Artificial finishing materials gradually experienced their boom, and gradually wood began to conquer the market again. This statement is relevant not only for the construction of houses, but also for their interior design with clapboards. Completely environmentally friendly cladding adds additional comfort, warmth and beauty to the premises. However, not knowing how to cover the lining, some owners leave it unprotected. As a result, beautiful wood, which with proper treatment could last for many years, needs to be replaced after 5-7 years. This happens due to its destruction, chipping, stains during cleaning, and contamination.

Varnishing of lining

What varnish to coat the lining in the steam room

The Russian bathhouse is one of the favorite places for many. When we build it for ourselves, most of all we want everything to be in harmony, convenient and healthy. Therefore, at the stage of choosing a material for wall decoration and working with it, much attention is paid. Among the materials for walls and ceilings, lining is the most popular.

Despite the fact that the lining is quite durable, it will be subject to critical operating conditions in the steam room. Those. There will be critically high temperatures, steam, exposure to moisture on wood, direct contact with human bodies and other factors. Therefore, when using varnish, it is important to protect the wood and only then transform its appearance by choosing color and texture.

What varnish is used to cover the lining in a bathhouse? Choosing a varnish is quite a difficult and responsible task, since a small mistake will lead to the fact that the varnish may leak and begin to emit an unpleasant odor. The texture of the wood may darken and crack, and the overall atmosphere in the steam room will be disrupted.

When covering lining on walls, it is important to protect it from moisture and cracking, as well as to allow it to breathe. The latter is important not only for the microclimate, but also to prevent the appearance of mold on the back side. For this reason, it is important to cover the walls with a protective compound.

“Senezh” for saunas has proven itself well, as it has an antiseptic effect. As for varnish, acrylic type impregnation is considered the most popular here. This varnish does not emit odor and enhances antiseptic properties. Many acrylic impregnations include wax, for example, varnish from the Neomid company. By the way, this is a domestic representative. Among the imported products, products from the company Natur are used.

Precautions during operation

When working with varnishes, observe safety precautions. Organic solvents are highly flammable, so do not use open flames or smoke. The room must have effective natural or forced ventilation, since the evaporation of volatile compounds in the air increases the level of toxic substances. When using the sprayer, wear a respirator or bandage to protect the respiratory system.

All materials are stored separately, avoiding places with direct sunlight and away from heating devices.

Treatment of dressing room walls

Let's find out which varnish is best to coat the lining in the dressing room. The dressing room - or it is often called the rest room, is the place where you will take a break before entering the steam room. There is less humidity here, there is no heat, there is ventilation.

For this reason, a water-based varnish is applied to the paneling in the dressing room. It is cheaper, but its properties are sufficient to maintain aesthetics for up to 5 years. It allows the wood to breathe, protecting the material from cracking.

Among the current manufacturers of varnishes, I would like to highlight “Tikurilla”, “Usadba”, “U-409”. Eurotex “sauna” impregnation is in great demand, which in a volume of 2.5 liters is enough to cover an area of about 35 square meters.

Antiseptic for baths and saunas

For the specified volume in different regions of the country you can pay from 450 to 700 rubles. After applying varnish to the wall in the dressing room, it is recommended to thoroughly ventilate it. There is almost no smell, the residual effect disappears after 2-3 visits.

Don't forget that you can order tinting for the varnish. This process refers to the ability to add a hint of color to the varnish. It is recommended to immediately calculate the total coverage area, since it is difficult to select a color in two different batches.

Protection procedure

Typically, coniferous and hardwood panels, which are subject to the aging process, are used to upholster the interior walls of rooms. Even if the type of wood was chosen, depending on the load planned for the room. However, such an undesirable aging process can be significantly slowed down.

Applying a protective layer to the lining

Speaking about the list of negative factors that have a detrimental effect on the lining, the following should be highlighted:

- FACTOR 1: Increased solar radiation.

