The main building material for a bathhouse is wood. And there’s nothing to say about its interior decoration. Traditionally, both the dressing room and the main part of the bathhouse, the steam room, are lined with wood. But comfortable and beautiful wooden finishes must be protected and preserved, especially in conditions of high humidity. To do this, wooden parts are impregnated, varnished, and painted. Nowadays, it is not so easy to understand how to paint the inside of a steam room in a bathhouse. Modern materials have appeared that reliably protect wooden structures and do not harm the health of bathhouse visitors.

All wooden surfaces inside the bathhouse must be treated with protective compounds Source bane.guru

Criterias of choice

For all its advantages, wood is susceptible to moisture. Over time, it dries out, darkens and begins to rot. Mold and microorganisms may appear on it. All this is true for normal external conditions. And in the steam room the conditions are extreme. Even in the dressing room there are no such impacts on the walls and floor. The influence of sudden changes in temperature and humidity in the steam room accelerates the destruction of wood. When exposed to high temperatures, conventional protective coatings can release harmful substances.

In addition, a steam room is not just a room in which a person is located. He remains there naked, his body in contact with wooden surfaces. And on some it even lies. This means that for shelves and benches you need to choose wood protection that will not be unpleasant upon contact.

Most often in the steam room they try to preserve the natural color of the wood, selecting species that look beautiful. But if you want to paint part of the steam room, then you need to take this into account when choosing an impregnation. Not every impregnation is suitable for subsequent painting.

Wood color after different impregnations Source elka-palka.ru

It is clear that it will not be possible to find the same impregnation for a bathhouse outside and inside. Even different parts of the steam room may require different protective equipment. Wood treatment in a steam room should be carried out with compounds adapted to its conditions. And the choice must be based on the following criteria:

- Which part of the steam room is the product intended for?

- Will it be primary impregnation of wood, or re-coating of a previously protected surface?

- Method of applying a protective substance to a wooden surface - with a brush, roller or spray

- Are there plans to further paint the impregnated wood?

Working with the area around the stove

In the area of the stove, the operating conditions for finishing materials are the most difficult relative to temperature. Therefore, the requirements for them include heat resistance and the absence of the ability to spontaneous combustion. The choice of protective equipment should be based not only on heat resistance, but on the properties of the screen.

Thus, for metal it is important to consider additives aimed at preventing the occurrence of corrosion. Brick with masonry mixture and grout in the joints between tiles must be treated with water repellents. It is better to additionally impregnate drywall or mineralite with antiseptics. Wood, as a rule, is not left open in this area due to its flammability, which cannot be reduced to zero.

Ceiling

Perhaps the least requirements are placed on this part of the steam room. It is exposed only to the temperature effects of steam. Water almost never reaches it. Therefore, it can simply be coated with a specialized bath varnish.

The ceiling in the bathhouse must be reliably protected from dampness and temperature Source eco-ceiling.ru

See also: Catalog of companies that specialize in paints and varnishes.

Floor

Unlike the ceiling, all the water that is used in the steam room ends up on the floor. Therefore, the anti-water protection for floor boards must be very good. In addition to antibacterial and anti-water impregnation, it is advisable to cover the floor with a protective layer of varnish. But not every varnish is suitable for the floor. The protective layer should not be slippery. This is a must to protect the floor. Of course, the soles of your feet should not stick to the floor. Do not think that repeatedly coating the floor with varnish increases its safety. The thick layer of varnish cracks and water reaches the wood. In addition, the wood cannot “breathe” through such a coating and will still deteriorate.

When building a bathhouse, do not forget about impregnating the logs on which the floor boards are laid. This, of course, is not the inside of the bathhouse, and there are no special protection requirements for them. But if water gets to them, then sooner or later the floor inside the bathhouse itself will suffer, no matter how well it is protected.

Walls

Most of the impregnation for the bathhouse inside is spent on protecting the lining, which is usually used to line the walls. Therefore, you should not use impregnations and varnishes that, when heated, can release strong-smelling substances. And do not cover it with a protective layer that does not allow the wood to “breathe.”

Improper use of protective compounds can lead to the regular appearance of condensation on the walls of the bath Source synteko.in.ua

Shelves and benches

The shelves are the main part of the entire steam room, for which it is, in fact, built. Lying on it should be comfortable, pleasant and safe for health. Wood is a poor heat conductor, so even at high temperatures you won’t get burned by it. It’s another matter if it is covered with a protective film, which can cause a burn if touched. Therefore, it is not recommended to use paints or varnishes for it. It is better to apply a special impregnation for the bath. Often such impregnations are wax-based.

The requirements for the safety and convenience of the surface of shelves and benches are so high that there are bathhouse lovers who believe that wood should be natural for them and not covered with anything at all. But this is still suitable for small bathhouses, where simple shelves can be replaced. And when real furniture masterpieces are built, it is better to find a high-quality composition and ensure their durability.

