Articles

All photos from the article

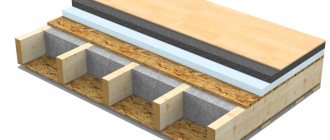

What is the substrate? Essentially, this is an additional layer in a wooden floor structure that improves its positive characteristics. It can be made of various materials, although the operating process does not change much.

But let's talk about everything in more detail.

Photo of the substrate rolled into a roll

General provisions

Insulating underlay under chipboard on a wooden floor

Of course, the finishing layer of the floor structure can be laid immediately on the rough board, as was done decades earlier (see also the article “Fibreboard on a wooden floor: selection and installation technology”).

But there are several reasons that make you think about the advisability of such an act:

- Firstly, you will then have to rely only on the thermal insulation properties of the base, since the decorative coating, as a rule, has high thermal conductivity;

- Secondly, the dampness that a floorboard can withstand may be too much for carpet or even laminate;

- Thirdly, direct contact with wood will not benefit every facing material.

Tips: which glue to choose for plywood on a wooden floor

There are cases when the surface of the floor boards is quite flat. In this case, you can glue the plywood sheets to the ceiling using polyvinyl acetate mastic.

Plywood sheets can be glued using mastic

The flow of work is as follows:

- The mastic should be applied in a thick layer using a notched trowel (teeth size 1.1-3 mm).

- For better adhesion of plywood sheets to the floor covering, the back side of the plywood sheet should be treated with a thin layer of epoxy adhesive, and then covered with a layer of coarse sand or other crushed natural material with a grain size of 1.8-2.8 mm.

- Polyvinyl acetate mastic should be applied only after the epoxy adhesive has completely dried and hardened.

Thus, with the help of plywood sheets, you can solve a number of problems that arise during the operation of plank flooring (repair or replacement of the floor). It should be added that laying plywood sheets in a certain way also allows you to compensate for significant differences in floor levels, for example, an old plank floor (up to 6 cm).

All about the substrate

First of all, let's look at the main functions of the substrate:

Purpose

A layer of insulation, noise absorption and moisture protection

| Function | Comments |

| Thermal insulation | For example, linoleum itself is cold, and laying it on a bare subfloor board, even if it is insulated between the joists, will lead to the formation of a cold zone in the foot area in winter. The substrate has a low thermal conductivity coefficient and will help retain the heat generated by radiators in the room. |

| Waterproofing | Moisture is the main enemy of wood. If you are the owner of a private house, then ground dampness will always threaten your flooring. An additional layer under the decorative layer will protect it from excessive humidity. |

| Noise insulation | When the thickness of the substrate is more than two millimeters, it perfectly absorbs all kinds of sounds. Thanks to this, you will certainly not disturb your neighbors below if you live in an apartment building. |

| Depreciation | For example, laminate can be deformed and quickly wear out when in contact with a rough board. The soft layer softens the contact between the two layers and significantly extends the service life of the decorative coating. |

Tip: to increase the thermal insulation effect, it is recommended to use a substrate with a foil layer. Such a coating, in addition to not allowing heat to pass through, also reflects it, thus increasing the room temperature by about 30%.

Plywood underlay on a wooden floor with a layer of aluminum foil

Kinds

Polyethylene underlay for carpet on wooden floors

Substrates can be made of various materials, which has some impact on their technical characteristics:

| Material | pros | Minuses |

| Polyethylene foam |

|

|

| Cork tree |

|

|

| Cork chips with bitumen |

|

|

| Extruded polystyrene foam |

|

|

| Composite |

|

|

Underlay for laminate on a wooden floor made of extruded polystyrene foam

Advice: if you don’t know what to put under linoleum on a wooden floor, then it’s best to opt for a balsa wood underlay. It has sufficient elasticity and reliability so that the linoleum coating does not sag in the future, and high thermal insulation so that your feet do not feel cold in the winter.

Laying linoleum on a wooden floor with a cork underlay

Laying

The instructions for placing the substrate on a wooden surface are simple:

- We prepare the rough foundation. We sand the wooden surface to eliminate the presence of sharp protrusions that could damage the backing material.

Tip: It is recommended to use an electric sander for sanding. It will allow you to cope with the task quickly and efficiently.

Sanding the plank base

- If the purchased backing is in a roll, then unwind it, measure the length equal to the longest side of the room and cut off the required number of sheets, after which we cover the floor with them. If the material is presented in the form of sheets, then immediately lay them out, making the necessary trimming at the end.

Unwinding a polyethylene foam roll

- We glue all joints with mounting tape in order to achieve maximum tightness of the coating. If this is not done, the waterproofing will be incomplete.

Underlay for linoleum on a wooden floor, taped with construction tape

After this, you can safely install any decorative layer, including laminate, parquet, chipboard, plywood and carpet, with confidence that it will be sufficiently protected from earth dampness, contact with base boards and heat loss.

How to lay plywood on a wooden floor: algorithm of actions

Home renovations often involve replacing old flooring. It is often not necessary to tear down the wood of the floors, but you can replace and refinish the flooring with plywood. You can lay plywood on an old plank floor if its level differs within 6 cm in a simple way.

First you need to remove the old paintwork from the floor.

