During construction work involving the use of lumber from coniferous trees, correct calculations of the specific gravity of pine wood are very important. Unlike other various building materials, this variety does not have a single specific gravity, which somewhat complicates the selection process. The fact is that pine wood, like any wood, is a natural porous material. Accordingly, depending on the type of pine and the percentage of humidity, the specific gravity of the pine changes.

As mentioned above, the main parameter affecting the volumetric weight of pine is humidity. For example, the highest specific gravity is found in still untouched, growing pine. This is due to the fact that the tree requires high humidity to grow. At the same time, humidity is both a useful substance and a carrier of other, no less useful, vitamins and minerals. The amount of moisture depends entirely on the type of pine, the harvesting season and the area. Humidity levels of “live” pine can vary from 29% to 81%. The lowest indicator, respectively, is for dried pine, since the humidity in this state tends to zero.

Experiment: weigh 1 cube of firewood.

The Drova72 company conducted an experiment, we weighed 1 folded cube (storage meter) of birch chopped firewood, natural humidity, ~50%.

We will discuss the results of this experiment in more detail below. This experiment in no way claims to be “scientific” or “100% objective”

, rather something between information from the Internet and laboratory research. But nevertheless, this is the first step on the path to truth and objectivity.

Next time we will repeat the experiment and try to find a moisture meter, as well as film the whole process on video.

In short, the results

At humidity ~50% and log length ~50cm:

- 1 folded cube weighs ~561 kg

; - 1 dense cubic cube weighs ~790 kg

.

In the text below, we reveal in detail the essence of the experiment. The calculation is based on information from

And

.

Calculations

When calculating the specific gravity of a specific feedstock, the mass is determined by weighing, and the volumetric indicator is calculated using a special method that takes into account not only the main body of the workpiece, but also the presence of voids in it. The final value of this parameter is determined as the difference between the volumes of wood pulp and the liquid filling the voids. Typically, specific gravity is calculated under natural moisture conditions for a specific wood species and entered into tables. So data can always be obtained from them.

On the other hand, based on specific gravity and volume, you can calculate the weight of lumber (timber or boards). So, in order to find out how much a cube of boards weighs, just find in the table the density indicator for a given type of wood and multiply it by one.

There is a very close relationship between the density of fibers in wood raw materials and its strength. At the same time, dense material samples are usually more durable.

Why do we need this?

A small retreat

The volume of firewood in storage meters is measured by multiplying the length, width and height of the woodpile. But the concept of “1 stacked cube of firewood” is quite vague, because firewood in the woodpile can be stacked with different packing densities

and there is no GOST or regulation that would explain what “laying density” is and how to measure it. That is, the same amount of firewood (1 conventional stacker) can be stacked from ~0.7 to ~1.3 stackometers, depending on the stacking density and the condition of the logs (their curvature, the presence of knots).

For clarity, look at the photo below. It is obvious that the firewood on the right is stacked thoroughly and the number of logs in such a woodpile is greater than in the one on the left. In both cases, the volume of firewood in the storage meters will be the same, but the mass will be different

. Those. in fact, the amount of firewood in the photo on the left is less.

In the photo above, please do not pay attention to the different types of firewood, this image shows the density of firewood stacking in the woodpile.

Specifics

Sometimes our clients and I have disagreements regarding the volume of firewood in storage meters. We brought the firewood for stacking in one volume, the client transferred the firewood to his woodpile, measured it, and the volume turned out to be less than originally stated.

In the example above, disagreements almost always arise due to packing density. Therefore, we decided to weigh 1 folded cube of birch firewood, and correlate its weight (mass) with the data,

which are presented in GOST 3243-88 and in the Handbook of Sawmilling, Moscow, Timber Industry Publishing House, 1980.

By comparing the weight of our firewood storage meter with data from the above sources, we will understand whether we are packing the firewood tightly enough into the car before delivering it to the buyer.

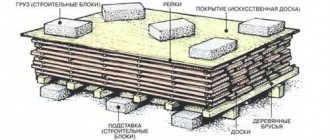

Sequencing:

- First we will put 1 folding cube in the woodpile.

- Let's weigh this cube on the scales.

- We compare the resulting weight with data from GOST 3243-88 and the Sawmilling Handbook.

