Landscaping a personal plot and dacha area involves creating a comfortable area for relaxing and receiving guests. When planning, it is necessary to carefully consider every detail so that the guests and their owners feel as comfortable as possible. In the summer, you can have intimate tea parties or long conversations among the lush vegetation.

Of particular importance is the choice of furniture paraphernalia for arranging a patio. Modern models of factory headset designs are highly expensive. This is why many people prefer to make garden furniture with their own hands. This process will allow you to reduce financial costs and make household items taking into account personal preferences.

What kind of garden furniture can be made at home? What will you need for work? You will find answers to these questions in our detailed guide.

Brief overview of the article

Materials and tools

What can garden furniture be made from? It is recommended to first draw a sketch of the future model. This way, you can have a clear idea of the final result and make timely changes to the product design. For this you can use:

- Wood;

- Plastic;

- Metal rods;

- Various details of previous furniture.

How to choose material for making garden furniture? Wood products occupy a leading position in landscape design. Wood is durable and has high performance qualities. Before purchasing a consumable, you need to think about its structure and appearance. The fibers should fit tightly together and there should be no traces of harmful insects on their surface.

Damaged cards are considered unsuitable for further use. Their base structure is already damaged. If there are traces of rot and mold in the cavity, then it is better to refuse to purchase such raw materials.

Anyone can work with wood. This material is easy to repair and various types of decorative finishing. For work, use a hacksaw, screwdriver, hammer and regular nails.

A significant disadvantage of such raw materials is its inability to withstand high humidity. That is why, upon completion of work, it is recommended to use paint and varnish compositions that will create a protective shell on the surface. This coating can last three years. It is not recommended to install the finished product in direct sunlight. After some time, numerous cracks may appear on the plane.

For work you can use:

- Wooden pallets. These structures remain after the purchase of building materials. They can be used to make comfortable sofas, large tables and armchairs;

- Car tires. These elements are used to create a base or to create a seat. Old tires are ideal for creating a garden swing. The soft base will not cause discomfort when moving;

- Metal and plastic pipes can be used as a frame or for standard fittings;

- To create complex structures, reinforcement and steel profiles are chosen. To work, you will need a welding machine and skills to work with this equipment. Thus, it is possible to create durable structures that are not afraid of climatic disasters. The soft base consists of large pillows with soft padding inside. Most often, the table frame consists of stiffening ribs. The tabletop is made of tempered glass or wood.

The list of consumables is quite varied. To create successful handmade garden furniture, it is recommended to follow the instructions of experts. Thanks to them, you can correctly calculate the load on the finished product, as well as avoid typical mistakes when processing the surface.

Selection of timber

Which timber is optimal for creating furniture or household utensils? Whole, chamber drying.

Why him?

- Timber with natural moisture requires long-term (up to six months) atmospheric drying. In addition, uneven evaporation of moisture can lead to its deformation or the appearance of deep cracks;

- Using laminated veneer lumber will expose the glue seams, significantly degrading the appearance of your masterpiece. In addition, the price of glued material is at least twice as high as that of solid material.

Coffee table. Material – solid oak timber.

What type of wood should you prefer? Unambiguous instructions are impossible here: each option has its own advantages and disadvantages.

| Wood type | Key Features | Cost per cubic meter, rubles |

| Pine | Light, light, resinous with an unexpressed texture. Rot resistance is limited | 8000 – 11000 |

| Larch | Bright, pronounced texture. Does not absorb water, does not rot | 14000 – 18000 |

| Oak | Does not rot, gains strength with prolonged contact with water. Extremely resistant to mechanical stress | 40000 – 80000 |

| Ash | Has all the properties of oak with a more pronounced texture | 35000 – 70000 |

Ash timber.

Useful: a special method of surface treatment - brushing - will help to emphasize the texture of pine and make it more expressive. We will talk about it in the corresponding section of the article.

How to take accurate measurements of kitchen furniture and create a sketch based on them

Let's give a simple example based on the linear arrangement of a kitchen unit.

The basics of creating kitchens show that in a small kitchen, for rational and convenient use of space, the linear type of furniture arrangement has a certain sequence. The main thing is to organize all parts of the kitchen in order:

- Fridge;

- Wash;

- Tabletop (at least 50 cm wide);

- Plate.

Many people wonder what is the logic of such a furniture arrangement? But the fact is that the basis of kitchen design is to place all parts of the kitchen in such a way that you spend less time, that is, make fewer movements when cooking. Thus, the kitchen becomes more comfortable for you.

Logs

A type of firewood is logs, often a cylindrical section of a tree trunk or branch. You can’t make beautiful furniture from these, but logs can have many uses in interior design. Starting with art objects...

...and ending with self-leveling floors made from thinly sliced wooden “slices”.

Some “interior designers” decide to experiment more boldly: they create a stylish mini-bar, a mirror frame or a hanger from logs.

