Medium Density Fiberboard (MDF) began to be produced on an industrial basis in the USA in 1966; in our country, the technology appeared only in 1997, the boards were called MDF. The name stands for medium density fibreboard.

What is MDF in furniture

At the experimental level, the American William Mason tried to create the first slabs in 1924; he found a way to process waste from the woodworking industry, separated them into individual fibers with a Mason gun and sent them for pressing.

Manufacturing technology

Medium density fiberboards (MDF) are produced from natural wood, depending on the company's reputation, the amount of waste is up to 20%, the rest is industrial wood. In this case, the volume of coniferous species cannot be lower than 70%. Production is carried out using the following technology.

- Grinding. All raw materials are fed into powerful crushers; while the rotor rotates, they are cut and crushed. The output should be wood chips. Subsequently, the raw materials are sent by a belt conveyor to drums for mixing with purchased wood chips.

- Preparing wood chips. It is sifted on sieves to remove fine wood dust, the purified product is supplied for washing (dirt and soil are removed) and cooking. The process takes place in large sealed boilers with superheated steam. Steam pressure is 10 bar, due to high parameters, decomposition is significantly accelerated, the amount of insufficiently processed wood chips is reduced.

- Grinding in a refiner. This unit splits wood chips into a fibrous state; the length varies and depends on the size of the wood chips and the characteristics of the technological process. The properties of the board depend on the length of the fibers; separate standards exist for MDF and HDF boards.

- Blow with dry air and mix with glue. The components are uniformly mixed, and the finished mixture is blown into a long pipe for final drying. The raw material should have a moisture content of 12–15% at the output.

- Separation of fibers from air. For this purpose, cyclones of a centrifugal operating principle are used. Heavy ingredients hit the walls and settle, clean air comes out into a special hole.

- Purification of the mixture. The raw materials should be cleaned of lumps of glue and large solid impurities; their quantity depends on the quality of the raw materials.

- Pre-pressing. The fibers are first fed to the spreading line, the height is leveled, and pre-pressed on a cold press. It is at this stage that the thickness of the MDF boards is established. During cold pressing, the final removal of air occurs; this parameter has a great influence on quality. At the exit from this press, the edges are cut and the specified parameters are controlled.

- Final pressing. The tape is sent to the main press, the process takes place at a temperature of +240°C and under high pressure. With the help of special profiles, the appearance acquires the intended structure.

Pressing

Plate after pressing

Trimming ends

Applying a decorative layer

Preparing for packaging

Packaged MDF products

*Click on image to enlarge.

Next, the products are cut, weighed and fed to a cooling drum to lower the temperature. The slabs are stored for temporary storage for 2–3 days, during which time the adhesive composition gains maximum strength. At the exit, another quality control is done.

At the final processing stage, the surface of the slabs is ground and cut to specified dimensions. Depending on the purpose of the boards and the requirements for their performance characteristics, they can be sold in sanded form or polyethylene film and veneer are applied to the surface.

Video - Production of MDF and HDF boards

Important. As can be seen from the description of the technological process, MDF boards cannot be classified as environmentally friendly products.

Production involves the use of adhesives based on artificial resins, rather than the mythical natural gluten from wood. During the manufacturing process, special fillers and ingredients can be added, due to which they are given wear resistance, biostability and water resistance. Additives affect the cost; they are on average 1.3 times higher than the price of chipboard. But due to the fairly high strength, it is possible to reduce the thickness of the slabs; in this parameter they exceed chipboard by about 1.8 times.