According to various sources, the humidity of freshly cut birch can vary from 60 to 80%. We purchase firewood birch, which was harvested (cut down) 1 to 4 months ago from the moment it was brought to us for subsequent processing. The humidity of birch is on average 40-50%. We will make calculations based on 50% humidity.

The weight of a dense cube of ordinary birch at a humidity of 50% is 790 kg. To convert the weight of a storage meter into a dense cube (or vice versa), you need to apply a coefficient. We will take it from, with a log length of up to 0.5 meters of split hardwood - the coefficient is 0.71.

790 * 0.71 = 560.9 kg

Those. The mass of our split birch firewood storage meter must be at least 561 kg.

Brief description of wood properties: Hornbeam.

Hornbeam is most widely distributed in Europe, Asia Minor and Iran. The wood is shiny, heavy, sticky. Color: whitish-gray. Density: 750 kg/m (cube). Brinell hardness: 3.5.

Lacewood. One of the most beautiful Australian trees. The color is light brown with a characteristic grain. Density: 910-1050 kg/m (cube). Brinell hardness: 5.5. Paduc. with bright positive energy. Color: Light yellowish-red to dark brick-red, mottled with darker lines. Density: 850-950 kg/m (cube). Brinell hardness: 4.2.

Wenge. The homeland of wenge wood is the tropical jungle of West Africa, all the way to Zaire. The structure of the material is large, even-grained, the wood is decorative and at the same time heavy and resistant to pressure and bending. Color: Golden brown to very dark brown with black streaks. Density: 850-900 kg/m (cube). Brinell hardness: 4.1.

Tigerwood (tiger tree). Grows in Western Tropical Africa. Colour: Yellowish-brown, sometimes marked with dark vein stripes. Density: 800-900 kg/m (cube). Brinell hardness: 4.1.

Cocobolo. High stability when changing humidity. Color: dark, deep red with black, irregular stripes. Bright, expressive, beautiful texture. Density: 800-980 kg/m (cube). Brinell hardness: 4.35.

Rosewood. The wood is very dense and heavy, polishes well, and sinks in the input. Color: attractive light brown with a violet-lilac tint. Density: 1000 kg/m(cube). Brinell hardness: 5.5.

Yarra. The name of one of more than 500 varieties of Australian eucalyptus. Color: all shades of red, from red-pink to dark red. Over time, the yarra darkens and its color can take on very diverse shades. Density: 820-850 kg/m(cube). Brinell hardness: 5.0.

Pear. The wood is dense, hard, easy to process, and rarely cracks. Color: from yellowish-white to brownish-red. To increase hardness, pear wood is placed in water and kept for a long time, after which it is dried for a long time in natural conditions. After drying, it acquires a brownish tint. Density: 700 kg/m (cube). Brinell hardness: 3.4. Oak (stained). The wood is strong, durable, resistant to external influences. After a long (50 to 300 years) soaking (staining) without oxygen, the wood acquires a velvety black color. Black color.

Bog oak is a precious wood material. For thousands of years, sunken oak trunks were located at the bottom of reservoirs, where, without access to air, during the process of staining they acquired strength not inferior to stone. Nature itself gives it strength, durability and a unique color scheme. Density: 750 kg/m (cube). Brinell hardness: 3.8. Boxwood. The wood is hard as bone, its specific gravity is greater than the specific gravity of water, boxwood sinks in water. Therefore, it is used for the manufacture of parts where significant rigidity is required. Color: light yellow, matte. Density: 1350 kg/m (cube). Brinell hardness: over 8.0. Makassar. A type of ebony common in Southeast Asia. Color: dark brown with black veins. It has a very beautiful texture. Density: 1000 kg/m (cube). Brinell hardness: 7.0.