It’s not enough to create beauty – you also need to protect it Source m.yukle.mobi

How to update the lining

Over time, the appearance of untreated lining ceases to please the owners. Wood tends to darken from moisture, but there is also soot that eats into the wood. For those who are no longer satisfied with this state of affairs and have decided to update the lining in the bathhouse, we have found tips that will help cope with any problem.

How and with what to remove soot

When carbon is not completely burned in a furnace (completely is CO2 or CO), it is released as an amorphous substance that we call “soot.” Soot deposited on the walls is soot.

Cleaning the lining in a bathhouse from soot is more difficult than it seems at first glance. It eats firmly into the wood. And when you try to wash it with soap and a brush, cleansing does not happen.

There are two proven methods for removing soot - mechanical and chemical.

Mechanically, everything is clear - the contaminated surface must be scraped off using any available method. Either manually or using a power tool - the same grinder with an abrasive wheel. As a result, the top layer of wood is removed, revealing a clean surface, and the result is what you need.

The chemical method does not require physical effort and takes much less time. On sale you can find products that were developed specifically to eliminate soot or soot from a fire.

As an example, let's name SYNTILOR Fuoco, DOCKER MAZBIT PLUS, “Facade Cleaner No. 2” from and the like.

The video clearly shows how the first of these tools works:

But here’s what’s interesting: all compounds that remove soot and soot contain... alkali as the main active component. No one says the composition, but there are just one or two strong alkalis, and their qualities are approximately the same. We mean sodium and potassium hydroxides - KOH and NaOH.

There is nothing stopping you from buying them at a store cheaply, diluting them with water and washing off the soot from the wood.

VERY IMPORTANT! If you don’t want chemical burns, don’t even try to work with alkali without covering your arms and legs with clothing, gloves and glasses. Chemical burns are worse than thermal burns, or rather deeper. And keep an acid solution nearby - vinegar, dilute citric acid - so you can immediately pour the place where the alkali got in. There is no use in rinsing with water!

After the soot disappears, be sure to wash off any remaining lye from the wall. We recommend doing this first with an acid solution (vinegar, lemon) so that the residues are neutralized, and then with clean water.

There is another way, but we like it even less than dangerous alkali. We are talking about a mixture of gasoline and washing powder with water . You already have a fire-hazardous building with a stove; soaking it in gasoline seems unnecessary.

But if you need to wash, say, a fireplace brick , but there is no alkali on hand, you can mix two tablespoons of washing powder, 100 ml of water, 100 ml of gasoline, then vigorously shake the mixture in a bottle and start scrubbing.

In general, it is clear that soot and soot are removed by degreasers. Yes, by the way, burnt baking sheets are washed in the same way as lining - with alkalis.

How to wash the paneling

We have already recommended a way to get rid of blue stains and lighten darkened wood using bleach (by the way, this is just a solution of sodium hypochlorite, bleach - you can prepare it yourself from powder).

BY THE WAY! If someone starts complaining that chlorine vapor will continue to be inhaled for a long time, don’t believe it. Because the smell (and therefore the volatile substances) disappears quickly, and there is no more cause for concern than when working with “Whiteness” at home. But it’s better not to pour it on your hands, of course.

You can do without bleach altogether if you walk over the darkened lining with a sander.

If the task is to get rid of sweat, grease and the like, then it will be enough to wash the lining in a bathhouse with a strong solution of laundry soap . Moreover, what is interesting: laundry soap contains residues of alkali from the saponification of vegetable fat (that’s how it is obtained), so it is not neutral, but slightly alkaline. So it turns out that you are again using alkali, only weak.

Some people may find washing with soap a long time - then just increase the alkaline component. Following the safety precautions described above, of course! Maybe you have a “MOLE” - breed it.

***

This is such a chemical and not only educational program. Like, share links with friends and subscribe to our channel in Telegram.

Protective compounds and their properties

For the sake of order, it is necessary to mention such a remedy as drying oil, which used to cover all the insides in the bathhouse. It is still used today, but it should not be used in a steam room. It will be cheap, but cheerful. In terms of protective properties, this is yesterday, and the smell from it when heated well is not pleasant.

Water-dispersed impregnations

They are made on a water basis, so they penetrate deeply into the wood structure. They are resistant to high temperatures, do not contain active chemical components and do not emit any harmful compounds when heated. Modern water impregnations contain antibacterial components. Available both colorless and with added dyes.

The disadvantage is their fragility. Over time, under the influence of water, they are washed out of the wood, so the impregnation must be renewed every two years.

Oil impregnations and varnishes

They impregnate and protect wood well from moisture, forming a film. But their inherent smell is a significant drawback. Therefore, they must be used with caution in the steam room. They are quite suitable for external impregnation and for protecting wood in the dressing room.