Types of MDF

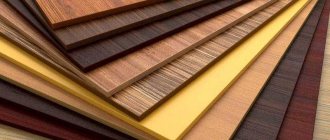

The thickness of the slabs ranges from a few millimeters to more than a centimeter, the length and width depend on the technical parameters of the production lines and existing industry standards. Taking into account the finishing of external surfaces, there are several types.

| Slab type | Brief technical specifications |

| During production, great quality is given to only one side, then it is covered with a special PVC film with different color shades and patterns. If previously imitation of natural wood was most often used, now photographs, including those using 3D technology, are very popular. The film is not afraid of moisture, has relatively high mechanical resistance parameters, and is made from modified raw materials with additives that increase resistance to hard ultraviolet rays. The surface can be easily washed with both conventional and acid-containing detergents. |

| More expensive panels have natural wood veneer glued to the outer surfaces. The thickness of the veneer depends on the purpose and grade of MDF. To protect external surfaces, veneer can be treated with especially durable varnishes. |

| Most often used in the furniture industry, their cost falls into the budget category. One side of the slab is smooth, which improves its appearance and allows it to be used without additional layers of topcoat. The glossy surface is impregnated with chemicals that increase the moisture resistance of the slab. |

When choosing, you need to choose a slab whose physical characteristics best meet the actual operating conditions.

Why is it so popular in door production?

MDF in the production of doors and moldings has gained its popularity due to its versatility, practicality, durability and environmental friendliness.

The physical characteristics of MDF for the manufacture of interior doors include:

- Sound insulation – ensured due to high density. As for doors, this indicator depends not only on the door leaf, but also on the box timber. Thus, MDF doors + box timber with a seal provide excellent sound insulation.

- Resistant to high humidity and temperature changes. MDF doors perfectly retain their shape and do not swell from humidity and vapors, while solid wood structures change in size, which in the future can affect not only the aesthetic appearance, but also the closure.

- Simplicity in finishing, as well as in manufacturing products. It is easy to work with MDF boards - you can use them to create completely different design options for a doorway. Thanks to the perfectly flat surface, any coating adheres firmly and reliably, without forming flaws or unevenness. The evenness of the surface of MDF sheets is very important when applying enamel.

MDF drawer door with eco-veneer coating

- Easy to process. High-density MDF allows you to create beautiful and clear panels with rounded edges, as well as milling, which are widely used in panel doors. It is easy to make individual door elements from this material (platbands, figured platbands, capitals).

- Environmental friendliness. In the manufacture of MDF boards, synthetic resins and other toxic substances are not used, which ensures complete environmental safety.

- Hygiene. This material is resistant to fungi and mold, which makes it easier to use the products in everyday life.

The density of MDF doors significantly affects their final cost. The thicker the sheets were used to make individual parts of door structures and the higher their density, the more expensive the product. Some models of MDF doors using panels, glass, milling, high-quality coating and other decorative features “catch up” with the cost of solid wood doors.

Due to its physical characteristics and main advantages, MDF material is widely used for the manufacture of various interior doors, which determines its popularity.

Using MDF

The main consumer of slabs is the furniture industry; they are often used for finishing interior spaces for various purposes.

Decorative wall panels

Laminate is made on the basis of MDF, furniture facades are finished with decorative threaded elements.

Furniture facades made of MDF

Another feature of the slabs is that during milling they emit dust, which makes them an excellent material for milling shapes of complex geometry.

3D CNC milling of MDF

Artistic milling of MDF

Specifications

The classification, definitions and accepted symbols of MDF boards are prescribed in GOST 34026-2016.

Wood fiber boards. Definition, classification and symbols.

Depending on the production technology, wood fiber types can be of two types.

- Wet production method. The most famous among builders and furniture manufacturers, they are distinguished by increased performance characteristics. A detailed description of the technological process is given in this article a little higher.

- Dry production method. By simplifying the technology, the cost is somewhat reduced; synthetic materials containing harmful compounds are used as adhesives. Not recommended for use in residential premises. Foreign inclusions are noticeable on external surfaces, which reduces quality.

Depending on the parameters of physical and mechanical strength, MDF is divided into grades, the grade of each of them is influenced by the quality of the surface. The pressing process can be continuous or batch. In the first case, the material is fed to the line by a continuous belt, cutting to size is performed at the finishing stage. In the second case, prepared raw materials are poured into special molds, and after leveling, the press piston performs reciprocating movements.