Eben. In trade there are many varieties of ebony. The rarest and most expensive grows only in the countries of Central Africa. So expensive that payment for it is in kilograms. Export supplies of African ebony are limited and are completely controlled by the governments of the countries where it is mined. The wood is very dense and heavy and sinks in water. Color: dark brown to velvety black with characteristic lighter (or light brown) longitudinal veins. Density: 1200 kg/m (cube). Brinell hardness: over 8.0. Jatoba. It is also called Brazilian cherry. The wood is heavy, durable, hard and at the same time surprisingly elastic. It is difficult to process, but can be ground and polished to an almost mirror-like shine. Color: Density: 960 kg/m (cube). Brinell hardness: 4.8. Zebrano. Grows in Gabon and Cameroon. The wood is hard and heavy. The surface is shiny, the texture is somewhat coarse. Color: light golden with narrow streaks ranging from dark brown to almost black. Density: 900 kg/m (cube). Brinell hardness: 4.5. Kewasingo. It grows from equatorial Africa, from Cameroon and Gabon to the Congo. Tree up to 35-40 meters tall, trunk diameter up to 1.5-2 meters. The wood is red-brown to dark red in color. It has a beautiful texture pattern. Dense, hard, stable. Density: 820-850 kg/m(cube). Brinell hardness: 5.0.

Black hornbeam. Grown in the Caucasus mountains. The tree was felled in winter when sap flow has stopped. The secret of painting is passed down from generation to generation. Black color. Density: 700 kg/m(cube). Brinell hardness: 3.4. Merbau. Grows in Southeast Asia (Malaysia, Indonesia, Philippines). The main advantages of merbau are that it contains oily substances in its pores, is very hard, resistant to moisture and does not dry out much. During use, merbau darkens, especially the light areas, as a result of which the color of the wood as a whole is evened out. Color: brown, from light to dark tones, interspersed with yellow streaks in places. Density: 840 kg/cub.m. Brinell hardness: 4.1. Ash. The wood is heavy, hard with high strength. Possessing toughness and one of the most valuable rocks in the world for the manufacture of sports equipment. Density: 700 kg/m(cube). Brinell hardness: 4.0-4.1.

We weigh

- To begin with, we placed 1 cubic meter of birch firewood in a woodpile, just like we deliver it to our customers.

In the photo below, the volume that we will measure is outlined in red. On the left and right, we used the bagged firewood as a support so that our woodpile would not fall apart while we were measuring it.

- Next, we take measurements to make sure that there is at least one stacked cubic meter of firewood in our woodpile.

The length and height of the woodpile are approximately the same, but there are discrepancies in the length of the logs due to hand sawing and splitting. The length of the logs varies from 42 to 48 cm, sometimes up to 52 cm, much more often in the range of 45-48 cm. After measuring several times, we get an average length of 45 cm.

Woodpile length 206cm, height 110cm. We calculated the length and height of the woodpile according to the minimum values. For example, the height of the woodpile turned out to have a slight difference, from 115 to 110 cm. Next, we convert the numbers into meters and multiply.

2.06 * 1.10 * 0.45 = 1.0197 or 1.02 foldometers.

How and with what will we weigh?

To weigh our volume of firewood, we decided to put the firewood into bags and weigh them with ordinary scales. Then, add up the weight of each bag and get the total weight of 1 folding cube.

Add and get the result

The mass of our cube is 566.5 kg.

As a result, we got 25 bags of firewood, the average weight of each bag is ~23 kg. And the total weight is 566.5 kg. Those. even a little more than we originally should have received.

566.5 kg > 560.9 kg

The density of wood is as a construction raw material.

Wood density is the ratio of wood mass to volume Pw=Mw/Vw Density depends on the species and humidity, usually determined from a table. All tree species are divided into 3 groups: 1) Low-density P 2) Medium-density 0.5