- FACTOR 2: High air humidity, contact of wood with water is especially detrimental.

- FACTOR 3: Pest bugs.

- FACTOR 4: Mechanical damage.

- FACTOR 5: Growth of microorganisms on the surface of the lining.

Using various types of impregnations and compositions, it is possible to achieve the appearance of a protective layer that will protect the wood from the negative influence of the environment. These include temperature changes, mechanical influences, increased moisture formation, etc.

Varnishing lining on the balcony

A balcony in a modern apartment is no longer a place for rubbish, as it was before. It's more of a relaxing place where you can sit back in the summer and enjoy a good cup of tea. Therefore, everything here should be in harmony.

As in a bathhouse, lining is often used when decorating a balcony. It is used to decorate the walls, the space under the radiator, and the ceilings. Most often, the balcony is not heated, so the lining must be protected from freezing in winter. The varnish used must match.

For your apartment, where you spend a lot of time, you can purchase a polyurethane-based varnish. This is not the cheapest segment, but it will last a long time and will withstand freezing perfectly. By the way, it is better not to use it for a bath, since it does not tolerate moisture well.

Varnished paneling on the balcony

Otherwise, polyurethane varnish on the balcony. Complete polymerization occurs within a day, after which a protective film forms on the surface. It provides a high degree of protection against cracking and shrinkage. The surface is easy to clean even with the use of chemically active products.

So what kind of varnish should I use to coat the lining on the balcony ? An example of an inexpensive varnish is the product Tikkurila Parketti-Assa 20. A liter jar will cost about 2 thousand rubles. Not cheap, but completely safe for health and for a long time.

The varnish is UV resistant. Another option, semi-matte Sherwin-Williams costs 6.5 thousand for 3.8 liters. The varnish is recommended for application in a few words, has deep absorption.

Requirements for paint and varnish materials for interior work

According to GOST 9825, 28246, 33289, varnish for lining is classified as a weather-resistant or limited weather-resistant volatile organic compound. The first type is used for exterior decoration, the second - indoors. They produce universal types of coatings that can be used in different conditions.

Guests regulate the characteristics of paints and varnishes for interior work:

- The appearance and color of the coating is indicated in the regulatory or technical document (ND, TD) for the product; wrinkles, craters or other defects on the surface after drying are not allowed;

- Drying time at a temperature of 20 °C – no more than 72 hours;

- Covering capacity 120-150 g/m²;

- Adhesion to various surfaces 0-1 point;

- Elasticity when bending the film up to 1 mm;

- Strength according to the device – U-1 40 cm;

- Hardness – 0.05-0.15 relative units;

- Conditional light fastness – 2-12 hours;

- Resistant to water for at least 24 hours;

- Wet abrasion in microns and vapor permeability in g/m² are indicated in ND or TD;

- Service life – at least 1-2 years;

- The content of non-volatile substances is not less than 30%.

Packaging and labeling of the material must comply with GOST 9980.3, 9980.4.

Information about the manufacturer is required, indicating the legal address, production date and ND for the product. Indicate the purpose, rules of use, precautions, expiration date. The manufacturer can undergo product certification on a voluntary basis.

Varnish for lining is designated by two capital letters corresponding to the name of the main film-forming substance in the composition. For example, AU is alkyd-urethane, EF is epoxy ester. Water-dispersed liquids have an additional index of VD.

The container must comply with standards and pass drop tests. Cans or canisters filled with a viscous substance with a given density are thrown from a height of 0.4-0.6 m. The packaging should not be damaged.

Use glass, metal or polymer jars, canisters, bottles with a volume of 0.04-20 dm³. The mass content of varnish in the container should not deviate from the nominal value by more than 5%.

Varnishes are allowed for production after a hygienic assessment by the bodies of the State Sanitary and Epidemiological Supervision of the Russian Federation with the issuance of a conclusion. The manufacturer guarantees the safety of the product for the life and health of the buyer, and the preservation of properties until the expiration date. After its expiration, paintwork materials are not used for their intended purpose.