Final processing

Any homemade country furniture needs protection from moisture. Wooden structures are impregnated with antiseptic compounds that prevent the appearance of insects. One or two layers of varnish or varnish are applied to the impregnation. All actions are performed with a regular brush. If you need to paint a large surface with a lot of small details, you can use a spray gun. Paints and varnishes must be designed for outdoor use: acrylic and alkyd paints with water-repellent properties are suitable.

It is important to pre-dry the wood intended for making garden furniture, since the paint quickly boils away on wet material.

To protect metal parts, it is recommended to use a special primer. A red leash would be ideal. In addition, there are special anti-rust coatings. They are useful in cases where the surface is difficult (or impractical) to clean with a wire brush. There are many suitable alkyd or pentaphthalic acid based materials on the market. It is not recommended to use water-based paints, which do not withstand extreme temperatures.

Making garden furniture with your own hands is a successful homemade product, drawings and photos of which are easy to find in the public domain - a great way to show creativity, imagination and refresh your skills in using tools. There is no need to copy ready-made templates; you can develop your own projects from unexpected and original sources. Creating a comfortable and attractive environment on a website does not require large financial investments, and simple ideas and plans always yield extremely positive results.

Peculiarities

The simplest garden furniture is outdoor benches used in parks and squares. However, summer residents and gardeners often make chairs, benches, and benches designed for use in the garden, and not just on the veranda or gazebo.

Do-it-yourself country furniture is much more durable than that bought in furniture stores. To save money, pieces of furniture are often made from chipboard, somehow protected from moisture using a film-adhesive layer. Sometimes wood dust with plastic is used - waste from other production as lumber. Both materials are diluted with epoxy resin or glue - this is how interior doors are cast, for example. It is not a problem to set up the production of similar furniture for a summer cottage: the slats and boards cast in this way have longitudinal voids inside, and in cross-section we see a box-shaped profile.

An example is the same Soviet benches installed in city parks back in the 70s of the last century, which in some places have survived to this day. There are no special secrets to their durability. These benches were painted with exterior paint every two years. It is resistant to fading under conditions of annual temperature changes, moisture and ultraviolet radiation.

Finally, making garden furniture is testing the skills of a real owner. If you are a jack of all trades, then you can make a chair using, for example, a dozen large scraps of wood after replacing the floors in the rooms.

Manufacturing furniture according to drawings

However, the simplicity of garden furniture designs requires preliminary preparation of diagrams and drawings. If you have design skills, you can also do this work yourself. Simple patterns are the easiest to draw.

If you want to create something unique, you must use your imagination. On Internet sites there are many diagrams and drawings on how to properly make garden furniture.

If desired, you can find a design pattern from any material.

What in the end...

Anything is possible if you implement your ideas carefully and with soul. But knowledge should not be neglected. The main rules that I have identified for myself for working with scrap boards are as follows. The most important thing, of course, is to take accurate measurements. Make holes for fasteners before assembly. It is better to use carbide blades for cutting boards. Well, if you have the opportunity to choose what the self-tapping screw is made of, it is better to give preference to stainless steel, then time will not affect the appearance of the product in any way.

Article on the topic: What can be made from 100x100 timber

Write in the comments what you think - is it worth spending time tinkering with old materials?

Adviсe

Stump of a garden chair

An old barrel, which in the future will turn into an unusual chair with a back, will help you make a piece of furniture from scrap material. In a short time, you can build a bench using boulders as support legs and a wooden plank as the seat. To build such a bench, you will need the following tools:

- board processing plan;

- drill with diamond tip;

- anchor bolts.

After processing the boards using a plane, the boulders are brought to the required height, after digging a hole and placing a sand cushion on the bottom. It is necessary to drill holes for anchor bolts in the panel and stones.

The final stage is tightening the bolts and coating the surface of the board with a layer of protective varnish.

Special design programs

These programs greatly simplify the design process. They help to make the correct sizing calculations and more. Using programs you can:

- Create a sketch of a certain thing;

- Create a design project, for example, a kitchen set;

- Narrow down the selection of materials to a specific category;

- Select options for decor, finishing, fittings;

- Build a 3D model of the future structure;

- Optimal placement of parts on the sheet - precise cutting of sheet material;

- Manage the material cutting process.

Using computer programs, you can create the correct sketch and accurate drawing of future furniture

In short, you can computerize the entire process, thereby ensuring that mistakes are avoided, and everything that is difficult to do with your own hands can be done on a computer.

Instructions for creating an unusual shop

Do not rush to get rid of old chairs whose surface has lost its attractive appearance. From these structures you can build an unusual store. There are many diagrams and drawings on the Internet on how to properly make garden furniture.

Each project has its own design and color palette. Based on ready-made options, you can create a single product based on personal preferences.

We bring to your attention a step-by-step process for making garden furniture with your own hands. First of all, it is necessary to prepare tools and materials to complete the work.

For this we need:

- 4 old chairs;

- Screwdriver;

- Set of self-tapping screws;

- Building level;

- Wood hacksaw;

- Sandpaper;

- Putty;

- Water-based acrylic paint;

- Red color scheme;

- Thin brush;

- Four boards of medium width.