3) Highly dense P>0.7 (g.cm3) (hornbeam) This property is characterized by the mass of a unit volume of material, and has a dimension in kg/m3 or g/cm3. a) Density of wood substance pd.v., g/cm, i.e. the density of the cell wall material is equal to: pd.v. = md.v. / vd.v., where md.v. and vd.v. - respectively, the mass, g, and volume, cm3, of the woody substance. This indicator is equal to 1.53 g/cm3 for all species, since the chemical composition of the cell walls of wood is the same. b) The density of absolutely dry wood p0 is equal to: p0 = m0 / v0, where m0, v0 are, respectively, the mass and volume of wood at W = 0%. The density of wood is less than the density of wood substance, since it includes voids (cell cavities and intercellular spaces filled with air). The relative volume of cavities filled with air characterizes the porosity of wood P: P = (v0 - vd.v.) / v0 * 100, where v0 and vd.v. - respectively, the volume of the sample and the wood substance contained in it at W = 0%. Wood porosity ranges from 40 to 80%. c) Density of wet wood: pw = mw / vw, where mw and vw are, respectively, the mass and volume of wood at humidity W. The density of wood depends on its moisture content. At humidity W g) Partial moisture content of wood p`w characterizes the content (mass) of dry wood per unit volume of wet wood: p`w = m0 / vw, where m0 is the mass of absolutely dry wood, g or kg; vw is the volume, cm3 or m3, of wood at a given humidity W. e) The basic density of wood is expressed by the ratio of the mass of an absolutely dry sample m0 to its volume at a humidity equal to or higher than the cell wall saturation limit Vmax: pB = m0 / vmax. This basic indicator of density, which is independent of humidity, is widely used to assess the quality of raw materials in the pulp and paper industry and in other cases. The density of wood varies over a very wide range. Among the species of Russia and neighboring countries, the wood with very low density is Siberian fir (345), white willow (415), and the most dense is boxwood (1040), pistachio core (1100). The range of changes in the density of foreign wood species is wider: from 100-130 (balsa) to 1300 (backout). Density values here and below are given in kilograms per cubic meter (kg/m3). Based on the density of wood at 12% moisture content, species are divided into 3 groups: with low (P12,740) wood density.

The volumetric weight of wood also depends on the width of the annual layer. In deciduous trees, the volumetric weight decreases with decreasing width of the annual layers. The greater the average width of the growth ring, the greater the volumetric weight of the same breed. This dependence is very noticeable in ring-pore rocks and somewhat less noticeable in open-pore rocks. In conifers, an inverse relationship is usually observed: the volumetric weight increases with a decrease in the width of the growth rings, although there are exceptions to this rule.

The volumetric weight of wood decreases from the base of the trunk to the top. In middle-aged pines this drop reaches 21% (at a height of 12 m), in old pines it reaches 27% (at a height of 18 m).

The decrease in volumetric weight along the height of the trunk reaches 15% (at the age of 60-70 years, at a height of 12 m).

There is no pattern in changes in the volumetric weight of wood along the diameter of the trunk: in some species the volumetric weight decreases slightly in the direction from the center to the periphery, in others it increases slightly.

A big difference is observed in the volumetric weight of early and late wood. Thus, the ratio of the volumetric weight of early wood to the weight of late wood in Oregon pine is 1: 3, in pine 1: 2.4, in larch 1: 3. Therefore, in coniferous species, the volumetric weight increases with an increase in the content of late wood.

Wood porosity. Wood porosity refers to the volume of pores as a percentage of the total volume of absolutely dry wood. Porosity depends on the volumetric weight of the wood: the higher the volumetric weight, the less porosity.

To approximately determine porosity, you can use the following formula:

C = 100 (1-0.65γ 0)%

where C is the porosity of wood in%, γ 0 is the volumetric weight of absolutely dry wood.

The table shows the weight of 1 m3 of wood relative to the percentage of moisture.

When organizing timber transportation, the density of the tree is an important indicator when selecting a timber truck and calculating the cost of transportation. This will help avoid overloading, which will consequently prevent you from being fined.

The density of the material has a special significance on the weight of m3 of wood; accordingly, to correctly solve the questions posed, it is necessary to determine the value of the density. There are two types of density: volumetric weight

(density of the structured physical body) and

specific gravity

(density of the wood substance).

Conclusions and comments

First of all, we wanted to test ourselves, because... Sometimes doubts arose about honesty towards our firewood buyers. Now the doubts are dispelled. Our stacking density and volume of firewood in stacked cubic meters corresponds to our measurement standards

.

If we turn to again, it is obvious that the weight of 1 folded cube at a humidity of 50% will not always be 560.9 kg, because the weight of one dense cube is 790 kg - this is an average value and can range from 553 kg to 1027 kg. And, therefore, 1 stacker of birch chopped firewood (taking into account the coefficient of 0.71) can weigh from 392 kg to 729 kg. This is probably due to different densities of wood, places of growth, etc.

Of course, this experiment cannot be considered 100% objective, because At a minimum, a moisture meter is needed to determine humidity. Our forest may have different humidity levels because... There are many suppliers and the procurement and delivery times are different for everyone; accordingly, forest moisture can vary from 30 to 60%. The indicated sources also provide average values, which may differ by a factor of 0.7 to 1.3.

Attention!