The varnish preserves the appearance of the wood, giving it a mysterious shine Source freepatriot.club

Acrylic based varnishes

Acrylic varnish for baths inside is considered safe. A modern product made from polyacrylates and organic solvents. Environmentally friendly and more durable than conventional water-dispersed products. Acrylic varnishes produced for baths and saunas necessarily contain antifungal components.

Water-based polyurethane varnish

Combines the advantages of water-dispersed and alkyd varnishes. It appeared on the market relatively recently, so it should be treated with caution, as with any new product. And its price is quite high.

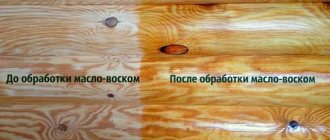

Wax-based impregnations

Wax, like drying oil, has long been used to protect and add shine to wooden surfaces. Nowadays purely wax impregnations are almost never used. It is common practice to add wax to protective products based on other components.

In addition to protective products, special detergents are also produced for cleaning and bleaching wood. They are used both before applying protection and for washing dirty and darkened surfaces.

Water-based polyurethane varnishes

When thinking about how to impregnate the inside of a bathhouse, you can pay attention to these new products on the market. They contain resins, water and solvents. They are not afraid of temperature or salt. Such varnishes are distinguished by the absence of cracks and peeling even for a long period of time after application. A relative disadvantage is the high cost, which is offset by its undeniable advantages - versatility for all rooms, ease of application and high performance characteristics.

Protective products for baths from different manufacturers

When processing wood inside a steam room, you should not experiment too much. You need to choose varnishes and impregnations made specifically for baths and saunas. Those who produce such products take into account the conditions and requirements for such premises.

The Finnish company Tikkurila is considered the leader of such products.

- Supi Saunasuoja – water-based impregnation with acrylic. Suitable for temperatures above 100 °C. A universal product for internal protection of steam rooms. Available in both a colorless version and a form suitable for tinting.

Impregnation Supi Saunasuoja Source marketut.ru

- Supi Laudesuoja – oil impregnation suitable for covering shelves

- Supi Saunavaha is a wax-based varnish. It is also considered universal and suitable for any bath surfaces.

Imported compounds have one drawback - the price. Domestic manufacturers provide cheaper products. Here are some designed specifically for bath conditions:

- Senezh sauna is an acrylate-based antiseptic to protect wood in saunas. Contains antimicrobial agents but is odorless.

- NEOMID 200 – antiseptic for wooden bath surfaces, including shelves and benches.

- NEOMID Sauna is a translucent acrylic-based varnish. For protecting and finishing wood in rooms with high humidity.

NEOMID Sauna varnish for baths Source gros-stroi.ru

How to treat bath shelves

Bath shelves are the place where your body will directly touch the wood, so you can treat bath shelves with the best natural impregnations. In most cases, they are made from vegetable oils and wax.

— In order to treat the bath shelves in the steam room, you can buy SATU for the shelves, this is a colorless protective oil that is absolutely harmless to the body. On sale 0.25 liters, cost 400 rubles. The shelves are treated with this oil in one or two layers according to the instructions. Other manufacturers also have similar oils for shelves - TEKNOS Sauna NATURA oil, etc. But the German company Biofa produces liquid wax, which is also very suitable for treating shelves in a steam room. A 0.2 liter jar will cost 1100 rubles, consumption 70 sq.m. per liter

Care Tips

In order for a bathhouse to serve its owners for many years and decades, it is necessary to adhere to certain rules. Some of them are common to any building:

- maintaining cleanliness and order;

- timely restoration of paintwork;

- necessary routine repairs.

The other has a specific “bath” character:

- ventilation and drying of the steam room after use;

- timely culling and replacement of stones in the heater;

- cleaning the stove and chimney from soot.

The last point can be implemented “with your own hands” without inviting a professional chimney sweep. In order to use the bathhouse for its intended purpose, it is enough to heat the stove with aspen wood during the breaks between fires. According to experts, aspen firewood perfectly cleans the stove and chimney of soot deposits.

What do consumers think?

Larch in the bathhouse has received a huge number of positive reviews. Most consumer reviews of larch wood coverings are positive, which once again confirms the practicality of the material. The attitude of 90% of consumers towards wood flooring can be expressed in literally three reviews from individuals that were collected online:

- About a year ago I was renovating the bathhouse and decided to use larch as a covering. Before this, there were oak boards in the steam room, but literally three years later a fungus ate them. I’ve been using the sauna for a year now and the floor hasn’t even darkened yet;

- I never thought that inexpensive larch would surpass beech in its technical qualities, but this is a fact. In the bathhouse, I laid a tongue and groove board on the screed more than 5 years ago, I still haven’t replaced a single plank, everything is intact;

- Finishing floors with wood is always a risky undertaking, especially in a room where water literally flows onto the surface in a stream. But the larch exceeded my expectations; in the wash room I lined the floor with pine boards, but even under constant exposure to water it did not warp.