We remove old chair upholstery. To do this, remove the seat completely. To work we need a frame.

Let's start building the seat for the bench. We measure the required length. Using a hacksaw we get rid of extra centimeters. Next, using a screwdriver, screw the wooden elements to the frame of the chairs.

Therefore, it turns out to be an excellent item for organizing a garden. To prevent wood fibers from causing discomfort, it is recommended to treat them with sandpaper. This creates a perfectly flat surface for further processing. Experienced professionals advise choosing sandpaper with a fine abrasive grain on the surface. Therefore, in the process of mechanical action on the surface, no new effects will appear.

If the chairs have chips and cracks, you can get rid of them with putty. Each layer must dry within 1 hour after application. Remove excess finishing mixture with sandpaper.

To work, you will need a small construction spatula. Thanks to this product, the building composition is applied evenly and in a thin layer.

Let's start painting the finished object. To do this, add any color that suits your taste to acrylic paint. Mix thoroughly with a concrete mixer or by hand. We spread the colored composition in a thin layer around the perimeter of the entire store. To work, you will need a thin brush that allows you to paint small elements. Some people prefer to use a puller. This device helps to apply the color base evenly and prevent smudging after drying.

Let it dry completely. To prevent the product from losing its decorative appearance during use, it is recommended to use transparent furniture varnish. The photo of handmade garden furniture shows the finished product.

Pouring the foundation

First, I cleared the area under the house from debris, bushes and other things that were in the way. After this, I began laying out the foundation.

I had to think for a long time about what type of foundation would be suitable specifically for my area. I studied the geological conditions, learned the composition of the soil and the level of groundwater. Specialized reference literature helped me with this. Additionally, I asked my neighbors what foundations their houses were on.

I live in the Ryazan region. Local conditions make it possible to save on the construction of foundations, so most neighbors have houses on light supports made of limestone and concrete. Most often, they even refuse reinforcement - such is the wonderful soil we have. The soil is sandy, therefore, it is not “heaving”. The water runs deep, and wooden houses weigh little. Therefore, there is no need to install buried monolithic supports in my region.

The foundation began by digging a trench. To begin with, I removed the fertile ball. Sand appeared. To make it seal better, I filled it with water. Then he lined the trenches with stone and laid two reinforcing bars. I tied them up in the corners. I think that the tape is best reinforced both at the bottom and at the top. So I did.

The foundation began by digging a trench

To save yourself from unnecessary work, you could order ready-made construction concrete for delivery. However, in my region this turned out to be unrealistic - there are simply no such proposals. And my plot is such that the truck would have to go through the garden, but I don’t need that.

Plus, ready-mixed concrete is expensive, but sand on my site is free. I ordered the stone with delivery - it turned out relatively inexpensively. I made inquiries: in Moscow, even calling an empty truck would be more expensive. It would have been possible to save additional money by collecting the stones myself on the river, but I had no such need.

Stone

I tried mixing concrete by hand. I quickly became convinced of the pointlessness of this event - it turns out to be too long and labor-intensive. I purchased a concrete mixer brand SM-160. It is relatively inexpensive, and will definitely come in handy on the farm.

I started mixing concrete. The process went quickly and fun. The concrete mixer is very easy to use - it can be moved along the dug hole without any difficulty. I used a sheet for pouring concrete, as can be seen in the picture. I placed several supports under the sheet to prevent the material from bending.

How I made the foundation

The seller of the concrete mixer immediately warned me that when using the unit, there is no need to cover the plastic casing where the motor is installed, otherwise it may overheat. After completing the work, I each time cover the concrete mixer with plastic wrap in case of rain.

The concrete mixer helped to quickly prepare the required amount of solution. I laid stones in the concrete. So I filled the foundation strip to the ground level. The above-ground part of the tape was laid out on a thicker mortar using the same stone.

A little short of reaching the top of the foundation, I installed a reinforcing frame. The masonry was done with smaller stones.

The foundation is almost ready. I left it to gain strength. The base does not look very neat and even, but in the future nothing will prevent it from being finished and put in order. For example, the finishing of the above-ground part of the base can be done using plaster - a traditional option for village and country houses. A more modern solution is special decorative panels.

How I made the foundation

I saved a lot while working. For example, I did not make formwork, but used cheap local materials - stones and sand - to construct the foundation. Even taking into account the cost of my concrete mixer, the foundation turned out cheaper than if I had ordered ready-made concrete and assembled the formwork.

Foundation

Alas, you won’t be able to save this much in every region. For example, if I lived somewhere in the Moscow region, I would have to make formwork, install a spatial reinforcing frame, and only then pour in the building mixture.

While the concrete gains strength (and it needs 3-4 weeks for this), I will start preparing consumables.

Examples of creative and stylish design of garden furniture

In order for the furniture not only to perform its functions for a long time and efficiently, but also to be an aesthetic decoration of the garden, it is often decorated with additional elements.

