Rafter legs are responsible for the integrity of the roof, so the quality of the material and its resistance to loads and bending resistance are important indicators when installing roofs. Splicing rafters along the length should not affect the strength of the structure. Let's figure out how to do this correctly, consider the types of wood from which rafters are made, and show how to calculate their length.

Rafter system Source www.stroimdom.com.ua

Types of wood for roofing

For rafter installation, depending on the purpose of the object, the following types of lumber are used:

- Clean-edged timber, two-edged and four-edged.

- Edged board.

Coniferous wood, for example, larch and pine, is most often used in the construction of rafter systems. It has sufficient strength, is easy to process and resists rotting. Before laying on the roof, the material is treated with a special impregnation.

A standard board is 6 meters long, a beam is 3 meters long.

Defects affecting the quality of lumber:

- Knots – technical conditions regulate the number of knots in the board, which does not affect the strength of the structure.

- Wane - for rafter structures it is completely cut off.

- Cracks - occur from improper drying or cracking in the cold. This material is not suitable for roof installation.

- Rot and fungus - from improper storage in damp conditions - are rejected.

The edged board must be free of defects Source yandex.net

Having chosen the right lumber, we begin measuring and splicing the rafters.

Practical advice

It has already been mentioned that the bending strength of the rafters at the splice is always less than that of the whole element. If possible , try to place this node as close as possible to the ridge, Mauerlat or various spacers . Such precautions minimize the risks of mechanical destruction of the rafter leg. If this possibility is not available for one reason or another, then it is not recommended to place the stop under the splice at a distance of more than 15% of the leg length from either end.

The node is located on the Mauerlat

Never use black self-tapping screws for connections . This metal has two significant drawbacks. The first is that it quickly oxidizes and loses its original strength. Secondly, the manufacturing technology of such self-tapping screws involves hardening. When the permissible load is exceeded, hardened screws do not stretch, but burst. During the operation of the roof, the relative humidity of wooden structures changes, and the thickness of the boards fluctuates accordingly. And this can significantly increase the tensile force of the self-tapping screw; it will not withstand it and will crack.

Black screws should not be used

Do not overdo it with the amount of hardware . If there are too many of them, then the holes will significantly reduce the strength of the parts being connected, as a result you will get the opposite effect, the build-up will not be strengthened, but weakened.

Calculation of rafter sizes by length and cross-section for the correct selection of lumber

At the design stage, the rafter system considers the options for lumber and the layout of their arrangement in the rafter structure. Further work on laying insulation, insulation and roofing depends on correct calculations. Resistance to loads during operation of the facility, resistance to atmospheric changes and tectonic influence also play a significant role. Therefore, the calculations and selection of high-quality lumber are approached very responsibly.

To calculate the required length of the rafters, determine the angle of inclination of the roof slope and calculate the height of the roof. The small size of the house will allow the use of solid boards and timber to create a rafter structure. With a wider bevel in a large structure, the length of the lumber may not be enough. Then they use splicing of two pieces of wood to make a rafter leg of the appropriate size with a small margin.

Calculation formula for calculating the length of rafters Source orchardo.ru

The size of the span between the ridge of the house and the top of the wall corresponds to the length of the rafter. The cross-section of the beam is determined based on the size of the loads and the distance between two adjacent rafter legs.

The load on the elements is created by the weight of the roof, for example, made of ceramic tiles or asbestos-cement slate. Such materials require an increased cross-section of the timber.

Example:

- The length of the beam is 6 meters.

- The end section is 10X20 cm.

- The distance between adjacent bars is 140 centimeters.

Tools and materials for work

Before performing the main work of cutting out locks, it is necessary to take into account and prepare all the necessary tools so that they are at hand at the right time.

What you need for work:

ruler and square;- marker;

- axe;

- chisel;

- chainsaw;

- electric drill;

- stationery knife;

- chisel;

- bolts, nuts, a key for them;

- antiseptics and fire retardants.

You may also need a sander or sandpaper to smooth the cut surfaces.

Scheme of the truss structure

Along the perimeter of the wall, a mauerlat is laid - a beam, which takes on part of the load-bearing function, evenly distributing it onto the load-bearing walls. The bases of all structural elements will be placed on it.

Purlins are laid across the building; the same purlins will serve as support for the rafter legs in the middle of the structure.

They raise trusses, pre-installed on the ground, that will hold the ridge and attach them to the mauerlat.

They install supports for the ridge, lay the ridge and attach diagonal, intermediate rafters to it.

Strengthen the structure with the help of struts, supports and crossbars.

