Tile is a very durable and easy-to-use finishing material, especially in rooms with high humidity or high operating load. But the surface on which the tiles need to be glued is not always concrete or brick. Wooden floors and partitions are quite common in apartments. How, then, to glue tiles to wood and how durable will such a coating be?

Why is this necessary?

The combination of materials can be safely called unusual; such a choice of components for work is resorted to in several cases, namely:

- When the partitions of a building are built from durable plywood with a thickness of more than 10 mm, such sheets are an excellent replacement for plasterboard and are not always additionally sheathed with other materials before applying tiles.

- Laying this type of cladding is needed on boxes covering communications, hot or cold water, and heating. These frames are always made from rigid blanks.

- If the owner wishes to improve the appearance of the kitchen furniture, the base of which is created from the same layers of veneer, the tiles adhere perfectly to the cabinet doors, adding zest to the interior design.

Based on these situations, one can only imagine what grandiose problems will be solved. If you clearly understand how to glue ceramic tiles to plywood, even your wildest fantasies can be realized in a short period of time.

Option No. 2

If there are problems with the wooden base, you will have to disassemble the structure completely. This will allow you to replace floor elements that have become unusable, add and level joists, and update waterproofing and insulation.

It is important not to forget to leave a gap between the insulation and the floor boards for natural ventilation.

The further algorithm of actions will be the same as in the case of a floor in good condition.

USEFUL INFORMATION: How to choose wallpaper for the living room: interior design

Where can you glue ceramic tiles to plywood?

If necessary or strongly desired, the owner of the building can afford to use installation technology on walls, floors and even ceilings.

If the work is not carried out by professionals, then it is important to familiarize yourself with all the features of laying tiles, although the method of implementing the idea is not much different from classic installation, but there are still some nuances.

Plywood is considered an inexpensive material, and the process of constructing partitions occurs quite quickly. Thanks to such indicators, millions of owners of private houses plan in advance the creation of support structures from natural veneer for further application of tiles to the base.

Combine incompatible

Ceramics and wood are two materials with different properties, which, at first glance, do not go together:

- Ceramics are characterized by absolute waterproofness, for which they are preferred when tiling wet rooms and surfaces - bathtubs, showers, kitchen splashbacks;

- Wood is characterized by vapor permeability - the surfaces do not interfere with the natural air exchange between the room and the street, due to which a house made of logs and timber always has a favorable microclimate.

The complexity of combining these materials is obvious: wood constantly communicates with the environment (temperature, humidity) and reacts to it by changing its volume and size. It turns out that if you cover the floor or walls with impenetrable tiles, this property is lost, and the use of classic masonry mortar will only aggravate the situation.

However, a bathroom in a wooden house is no different from a similar room in a stone building, which means that the surfaces still need to be protected from dampness, and ceramic tiles for walls and floors made of wood cope with this task brilliantly.

Possible problems

When choosing adhesive for tiles on plywood, you should buy exactly the product sample that will not penetrate deeply into the structure of the material, otherwise the base may begin to delaminate or deform over time.

When working with large walls, it is important to take into account that plywood is quite flexible and under significant loads the overall level of the partition often suffers, this negatively affects the appearance of the room.

Professional builders carry out installation using elastic adhesives to avoid many problems, such as:

- Mechanical damage to elements.

- The slab falls away from the base.

- Cracking of seams between tiles.

Among the presented models of bulk powders and ready-made fixing compositions, you can choose the ideal option for a specific situation. Before going to the store, it is better to familiarize yourself in advance with the types of solutions, as well as the technical characteristics of specialized mixtures.

Why is there a need to lay tiles on a wooden base?

Is it possible to lay tiles on a wooden floor or not? No one will argue that it is best to make a stronger concrete base under the tiles, but, unfortunately, this is not always possible.

For most residents of old high-rise buildings with wooden floors, the only relevant question is how to lay a wooden floor (or strengthen the existing one) so that it can withstand additional load.

It is important! If the existing wooden base is shaky, and there is no way to strengthen it enough to make it strong, then the idea of how to lay tiles on a wooden floor needs to be buried.

Types and requirements for glue

If we glue tiles onto plywood, then it should be clearly understood that the material is considered mobile; to fix the tiles, a polyurethane composition is most often selected, which is distinguished by its elasticity; for example, Thomsit P 625 is worth mentioning.

This model does not assume the presence of water in the composition, so the base will not be subject to destruction, peeling or swelling. The adhesion of the two planes is at a high level; the coating does not lose strength even after several years of operation.

Ceresit CM 9 is considered an equally popular type of glue; one of the components is silane; this ingredient in the solution guarantees good results even in rooms with high humidity.