Of course, coniferous wood has many advantages compared to other types of materials. But in order for the coating to last a really long time, the laying of the boards must be carried out taking into account many nuances, which we will talk about a little later.

Construction and installation of a floor in a bathhouse on screw piles

Why carry out processing?

For the interior decoration of the dressing room and recreation area, you can use different materials - artificial or natural stone, ceramic tiles, porcelain stoneware, plastic panels, sawdust chipboards. Lining is more suitable for a steam room. Advantages of the material:

- high strength, durability;

- low thermal conductivity;

- attractive look.

Most benefits will be negated without special coverage. Processing the lining in a steam room is necessary to protect the material from the effects of:

- moisture;

- mold, mildew;

- fire (various fire retardants).

Using protective equipment you can improve the appearance of the lining.

Localization

The bathhouse consists of several compartments, some of which are highly susceptible to mold:

- Steam compartment. There is often no window or ventilation. The room dimensions are small, the temperature and humidity are high.

- Waiting room. Damp, warm room. Microclimate conditions are favorable for breeding large-scale colonies of molds.

- Shower room. A small room without windows. There is constant humidity around the pan, in places where water drains.

- The inner surface of the walls where the bath broom is hung. A damp object in an unventilated room takes a long time to dry, and dampness between the product and the side of the room remains for a considerable time.

- Joint of logs. If the bathhouse is built of timber, moisture accumulates between the structural elements.

- Bath shelves. Water often remains on the outer surface of products. If the liquid is not removed, a favorable environment is created for fungi.

Sauna owners were a little luckier. Dry air inside the steam compartment and high temperature conditions prevent the spread of mold.

Corner areas of the room are considered the most susceptible places. Even in a well-ventilated room, air flows in poorly. The ceiling often suffers from mold. Due to the accumulation of warm air masses, condensation appears. Moisture accumulates on the inside and drops form. Late detection of mold leads to a large-scale spread of infection to clean areas of the building.

The fungus often takes root on wooden materials and lining. Concrete and brick are less susceptible to mold, but there is a risk. No type of building materials is protected from damage.

Briefly about the main thing

To process lining in a bathhouse, materials that are resistant to temperature changes, humidity, and washing are used. Also important is inertness to fungus, mold, bacteria, and a safe composition for humans.

When heated, many materials release toxins and other harmful substances, so the use of antiseptics, fire retardants, drying oils, varnishes with solvents and acrylic resins is unacceptable for the steam room.

For walls and ceilings, impregnations, mastics, oils and some varnishes are used. For shelves only oil or wax based formulations. This prevents the formation of a thick film to avoid burns.

Bleach is used in any room of the bathhouse, but before further processing of the wood, it is necessary to wait until the chlorine evaporates and the hydrogen peroxide decomposes.

Antiseptics and fire retardants are classified as pre-treatment agents for wood, but are not used as independent coatings. They protect the lining and help reduce the consumption of the finishing coating.

Source

Waterproofing concrete floor

In the sections of the bathhouse with the highest level of humidity - the steam room and the wash room - a concrete floor is often made with a porcelain stoneware finish; it is more reliable than ordinary floor tiles. On top of such a covering, you can lay several wooden gratings, making a collapsible flooring, which is periodically taken out of the bathhouse for drying. Concrete screed can be destroyed by moisture, so a layer of waterproofing is required between it and the finishing coating.

Waterproofing begins after the screed has dried.

When arranging it, a slope is formed towards the drain, but there should be no depressions or bumps on the surface, and it must be thoroughly cleaned of dirt. The technology for screeding with a slope is the same as when leveling the floor on an open balcony. To reliably protect the screed in a bathhouse, it is recommended to combine coating waterproofing with lining waterproofing.

- First, mastic is applied in 2-3 layers, and if the first layer is spread in the longitudinal direction, then the second layer is spread in the transverse direction. Rolled material is glued on top of the mastic - PVC film, membrane, roofing felt

You can also limit yourself to applying bitumen, bitumen-polymer mastic, or use penetrating waterproofing, which seals the pores of concrete.

Instead of expensive concrete or polymer-cement penetrating waterproofing, you can apply liquid glass. It has excellent adhesion to concrete, fills all cracks well and is completely waterproof after hardening. The main disadvantage of this composition is its fragility; usually after 5 years the silicate mass is destroyed.

If a concrete floor is insulated with high-density mineral wool or extruded polystyrene foam, it is advisable to protect the insulation on both sides. A water vapor barrier membrane is laid on top of the rough screed.

Before finishing the screed, the insulation is covered with rolled waterproofing. It is advisable to reinforce the screed in order to reduce the load on the insulation, so the film or membrane must be dense enough so that it is not damaged by the reinforcing mesh.