The consequence of long-term use of a wooden house is the wood turning blue. The reason for the appearance of blue is certain types of fungus, which forms over time on the surface of an old wooden house, especially in cases where the wooden structure has not been periodically treated with protective agents. However, a healthy tree can have multi-colored spots if the natural pigment is unevenly distributed. Darkened and unevenly colored wood greatly spoils the appearance of the house; in addition, fungi can cause rot and destruction of the wood structure. An effective way to combat blue stains is to bleach wood. What means and how to whiten the walls of a wooden house will be discussed in the article.

Causes of fungus formation

Fungus and mold can develop on any wooden surface, regardless of lumber; even imitation timber and laminated veneer lumber are not immune to damage by microorganisms.

The type of wood also does not matter in this case; fungus can appear on both inexpensive pine and elite oak. A very common reason for the appearance of blue stains is improper transportation and violation of storage conditions of logs and timber. Lumber should be stored in a well-ventilated, dry place. It is advisable that the area is in the shade and that the tree is not exposed to precipitation.

Fungi that contribute to the formation of blue and gray plaque on wood develop very quickly, especially in suitable conditions. Therefore, you need to get rid of mold and mildew as soon as traces of their presence are discovered, especially in the bathhouse. This room creates the most favorable conditions for the proliferation of microorganisms - high temperature and high humidity, which significantly speed up the process.

How to notice the emergence of negative processes

Each type of wood has a characteristic shade, which the affected layer of material receives as a result of negative influence.

It is these signs that you need to focus on when conducting an inspection:

- The oak takes on a golden hue;

- Birch is covered with bluish spots;

- Pine and other conifers get a clear blue or even black surface;

- Dark ash lightens several tones;

- The walnut acquires a bright red color.

It all starts with the invisible appearance and spread of microorganisms. They first occupy small areas and spots appear with a characteristic color change.

Gradually, the dots grow, merging together, and a clear change in shade occurs. If the affected surface is not treated in time, the deterioration process will worsen. In the future, it will not always be possible to cure blackened wood using simple treatment. Therefore, it is advisable to carry out the whitening process as quickly as possible.

Whitening products

Bleaching of logs is carried out using special bleaching agents, which are divided into two large groups:

- Chlorine-containing products. These include products containing: sodium or potassium hypochlorite, bleach, chlorine dioxide.

- Compositions without chlorine, in which the active substances are ammonia, hydrogen peroxide, oxalic acid and alkalis.

Any composition for bleaching wood operates on the same principle: it causes an oxidative process, as a result of which the coloring pigment becomes discolored and the fungal molecules are destroyed.

Subtleties of choosing and working with wood brighteners

The choice of means for lightening lumber depends on the degree of damage, as well as the type of wood. For example, chlorine-containing substances do not penetrate deep inside; they can only remove fresh, small-scale superficial stains.

- The treatment can be carried out even using household whitening.

- Alkaline compounds have a negative effect on the color of some types of wood.

- For example, oak wood will turn green as a result of processing.

- The best effect will be noticeable on light wood species.

In most cases, the substances used are toxic and require careful handling. Treatment is carried out with only one composition. Alternate use of different products or their combination is not permissible.

General recommendations for whitening

Before treating wood with bleaching agents, the surface must be sanded well. As a result of sanding, up to 20% of the blue stain is removed. In addition, bleach penetrates and is absorbed into the wood structure better if it is applied to sanded boards. So, the main recommendations:

- after bleaching, any composition must be washed off with water;

- acid-based bleach is washed off with an aqueous solution of soda;

- You cannot combine different compositions; the surface can only be treated with one product.

- if the wood is severely affected by fungus, it is necessary to treat it with a more concentrated composition.

- bleaching is most effective if it is carried out at a temperature of 18-20 degrees Celsius and at a humidity of about 60%;

- When processing wood inside the house, it is necessary to ensure ventilation of the room, because Almost all formulations contain components that are unsafe for health. If the treatment was carried out in a bathhouse, it is necessary to dry-heat the room twice before taking bath procedures to remove chlorine fumes.

Below you will learn how to whiten a log house after sanding.

How and with what to whiten a log house made of logs and timber inside and out

Fungi and algae multiply very quickly in wood under favorable conditions. Sometimes logs leave the manufacturer’s site without damage, at least visible ones, but arrive at your site with a blue stain. But this only happens with a damp log (freshly cut or not sufficiently dried). Dry wood will not bloom under any circumstances, even without protective impregnation: moisture is one of the prerequisites for the development of fungus.