You can forget about fungus or mold in the joints; adhesion instills confidence in the owners of the building, and the seams are flexible and neat. Even when the frame bends due to seasonal temperature changes, the tiles do not fall off, and no mechanical damage was noticed.

Possible bases for tiles

Laying tiles on a plywood base is done using conventional technology, but the service life of this approach will be much less than desired.

It is worth immediately considering that wood is a natural component that breathes, i.e. its physical dimensions depend directly on air humidity and temperature. Along the way, there are a number of additional smaller factors that force you to think through each step in more detail.

The easiest way out of this situation is a plywood base. Plywood is made from wood, but after a number of chemical and thermal procedures it becomes almost impervious to any influences. Usually, immediately after installing the plywood, tiles can be laid at the location using conventional technology. The disadvantage of this approach is that plywood still has a small deformation amplitude, which is why the service life is still shorter than desired.

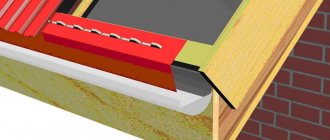

Magnesite boards and GVLV (moisture-resistant gypsum fiber sheet) require special attention. Initially, a layer of vapor barrier is laid on the walls (the rough side of the membrane is directed inward, and the smooth side is directed outward), then the slabs and the installation process. This option is the most difficult to implement, so this is what needs to be described.

Liquid nails are a quick but unreliable option for attaching tiles to wood. The service life of such fixation is no more than 2-3 years.

When working on the floor, you can organize an additional level of independent screed. It will only take 7-8 cm of space, but the effect will be 100%. “Floor” extruded polystyrene foam is laid out at the feet so that all joints are perfect, and if the house is more than 5 years old (time for complete shrinkage), then it can be immediately fixed with dowels. At the very end of the process, a self-leveling screed is poured and left in this position for 3-5 days, depending on the time of complete hardening.

You may be interested in: Finishing ordinary walls with stone

Liquid nails are a universal glue for such situations, but due to the fact that the wood “plays”, this option remains the most unreliable. First, the walls are leveled and primed to ensure a joint, and after that the tiles are immediately fixed. The use of this option is determined by the need to get the finished result “today and now”, because In less than 2-3 years, everything will have to be redone.

Suitable adhesive

When seriously thinking about solving the question of how to glue porcelain tiles to plywood, you should carefully familiarize yourself with the composition of the fixing mixture; it should include components such as: fiberglass, silane, microfiber, silicone or other highly elastic additives.

Experts believe that the following are ideally suited for the process:

- Liquid Nails.

- Polyurethane foam.

- Styrofoam shavings and acetone.

- Liquid glass.

But specialized tools were created for gluing tiles to plywood, so if you have an unlimited construction budget, you should purchase them.

Finishers advise using liquid mixtures so that when applying the elements, the fixing base can independently fill cracks or hard-to-reach places. The need to tap the tiles is eliminated, which reduces the risk of cracks in fragile components.

Simple and complex solutions

To understand all the intricacies of the process, how to glue tiles to walls or floors, you can use the advice of professionals. These people had encountered many different house and apartment layouts and were kind enough to share their experiences.

Regular glue for ceramics on concrete or plaster will not work, you need to be realistic; it is prepared using water, which has a detrimental effect on the wood until it completely hardens.

But there are other difficult situations when a plywood frame needs to be pre-prepared for cladding; there are several time-tested recommendations to help achieve the ideal state of the structure.

Drywall

Many owners have long known how to glue ceramic tiles to gypsum plasterboard and that the work is not labor-intensive, and adhesion is at a high level.

In cases where the base frame has significant damage, plasterboard sheets can be used as an intermediate coating to level out depressions and cracks.

The material is attached in this way:

- Having the dimensions in hand, you should cut the workpieces.

- Using a screwdriver and self-tapping screws, fix the gypsum board directly onto the plywood.

- By mixing regular tile adhesive, you can begin laying the cladding; there is no need to fill in the marks from the screws; they will disappear under the layer of the mixture.

The method will help out in many situations, but it has several disadvantages: additional funds will be required for repairs, the work is dusty, and the technique is clearly not suitable for decorating kitchen furniture.

Liquid Nails

This method becomes relevant when it is necessary to lay tiles on plywood on the floor, because the solution has excellent adhesion between two planes.

The only thing you need to note is that the consumption of the mixture will be large; you will have to allocate quite a lot of money from the family budget to purchase tubes.

Thick universal adhesive is applied along the edge of each tile, after which the workpiece is pressed to the base; epoxy-based compounds are most often used for grouting joints.

Silicone sealant

When figuring out how to lay tiles on wood-framed walls, many craftsmen suggest that building owners resort to using silicone sealant.

