One of the most effective methods for stabilizing wood is impregnation with oil compounds and waxing. You can find a lot of specialized information about the types of oils and the technology for their application, but there is much less data on how to coat wood after oiling.

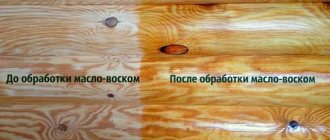

This is partly due to the fact that after coating with oil-based protective compounds, the wood immediately takes on an excellent appearance and, in most cases, does not require additional actions.

Therefore, the entire post-processing cycle can be described in one phrase: re-grinding the coating after polymerization of the oil, the need for which arises quite rarely.

However, this case also has its own nuances, most of which are discussed in this review.

What does oiling wood do?

Just 20-30 years ago, most people associated a wooden house with a nondescript, dark gray structure and constant problems with the geometry of the log house.

Today, even a small bathhouse looks like a small masterpiece, captivating with the amber shade of the walls and the amazing texture of the wood pattern.

All this became possible thanks to the advent of wood protection technology based on oil impregnations, the widespread use of which made it possible to achieve the following goals:

- Slow down the aging process of wood several times.

- Achieve an original decorative effect without the usual problems of paint and varnish coatings.

- Implement an external water-repellent effect that significantly extends the life of a log or timber house.

- Restore old log houses with almost any degree of wear.

- Create a long-term antiseptic effect, including for the lower crowns of the log house, without disturbing the artistic concept of the house.

The physical and chemical principle of oil impregnation is simple: the ends and outer layer of logs or boards are impregnated with a hydrophobic composition - a mixture of special oils and additives that allow complete polymerization upon contact with oxygen and sunlight.

To be fair, it should be noted that the method of stabilizing wood using oil impregnations is far from new and has been successfully used in wooden architecture and shipbuilding for hundreds of years.

However, it is only now that compositions combining the optimal combination of operational and technological qualities and an affordable price have become available to the masses.

In addition, most oils for impregnation can be tinted in a wide range of colors and shades, so the treatment of wood with oils has long gone beyond the scope of protective coatings, and is gradually replacing traditional painting methods.

Material selection

Wooden stairs are most often made from:

- beech;

- ash;

- oak;

- maple and larch.

Exotic wood species are gaining popularity, although of course more expensive, for example:

- merbau;

- teak or jatoba.

Cheap wooden stairs are made of pine or spruce. This tree should not be used when the staircase is used very often, for example, if it is located in or next to the living room, which connects both floors.

Although this is not so flashy and few people know, moving either down or up the stairs, a person exposes it to the same intense use.

Advantages and disadvantages of oil coating

There are few completely universal technologies in nature, so treating wood with oil has both advantages and disadvantages.

The advantages of oil coatings today include the following qualities:

- Good vapor permeability.

- Relative ease of processing (compared to traditional painting methods).

- The absence of dangerous chemical compounds in their composition.

- Ease of recovery.

- Possibility to vary the protective and decorative effect over a wide range (density of the outer layer, color shades).

Separately, we emphasize that oil impregnations, unlike most traditional painting and varnishing compositions, do not clog capillary networks “tightly”, but create a coating that allows water to pass through in a vapor state. That is, oil-painted logs continue to “breathe” like regular wood.

Let us also recall that the labor costs for updating a traditional paint coating are an order of magnitude higher than for the initial painting (removing old paint, stripping, re-priming, etc.). Restoring oil-painted surfaces in most cases involves applying one new layer of impregnation.

Among the disadvantages of oil processing, the following should be noted:

- Relatively high cost.

- The need for preliminary cleaning and grinding of the surface to be treated.

- Low duration of maintenance-free operation.

- Difficulty in processing wood with a high resin content.

If we analyze the reviews of developers who in practice have encountered the peculiarities of oil impregnations, then the only and main disadvantage of using oils is the low stability of external protection. That is, surfaces covered in this way must be renewed every 2-3 years.

Please note that if you use high-quality products and follow the technology, the processing period can be increased to 5-9 years.

To some extent, this disadvantage is compensated by the ease of restoration - it is enough to cover the wood with another layer of oil. But if the area of the protected structures is large, then you should think about combined options, the duration of maintenance-free operation of which is much longer.