When selling chopped birch and aspen firewood, our company does not use information from the above listed sources (state standards, that and reference books) in calculations. These sources are given due to the coincidence of some calculations with ours, for example, weight calculations.

We sell birch and aspen firewood in folding (folded) cubic meters, the firewood is placed in rows in the body. The final volume is calculated based on the volume of the car body by multiplying the length, width of the body and the height of the woodpile in the body. When selling birch and aspen chopped firewood in bulk (without stacking in the body), we apply a coefficient of 0.7 to the volume of firewood in the body. These calculations do not apply to pine cuttings and slabs.

If you have any suggestions or comments on this material, please write to our email.

Weight of 1 m3 of different types of wood

The table shows data on the weight of a cubic meter (cube) of 170 different types of wood at a standard humidity of 12%.

| Wood type | Weight of a cubic meter (cube) of wood in kilograms |

| Abacha | 420 |

| Apricot | 780 |

| Awodire | 690-750 |

| Azobi | 960-1120 |

| Quince | 640 |

| Ailanthus | 680 |

| Acacia | 690-750 |

| Amazaku | 850 |

| Amaranth | 800-950 |

| Anegri | 510-570 |

| Anchar | 550 |

| Afromosia | 710 |

| Bagassa | 800 |

| Lignum vitae | 1300 |

| Balau | 880-950 |

| Balsa (balsa) | 130-225 |

| Bamboo | 510 |

| Velvet | 160 |

| Belian (bitis) | 1200-1300 |

| Birch | 640 |

| Karelian birch | 600-750 |

| Bibolo | 580 |

| Bilinga | 740-810 |

| Bokote | 650 |

| Hawthorn | 760 |

| Bubingo | 800-960 |

| Beech | 650 |

| Wenge | 850-1000 |

| Faith | 1100 |

| Heather | 840 |

| Cherry | 530 |

| Elm | 650 |

| Gabon | 450 |

| Garapa | 830 |

| Hevea | 650-800 |

| Goyabao | 650 |

| Gombeira | 1150 |

| Goncalo | 850-950 |

| Hornbeam | 800 |

| Grenadill | 1200-1500 |

| Pear | 700-750 |

| Guarea | 640 |

| Dabema | 560-710 |

| Daru | 850-960 |

| Denya (okan) | 960 |

| Jelutong | 450 |

| Doxia | 650-1050 |

| Oak | 700 |

| Red oak | 650 |

| Stained oak | 950-1100 |

| Cork oak | 140 |

| Douglasia | 480-540 |

| Dussia | 800-830 |

| Spruce | 450 |

| Zebrano | 690-740 |

| Zirikote | 900 |

| Willow | 450 |

| Ipe (lapacho) | 960-1200 |

| Iroko | 660 |

| Elm | 660 |

| Cassia | 900-1300 |

| Cowrie | 380-560 |

| Chestnut | 600-720 |

| Horse chestnut | 470-580 |

| Cedar | 580 |

| Keltis | 800 |

| Kempas | 880 |

| Keruing | 640-860 |

| Kingwood | 1200 |

| Cypress | 460-485 |

| Cladrastas | 450 |

| Maple | 530-650 |

| Sugar maple | 740 |

| Cocobolo | 990 |

| Coconut | 690 |

| Kosipo | 640 |

| Koto | 580-650 |

| Kulim | 750 |

| Kumara | 1100 |

| Kumier | 1010-1150 |

| Kurupai | 1000 |

| Lacewood | 550-580 |

| Lauren | 710 |

| Limba (ofram) | 560 |

| Linden | 380 |

| Larch | 650-800 |

| Loro preto | 680 |

| Magnolia | 500-560 |

| Madrona | 620-660 |

| Maysamsa | 950 |

| Macassar | 850-900 |

| Maclura | 850 |

| Makore | 640 |

| Mansonia | 610 |

| Maraullah | 700 |

| Marfim | 850-930 |

| Mahogany | 620-650 |

| Meranti | 500-700 |

| Merbau | 830 |

| Miroxylon | 850-1050 |

| Myrtle | 950 |

| Moabi | 800 |

| Movingu | 690 |

| Juniper | 920 |

| Morado | 870 |

| Muirapiranga | 800-1060 |

| Niove | 880 |

| Olive | 850-950 |

| Alder | 420-640 |

| Nut | 600-650 |

| Black walnut | 660 |

| Ormozia | 740 |

| Aspen | 480 |

| Holly | 640 |

| Paduc | 750 |

| Rosewood | 770-830 |

| Parrotia | 900-1050 |

| Pecan (hickory) | 900 |

| Peroba | 750 |

| Pinkado | 990 |

| Fir | 450 |

| Sycamore wedge-leaved | 620-660 |

| Gonistylus macrofolia | 670-710 |

| Red gum | 500 |

| Rosewood | 860-1030 |

| Rosul | 960 |

| Mountain ash | 600 |

| Boxwood evergreen | 830-1100 |

| Sunbau | 760 |

| Santal | 660-720 |

| Sapelli | 600-650 |

| Sassafras whitish | 480 |