The connection of the elements turns out to be very reliable, and if you don’t skimp and coat the entire area of the base, then you can count on the plywood’s resistance to moisture; damage due to the harmful effects of liquids or steam is completely excluded.

Transparent product samples are ideal for laying cladding; the joints can be filled with your favorite grout of a certain shade. But before fixing the workpieces, the walls or floors should be primed with a hydrophobic compound.

Styrofoam and acetone

When deciding how to stick tiles, professional tilers often create non-standard solutions; after visiting several forums, we were able to obtain the exact recipe for a mixture of acetone and polystyrene foam. The algorithm of actions looks like this:

- Having prepared the foam chips, they are placed in a large container.

- The contents of the vessel are filled with acetone.

- After a certain time, the two components will turn into a homogeneous consistency, onto which the elements are attached.

To scoop up the solution, they often take a large spoon; due to the increased fluidity of the mixture, spreading it onto a flat surface with a spatula is extremely inconvenient.

Polyurethane foam

By purchasing a bottle with a dispenser or a container for a special gun, you will be able to securely fix the tiles to a wood frame. The technology of the work does not imply the presence of joints between the elements, so there is no need to worry about an excessive increase in the volume of foam.

When implementing this technique, you need to have some skills in using a polyurethane base, otherwise you will not be able to save building materials and also maintain cleanliness in the room.

Alternatives

Tiles are also attached to acrylic putty; this solution is securely connected to both the veneer and the back side of the tile; the purchase will cost less money compared to liquid nails.

Epoxy resin is no less effective, but its price may seem high for such purposes; it will take a long time to completely harden, while ensuring sufficient ventilation of the room and maintaining the required temperature.

Let's see what's inside

When the existing coating is not in the best condition, the owner himself may be surprised to see the condition of the invisible part, and then it will immediately become clear why laying ceramic tiles on a wooden floor in such a condition could not be done.

Let's get to work.

- First of all, walk along the floor and note for yourself those places where you can hear a creak or notice a drop in the floor level - most likely, a problem will be found there.

- If the flooring boards are planned to be reused, then they must be dismantled carefully, being careful not to break them. They are stored aside in such a way that you do not accidentally injure yourself on protruding nails, which will need to be pulled out later.

- Inspect all the joists (especially in those places where creaking was previously heard) to see if the shashel has been undermined somewhere (and if the flooring boards are reused, then they also need to be checked). Particular care should be taken to inspect those places where the joists enter the wall.

- If a problem is detected, it must be eliminated (up to and including replacing the joists).

Having eliminated all the shortcomings, each wooden part must be treated with antifungal impregnation.

Assembling and fixing the plywood base

All blanks are arranged in a checkerboard pattern so that the plane is as strong as possible; if we are talking about floors, then the logs are laid out as close to each other as possible, as far as the availability of material allows this, at least 30 cm per pair of boards.

The sheets are fixed evenly; for this, professional builders use a water level; it is better to take a tool 1.5 or 2 meters long in order to apply it over the entire plane. The joints are sometimes additionally sealed with sealant or wood glue to ensure the reliability of the erected frame.

Since wood can expand under the influence of temperature and increased humidity, in the bathroom or kitchen it is better to provide gaps between the sheets, as well as in the corners, 3-5 mm will be enough.

How to pour screed on a wooden base

A screed on a wooden floor will make the base more rigid, but since a large load is unacceptable, we will try to make the poured layer as thin as possible according to technical parameters.

- A screed less than 3 cm thick will be unreliable, so we will build on this indicator.

- We attach a reinforcing metal mesh to the floor, at a height of 1 cm, with self-tapping screws.

- To fill the screed, we will use a cement-sand mortar or fill the base with a polymer screed, but it is better to use KS glue (the basis of which is liquid glass), or two-component polyurethane glue. These compositions are more plastic and can to some extent compensate for the deformations occurring in the wooden material.

- When laying tiles on a wooden floor in non-humid rooms of the bathhouse, you can use dry leveling using moisture-resistant plasterboard or fiberglass boards. The tiles can also be glued directly to the plywood.

It is important! In the bathroom and toilet, the floor should be located slightly lower than in all other rooms, so that in the event of a leak, water does not leak outside the bathroom.

The preparation technology may differ, but regardless of the chosen method, the wooden base should be durable and protected from moisture.

Preparation Guide

To avoid problems, it is better to lay plywood in two layers, then the tiles will lie perfectly flat, and possible delamination of elements will be minimized. Before installing the cladding, the surface is primed, you can go over it several times with specialized liquids, and also use antiseptics.

If you immediately prepare the tools and materials, the process of implementing your plan will go much faster; to carry out the manipulations you will need: a ladder, self-tapping screws, a screwdriver, and adhesives. As well as crosses for marking seams, a spatula, a jigsaw and a level.