One of the most striking examples of decor is fresh flowers, wildflowers look especially bright.

Another way to turn your outdoor furniture into a work of art is to decorate it with a beautiful accessory such as a blanket or pillows.

It is better to make furniture for your dacha yourself, taking into account the opinions of all family members.

Decorating garden tables with glass or plastic shelves looks no less attractive.

After carefully studying and applying the tips for making rustic wooden furniture with your own hands, the drawings and assembly diagrams should not be thrown away; they may come in handy in the future. If you also apply the decorating techniques with additional accessories presented earlier in the text, the furniture will become an excellent place for a family vacation.

With such furniture, spending time at the dacha will be pleasant and comfortable.

Original do-it-yourself crib ideas for a baby

Caring parents give preference to natural materials when choosing furniture for the children's room. A children's bed made of laminated veneer lumber is an innovation for many. This kind of wooden furniture was in use among our ancestors. Every year there is more and more plastic, cheap wood and metal in the store. You can easily make a crib for a nursery from natural wood yourself without the help of others. To do this, you need to draw a sketch with exact dimensions, and following it, make a cradle.

We make garden furniture ourselves

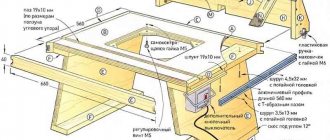

Now let's look at the basic intricacies of assembling such furniture. It all starts with design. In this chapter, several drawings will be analyzed.

Drawings with dimensions of a wooden chair

There must be space in the garden. A comfortable and beautiful chair will be an excellent solution.

DIY garden furniture made from boards

- This picture shows a wooden garden chair. It has an inclined back and an anatomical seat, which makes it comfortable, despite the hardness of the material itself.

- It may seem that the chair is designed too intricately and there are shaped parts in its design, but they are all made of boards and slats - they just need to be cut out of solid wood with a jigsaw.

- The chair has the following parts: 2 racks with additional supports for handrails; the handrails themselves; 2 side guides defining the anatomical shape of the seat; backrest guides and jumpers; strip for seat and back upholstery.

- All connections are made with self-tapping screws. In order for such a chair to be durable, it is necessary to carefully make cuts when forming parts. A perfect fit will also extend the service life.

Advice! When connecting wooden parts with self-tapping screws, it is recommended to coat all joints with wood glue. This will get rid of annoying squeaks.

Drawings of a table with benches

In addition, you cannot do without a comfortable and durable dining table. The following diagram shows the structure of a simple and functional table combined with benches.

DIY garden furniture from bar structures

This type of garden furniture is suitable for children, although the size can be increased and adults will find it just as comfortable. In construction, the main materials are boards and beams. It consists of the following parts:

- The tabletop consists of seven boards with a cross-section of 100 * 20 (you can take thicker lumber) and three bars with which these boards are tied. Tabletop dimensions 1400 * 700 mm.

Advice! Please note that the central beam is laid on the boards with its wide side. Galvanized steel corners are attached to it, to which the slopes will fit, which will create perpendicular rigidity of the structure and prevent the legs from flying apart.

- The mowers themselves. For their manufacture, timber with a cross section of 50 * 50 mm is used. Its length is 600 mm. The edges of these parts are cut at an angle so that they can be conveniently connected to the steel angles. For the beam, 5 * 40 self-tapping screws and M 10 * 60 bolts are used.

The main connections that can withstand high loads are made with bolts

- The legs are oblique trusses consisting of 6 parts of different sizes and shapes. For their manufacture, the same board was used as the tabletop. The legs are crossed by two parallel lintels that protrude beyond the edges of the tabletop. A seat will be attached to them, and it is also possible to attach an additional backrest.

- The last detail is the seat. Here we used a more powerful board 150 * 30mm. Along the edges with a certain recess, bars are wound, which will be inserted between the crossbars of the trusses and pulled together with them using screws or bolts.

The disadvantage of this design is that there is nothing to attach the central supports to if you want to increase the length of the table and bench, and without additional support the seat will fold. Therefore, the scheme will have to be complicated and slightly modified if you need a large table for adults.

Drawings and examples of furniture made from pallets

You cannot do without a reliable and large wooden bench in the garden, which can be made in the form of a sofa. As the main building material, you can take pallets that are already adjusted to the required dimensions, so all that remains is to carry out the correct assembly.

To assemble such a store, you will need only 6 pallets. Unfortunately, the diagram does not show how they need to be cut and connected correctly, but all sizes are clearly shown. And with the first one, in principle, everyone can figure it out for themselves.

Garden furniture - successful pallet designs

The main disadvantage of pallets is that the wood for them is not initially treated in such a way as to adapt to the furniture material. For this reason, partial or complete disassembly and reassembly may be required. However, the construction process itself is not complicated, and the end result has an attractive appearance and is very durable.