Darkening or blueing of wood does not entail any negative consequences. This is only an external defect. If the log house will be sheathed, there is no point in bleaching the wood. Without access to sunlight, fungi will not develop (the presence of sunlight is the second condition necessary for their development), and the darkening behind the casing is not visible. If you plan to paint the wood with transparent or translucent compounds, you will have to struggle.

This is what a log house may look like after drying: there is some decent darkening. The only way to combat them is with bleach.

Preventive action

To prevent the development of fungus before shipping, it is advisable to coat them with transport antiseptics, which protect the wood for 10-15 days. Even despite these measures, blue discoloration (the result of fungal activity) often appears even after treatment. Then the question arises: how to bleach a log?

Here everything is much worse: white mold has been added to the blue, and it must be fought mercilessly: it destroys the structure of the tree.

Therefore, it definitely requires treatment with bleach and then a powerful bioprotective impregnation.

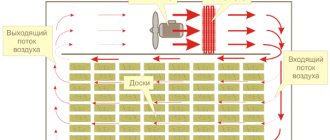

To prevent or stop/slow down the development of fungus, it is important to properly store lumber until the construction of the log house begins.

It is not always possible to lay a frame straight from the wheels. Even if it was planned this way, in most cases there are hiccups. And an incorrectly folded log is quickly damaged by fungus.

Therefore, immediately make ventilated stacks. They should be located on a dry area of soil, preferably in the shade. But questions of light and shadow are not fundamental. It is much more important to find a dry area.

It is equally advisable to protect the logs from precipitation: install a temporary canopy. At the same time, do not close the sides. In this case, good ventilation is more important than inaccessibility to droplets.

Wood bleaching products

All bleaches are made from bleach or hydrogen peroxide. Which one is better to use? One that effectively removes blackening of wood. There is no particular point in choosing a composition based on the principle “which is less harmful to the body.”

If you think that peroxide-based compounds are not harmful to health, then you are very mistaken. Both substances belong to the same group of hazardous substances - II (highly hazardous substances).

Judging by the concentration standards in drinking water, chlorine does less harm: the maximum permissible concentration of chlorine is 0.3 - 0.5 mg/l, hydrogen peroxide - 0.1 mg/l. Therefore, it is worth focusing on the efficiency of processing, and not on the composition.

Many people believe that bleaches only remove external manifestations of fungal activity. This is wrong. Both bleach and active oxygen are very active oxidizing agents. They destroy fungi and their spores. Another thing is that they cannot always penetrate the entire depth of the lesion.

If spores remain after treatment, then under appropriate conditions (high humidity and sunlight), they can multiply again (after the composition has completely evaporated).

Therefore, during construction and finishing work, you need to do everything so that the moisture that inevitably gets into the wood is quickly and effectively removed.

The most popular brands of wood bleaches: Senezh Neo or Effo, Neomid 500, Sagus, Frost (regular or Prof)

If we talk about brands, the most widely used are:

- Neomid (500 - bleach);

- Senezh (NEO - for gentle bleaching and removing fungus from the surface, EFFO for deep bleaching, but also kills fungus on the surface);

- Frost and Frost Prof (Prof - for deep whitening, Simply Frost - for gentle);

- Sagus - has mixed reviews. For some it works well, for others it doesn’t work at all, so you have to try.

Each of these compounds is used, sometimes more successfully, sometimes less. So it’s difficult to tell you clearly what composition to use. It is important that no protective film-forming compound is applied to the log: then any of the compounds will not penetrate inside and there will be no result at all, or it will be weak.

Treatment with chlorine-containing agents

Wood can be bleached with bleach.

Before applying the product, it is necessary to remove the resin from the tree; to do this, the surface is treated with soda ash. Next, you need to dilute bleach with water in the following proportion: 2 kg of dry matter per bucket of liquid. Add 250 g of soda to the diluted solution, mix everything and let stand for a while. The product is applied with a brush or roller, and 5 minutes after treatment the surface is wiped with acetic acid. After about fifteen minutes, the wood should lighten. If the wood is not lightened enough, the procedure can be repeated.

Another chlorine-based bleach is bleach. It is especially effective for outdoor use. The wood is generously moistened with the liquid and then rubbed well into the surface. When using white, you must protect your eyes and hands from contact with the product.

Step-by-step removal of mold in wooden products

Elimination of consequences and prevention of further proliferation of fungal spores is carried out in several stages. How to remove mold from a wooden surface if the problem is found in a neglected state:

- Cleaning damaged areas. You will need a spatula and a chisel. Remove the top layers with a spatula. A chisel and knife are used if damage to the internal structure of the wood is detected.

