How to dry pine

In industry, pine is dried in two ways: in a special chamber and in the fresh air in the shade. In the second case, the main disadvantage is the rather long drying time.

However, you still have to dry lumber at home, so this process is carried out in a natural way.

To do this, you first need to prepare a flat surface and always under a canopy or in the shade under thick tree branches through which the sun's rays do not pass.

Interesting video: DIY pine drying chamber

This area must be covered with any waterproofing material. A garage or other room with insufficient fresh air will not be suitable.

Modern production rejects this drying method and chooses special chambers.

Here the wood is first well heated, then dried, and then subjected to final heat treatment. The pine is dried to standard humidity, which is 12%.

If the humidity in the environment increases, the wood begins to absorb it.

Why does wood crack?

If the relative air humidity is too low, water from the surface layers will move into the air, wood is a hygroscopic material, which means it is capable of changing volume and shape, and will dry out and crack.

.

Interesting materials:

Where can I complain about my employer anonymously? Where can I complain about a district judge? Where can I complain about placement in a kindergarten? Where can I complain about a restaurant? Where can I complain about my manager? Where can I complain about the kindergarten? Where can I complain about the village administration? Where can I complain about noise at night? Where to complain about an ambulance in the Moscow region? Where to complain about an ambulance?

How to dry spruce

Drying spruce in a chamber is the main method of drying lumber of this type of wood, although the owners do it in a natural way.

Fast and high-quality drying requires the availability of the necessary equipment. Only in the chamber can you regulate humidity, air circulation and temperature.

Drying on the street can only serve as a preliminary drying of boards, logs and other lumber that are stacked.

Interesting! How much wood will there be in a cubic meter? HERE!

In this case, dry wooden spacers must be placed between the rows. The formation of stacks is carried out from lumber of the same species. In addition, the size of the boards should be the same.

The correctness of their installation is checked using the template method.

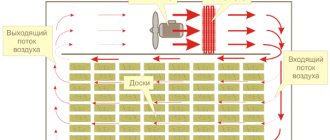

The boards are laid out depending on the direction of the air flow. Pre-stacks are formed on a pre-prepared site. This happens next to the drying chamber.

If the boards are laid manually, it means that vertical lifts are used, which significantly increases productivity.

How to dry cedar

When drying cedar wood, be sure to follow a gentle regime. This is due to the fact that cedar can crack. If you dry this type of wood under a canopy, the percentage of defects will be reduced to a minimum.

Before drying cedar, the ends of the boards or logs are coated with paint or lime. This reduces the likelihood of cracks occurring. And although this lumber is quite strong, it still remains soft and flexible.

Due to its high resistance to moisture, cedar is successfully used in the production of external carved elements.

Drying of cedar boards is carried out at a given temperature (25ºC) and the required humidity concentration (18%).

This concept includes the alternation of temperature and humidity processes that act on lumber. The temperature rises gradually, and the humidity, on the contrary, decreases.

The drying modes are set by the master, taking into account not only the type of wood, but also the thickness of the boards, their quality category, the required final humidity and the type of chamber.

How to dry larch

Coniferous wood is dried at a temperature of 25ºC. This regime can only be maintained in a chamber, but under a canopy, drying the larch can continue for quite a long time.

At woodworking plants, the drying process is automated, so everything takes place in the same time interval. Today there are highly specialized enterprises that work with a specific type of wood, for example larch.

Previously, such mills sent lumber to customers without preliminary drying, but this brought in less income than the sale of dry wood.

The fact is that green lumber is too heavy, so approximately 20 m³ of wood could be loaded onto the truck, and more than 30 m³ of dried lumber.

In addition, dry lumber is sold at higher prices.

Transport costs have also decreased several times.

The most popular are Italian drying chambers with a loading volume of 200 m³. They produce a small percentage of defects - a maximum of 3%.

It takes only 6 days to completely dry thin boards.

How to dry fir

Before the fir drying process begins, it is heated with steam to a certain temperature.

Steam is supplied through special pipes. At this time, powerful fans and heating devices are operating in the chamber, but at the same time, the supply and exhaust ducts are blocked.

The duration of the initial warm-up is directly related to the type of wood. The fir is heated for a maximum of two hours.

Then the drying process itself begins. To do this, all parameters (temperature, humidity and air flow) are adjusted to the required values. All this happens automatically with open supply and exhaust channels.

And since residual internal stress is formed during drying, it is eliminated by intermediate moisture-heat treatment.

The boards are dried to operating humidity, that is, when they become suitable for mechanical processing with carpentry tools.

Lumber from fir and other coniferous species, the minimum thickness of which is 60 mm, undergoes moisture-heat treatment.

