Moisture-resistant parquet boards that do not lose their shape under the influence of moisture and temperature changes can expand the use of traditional parquet. You can lay flooring from waterproof boards in bathrooms, kitchens, and toilets. What criteria should you use to choose a board and which manufacturers should you give preference to? More on this below.

A moisture-resistant parquet board may be needed for flooring, for example, in a bathroom

How to choose moisture-resistant lumber

Even those people who have never been involved in construction know that coniferous lumber resists moisture better. This is explained by the fact that their wood contains special resinous substances that increase resistance to fungus and damage by various microorganisms. In addition, moisture does not penetrate deep into the wood so quickly, so wood with a large amount of resin swells and warps less. Valuable wood species, especially red and iron, are not afraid of water in any state of aggregation. However, their wood is very expensive, and therefore can only be used in the most prestigious projects.

To choose wood for finishing a bathroom or bathhouse, you should study the characteristics of different species and compare them with each other. Prices can also be compared, because sometimes the family budget is not too large. However, it is still more profitable to make floors “for centuries”, because their repair is a rather labor-intensive process.

Don’t forget about one more important point: the quality of the wood. Even for the same breed, the difference between varieties will be quite significant. In order not to regret wasted money, you should contact a trusted manufacturer with modern equipment. Compliance with drying technology is especially important: if the boards are not dried enough, they can “lead.” Although larch is not too prone to warping, well-dried boards will behave absolutely predictably in construction, but excessively wet ones will require additional trouble.

Fernambuc

Caesalpinia or fernambuco is a tree growing in the forests of Brazil, from which the country got its name. Due to the interesting property of wood to change color in the open air, this plant has long been considered a source of dye for fabrics. Later, the dense and durable trunk of fernambuco began to be used for the manufacture of billiard cues, bows for stringed musical instruments and conductor's batons.

Wood processing is quite difficult. The main difficulty is that a recently cut trunk immediately dries out and cracks. Dried wood does not warp, is strong and has an elegant texture, so fernamboo is convenient to use when decorating furniture with mosaic decor.

Moisture-resistant wood species

If you decide to purchase softwood lumber, the most inexpensive option is pine. This fast-growing and beautiful tree is well protected from water, but it also has a drawback: softness. Pine boards are very easy to scratch, so it is best used for walls, not floors. Lumber from spruce, larch and cedar will cost a little more. Larch wood is especially popular, because in terms of moisture resistance it is significantly ahead of other species.

Siberian larch is one of the few trees that only benefit from contact with water (among deciduous trees, oak has the same property). If you make a bathroom floor from this wood, it is unlikely to require replacement within the next 50-60 years. Sometimes larch floors last for more than a century, and the boards become stronger and stronger.

If the construction project involves the use of larch, additional protection of the wood from moisture is unlikely to be required. However, you can use impregnations if you are going to do the exterior decoration of the house: the wood should be protected from ultraviolet radiation.

Top Manufacturers of Waterproof Floor Boards

You should choose a material for finishing floors in rooms with high levels of humidity among the products of manufacturers specializing in the production of moisture-resistant varieties. These can be both European and domestic companies. Naturally, products from a domestic manufacturer will cost less, but the quality level of products from a Western supplier is still higher.

The top rating of waterproof board manufacturers includes companies from Austria and Germany, France and Holland:

- Fairholz, Teak Austria, Mirako (Austrian production);

- Alpenholz and Parador (German quality);

- Tarkett (French supplier);

- Wood Bee (Dutch production).

For each of the listed manufacturers, waterproof parquet boards meet the requirements for resistance to high levels of humidity and temperature fluctuations, so you should choose based on product reviews, available color and texture options, and cost. Below are useful tips on choosing the right material.

Parquet from one of the popular manufacturers of moisture-resistant parquet boards - Fairholz

Where are moisture-resistant lumber used?