Processing lining inside the house

When answering the question of what varnish to coat the lining inside the house with , you need to know the following. Inside houses, lining is used for finishing corridors, stairs, hallways, and utility rooms. There is moderate humidity, air temperature around 20 degrees Celsius, minimum ultraviolet radiation. Therefore, the most important requirement for varnish is its environmental safety, resistance to mechanical stress, and absence of odor.

For interior work, experts recommend using a two-component water-based varnish. It leaves no odor when it dries completely, which is achieved after one day. The presence of two components: the hardener and the base itself ensures high reliability and durability of application. A wide range of shades allows you to cover the lining under ash, oak, pine and other tree species.

The products of the Optimist L210 company have good quality. Pinotex is also famous for its Classic series. The high quality of the varnish makes the surface resistant to ultraviolet radiation, fading, and yellowing. The surface is easy to clean.

Protective compounds

The division of coatings for lining into protective and decorative is arbitrary, since substances from the first group often act as components of products from the second, and can themselves be supplemented with pigments and mixed with each other.

Fire retardants

Compositions based on sodium salts and phosphoric acids foam when heated and release gases, preventing ignition and the spread of fire. Eurolining, made in accordance with international standards, is already treated with high-quality fire retardant. Low-price materials require the application of fire-resistant impregnation before installation so that the slats are protected on all sides.

Antiseptics

The products are made on the basis of water, solvent, organic and artificial oils. Water and nitroantiseptics insure the lining against rot, fungus and parasites, but they cope poorly with the already existing massive infection. Oil compositions act longer and more effectively, and also impart water-repellent properties to the wood.

Oil

Impregnating the lining with natural oils, such as linseed or teak, gives it a light, noble shine, makes the color deeper and the design more distinct. At the same time, the tree does not lose its ability to breathe, but it better resists the effects of high humidity. Drying oil is now rarely used for such purposes, since it needs renewal and makes the wood sticky.

Wax

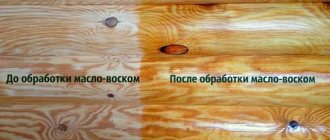

Paraffin-based preparations protect the lining from getting wet more reliably than oils, but are usually combined with them. There is a transparent and tinting oil-wax with a disinfecting and fire-resistant function. Such products are produced in solid and liquid form, which determines the method of application: with a brush, rags, lint-free swabs. The effect is also different - from light gloss to pronounced shine.

Primer

Good primer mixtures are made on alkyd, acrylic and shellac bases. You can prepare your own PVA adhesive solution, but its effectiveness will be lower. Preliminary priming of wood is necessary so that the final coating goes on smoother and lasts longer. The primer is usually sprayed with a spray gun in 2-3 layers, each of which must dry.

Bleach

Bleached wood looks great in rustic interiors (country, Provence), but the use of bleaches and disinfectants is often driven not by style, but by fungal infection of the lining or unsightly traces of rust around metal fasteners. Chlorine-containing preparations can radically solve this problem, and gentle compositions based on peroxide, oxalic acid or ammonia can provide a slight lightening effect. Before application, dirty deposits are scraped off the surface, and upon completion of exposure, wash and dry.

What paint should I use to paint varnished lining?

The varnish looks good even after many years. But, if you are pretty tired of the color of your walls and you want to use paint, then there are a number of nuances that you may encounter. The main problem lies in the fact that the varnish can swell and peel off when applying paint, which will lead to loss of appearance.

Therefore, many experts recommend sanding the surface before painting. This is especially true when you want to keep the tree structure open. If you are painting the entire surface, then use acrylic paints over the varnish. Checked, the varnish is not deformed!

Painting the lining with paint

The paint will penetrate through it into the wood. The surface will be homogeneous, the natural relief will be hidden. There are almost no analogues to acrylic, except perhaps the so-called liquid plastic, better known as polyurethane enamel.