Racks for rafters Source domdkm.ru

Rafters are laid on the structure, taking into account the design distance between the individual beams. The ends of the legs rest against the mauerlat, and the top is sawed off and connected with metal fasteners at the beveled corners. Waterproofing, insulation and roofing are laid on the finished base.

The correct location and methods of connecting the beams guarantee stability when laying insulation and roofing. Further operation of the facility largely depends on accurate design and correctly selected lumber.

It is preferable to lay spliced rafters when installing steep roof slopes, where atmospheric loads are several times lower than on flat slopes. Flat slopes in winter are loaded under the influence of snow, which puts pressure on the lumber under the roof.

Preparing blanks for gluing

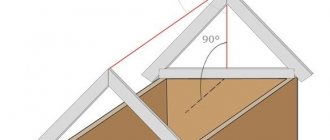

In order to avoid problems with glued solid wood, it is necessary to align the workpieces to a right angle of 90 degrees. The edges of the workpieces should be clear and smooth. The more carefully this work is done, the better the product will turn out. If the workpieces are not prepared properly, the entire panel will eventually take on the shape of a bowl in width. Problems may also arise when gluing and tightening workpieces into an array.

To level the workpieces, use a plane, jointer or circular saw.

Design features of splicing rafter legs

The rafter leg is the distance from the top level of the wall of the building to the ridge of the roof. If overhanging rafters are provided, the length of the board or beam should be increased to the specified length.

Table of length and thickness of rafter legs Source postroyka-dom.com

By connecting pieces of plank, the required size of rafter legs is achieved. It is taken into account that the connection node behaves like a bending hinge, so the joint should be located in an area where there will be no bending stress. The calculated location of the joint near a support, crossbar or other element that relieves the load. The beam must have a sufficient margin of rigidity along its entire length.

Additional support is provided between the Mauerlat and the ridge. The connection distance from the support is 1/6 of the length of the entire board. Adhering to the specified parameters, they ensure uniform rigidity on the supports.

Hip and half-hip roofs with diagonal rafters are mounted from longer and stronger timber, which serves as a support for short roofs. You cannot splice splices, only solid timber.

Rafters are increased in length in several ways, which are used taking into account the construction features and the need for load resistance.

Splicing methods:

- Direct docking - on short slopes;

- Oblique cut - for timber;

- Overlapping - suitable for boards;

- Double splice - board only.

Joining with an oblique cut Source build-experts.ru

See also: Popular designs of houses with a gable roof and an attic.

For work, a miter box is used that ensures precise cutting at a given angle.

Direct docking

The method allows you to build up an element of any length using different overlays. Parts of the overlays can be removed from disassembled formwork, trimming lumber or remnants of laid rafters. It is allowed to choose a board or three-layer plywood as an overlay.

Direct docking Source blog-potolok.ru

Sequence of work:

- The joint is cut strictly at a right angle to ensure the most even joining and to prevent deflection under full load on the connecting unit;

- The cuttings of the board serve as overlays, which are secured to the timber with pins.

- Prepare a level area of sufficient length in advance. The beam or board is placed on a flat surface, placing bars under it, 30 centimeters high, so that when cutting with a circular saw it does not touch the ground;

- Select overlays. For overlays, cut boards or three-layer plywood are used after removing the formwork. The length of the overlay is calculated as four times the width of the board. And if the roof is planned to be insulated with mineral wool or it will have a slight slope, then the loads on the structure will increase, and the length of the linings should also be made longer;

- The cut part is joined to the second half, pressed tightly and covered with connecting pads. The boards usually vary slightly in thickness, so during the preparation process, the edges are lightly filed or sanded.

Joining and connecting boards with overlays Source obustroeno.com

Important ! When cutting, the board should not delaminate or break; the cut should be smooth, without nicks or burrs.

- The entire structure is clamped with clamps and the studs are driven in, tightening the nuts until they cut into the wood. The use of nails is not recommended due to cracking of the wood and weakening of the tensile properties of the finished element. The studs take at least 8 mm; a smaller size will not sufficiently strengthen the joints, and a larger size will push the layers apart;

- It is recommended to take wide washers and recess them into the wood;

- The amount of fasteners should not weigh down the element too much, otherwise you will have to order a recalculation of the project;

- It is permissible to additionally glue the plywood onto the board and compress it with clamps until the glue dries completely.

See also: Companies specializing in attic reconstruction and roofing materials.

Oblique cut

A beam with a large cross-section does not lend itself well to direct joining, so the beams are joined together along the length using the oblique cutting method. The name of the technology comes from the type of trimming of the ends of the timber.