Waterproof types of lumber are in great demand among builders and organizations specializing in repairs, landscape design, and creating unusual interiors. Exterior decoration and landscaping is perhaps the most famous area of application for Siberian larch. It is used to create terraces, recreation areas near swimming pools, piers and piers, as well as a variety of buildings: baths, saunas, gazebos, guest houses. The interior decoration of a bathhouse or sauna also requires the use of moisture-resistant lumber, especially when it comes to steam rooms and showers.

Inside a private house or apartment, moisture-resistant wood is needed in two rooms: the bathroom and the kitchen. In the bathroom, excess moisture is formed during water procedures, and in the kitchen - during cooking. If you are engaged in canning or preparing large amounts of food for a family celebration, condensation will form on the walls.

Siberian larch is so little susceptible to moisture that it can be used to make countertops, window sills and even sinks. And in Solovki and Novgorod, in the past, even water pipes were made from larch trunks, some of which are still in use today. In more southern regions, oak logs were used instead of larch logs. Of course, today hardly anyone will decide to replace plastic pipes with wooden ones, but a bathtub can be made from moisture-resistant wood.

Waterproof wood

Moisture-resistant wood species are species that are least susceptible to moisture (steam, precipitation and other liquids). The moisture resistance of natural wood is determined by the structure of the wood or the presence of certain substances in it (natural resins or essential oils) that prevent moisture from penetrating into the “body” of the tree. Different tree species have varying degrees of resistance to moisture.

Some of the wood species processed by modern industry are so moisture resistant that building materials from them can even be used in the construction of bridges and piers.

Moisture-resistant wood for exterior use can be used for decoration or cladding of a building. For interior work, parquet boards or wall panels made of waterproof wood can be installed even in the bathroom.

The most moisture-resistant include, first of all, wood from tropical tree species.

High coefficients of resistance to the effects of a humid environment are determined by the natural climate of growth of such trees. The tropics mean high humidity all year round. In addition, trees in tropical forests grow very slowly.

How to increase the service life of lumber

When engaged in construction or finishing, it is very important to take timely measures so that softwood lumber will not require replacement for a long time. It all starts with choosing the right type of wood. For critical structures, grade A or B is best suited. But for the subfloor, you can use lower quality wood. The main thing is that it is dried to a level of 12%.

Even the highest quality material can be ruined if used without following certain rules. Purchased boards should be allowed to rest in the room where they are intended to be used. In 10-14 days, the humidity level will completely level out and you will not have problems with warping.

Good manufacturers of lumber from Siberian larch often offer boards that are completely ready for use, including those with impregnation. If there are none, be sure to protect the wood from ultraviolet radiation and fungus. Additional resistance to moisture will be provided by painting or opening with varnish.

The moisture-resistant wood of Siberian larch is not only durable, but also very beautiful. Hiding her design is a real crime, so it is better to use a clear varnish. Some people even refuse this, treating the wood with special oils or wax from time to time.

Both the larch lumber itself and the means to protect it can be ordered on our website. If you have any questions, we will be happy to advise you on the choice of optimal materials for construction and finishing of housing.

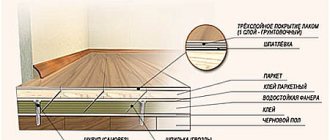

The structure of the board is waterproof - what does it consist of?

A high-quality waterproof parquet board consists of several well-thought-out layers. The top one is a solid lamella made of natural wood with a thickness of up to 4 mm. It is this layer that will be the main visual component of the wooden floor. Board options with a top layer of:

- beech;

- oak;

- ash;

- exotic breeds.

The middle layer of the board is a more affordable option for mixed wood species. It is this layer that is responsible for the density of the material and its thickness. Locking connections are also placed here to speed up and simplify the installation of the coating.

Sucking a parquet board with a special locking connection that securely presses the boards together

The bottom layer of the waterproof board with a thickness of only 1.5 mm is made of veneer. Its task is to prevent floor deformation and enhance its tensile flexibility.

A separate finishing layer can be considered a moisture-resistant board varnish coating. It is the varnish, applied in several layers, that prolongs the life of the floor and protects it from abrasion even under the influence of mechanical stress and UV rays.