Where is it used?

It is considered the best alternative to many finishing materials, therefore it is widely used in many areas. Its decorative boards are used for the production of furniture, especially the unforgettable facades of cabinets in the kitchen, children's room, hallway and living room. In the automotive industry, they are used to trim parts in car interiors. Construction companies use MDF for repairs and finishing of floors and walls. It is also used for the manufacture of various containers. This material makes excellent doors and door frames, as well as wall partitions. You can find out what MDF plinth is from our article.

MDF is used in the advertising business - exhibition stands are made from it. In electronics, it has found application in the production of speakers and other acoustic systems.

As part of the topic, it is useful to read about what fiberboard is.

MDF is a decorative material that has found application in various industries. It adequately replaces wood and at the same time costs half as much. It is not inferior to it in quality, and in some characteristics it far exceeds the indicators. In order not to get confused in concepts, it is also worth finding out what HDF is and whether it is suitable for your work. It is the best option for those who want to carry out repairs or assemble furniture using high-quality materials, without prohibitive costs.

Classification of slabs according to the characteristics of the front layer

This is a very important parameter of products; consumers choose products for themselves taking into account their specific purpose and operating characteristics. The front surface can be of several types.

- The surface is untreated. The cheapest slabs are recommended for use as secondary or temporary structures. Additionally, the layer can be tinted. The low cost fully corresponds to the same quality.

- There is a finely dispersed mass on the front layer. Due to this, large irregularities are eliminated. The surface can be painted or left in its natural state.

- With increased water resistance. Surfaces can be ordinary or with a finely dispersed layer.

Untreated surface

MDF panels for walls

*Click on image to enlarge.

MDF SPA panels

Safety classification

We have already mentioned that there are no MDF boards that are completely safe for health; during their production, synthetic urea-formaldehyde resins are used in quantities of up to 120 kg/m3 and a hardener of up to 5 kg per cubic meter. All of them release formaldehyde into the air. Each country has its own requirements for the amount of harmful compounds; the permissible parameters are often influenced by the industrial lobby. We have three classes of formaldehyde emission: E0.5, E1, E2. The first ones are the safest, the third ones are prohibited for use in residential premises. But you need to know that physical strength is inversely proportional to the safety class. The more glue, the stronger the board, but the more formaldehyde is released.

Advantages and classification of MDF

History of origin

MDF was first used in America in the 60s of the last century. This material appeared as a result of improvements in the fiberboard production process and was called Medium Density Fiberboard, which translated means medium-density fiberboard. The expensive and hazardous “wet” process for making fiberboard has been replaced by dry pressing of shredded wood chips. In the USSR, MDF production was not established. In the CIS countries, the production of this unique material was mastered in 1997. Today, China is the world leader in the production of MDF boards.

Classification according to acceptable use

Taking into account the recommended purpose, the slabs are divided into several categories:

- general use in rooms with humidity not more than 65%, air temperature not less than +20°C;

- for use only indoors without direct contact with water;

- for humid conditions (relative humidity exceeds 85% for several weeks of the year);

- withstands static and dynamic forces;

- fire-resistant and bioresistant.

It must be borne in mind that additional finishing coatings significantly change the factory properties of MDF boards.

Varnish for MDF

So how to choose the material for your furniture?

Here is our memo in the form of simple theses:

- Laminated chipboard is perfect for the living room and hallway. Just make sure that the stove is of high quality. Request a certificate confirming the class of the slab.

- The combination of chipboard and MDF is suitable for children's bedrooms and bedrooms, but the rule is the same: the material must be of high quality, and the product must be well glued, including edges and joints.

- For the kitchen and bathroom, it is better to choose MDF: in these rooms it is most often exposed to changes in temperature and humidity.

Legend

The consumer should obtain the maximum amount of information directly from the designation of the slabs. State regulations require mandatory indication of information about the brand, quality group, grade, linear parameters and standard for a specific type of slab. All data is printed on the reverse side of the sheet. Additionally, consumers can demand a quality certificate from the manufacturer, but such rights are given only to wholesale buyers.