Browse the following photo gallery to see different pallet garden furniture options:

Garden swing made of pallets Table made of pallets on wheels Chain chair and sofa Bar counter made of pallets in the yard Sofa made of pallets with soft pillows Complete set - chairs and table Furniture set Chaise lounge made of pallets Chair option

Drawings and dimensions of a rocking chair

If you have experience assembling furniture yourself, you may want to give yourself a more challenging task. The following picture shows a real rocking chair.

Disassembled diagram of a rocking chair - complex outline of parts

A large number of curved details immediately catches the eye, especially when looking at the seat. All of them are carefully cut from a solid board, in which there should be no cracks or falling knots, otherwise they will not cope with the load of the human body.

The peculiarity of this design is that the main joints are made according to the principle of turning pins, and round pins are formed on the parts. This is done using special rounding cutters.

Every detail is carefully polished. It is recommended to treat all non-glued joints with paraffin, which will eliminate the appearance of squeaks in the future.

Advice! To avoid paint bleeding, parts must be painted and varnished before assembling the structure. In this case, the parts to be joined must be left unprocessed.

All the parts that make up the chair are shown in the drawing. Their size and quantity are also indicated there.

The presented rocking chair is quite complex in design. Alternatively, you can assemble something simpler.

An example of a simple design An armchair with a footrest A rocking chair made of plywood A folded board is used here - this is very difficult to do at home An armchair with a straight seat and back The furniture is assembled from massive parts An elegant option A carved armchair Simple and comfortable

Facades

Kitchen fronts and furniture doors are usually made of more elegant material. But if you are making a drawer door inside a sliding wardrobe that no one will see, you can use regular 16 mm laminated chipboard with a 2 mm PVC edge for it. But the cabinets in the kitchen should look more presentable.

The facade is a separate furniture element. It is usually made to order. If the dimensions of the facades are non-standard, their production may take several months.

You can easily navigate the standard dimensions: usually the facades are made 2 mm smaller than the cabinet itself on each side. Therefore, for a standard 600 mm cabinet, a 596 mm façade is used.

The height of the kitchen cabinet also depends on the facade and ranges from 715 to 725 mm for floor cabinets (without legs) and low wall cabinets, and 915-925 mm for high wall cabinets.

Standard front sizes for kitchen cabinets

Types of facades

Since facades serve mainly a decorative function, the choice is huge; they differ in appearance and material.

MDF facades

- In addition to standard blank facades, there are also options with figured cutouts for stained glass. The glass is attached to the cover on the reverse side.

- Softforming - such facades are similar to ordinary MDF, but have a characteristic two-color layout with relief on both sides. They can only be used in dry rooms, bedrooms or living rooms.

Softforming

Postforming

Plastic facades in aluminum profile

Wooden facades

Aluminum facades with glass are suitable for a high-tech kitchen. They look modern, but are difficult to manufacture and install. Non-standard fittings are used for their fastening.

Tires

From old car tires you can make beautiful and elegant garden furniture, which can be installed not only in the garden, but also on the terrace.

In an open and closed gazebo, coffee tables and comfortable ottomans with a soft surface, chairs and armchairs made from tires, and even hanging swings will look great.

Portable shower

A thing that not only our parents will envy. An easy-to-carry portable shower will always have a use. Wash after work or just cool down on a hot summer day. It fits into a small bag and can easily be used not only in the country, but also on a hike.

It is easy to use: just fill the container with water and use a special pedal to build up pressure in the system. You don't have to press the pedal all the time. Using the safety lever on the shower head, you can gradually use the pressure built up by the pedal.

The shower is made of dense high-quality material, which allows you to keep it in good condition for many years. The price of this indispensable device in the summer is only 2,700 rubles. Relatively little for comfortable washing and maintaining your personal hygiene anywhere.

Wood species for garden furniture

Let's leave the forest alone for now and look at other raw materials for wooden furniture. There isn't much of it. Hardwoods are preferred for garden furniture. These are birch, oak, larch. They are more difficult to work with than pine or basswood, but can last much longer. And if the furniture is treated with special compounds to reduce wettability and provide bactericidal protection, such furniture will last a hundred years. Elite garden furniture is made from these types of wood.

Pressed plywood ranks second after hardwood. You can make furniture from it entirely according to drawings and models, which we tried to present as widely as possible, and they will serve as precise connecting elements that can withstand greater loads than simple wood.

Assembling tragus elements: the better to fix them

First you need to collect 2 main elements (for one goat). To do this, squares are made from sawn scraps, and the parts in the corners are superimposed on one another.

The folded scraps are first coated with PVA glue, after which they are slightly pressed with clamps. Next, they are leveled with a square to a perfect 90°, and only then the clamp is pulled out completely. This way the connection will no longer move.

Now self-tapping screws are used. You will need 4 of them. per connection. After all four screws are fully tightened, the clamp can be removed.

Securing each connection in turn, you need to assemble a square with right angles

The second element of the goat is assembled in a similar way. However, it is unlikely that you will be able to stand on one goat, which means you will need to collect 2 more squares.