At the end of drying, all modes in the chamber are reduced to certain parameters, and the lumber is kept for another three hours, after which the chambers are turned off.

How to dry plums in an electric dryer

Furniture made from wood without pre-drying will warp and dry out.

Therefore, any tree species is pre-dried to a certain humidity, which will correspond to the operating conditions of future products.

Most often, wood is supplied to furniture factories with a high degree of humidity.

The main drying modes for plum boards in the electric dryer include two processes, one of which is high-temperature and the other is low-temperature. At low temperature conditions, the air in the chamber warms up to 100°C.

True, a lot depends on the purpose of the lumber. And since increased demands are placed on them, drying modes are divided into the following categories: normal, soft and forced.

In the first option, after the wood leaves the electric drying chamber, no defects are detected. Slight color variation may occur.

If the soft drying mode is turned on in the chamber, then the color of the wood does not change and the physical and mechanical properties are preserved. After the forced mode, wooden parts sometimes darken, but its strength is maintained.

How to dry an apple tree

Every craftsman who works with wood is interested in the issue of accelerated but high-quality drying.

The importance of properly dried apple trees cannot be overestimated. For example, furniture made from damp wood may become unusable while still in the store.

The same fate awaits over-dried lumber. For example, the front door or cabinet door will not close because it will be saturated with moisture from the air and swell.

For this purpose, a technology has been developed for drying each type of wood separately.

In modern chambers it is easier to achieve the required humidity (18°C), because everything here is automated. And drying apple tree boards in the fresh air requires certain knowledge and experience.

After all, you need to be able to determine when to stop the drying process.

But in any case, raw wood cannot be used, especially in construction.

Drying lumber is a rather lengthy process.

And if you do this on your own personal plot, where there are no modern automated drying chambers, then this procedure will become unpredictable. Therefore, it is better not to save money, but to immediately buy dried wood.

How to dry a whole pear in an electric dryer

Pears, like other types of wood, are best dried in an electric dryer.

You can put them in the unit as a whole or cut them into boards and other parts.

Some people think that it is better to buy already dried lumber, but the majority of owners prefer to save a significant portion of their money and purchase raw wood.

In this case, they do the drying themselves.

In production, boards are dried in steam chambers and electric dryers.

In both cases, they are spacious rooms with a large number of powerful fans. And the very fact of drying lumber in closed chambers eliminates the possibility of damage.

The process of removing moisture from a pear is not as simple as it might seem, because this type of wood contains two types of moisture. It is present in the walls of plant cells, as well as in their cavities.

If the humidity is 30%, then the wood has a lot of free intercellular moisture. Therefore, different types of wood are dried differently and the percentage of moisture left is different.

8% moisture is left in pear trunks and boards. When the moisture content of lumber exceeds 22%, their transportation becomes unprofitable. After all, even the largest truck has a loading weight limit.

How to dry quince

Wood moisture can vary and is divided into several categories.

For example, quince moldings are dried until 15% moisture remains. Fluctuation in any direction up to 2% is allowed.

In products made from laminated and solid wood, moisture fluctuations from 7% to 15% are allowed. As for the production of furniture, the best characteristics are demonstrated by lumber with a moisture content of 8%.

They glue securely and are easy to process. This also increases the service life of the finished product. Today you simply cannot do without drying chambers.

They rid the wood of excess moisture. One of the economical and popular technologies for artificial dehydration of quince building materials is drying.

A modern drying chamber is a spacious room equipped with the necessary equipment operating in automatic mode.

Loading of lumber from quince and other fruit trees into the chamber is carried out using forklifts, lifting devices, carts moving on rails, etc.

Well-dried quince boards are durable and high-quality material.

How to dry cherries

The main equipment intended for drying chambers is a heat supply system, numerous fans and supply and exhaust ventilation.

The most popular is the automated control of the drying process. If you load cherry trunks or lumber into such a chamber and turn on the automatic mode, then you don’t have to monitor the drying process, since everything will be done by electronics and automation.

Temperature and humidity will be maintained at the specified level and, if necessary, increased or decreased.

Temperature is regulated by supplying hot air or steam, and humidity is controlled by supply and exhaust ventilation. The entire drying process can be controlled remotely.

Now, to measure the percentage of moisture in wood, it is not necessary to enter the chamber. This can be done using a remote moisture meter.

Moreover, humidity is checked at any points. When drying cherry lumber, a mild temperature regime is used: up to 75°C. This is done due to the high density of this tree species.

The air humidity in the chamber does not exceed the permissible norm - 80%.

Anyone who has started building their own house must remember that saving on drying lumber will lead to disastrous consequences. And correcting them will require additional financial costs.