| Sequoia evergreen | 290 |

| Sep | 560 |

| Sitka | 430 |

| Homemade plum | 750-850 |

| Snakewood (Piratinera guianensis) | 1300 |

| Pine | 460-620 |

| Cedar pine | 450 |

| Sapupira | 990 |

| Tali | 910 |

| Tamo | 720 |

| Tauari | 620 |

| Teak | 620-750 |

| Yew berry | 620 |

| Poplar black | 380 |

| Thuja | 510 |

| Tyama | 560 |

| Tulipea | 480 |

| Ulin | 860-980 |

| Umnini | 990-1050 |

| Fernambuc | 620 |

| Pistachio | 860 |

| Framir | 480-625 |

| Hemlock | 490 |

| Persimmon | 830 |

| Zeder | 480 |

| Che | 1200-1300 |

| Bird cherry | 720 |

| Cherries | 580 |

| Mulberry | 800 |

| Eben | 1200-1300 |

| Eucalyptus | 650 |

| This | 580 |

| Apple tree | 780 |

| Sycamore | 650 |

| Yacaranda | 830 |

| Yarra | 850-1100 |

| Tall ash | 700 |

| Jatoba | 840 |

Why do you need to know the weight of the timber?

When planning to build a house made of wood, it is important to determine in advance how much material will be needed for the construction of walls, floors, floors and roofing. Since it is impossible to determine the weight of a beam by eye, you should spend a little time doing the calculations. This way, you will be sure that the seller supplied you with the products correctly.

The data obtained is also necessary to determine the carrying capacity of the transport that will be used to transport cargo. However, the weight of the timber is most important for choosing a future foundation - you will need to calculate the total load that is created under the weight of the timber walls.

engages in the manufacture and supply of a wide range of lumber. We use wood dried using advanced technologies and provide a guarantee on all lumber. From our employees you can find out the weight of pine, larch, spruce and other species of timber, and also use their help to calculate the amount of lumber for construction.

What can affect your weight?

The main influencing factor is humidity. The higher it is, the heavier the given volume of wood materials will be.

Naturally, recently cut pine will be heavier than dried pine. On average, freshly cut pine weighs 900 kg per cubic meter. In this case, various factors of the procurement region play a role:

- Resinousness of trees;

- Depth of groundwater (the shallower, the more water in the tree trunk, the higher the weight);

- General climate humidity in the region.

The harvesting season also plays a role: for example, a tree cut down after January will be 10-15% lighter than a tree cut down in the fall.

However, this all applies to fresh pine. Can anything affect the weight of dried wood or lumber?

Yes, and the main factor is treatment with various compounds:

- antiseptics;

- flame retardants;

- waterproof impregnations.

The treated wood material will be approximately 15-25% heavier. And, in this case, this will not be an indicator of poor quality or poor storage conditions.

There may be some fluctuations in the weight of pine lumber, due to several reasons. For example, a material made from the bottom of a tree will be slightly heavier than a similar material made from the middle or top.

It can also be noted that the core of pine is looser and less dense than the rest of the wood. Accordingly, the materials used to make the core will be, on average, a little lighter for the same volume.

The board is a certain lumber that is up to 100 mm thick and, usually, twice as wide. It is made from beams or logs of various tree species as a result of longitudinal division of round timber and division of the resulting parts. All this production is carried out on special equipment and machines. This type of material is used in all areas of production or construction work where the use of wood is necessary.

When working with materials such as boards, it is necessary to take into account its quality. A characteristic such as specific gravity will help determine this parameter.