Types of coatings

Recently, the following types of waterproof wood paints can most often be found in stores:

- Water-dispersed;

- Alkyd;

- Polyurethane;

- Oily.

Below we will take a closer look at their features.

Latex paint

Water-dispersed

A feature of water-dispersion paints is that water is used as their solvent. Thanks to this, they are odorless and completely environmentally friendly.

In addition, they have the following qualities:

- Dries quickly.

- They are resistant to atmospheric influences.

- They protect wood from environmental influences for a long time.

- They do not fade in the sun.

- They can be either matte or glossy.

- They are vapor permeable.

It should be noted that water-dispersion moisture-resistant paint for wood comes in several types:

| Type | Peculiarities |

| Acrylic | Forms a thin matte film on the surface that does not hide the wood grain. It must be said that the cost of acrylic paints is the lowest among water-dispersed compositions. |

| Latex | It is characterized by increased strength and abrasion resistance. At the same time the price is higher. |

| Silicone | It is the most reliable and durable among water-dispersion paintwork. This coating can form both a matte and glossy surface on the painted surface. The only drawback is the high cost. |

Due to their environmental friendliness and quick drying, water-dispersed compositions are excellent for interior work. However, their properties make it possible to perform outdoor work.

Alkyd enamel

Alkyd

Alkyd enamels for wood are made on the basis of alkyd resin. Unlike water-dispersed compositions, they have a strong, pungent toxic odor, which disappears after application.

Alkyd moisture-resistant paint for wood has the following properties:

- Forms a waterproof glossy film with a bright, rich color on the surface.

- It is resistant to sub-zero temperatures.

- It is resistant to abrasion.

- Dries quickly.

- The composition adheres well, distributed over the surface in an even layer without streaks.

Application of alkyd enamel

It should be noted that alkyd weatherproof paint for wood is inexpensive compared to other paints, so it has recently been in great demand. Moreover, it is used for both external and internal work. In particular, due to its abrasion resistance, the coating can be used for painting floors.

Note! When performing interior work with alkyd enamel, it is necessary to ensure ventilation of the room.

Polyurethane enamel

Polyurethane

Polyurethane moisture-resistant paint for wood has a number of positive qualities:

- Waterproof;

- Chemical resistance;

- Resistance to mechanical stress;

- Durability.

Like alkyd enamel, polyurethane compounds emit a toxic odor during application and drying. Their main advantage is high strength, however, it should be borne in mind that this paintwork is quite expensive. Therefore, it does not always make sense to use weather-resistant polyurethane paints on wood.

Oily

Not so long ago, these compounds were the most common and were used everywhere for external and internal work.

However, recently they are used less and less, for a number of reasons:

- They are highly toxic.

- The surface quickly cracks and begins to peel off.

- They turn yellow in the sun.

- They take a long time to dry.

Their only advantage is their low cost. It should be noted that recently oil-based coloring compositions have been produced only by domestic manufacturers.

Coating wood with a moisture-resistant coating

Why know wood moisture content?

One of the most important indicators for carpentry work is wood moisture content. Oddly enough, it reflects the level of moisture content in the material. Why is excess humidity dangerous?

- Change in size due to shrinkage. As a result, the geometry of the parts and the entire product is disrupted. Moreover, the furniture may simply break. When drying, a number of negative consequences appear: from warping to the appearance of cracks.

- Reduced strength compared to standard values. Due to incorrect determination of the quality of lumber, errors can be made in load calculations and the furniture turns out to be non-functional.

- An increase in mass, which also leads to improper distribution of loads in the furniture.

- Deterioration of machinability by various methods.

- Reduced thermal insulation and increased sound conductivity. These factors worry builders more, but they cannot be ignored.

Are there any negative consequences from using overdried wood? Undoubtedly:

- Even dry wood has many pores and channels that instantly fill with water upon contact with it. As a result, the wood will swell, which will lead to the same consequences as shrinkage.

- Overdried material loses strength and becomes brittle. It crumbles and is poorly processed.