Next, the baseboards are torn off and all their attachment points are chipped. The height of the door is adjusted taking into account the designed floor level. To level out differences in the floor, it is necessary to screw screws into the boards according to the size of the plywood sheet in a checkerboard pattern to a given depth. As a result, the heads of the screws must be at the same height, which is set by the laser level. Therefore, you should choose in advance which screws will be used for the work - these are screws of different lengths, but having the same slot for a screwdriver. Self-tapping screws are screwed strictly vertically into the boards in increments of 0.25-0.3 m.

Related article: What kind of decorative stone is there for interior decoration?

By following the technology of laying plywood sheets, you can get a perfectly flat floor

Further:

- The floor surface is wetted with water.

- Polyurethane foam is applied along the perimeter at the wall-floor joints on the boards.

- Also, in a checkerboard pattern with increments of 10-15 cm, the foam is applied in islands on the boards according to the size of the plywood sheet. The height of the foam island should approximately correspond to the height of the nearest screwed-in screw. In this way, a base cushion is created for laying plywood.

- A sheet of plywood must be placed on the screws and foam. This laying method allows you to get a perfectly flat plywood floor.

- Technological gaps between the walls and the plywood sheet should be within 10-15 mm, and between the plywood sheets - 4.4 mm.

It should be noted that, as a rule, this technology for laying plywood sheets allows you to obtain a perfectly flat and durable floor. In some cases, to relieve stress in a sheet of plywood, before laying the sheets, they should be cut into 4 equal parts each.

Laying laminate

Substrate preparation

Before laying the lamellas, you should lay the underlay, it must be placed on the walls, and then cut off. The joining is carried out without overlaps, so as not to create unevenness.

Laminate layout

Laying the lamellas begins from the door, if it opens into the room, or from the corner. The most optimal method is considered to be “in the direction of the light” or “in the direction of travel”. Diagonal layouts usually lose in appearance and require more material.

A gap of 1 cm must be maintained between walls, heating pipes and other obstacles; for this, special wedges can be inserted into the seam.

It is not recommended to make the seam larger - this way the baseboard may not cover it.

The laminate should be laid in rows, that is, first the lamellas are connected sequentially one after another (along the narrow side). Then the next one is also assembled, only after that the two adjacent rows are joined.

Most modern laminates are designed for interlocking installation, which means that no additional tools are required to fasten the slats together. Docking can be done by hand; in some cases, you can seat the element with a rubber hammer.

Each subsequent row is shifted by ½ (classic laying) or ⅓ (half laying) relative to the previous one.

You need to make round cutouts for the heating pipes.

Types of flooring

The underlay is a material that is used as an additional layer between the base and the finished floor.

Today, the market offers a huge number of different types of flooring, for every taste, color and budget. And what’s interesting is that the development of innovative technologies contributes to the emergence of new, increasingly high-quality and practical varieties. So, when you visit a construction market, you will have plenty to choose from.

The most popular types of floor coverings include:

- laminate;

- parquet board;

- linoleum;

- massive board;

- ceramic tiles;

- carpet;

- A backing is also required for wooden joists.

Having a floor covering is, of course, good, but the quality and practical characteristics of floors can be made even better. To do this you need to use a substrate. The underlay is a material that is used as an additional layer between the base and the finished floor.

Installation of skirting boards

The plastic plinth with cable duct consists of two parts. The first is a wall mount, and the second is a decorative attachment that snaps on top. There is another type of fastening - first, metal brackets are attached, and then a plinth is put on them.

We drill holes for dowels approximately every 30 cm and fasten one part of the plinth. We fasten the main part, hide the wires, then put on the decorative attachment. For a beautiful connection, we use special components for the plinth: adapters, external and internal corners, plugs.

We put a special lining around the pipe to hide the gap (it costs about 50 rubles). In our case, the pipe was very close to the wall, so we had to trim the baseboard and saw off the lining, and then glue it with liquid nails.

Buy the plinth and all components together with the laminate. Otherwise, if there is a shortage of material, you will have to visit many stores before you can find the right color.

And the final touch is to attach the threshold to the door. It is needed to hide the height difference between rooms. The rules for laying laminate flooring require separating different rooms with a gap so that the coverings are independent. However, in practice, if the same covering is chosen for adjacent rooms, you can not use the threshold, but do everything without seams: it will be prettier and easier to clean. If some kind of defect later appears, it is more convenient to actually saw off the coverings in the doorway.

Errors

If we insulate the floor and ceilings correctly, this will ensure a long service life of all materials used without any unpleasant stories in the form of moisture accumulation or cold penetration. A typical mistake made by beginners is inattention when following the stages of laying materials, which can lead to their premature wear and the need to start all over again.

To prevent this from happening, it is important not to forget which layer of the “pie” follows which, especially if a novice master is doing this for the first time in his life

If you want to provide not only thermal insulation, but also enhance the sound-absorbing properties of the “insulation pie,” it is important not to forget to add two plywood layers to it, which will ensure the creation of a good sound barrier. If expanded clay is used as the main material, during the course of work it will be necessary not to lose sight of an important part of the structure in the form of a concrete screed, which will prevent its premature shrinkage and protect it from excessive moisture absorption