Metal objects

Metal is a very practical and durable material. But as you work towards it, you'll need a number of specific tools and skills. Metal parts can be connected to each other by welding or bolts and screws. Another option is to give the desired shape by bending individual sections or structural elements.

How to create chairs and benches for a picnic?

Soft outdoor chair

Understated style, soft handcrafted cushions: unrivaled comfort for the garden. It's easy to take care of yourself by looking at the design of this chair. For convenience, all dimensions can be converted into centimeters, for example 23 1/4 “= 59 cm, etc.

Basic instructions:

- Firstly, all necessary measures must be taken to ensure safe and comfortable work. You need to work on a clean surface free of defects and debris.

- To make DIY rustic furniture, you should always use straight boards.

- The assembly is checked after each step.

- Before connecting parts with self-tapping screws, be sure to drill holes.

- Glue is used for secure fastening.

- Before painting or varnishing, the wood is sanded.

- To level the surfaces, you can use wood putty.

- Wood must be treated with special compounds to prevent rotting.

Dimensions:

Step 1. Make the first part with your own hands, as shown in the picture.

Step 2. Assembling the front frame.

Step 3: To create the seat, the two previously made pieces are joined using two other boards. After this, crossbars are attached to make the chair legs stable.

Step 4. Now the back of the chair is assembled as shown in the picture. Remember that the bottom of the chair will be positioned at an obtuse angle in relation to it to create an ergonomic backrest angle.

Step 5. Now you can attach the backrest to the seat.

Step 6. Next, you can begin making the armrests, which are also placed at an angle for convenience.

Step 7. And finally, you can begin installing the slats on which the pillows will be placed.

Furniture fasteners

Furniture fasteners are hardware (metal products) that are used to connect parts. Most often, connections are made at right angles.

Dowels

Furniture corner

Euroscrew (confirmed) – furniture screw. This is the main fastener for parts in modern furniture. Furniture makers almost never use ordinary self-tapping screws. Confirmats have a larger thread, so they stay inside the chipboard much better. Confirmat

The holes for them can be drilled directly on site. To do this, use a special drill that makes a hole with different diameters for the thread, neck and head of the Euroscrew. The most commonly used confirmats are 7*50 mm

When drilling, special attention should be paid to the perpendicularity of the drilling so as not to spoil the coating of the part with a through hole

Drill for euroscrew

Furniture screws are tightened with a hex key or a screwdriver attachment. The caps for a Phillips screwdriver cannot be tightened tightly until the end.

The main disadvantage of this type of fastening is that screwed-in caps remain visible. To hide them, use plastic plugs matching the color of the chipboard.

Eccentric ties are a modern and correct method of fastening. It leaves a hole only on the inside of the product, but requires very precise drilling. Eccentric coupler

To obtain the required holes, use a Forstner drill. There's not much point in going to the trouble of using them to assemble items that will be hidden, but they work well for attaching drawer doors.

Forstner drill

Article on the topic: DIY kitchen assembly.

Photo of homemade garden furniture

Details

Definition with construction

Before you start making garden furniture with your own hands, you need to have a very clear idea of the final appearance of the structure as a whole. Even a small sketch is enough to roughly calculate the amount of material needed. You can make garden furniture very quickly, the main thing is to use high-quality materials for such purposes. Most often, they make chairs, tables, loungers or beds, shelves or racks with their own hands.

Tools and materials

On the one hand, to create most furniture elements you can completely use even improvised means, but to create more durable and reliable furniture you may need a special set of tools:

- Grinding machine.

- Electric screwdriver.

- An electric jigsaw (or a hand saw), as well as a circular saw.

- Drill with a wood drill to the size of the screws.

To create a simple piece of furniture you will need the following tools:

- Fastening mobile corners.

- Pencil.

- Construction tape.

- Sandpaper.

- Self-tapping screws.

- Screwdrivers.

- Hammer.

This is the advantage of garden furniture, which will look appropriate even if unruly. Not to mention the high-end approach: this handmade garden interior can surprise even connoisseurs.

Making a project and drawing up a drawing

When creating garden furniture with your own hands, diagrams and drawings should first start with the appearance. When determining the future appearance of furniture, it is necessary to move on to an extremely important new stage - the production of drawings.

Remember that the deeper you go into this process, the better the end result will be.

When drawing up a drawing, it is necessary to carefully calculate each of the details; this will not make it possible to lose sight of even the most insignificant nuances. Next, we work out the methods of fastening, and also calculate the number of necessary fastenings. The dimensions of your garden furniture are important and at the end of this process it is advisable to take another close look at the resulting plan - if you don't make changes now it will be extremely difficult to do so later. And if you are completely satisfied with the drawn up diagram, you can move on to implementing the idea. Yes, the production of garden furniture for a summer house will begin with an idea that is displayed in sketches, drawings and layouts.