Rules for splicing with an oblique cut Source krovgid.com

Stages of oblique cutting:

- Measure the distance at which the cut will be made. This is necessary so that the finished elements match as much as possible without the slightest gap. Mark the cut location on both ends of the beams with a pencil;

- The ends are cut at a certain angle, using a miter box, so that the angles coincide as much as possible along the cut, usually this is an angle of 45°;

- The beveled ends are joined, achieving maximum coincidence of the planes. Secure with a clamp;

- Drill a through hole, one millimeter smaller than a pin or self-tapping screw, so that it enters with difficulty, without moving the wood fibers apart. This condition will allow you to avoid play during installation and subsequent operational loads;

- The cut is tightened with self-tapping screws or pins and washers of sufficient width so that they do not subsequently become buried in the wood and lead to weakening of the structure. It is recommended to place a ring under them.

Overlapping

The method is suitable if the question arises: how to join two boards. The rigid connection of the structure makes it popular in many construction operations. The method is quite simple - two boards are laid overlapping one on top of the other.

Overlapping splicing Source obustroeno.com

Selecting a splicing scheme depending on the load on the finished product

If the product will only be subjected to compression, then it is enough to use the simplest type of splicing, connecting the parts with an overlay (oblique or straight cuts). To increase the resistance of the product under lateral loads, a rim lock type connection is used. In this case, an overlay is made using beveled ends or with an end tenon.

For products designed for tensile loads, padlock connections (notched or simple) are used. To perform it, recesses and protrusions are cut out on the workpieces to be joined. The serrated rim lock design allows for high joint strength that can withstand compressive, tensile and lateral loads.

The double pan joint is a straight overlay with a tenon called a dovetail. Shows high strength under different loads - lateral displacements, tension and compression.

The “sliding lock” connection scheme in the form of an overlay with a beveled stop can impart strength to a product subject to tension and lateral loads.

There is a scheme in which increased rigidity of the structure of overhead locks is achieved by driving additional wedges between the protrusions. Such locks are called tension locks. They are made either detachable or glued together. Detachable tension locks should be oiled or painted, which will help protect the lock from moisture.

Video description

This video will tell you how to join rafters and make calculations:

The advantages of such joining are the simplicity of the operations; it can be done even by a non-professional at a home construction site.

Double splice

There is also a rather interesting method of lengthening - composite rafters. It is performed using boards and short pieces of boards. The advantage of this method is virtually waste-free construction when the shortest elements are used.

Double splicing method Source yandex.net

How to join boards with glue

A very popular method of joining boards and bars is longitudinal and transverse gluing. When connecting boards with the wide side, the end can be smooth, although in most cases a tongue-and-groove profile is used. It is very important to tightly fit the parts so that the glue layer is as thin as possible, this is the only way to achieve maximum strength. Sometimes a small amount of cotton fiber is applied to the end, lubricated with glue, this improves the quality of the coupling.

The boards can also be joined in profile, but this will require wedge-shaped gear cutting of both ends with the teeth offset to the floor for different parts. At home, this operation can be performed using a hand router.

To glue the parts together, casein glue or high concentration PVA is used; to give strength, sifted wood flour is added to the adhesive. The surfaces are covered with glue and kept in air for 3–5 minutes, after which they are placed under pressure or squeezed with clamps. This connection is stronger than the wood itself and never breaks along the joint.

Video description

In this video you will see what methods of connecting rafters can be used:

Connection of logs and beams in length

Splicing timber and logs along the length has deep roots in ancient methods, when only log cabins were built. Our ancestors knew how to extend the rafters correctly. This is evidenced by ancient wooden buildings that have survived to this day.

Stages of connecting logs:

- Trim the edges of the logs so that they fit snugly together;

- Drill a hole for the pin at the ends;

- The size of the hole should be 1-2 mm smaller than the insert so that the pin fits tightly into place without splitting the edge;

- Insert the pin and connect the logs tightly.

Connecting logs and beams with a direct lock:

- Cut out grooves at the end of the timber being joined;

- Carve out the corresponding size in another;

- Connect the grooves and secure them with studs or clamps.

Connecting beams to each other Source masterbrusa.ru

They also join together with an oblique lock and a wedge.

Each connection is very strong and can be used in rafter legs. The fit must be precise. Filling cracks and chips with wood chips or other material will reduce the durability of the timber. It will become unsuitable for laying rafters. For a clear result, the cutting locations are measured and marked in advance.

What rules should you follow?

In addition to the basic calculations for the length of the beams and cutouts with which the connection will be made, it is necessary to take into account other nuances that make it possible to lengthen and install the ceiling efficiently.