Brands and varieties

Panel price

Factors influencing pricing:

- status and image of the manufacturer;

- dimensions of the plate;

- material density;

- decorative finishing.

The range in pricing policy is also dictated by the time of development of the woodworking market. Since MDF products have been produced in Europe for more than 20 years, the companies have already managed to win the trust of consumers.

Therefore, the cost of wall slabs is an order of magnitude higher than domestic ones.

- Kronostar (Russia): color - walnut, size - 2600x250x7 mm, price per piece - 118 rubles.

- Eurostar (Russia): color - savanna beige, size - 2600x250x7 mm, price per piece - 160 rubles.

- Kronospan (Poland): color - maple, size - 2600x153x7 mm, price per piece - 134 rubles.

- LAATUpaneeli (Finland): color - oak, size - 2016x232x11 mm, price per m2 - 3900 rub.

- Egger (Germany): color - white, size - 2800x2070x16 mm, price per sheet - 2770 rubles.

Step-by-step instructions for installing an MDF apron

As an example, let's look at the instructions for installing an MDF apron with decorative photo printing. The installation is done in an existing kitchen; there is no need to do any special preparatory work.

Step 1. Bring the stove into the room and remove the packaging materials.

Removing packaging

Removing the packaging film

If the apron was stored in an unheated room in winter, then you need to give it at least a day to acclimatize. During this time, the temperature in the room and on the front side will equalize, and the condensation will evaporate. Do not rush to get to work right away; check the moisture content of the ends of the slab by touch.

Step 2. Place the stove on a flat surface; the dimensions of the table should be approximately equal to its linear parameters. Always remember that manufacturers advertise only the positive aspects of their products. If they claim that MDF is easy to cut, and this is true, then at the same time this means that it has low mechanical strength. If a large area hangs down, it may crack under its own weight. Take the dimensions of the apron and transfer them to the back side of the slab.

Marking along a ruler

Step 3. Using an electric jigsaw or other tool, carefully cut off the excess. You should work very carefully, as a small piece of MDF may break off and the edge will become uneven. Use one hand to support the material at all times. If it’s hard, stop longitudinal cutting, make a transverse cut and break off part of the slab.

Cutting the apron

Step 4. Transfer the locations of the sockets in the kitchen area to the apron. This is done in several stages.

- Remove the protective decorative covers from the sockets. Pay attention to the margin with which they overlap electrical boxes; this data will help you navigate with maximum tolerances.

Measurements of socket boxes - Make marks on the surface of the sheet. If you are working on the front side, then you should use only children's markers. They are made with water and are easily washed off; if you work on the reverse, then the locations of the sockets should be marked in mirror images.

Transferring markings to the apron

Step 5: Cut holes. First you should drill, the diameter of the drill should allow the jigsaw to enter them.

Drilling holes

When working, it is advisable to place paper or cardboard under the jigsaw table, this will prevent damage to the front side of the apron.

Sawing with a jigsaw

Holes for sockets and switch

Step 6. Apply liquid nails to the wall, do not skimp on material. It is necessary to ensure strong adhesion.

Application of adhesive composition

Spot application

Step 7: Lean the slab down and press it firmly with your hands.

The plate is pressed tightly against the wall

Do not leave gaps; the material must adhere to the entire surface. If the wall is uneven, then you should increase the amount of glue; do not be afraid that there will be too much of it and it will remain liquid. The composition hardens not when moisture evaporates, but due to chemical reactions. The catalyst is moisture in the air. This means that, despite the thickness, the glue will harden and will firmly hold the apron.

Step 8. Insert all the elements of the sockets into place; they will additionally secure the apron.

Installation of sockets

Attaching decorative trims

Completion of installation of switches and sockets

The rod is fixed

MDF apron

The technology for installing these kitchen design elements is so simple that almost all beginners can do it.