In particular, large houses made of timber or logs can be treated with oil and wax. In this case, the vapor permeability of the coating will be lost, but the interval between updates will increase two to three times.

Service life of wooden structures treated with impregnations and other means

The first question that worries everyone even at the stage of purchasing the first set of wood products is how long it will last.

It is practically impossible to answer this question unambiguously and accurately: service life always depends on strict adherence to the instructions. In addition, it is difficult to predict the operating conditions of your specific wooden structure.

Here it is necessary to explain where real, and not unfounded, guarantees of the durability of paint and varnish products come from. To be able to officially declare a certain period, the manufacturer must order an expensive and long-term study from an independent laboratory.

Laboratories are physically unable to reproduce the effects on treated wood of real atmospheric conditions, time and mechanical influences, so products are tested in so-called artificial aging chambers, where impacts are created even more severe on the product than would be the case under real conditions. Based on the research results, the manufacturer is issued a test certificate. For example, a test report issued by an independent laboratory confirms the durability of the Belinka Base + Toplasur complex for 10 years, but it is likely that such a coating will last even longer in real conditions.

However, durability research takes a long time. So you shouldn’t trust a brand that appeared on the market a year ago and claims a “25-year guarantee.”

In what cases is oil impregnation recommended?

At the moment, it is difficult to identify situations where oil treatment is the only solution. Any oiled surfaces could almost always be painted over.

However, in some cases, oil protection will be more effective and will allow you to achieve results that would not be possible with similar treatment with traditional paints and varnishes.

The lower crowns of the log house

The lower crowns of a log house are the Achilles heel of a wooden house, and their protection should be treated with maximum attention. Due to the vapor permeability of the coating, oil treatment in this case is the most preferable of all possible options.

The oil protective layer creates an optimal microclimate inside the logs, with minimal risk of developing fungal diseases.

Internal wall surfaces

Of all the existing types of painting of wooden buildings, impregnation with pure oils is the most environmentally friendly.

Considering that such processing also enhances the decorative effect, the use of oils for the interior decoration of wooden cottages has become a de facto standard in the modern architecture of houses made of timber and logs.

Surfaces with complex terrain

When designing the design of a house and outbuildings, it is necessary to consider not only the initial appearance of their coating, but also how this coating will be updated.

Obviously, boards decorated with carvings or profiled for technological reasons are extremely difficult to repaint if traditional paints and varnishes were originally used.

In this connection, oil impregnations are definitely more convenient for processing carved platbands, decking boards, steps and garden furniture.

Oil variants

In modern realities, natural, but more often artificial, oily substances are used to produce materials with excellent quality indicators. According to their characteristics, there are several types of oils that are considered one of the best:

- Soy;

- Sunflower;

- Talova;

- Linen.

It doesn’t matter which type of the above oils you prefer. They all provide excellent wear resistance and hardness to the wood when applied.

What to do with wood after oil

The technology of coating wood with oil impregnations always involves preliminary grinding of the surface to be treated. This means that after polymerization of the protective composition there is no need for additional processing.

Moreover, some modifications of impregnations contain additives that form an outer protective layer, which is not recommended to be damaged.

However, in practice, additional treatment of coated surfaces is often carried out in the form of polishing with cloth cloths or special nozzles with low roughness.

In some cases - for example, when treating floors with oil and wax - it is necessary to polish the new coating.

Please note that there are two different approaches to creating an outer protective layer of wax:

- Separate coating after impregnation.

- Dissolving wax in the impregnating composition.

In modern conditions, the second option is most often used, since a large number of impregnations with pre-dissolved wax are available for sale.

Some manufacturers of oil impregnations include in their product range oils that can be subsequently painted with varnish or paint. In this case, the surface is first treated with a special primer and only then the finishing decorative coating is applied.

How to understand that it’s time to renew a layer of varnish or impregnation

Of course, you will know whether it is time to repaint the tree by its appearance. Peeling, swelling, cracking of the surface are clear signs of an approaching repair period. Carefully inspect the surface: the coating film should be uniform everywhere; if this is not the case, a repair application, possibly local, will be required.

Which is better: heated floors or radiators?

Warm floorBatteries

Another way to identify the need for repairs is the drop method. By the way, this is the main method for diagnosing surfaces treated with oils. The essence of the method is clearly visible in the video “When is it necessary to update coatings?”.