MK for arranging garden furniture with your own hands

As mentioned earlier, the process of creating wooden garden furniture with your own hands is quite exciting and responsible. So, we will take a detailed look at the most popular and frequently collected interior items. To make the seats comfortable, they need to be swaddled with removable cushions.

How to make a garden chair

A garden table can be made in the simplest form, for example, a base screwed to a stump in the shape of a seat, or you can approach this process more deeply. To assemble the garden chair, use the pre-selected type as well as the size of wood. It is recommended to buy bars measuring at least 4 cm on one side. This provides reliable support for a person with an average weight of 80-90 kg. If you need to place a heavy person on such furniture, the size of the plank will increase to 6-8 cm. If you have a carpentry workshop operated by modern standards, making a wooden garden chair with your own hands is quite simple. Mark the material with a tape measure and pencil according to the drawn pattern.

So we saw. You can use hand tools for this process, but you can get faster and better results with a jigsaw or circular saw. Square bars are usually used for the frame, and rectangular bars for the base and back. Additional joints between elements can be treated with wood glue, and such an assembly will be professional. It is best to sand the surface of the wood before starting the assembly process; this will prevent cracking of the structure under the skin both during the assembly process and in the further use of the furniture. Mark the mounting locations with a drill and begin the final assembly process.

Please note that if you plan to use such furniture outdoors, the wood must be coated with a moisture-proofing compound, special varnish and varnish material.

Instructions for making a bench-table

The final appearance of such a product will directly depend on the concept, as well as on human capabilities. In its simplest form, this table and benches can be made of logs covered with a wooden base. More often than not, this issue is taken much more seriously, because outdoor headsets will be used for large companies, and the more you delve into the creation problem, the better the end result. The most popular option would be a rectangular table with a table closed on all sides. To make it, create a frame from bars and wood upholstery over the entire area of the side surface. Prepare the material in advance: sand it and work with compounds that allow you to use furniture in outdoor conditions, which can be purchased at construction and furniture stores.

You can assemble this furniture in just a couple of hours and decorate your garden with beautiful tables for dining and picnics. Assemble benches according to the size of the table. Their length should be commensurate with the table, the width can vary depending on the planned budget and the materials at hand. To make it comfortable for a person to sit on a bench, we recommend making it at least 0.2 meters wide.

Cot

Diagrams and drawings with dimensions of garden furniture are important for understanding its final appearance before assembly. It can be an easy-to-assemble chair with a fabric base that acts as a seat and backrest.

You can also make a monolithic recumbent version of the lounger. The first will be more acceptable for those cases when it is planned to change its position, and the second, due to its heavy weight and inconvenience of movement, will be installed in a certain place and will rarely be rearranged. A chaise longue is a light and comfortable designer chair that is used for relaxation areas (on the beach, by the pool, an integral part of the decor of the cottage).

In any case, it is necessary to make a frame of wood. A small chair requires a crossbar of 0.25 * 0.3 meters. You need to make a couple of long legs and a couple of short ones. Connect them together and, if necessary, leave the structure so that it can be assembled - in its simplest form, it is enough to secure the screws for fastening with nuts with lugs. Connect the legs with strips together and thread fabric through them, ideally it should be burlap - it's more durable for outdoor use. The lower and upper legs need to be additionally strengthened with metal spacers - to do this, it will be enough to insert a metal rod into the two legs on both sides. For a large bed, the first step is to assemble the base, which will then be covered with rectangular slats. It is important to sand the facade of this structure and cover it with a protective layer - varnish or furniture paint.

Pallet table

When creating a table, special attention should be paid to the quality of materials; old pallets will look rather modest and will not differ in quality, and even more so if they have been exposed to moisture for a long time. For this reason, the main recommendation would be to use new pallets. Wooden pallets are a building material that allows almost unlimited freedom of ideas and creativity. To assemble the simplest of several options, three pallets are enough - a pair of legs and one for the lid. Most often, pallets are used as a cover, fastened together, and the legs are made from additional building materials - timber, tall hemp or tree trunks that remain after sawing.

When assembling a table, the main thing is high-quality grinding of all its components, and even more so the surface coating. Fasten the pallets together with long screws. It is also recommended to additionally prepare the surface of the resulting product with varnish or varnish to protect it from negative environmental factors.

Wicker furniture

Wicker garden furniture without patterns and designs is quite problematic to assemble. For this reason, if you decide that you need such a piece of furniture, you must first properly think through the drawing and, based on it, calculate the required amount of material needed. If you have no experience in making such furniture, you can find ready-made diagrams on the Internet and use them to purchase all the necessary materials. Rattan or vine can be used as the basis for such furniture. When weaving individual elements, continuous weaving is usually used: with this method, individual branches will be twisted in turn into perpendicular poles, bending around the branch on one side or the other. The resulting texture is extremely durable and reliable. The backrest and seats are usually made with perforated weave, because this type of processing in itself is very beautiful. By purchasing high-quality wicker material, you can ensure the longevity of your furniture. No additional processing is required.