- Dispose of all removed wood. It is advisable to burn all cut layers of wood.

- Washing the material. Prepare a concentrated solution of laundry soap and carefully treat cleaned wooden surfaces.

- After treatment with soapy water, the wood is allowed to dry. Then they are treated with a wood antiseptic. After disinfection, the wood is allowed to dry and the treatment of problem areas is repeated.

Lightening wood with oxalic acid

Oxalic acid should be used with caution as it is very poisonous. Before applying the acid, the surface is treated with sodium hydrosulfite, and then almost immediately the wood is coated with a 10% solution of oxalic acid. After five minutes, both compositions are washed off with water.

Oxalic acid is well suited for bleaching light wood: maple, poplar, birch, linden. To achieve the desired effect, 6 ml of oxalic acid is diluted with 0.1 liter of water. The acid remaining on the wood is neutralized with the following composition: 15 g of bleach, 3 g of soda ash and 0.1 l of water. Then the wooden surface is washed with water.

Methods for “healing” warped lumber

The first method to save wood building material is to treat it with disinfectant mixtures before darkening occurs.

When asked what to do if the boards become moldy, blue or blackened, there is only one answer: immediate treatment.

The method of action is as follows:

- Wood bleach treatment. Let's say the timber has darkened by 3-4 centimeters, this can be seen in the cross section. Bleach will help here, penetrating up to 5 cm deep.

- Treatment with a disinfectant that prevents the development of microbes in the body of the board.

Industrial bleaches

Domestic and foreign industry today produces many effective and affordable products that can be used to whiten a log or timber house.

According to experts, one of the best bleaches is the Russian drug “Sagus”, which is used to prevent the formation of corrosion, and also effectively treats wood from fungus and whitens the surface.

Sagus not only lightens the wood, wood bleached with the product acquires an even shade, and black spots and spots disappear from it. The composition is resistant to weather conditions and humidity, so it can be used both inside and outside the house.

Another domestic product that is used to bleach wood is Neomid 500. It rids wood of fungus and mold, evens out the color, and also protects it from insects. For deep lesions, a concentrated composition is used. If there are only small pockets of fungus on the tree, the composition is diluted with water in a 1:1 ratio.

How to get rid of mold on a wooden surface

If the material is only slightly affected, the following will help get rid of mold:

- chisel and spatula;

- sandpaper;

- hammer;

- soft rags and fine sandpaper.

The scale of mechanical intervention depends on the depth of penetration of fungal spores. Sometimes it is enough to remove the thin top layer and then perform disinfection without severe damage to the timber.

Antiseptic

A properly selected chemical solution will destroy mold growth areas. As a rule, universal antiseptics and active fungicides are used for these purposes. The following have proven themselves well in the fight against disputes:

Important! Any chosen anti-mold product is used strictly according to the instructions. In addition to the recommended dosage, it is important to pay attention to the optimal temperatures at which processing is performed.

These antiseptics do not contain dangerous chlorine compounds and volatile toxins. At the same time, they are capable of not only destroying areas of bacterial growth, but also subsequently protecting the wood from spores. In addition, there are solutions that additionally have a toning effect. This allows the lumber to retain its natural appearance.

Folk remedies

Before treating the timber against fungus and mold using professional means, you can try traditional methods of combating it. Such means were successfully used for control even before special chemical solutions appeared on the construction market. Among the most popular are the following:

- Acetic acid. Lumber is treated with acetic acid in two stages. Spraying is performed for the first time. After complete drying, wipe again with a dampened rag. This method is completely safe, but gives a short-term effect.

- Hydrogen peroxide. Carefully treat the damaged areas with peroxide and leave for 15 minutes. Then clean the surface with a metal brush. The disadvantages include the risk of losing the appearance of the material.

- Baking soda. Add water to the soda and stir thoroughly until a thick paste is obtained. The product is applied to the damaged areas and left for 30 minutes. Then the surface is cleaned with a stiff brush.

- White. The most effective and most dangerous way to destroy mold fungi. Whiteness is applied to the areas where spores have been identified and left for 15 minutes. Wash off with soap concentrate.

Important! When planning to resort to folk remedies to combat mold, you should not use highly concentrated chlorine solutions. When using such products, you must wear a protective mask and rubber gloves.

Folk remedies are not always effective, and in some cases even dangerous to human health. Therefore, it is better to give preference to modern antifungal drugs with a multicomponent composition.

What are the dangers of self-processing wood?

Home craftsmen, doing bleaching with their own hands, have very little idea of how complicated and dangerous this process is. All bleaching compounds are based on poisonous and toxic substances, which, if used incorrectly, can damage the surface and cause irreparable harm to health.