Should I turn to professionals?

Despite the apparent simplicity of the technology, in order to saturate wood with oil to create a high-quality and long-lasting coating, it is necessary not only to be fluent in the technology of applying oil, but also to know the features of the protective compounds used.

Since our company is the official supplier of the most famous brands of protective oils, all specialists directly involved in the work regularly attend advanced training courses, which guarantees full compliance of the coatings created with all working regulations.

accepts orders for repair or finishing treatment of wooden log houses and outbuildings, including oil painting and final sanding of coatings. You can clarify the details of cooperation and order a visit from a specialist to draw up an accurate work plan by contacting us by e-mail or by phone numbers published in the “Contacts” section.

Calculate the cost of painting and insulating your home right now

Select types of work:

Select materials:

Do I need to prime wood before staining?

In the vast majority of cases, there is no need to prime the surface before applying stain. The stain is applied in two or even more layers. The first layer is the primer. But there may be nuances (this applies more to coniferous wood).

Interesting materials:

What faculties are there at MPT? What shapes are there in Paint? What fruits are there in Cuba in December? What fruits are there in Georgia? What fruits can you eat in winter? What generative organs do flowering plants have? What verbs are in the present tense? What cities are there in the Republic of Khakassia? What mountains are there in the Republic of Korea? What states of the Ancient World are there?

Can varnish be applied to paint?

As a rule, wood is coated with this substance. However, sometimes there is a need to protect, provide additional gloss, hardness and strength to coatings made from other materials. In most cases, we are talking about water-based or acrylic paint.

The dye on the material must adhere firmly and retain its properties and color. The substance will help increase the strength of the prepared surface and enhance the shine effect. But a special composition should be used. It is recommended to use acrylic products that are odorless, quick-drying, and do not allow the paint to flow.

Do I need to prepare the painted surface for coating? Certain actions will still need to be taken. There should be no traces of dust, grease or other contaminants on the surface. Therefore, the painted base must be primed. You can find out how long it takes for the primer to dry on different surfaces from our article. In addition, the substance and dye must be compatible.

How do you know if the varnish product and paint are compatible? To determine their compatibility, the emulsion is lightly applied to the surface in an inconspicuous place, using a small area for the experiment, just for testing. If no negative changes are found on the surface, then the entire area can be varnished.

IMPORTANT! Do not apply the product to a wet surface. The item must be completely dry.

Can varnish be coated with varnish?

Over time, the varnish film becomes cloudy, wears out, and becomes covered with microcracks and scratches. Usually the owners decide to re-coat the interior detail with the substance. That's when you have to decide whether you can apply varnish over the varnish, or whether you will need to remove the old treatment first.

Let's say the old layer is so worn out and cracked that it spoils the appearance. According to experts, such a foundation requires complete replacement. If this is not done, attempts to update the item will remain unsuccessful. Chips, cracks, peeling areas will begin to stand out. Moreover, in some places the old emulsion will begin to swell when coated with a new composition (the effect of an unsuitable solvent will appear) and peel off from the base.

You will also need to remove the old composition if it has become cloudy, faded, or dull. This surface is first sanded using fine-grained sandpaper. And after that you can apply the product.

And yet, is it right to carry out such work? There is no consensus. Many experts are convinced that the previous coating should be completely removed. After all, you need to take into account such a factor as incompatibility of products. If the old and new compositions turn out to be incompatible, the subsequent layer will begin to peel off.

Other experienced craftsmen recommend not wasting energy on doing unnecessary work. And if you follow certain rules, after such preparatory measures it is quite possible to cover the previous layer with a new one.

IMPORTANT! If a water-based solution was used, then it is necessary to use the same type. Polymer mixtures and nitro varnishes can be renewed with various liquids, including water.

How to treat a wooden staircase

Regardless of what type of wood is chosen, the protection of the internal wooden stairs can be ensured in two ways, using oil or varnish. Before choosing one of the methods, it is worth familiarizing yourself with their characteristics, since each of them has its own advantages and disadvantages, as well as properties that give the surface of the stairs not always the expected effect.

In order for the staircase to be admired for many years and to be the calling card of any home, especially if it is in a presentable part, the wood must be properly protected.