Top unique street models

Rocking chair

Having learned to design the simplest models for a summer house, such as tables and chairs of a regular shape, you can proceed to more complex models. For example, to make a rocking chair for the garden.

A drawing of a rocking chair can look completely different, depending on the ideas. The simplest wooden model for a summer residence requires the presence of sidewalls that allow the chair to move in the absence of armrests.

Making such furniture is quite painstaking work, since it will be quite difficult to transfer the drawing onto a sheet of thick plywood.

If desired, a country rocking bed can be easily made according to the drawings. It will be the best place to relax after hard work.

The length of such a rocking chair for a summer house is 1.82 m, which allows it to be used for sleeping. To simplify manufacturing, first the drawing is transferred to paper. Then it can be divided into cells and a pattern can be made cell by cell or the form can be immediately copied onto a sheet of plywood.

Of course, the drawing of a more traditionally shaped rocking chair looks a little different, and you can use it too.

Adirondack style chair

A DIY Adirondack chair is a unique and stylish model made of wood or artificial materials that is used outdoors. The first such chair was developed by American Thomas Lee while on vacation in the Adirondack Mountains in 1903. Over time, this particular style has become especially popular around the world. Today, such a wooden model can easily be made according to a drawing. An attractive and durable cottage structure can be created using simple methods using basic tools. Guests or neighbors probably won’t be able to help but guess that the chair was made by hand!

Making a wooden bench

This is an important attribute in a summer cottage - it is practical, useful, helps create coziness, looks impressive and fits well into the countryside environment. You can take any version of such garden furniture as a basis, creating your own original design. The process is quite simple and does not require special skills, but it helps to bring some ideas to life.

Tools and materials

- wood hacksaw;

- a circular saw;

- two-handed saw;

- hammer;

- airplane;

- pliers;

- screwdriver;

- nail puller;

- L.B.M.

- wooden boards - 12 pieces measuring 870x100x50 mm;

- beams;

- antiseptic to protect wood from fungus and moisture;

- paint or varnish.

Sources

- https://giddesign.ru/sadovaya-mebel-svoimi-rukami/

- https://nikastroy.ru/certezi-s-razmerami-sadovoj-mebeli-foto/

- https://kupi-krasku.ru/komnaty/chertezhi-sadovoj-mebeli.html

- https://tytdesign.info/sadovaya-mebel-svoimi-rukami/

- https://kakpravilnosdelat.ru/sadovaya-mebel-svoimi-rukami/

- https://severdv.ru/mebel/kak-izgotovit-sadovuyu-mebel-svoimi-rukami/

- https://mebel-sovet.ru/dachnaya-i-sadovaya/300-svoimi-rukami-udachnye-samodelki-foto-chertezhi

- https://Proekt-sam.ru/landshaftniy-dizain/chertezh-sadovoj-mebeli.html

- https://DrevoGid.com/izdeliya/mebel/sadovaya.html

- https://vsesvoimirykami.ru/sadovaya-mebel-svoimi-rukami/

- https://NedvijDom.ru/mebel-dlja-dachi/raznoe/luchshie-chertezhi-ulichnoy-mebeli.html

- https://domsdelat.ru/poleznie-soveti/chertezhi-sadovoj-mebeli-iz-dereva-s-razmerami.html

- https://proteplo46.ru/interer/chertezhi-sadovoj-mebeli-iz-dereva-s-razmerami.html

Wood preparation: what work will need to be done

If a person was building a house, then he would definitely have a hand saw at hand, and ideally a circular saw. With its help, you can quickly cut the remaining boards to a single size. In our case, the size 120×120 mm² was chosen, but this is not important.

Folded smooth planks already look good, but you need to give the appearance more color, highlighting the texture more clearly. You don't need any serious tools for this. An ordinary ax and hammer are enough.

Former waste is already beginning to take on a noble appearance PHOTO: youtube.com

Highlighting the structure: a torn surface looks more interesting

Now you can sit comfortably on a chair in front of the block of wood and create the perfect material for decoration. To do this, you need to cut each plank in half along the plane. Having inserted the ax, you need to lightly hit the butt with a hammer. The wood splits quite easily. It is the inner sides of the halves that will be the front sides when finishing.

It is necessary to split each plank in half along the plane PHOTO: youtube.com

Firing and varnishing the structural side of the material

When splitting wood, it is advisable to divide it into several parts. For example, you can separate oak elements from pine. Another group needs to highlight those that have the most beautiful structure.

Pine wood makes sense to enhance the look of the structure with a gas torch.

Article on the topic: How to create a house project from pesto timber

After firing, the drawing began to stand out much more clearly PHOTO: youtube.com

Oak planks should be put aside altogether; there is no need to emphasize their structure. But with the third group of elements it is worth working more intensively. They should be burned with the same burner until they turn black.

Charred wood will add contrast to the wall PHOTO: youtube.com

All elements must be varnished. This will further emphasize the direction of the grain and protect the wood. It is best to choose acrylic varnish - it is safer.