Non-professionals often incorrectly calculate the concentration of the product, violate the proportions, and do not include the necessary components in the composition, which negatively affects the wood.

It is necessary to strictly follow the technology of applying and rinsing off the product. The slightest violation of the technological process can lead to very sad consequences.

To avoid mistakes and prevent negative consequences, it is necessary to entrust bleaching of a wooden surface to specialists.

We employ professional craftsmen who know exactly the technology of wood bleaching and have successfully carried out this operation more than once.

If the walls of your wooden house are corroded by fungus, darkened and acquired a blue tint, contact our company. We will efficiently and quickly carry out all the necessary measures to whiten and renovate your home, which will again regain its lost beauty.

On the “Contacts” page you will find all our coordinates where you can contact us in a way convenient for you.

Calculate the cost of painting and insulating your home right now

Select types of work:

Select materials:

What to do if the lumber has darkened, turned black or started to become moldy?

Sultry hot days in summer, high humidity, not the conditions that would have a beneficial effect on coniferous wood. But no one has canceled the construction season. At stake is the renovation of houses and their construction from wood. In this regard, the question arises, what to do if the purchased wood has acquired a blue color.

Choosing paint

How to bleach yellow plastic on a refrigerator

If we are talking about painting directly, you will need paint for the lining of one of the following types:

- Oil paint. Penetrates deeply, protects from external influences, and is suitable for painting lining on the balcony. Disadvantages: takes a long time to dry, fades over time.

- Alkyd enamel. A universal paint that creates a dense, most often glossy coating that is resistant to external influences and durable. The disadvantage is the limited selection of shades.

- Acrylic water-based paint. Used more often than others, it creates a matte, translucent coating. When applied in a thin layer, it allows you to preserve the structure of the wood.

Peculiarities

How to bleach tulle at home: folk recipes and special chemistry

Lamarty chipboard is the best choice of every consumer. And it is not just words! This statement is due to many years of experience, perfect quality and reliability of the products. The Lamarty company has been manufacturing similar products for a long time. In 2013, its factories began producing moisture-resistant laminated chipboard, which is used to make exquisite, safe and incredibly beautiful furniture for the bathroom and kitchen.

Why are Lamarty products so popular? Initially, this is due to the technology of its production.

- The process of manufacturing laminated chipboards at the company's factories is fully automated. The absence of the “human factor” in the creation of products ensures their stable quality.

- The internal layered structure of the slab is constant.

- Modern materials and equipment are used, thanks to which products are mainly manufactured quickly and efficiently, to order. This production scheme ensures that the slabs do not accumulate in warehouses, losing their original properties.

- Strict control over the production process and quality of already manufactured chipboard.

All this enabled the company to receive a lot of certificates that confirm the high class of products manufactured at Lamarty factories. The manufacturing process of Lamarty chipboard is quite simple: to produce it, the manufacturer uses lamination materials and the chipboard sheet itself. Thanks to a serious approach to the production process and manufacturer responsibility, the final product has the following features:

- heat resistance;

- impact resistance;

- wear resistance;

- color fastness;

- high hygiene, safety and environmental friendliness;

- resistance to chemicals;

- high coefficient of strength and reliability.

Prevention

Knowing the reasons for darkening, making white wood as durable as possible and preventing discoloration is not too difficult.

Antiseptic treatment

It will prevent the development of mold fungi in the wood.

Antiseptic composition with fire retardant additives.

What are antiseptics?

- Water soluble. This type of primer will provide a lasting effect either indoors or if a water-repellent protective layer (varnish, oil-wax impregnation, paint, etc.) is applied to the surface of the wood.

- Oil based. The composition performs two functions at once: it kills mold spores and protects the wood from moisture.

- Solvent based. The soil provides maximum penetration depth and effective wood preservation; however, it usually significantly reduces the air and vapor permeability of walls.

Hydrophobization

The list of protective coatings for wooden bases is a topic for a separate study. Briefly, they can be divided into oil-wax compositions, which allow the wood to remain permeable to air, and various varnishes: polyurethane, alkyd, acrylic, etc.

The main function of the compositions is to reliably prevent fluctuations in wood moisture content, preserving it at the lowest possible level.

UV filter

UV protection is an optional quality of protective varnishes and impregnations for painting wood. Special additives make the surface layer impenetrable to the shortest waves of the solar spectrum. Here, alas, you will have to completely trust the manufacturer: it is impossible to check the quality of ultraviolet protection with your own hands at the purchase stage.

The presence of UV protection is usually mentioned on the packaging.