- To join beams, choose wood of the same species and preferably the same color, if the beams will not be hidden under the finishing. Different types of wood behave differently, some are stronger, others are more prone to cracking.

- The moisture content of materials should not exceed 15%. It must be dried wood that will not dry out during use, forming a gap in the clutch area. If it is not possible to achieve the same indicator for 2 bars, the difference should not exceed 3%.

- The wood chosen is of high quality, without defects, blue stains, or rot. You shouldn’t take risks trying to save money, especially when it comes to attic flooring.

- Before installing beams and connecting, lumber must be treated with an antiseptic and fire retardants.

- After gluing the parts, the remaining adhesive must be removed on site. Once it dries, it will be more difficult to clean the surface.

- Splicing is done vertically relative to the front side. That is, the cut itself must be parallel to the wind flow to avoid blowing through the gap.

- At the junction, a layer of insulation is laid before the connection. The wood should not touch each other at the cut site. If parts of the timber begin to dry out, the insulation in the lock area will prevent blowing.

- The timber for splicing is chosen to be of one caliber (one thickness).

- The extended beam should not thicken at the joint.

- The splicing of beams must be done in a running start, not in one line, so as not to create pressure on one, the most vulnerable section of the floor.

Briefly about the main thing

Splicing rafters provides significant savings in construction wood. There will be a minimum of wood waste left on the construction site.

There are several practical options for splicing rafter legs, each of which can be used during the construction of a house:

- For boards: overlap or double splice method;

- For a log house: direct joint or oblique joint.

When installing a rafter system, it is important to remember that the connection with fasteners should not weigh down the elements so much as to become problematic for the overall weight of the structure under the roof.

Proper rafting provides the same load resistance as solid timber.

Key points in creating an artificial array

So, you have set yourself the task of assembling several (maybe even several dozen) boards together so that the finished panel looks like one whole artificial mass.

Wide pieces of blanks are not suitable for merging into an array. Since wide workpieces can be more noticeably deformed in case of changes in atmospheric humidity or the humidity of another external environment. The finished, glued array does not deform (but it can) if gluing is done correctly.

You can avoid warping of the array by changing the direction of the growth rings in the bars across the entire width of the array.

If you choose a straight board without flaws, this will greatly facilitate the process of merging into an array. Be careful when choosing lumber to avoid unpleasant “surprises” when the work is almost finished.

Gluing should be done in such a way that the joints are almost invisible.

Composite option

Overlapping rafters can be connected in another way. In this embodiment, the element not only lengthens, but also its cross-section increases. Here you need to join not two, but three boards. The essence of the method is as follows:

- Two other boards are overlapped to one board at both ends. Between the extended components there remains a space that is equal to the thickness of a single element. The result is rafters with different sections at the ends;

- Tabs are installed in the gap between the double components. Their length should be twice the thickness of a single board of spliced rafters. The distance between the tabs is made at least twice their length;

- Mineral wool or jute can be tightly placed in the remaining space. This layer will compensate for wood shrinkage;

- Fastening is carried out using nails arranged in a checkerboard pattern.

This method of splicing rafters is characterized by the fact that a thin end is obtained at the top, and a thick, reinforced one at the bottom. This design option is used when constructing a sloping roof and when installing diagonal rafter legs.

Butt connection

This method is perfect for splicing rafter boards. When connecting butts, a special overlay is used.

Before splicing the rafters, it is necessary to cut off the joining ends of the beams or boards strictly at right angles. This is done so that a deflection does not form at the junction of the rafters under load.

The ends of the spliced rafters are fixed using overlays made of boards or metal fasteners. They should be installed on both sides of the joint. The overlays must be nailed in a checkerboard pattern.

Electric two wheel skate

A skateboard on 2 wheels, as the surprisingly successful hybrid of a skateboard and a Segway is called, is intended for an active person of any age. An electric skate is an ideal way to travel in urban areas and at the same time the best entertainment.

These designs have recently surpassed even the beloved skateboards in popularity, being not just a sports equipment, but a universal and functional vehicle.

The main advantage of electric skateboards on two wheels over other types of individual electric transport is their low weight and size.

The device of an electric two-wheeled skate

Externally, a skateboard that rides on its own is not much different from a skateboard, but its platform is located not in the direction of movement, but across it. The rather large wheels are independently driven by separate electric motors powered by high-capacity batteries.

The control of the device is based on the principle of self-balancing, for which the gyroscope is responsible. By slightly changing your body position, you can control the electric skateboard, i.e. there is no need to push off the ground with your foot.