home, close to nature.

Advantages and disadvantages

A sauna made from chopped logs is not only warm and reliable, but also colorful.

Manual logging is considered by many to be an anachronism, especially given modern material processing capabilities. Nevertheless, chopped logs are in demand, which is due to a number of advantages characteristic of this type of raw material.

We list the main ones:

- The highest environmental friendliness. Unlike competitive materials, chopped wood undergoes minimal processing and retains its natural characteristics as much as possible;

- Higher resistance to biological corrosion is observed. Only laminated timber can boast greater stability;

- Higher heat saving rates are due to the preservation of natural layers of the trunk, such as sapwood;

- Large diameter parts are available – up to 52 cm;

- The material is stronger, the center of the barrel is not displaced;

- It is possible to use larch for the lower crowns. Not every manufacturer will undertake to process this rock to create rounded parts;

- Less susceptible to cracking and moisture absorption;

- House designs made from chopped logs are distinguished by the special aesthetics of Russian antiquity, which is well suited for traditional styles.

Large diameter material can be found.

Important! Despite its great resistance to corrosion and moisture, wood requires treatment with antiseptics, fungicides and fire retardants.

Houses and bathhouses made from chopped logs have recently become increasingly popular due to their unique aesthetics, which reliably imitate the traditional buildings of Ancient Rus' and Scandinavia. This increases the demand for this raw material among owners of country hotels, restaurants, holiday homes and simply connoisseurs of antiquity.

Chopped log furniture will be a good addition to your home.

In order for our review to be objective, it is necessary to discuss not only the advantages, but also the disadvantages.

Of course, they are also available:

- Hand harvesting is more expensive;

- More careful selection of wood is required, so sometimes there is a shortage and shortage of material;

- The construction of a house is highly dependent on the human factor, since its result is directly determined by the skill of the carpenters and builders;

- Preparing and assembling a log house is more expensive due to the increased complexity of the work;

- The diameter of the log changes from the butt part to the top (decreases), as a result, the joining of the crowns is difficult. In addition, not everyone likes the look of such a log house.

The instructions require treating the log house with an antiseptic.

It should also be taken into account that this material takes a long time to shrink. Unlike timber, a log house can exhibit noticeable shrinkage over four to five years, and this feature must be taken into account.

Another not the most convenient point: even when using a wall sealant, the walls need periodic caulking. If you do not monitor the condition of the joints and promptly eliminate cracks, your home may begin to leak drafts.

“Cut House Kirov” is a guarantee of the quality of logs and finished buildings

To get all the advantages of manual technology and not encounter the disadvantages, it is very important to choose a contractor responsibly. The labor intensity of production, the complexity of making corner joints, and laying crowns increase the requirements for performers.

By contacting a house-building company, you will receive quality guarantees for each of the works - from the choice of wood for harvesting to the final finishing touches. We:

- We harvest Vyatka pine forest and sort it according to GOST No. 9848 - we use logs with a dense, thin-ring structure that retains maximum thermal insulation properties;

- We check the layout down to the millimeter and control the assembly to eliminate “cold bridges” and cracks;

- We carry out all the work ourselves, without resorting to intermediaries and subcontractors - we bring building materials, pour the foundation.

We provide a guarantee for houses up to 20 years. When operating buildings, our company provides full maintenance and condition monitoring.

What it is?

A chopped log is a tree trunk that has been completely cleared of bark with hand tools, sanded and treated with antiseptics against fungi and insects. A special feature of chopped material is that it is prepared directly at the construction site, carefully adjusting the logs one to another.

Varieties of hand-cut material

To perform this work efficiently, the master must be very experienced . The production of such material is carried out by specialists with at least 10 years of experience. Chopped material differs according to the processing method.

The first and most ancient method is when a craftsman removes the bark from a tree with an ax, selects a longitudinal groove, and cuts out a bowl so that the logs can be perfectly matched to one another.- The second method is processing using an electric planer.

In this case, the bark and thin layer of wood are removed using a power tool without affecting the protective top layer, called sapwood. Next, use an adze to select a groove, giving the log a semicircular shape to better fit the adjacent log.