This paint is not for everyone, as it has the maximum gloss effect. Knowing what paint to paint varnished paneling , you can make repairs in your home without overpaying for sanding.

Fighting methods

There are many methods, natural and synthetic products.

Medium 1: resin

Resin heated before application helps against fungal spores.

Pros:

- effective,

- safe,

- cheap.

Minuses:

- The surface remains sticky.

- The resin is viscous, difficult to apply, you need to stretch it.

Remedy 2: silicate glue

Silicate glue diluted to a state of medium ductility is used. It is used to treat the surfaces of wooden products and coatings 1–2 times.

This is a safe hypoallergenic composition. Has a short-term effect, not suitable for some types of mold.

Remedy 3: potassium dichromate, sulfuric acid

A 5% solution of potassium dichromate and a 5% sulfuric acid concentrate are mixed in equal proportions.

The resulting solution is used to treat the boards and soil adjacent to the structures. The method is effective, but dangerous for the soil.

To get rid of an existing outbreak, sprinkle the area with soda and spray with 9 or 6% acetic acid.

Remedy 5: salt, acid, boiling water

Prepare a solution from 5 liters of hot boiled water, 1 kg of table salt, 50 g of boric acid. Mix thoroughly and process the wood.

Remedy 6: copper sulfate

Take 100 g of dry matter and dilute it in 10 liters of water. The boards are treated with the solution, then dried and used for construction.

Remedy 7: whiteness

Chlorine bleach works well to remove fungus, but keep in mind that the liquid lightens the wood.

In baths and saunas, it is possible to remove mushrooms only using folk remedies. To cure the affected area, clean the boards with soda, pour vinegar on them, and wait for the reaction to complete. Then wash off the reagents with water and cover the area with tea tree oil diluted in warm water.

Folk remedies are not always effective and safe. They are used when there are no special drugs at hand, and the problem needs to be solved quickly.

Impregnations

In addition to varnish mixtures, special impregnations are also used to protect the lining. They penetrate deeply into the surface of the wood and create a reliable protective layer. Quite often, impregnations or stains that have a wax base are used on balconies. The simplest impregnation option is stain, which is quite inexpensive, and its characteristics are practically no worse than expensive materials.

Different types of stains have an alcohol, acrylic, oil and water base. In addition, powder, gel and ready-to-use stains are produced; they are intended for either external or internal use. Impregnation, which has a wax base, protects the wood from high air humidity, so the wood does not begin to rot. The protective layer formed on the surface withstands temperature changes, the surface becomes very attractive. Impregnations are often used to protect the lining from harsh climates, large temperature fluctuations and high humidity; they are applied to the internal surfaces of saunas and baths.

Povagonke.ru

Artificial finishing materials gradually experienced their boom, and gradually wood began to conquer the market again. This statement is relevant not only for the construction of houses, but also for their interior design with clapboards. Completely environmentally friendly cladding adds additional comfort, warmth and beauty to the premises. However, not knowing how to cover the lining, some owners leave it unprotected. As a result, beautiful wood, which with proper treatment could last for many years, needs to be replaced after 5-7 years. This happens due to its destruction, chipping, stains during cleaning, and contamination.

Varnishing of lining

Preserving texture

It is possible to cover the lining with paint and varnish material without hiding its texture. To do this, you will need to treat it with oil with added pigment, wax or glaze.

Such compositions cover the surface well, softly envelop the wood fibers without hiding the natural pattern.

- Correct application of paints and varnishes involves fragment painting.

- In other words, using a brush, you apply a little paint along the entire length of the board, and then shade it.

- Afterwards, let the paint sit for a few minutes so that it is absorbed into the fibers.

- Remove excess with a cloth. This way you will receive the required invoice.

This technique is called texturing the material. Wood treated in this way harmonizes very well with the main interior.