Presentation. Properties of wood. 6th grade presentation for the lesson

Slide 1

Properties of wood Author: Masalitin N.I., teacher of Fine Arts and Technology, MAOUSOSH No. 2 named after Yu.A. Gagarin, Uspenskoye village, Krasnodar region

Slide 2

Physical and mechanical properties of wood

Slide 3

PROPERTIES OF WOOD physical mechanical Distinctive qualities of materials, which are manifested in the ability to resist external mechanical forces. (strength, hardness, elasticity) Distinctive aspects that appear when they interact with the environment. (color, smell, density, humidity, shine, heat-sound-electrical conductivity)

Slide 4

Physical properties Density - the amount of wood mass contained in a unit volume. m is the mass of wood, V is the volume of wood.

Slide 5

High density - oak, birch, maple, larch, apple, pear from approximately 700 to 900 (kg/m3); Average density - horse chestnut, walnut, cherry, teak, beech from 560-700 (kg/m3); Low density - linden, poplar, cedar, elm, spruce, pine - from 400 to 600 (kg/m3); Density of various rocks

Slide 6

Wood moisture content Wood moisture content is the amount of moisture it contains. m1 is the mass of the sample before drying, m2 is the mass of the sample after drying.

Slide 7

Degree of moisture content of wood: wet - kept in water for a long time, humidity above 100%; freshly cut – humidity 50-100%; air-dry – stored in air for a long time, humidity – 15-20% (depending on climatic conditions and time of year); room-dry – humidity -8-12% absolutely dry – humidity -0%.

Slide 8

Moisture meter for lumber Wood moisture meter

Slide 9

Mechanical properties hardness elasticity strength The ability of wood to resist the penetration of other bodies into it. (difficult or easy to drive a nail) The ability of wood to restore its original shape after removing the load. (a wooden ruler does not break after bending) The ability of wood to withstand certain loads without breaking. (the chair does not collapse under heavy weight)

Slide 10

Device for testing materials for hardness

Slide 11

Laboratory practical work No. 3 “Study of wood density” Obtain samples of dry wood from the teacher, measure their length a, width b, thickness c and calculate their volume V (in cm 3). Record the results in the table. Weigh the samples and record their mass m in the table. Using the formula, determine the wood density p.

Slide 12

Tabulate the results

Slide 13

Laboratory and practical work No. 4 “Study of wood moisture content” 1. Obtain samples of dry wood from the teacher, weigh them and write down the mass t 2 in the table. 2. Do the following experiment: immerse the samples in water for 5-10 minutes, then remove them from the water and wipe dry with a cloth; weigh the samples and record their mass m x in the table. 3. Determine the mass difference (t x - t 2) and wood moisture content (Vl) using the formula given on page 13. Write the results in the table.

Slide 14

Tabulate the results

Physical and mechanical properties of wood

Lesson topic: Physical and mechanical properties of wood

Objectives: to introduce the physical and mechanical properties of wood, to teach how to determine the density and moisture content of various types of wood, to contribute to the formation and development of moral and aesthetic qualities of the individual.

Tools and equipment: collection of wood species, ruler, calipers, laboratory scales, container with water, dry rags.

During the classes

- Organizing time

- Updating knowledge.

Teacher. A tree is one of the most amazing and most perfect creations of nature. Since ancient times, trees have been the subject of people's admiration. They were worshiped and served as a source of inspiration for poets, artists, architects, sculptors, and masters of decorative and applied arts . . Wood has traditionally been one of the most important building materials, which is facilitated by its excellent decorative properties, widespread distribution, and ease of extraction and processing. Wood is a widely used construction and ornamental material. Wood is used to build houses, bridges, make furniture, musical instruments, machine parts, carpentry and construction structures, wooden utensils and much more. Wood is used in the chemical, pulp and paper industries. The scope of application of this valuable material is so wide that it is difficult to even list everything.

Wood is usually called the material used in production, cleared of bark and branches.

. Wood is not difficult to process if you know its species, structure, defects and properties . Today in lessons you will get acquainted with the properties of wood .

State the topic and purpose of the lesson.

- Repetition of material about the types and properties of wood studied in 6th grade.

· Who can say what the structure of wood is?

What types of wood do you know?

· What kind of lumber is made from wood?

· Name the tree species known to you from the samples presented at the demonstration stand.

· What is an indicator of the presence of wood defects?

· Tell us what types of wood you used when making certain products. Which objects, and from which species are the most successful, are best processed?

· Why is it necessary to study the structure of wood, its defects, and properties?

That's right, guys. These data contribute to expanding the scope of application, rational use, and improving wood processing technology. But in addition to defects and structure, you also need to know the properties of wood.

4. Presentation of program material.

Wood properties:

- physical - properties that manifest themselves when interacting with the environment. Physical properties include: color, smell, humidity, density. (write it down in a notebook)

- mechanical - properties that manifest themselves in the ability to resist external mechanical forces. Mechanical properties include: hardness, strength, elasticity. (write it down in a notebook)

Let's look at the physical properties of wood.

- The appearance of wood is characterized by color, shine, texture.

The color of wood depends on the species, age of the tree, and the climate of the area where it grows. Wood can change color when exposed to air and light, when damaged by fungi, or when exposed to water for a long time. The color of many breeds is so characteristic that it can serve as one of the signs for their recognition. Gloss is the ability to directionally reflect light flux. The wood that has the greatest shine is oak, beech, and mahogany (mahogany). Texture is a pattern formed on the surface of wood as a result of cutting anatomical elements (growth rings, medullary rays)

- You probably noticed that wood of different species can be lighter and heavier, i.e. less dense and more dense. Density is the amount of wood mass contained in a unit volume. The density is found using the formula, where m is the mass of wood, V is the volume of wood, write down the definition and formula in a notebook.

p= m / V (g/cm3)

Different types of wood have different densities, write down some examples.

Low density - linden, poplar, cedar, elm, spruce, pine - from 400 to 600 (kg/m3); high density - oak, birch, larch, maple, apple, pear from approximately 700 to 900 (kg/m3). Wood with a high density is more difficult to process, but such wood is less susceptible to wear.

- The next property is humidity - the amount of moisture contained in wood. Humidity is found by the formula, m1 is the mass of the sample before drying, m2 is the mass of the sample after drying. We write down the definition and formula in a notebook.

The following levels of wood moisture content are distinguished:

- wet – kept in water for a long time, humidity above 100%;

- freshly cut – humidity 50–100%;

- air-dry – stored in air for a long time, humidity – 15–20% (depending on climatic conditions and time of year);

- room-dry – humidity – 8–12%

- absolutely dry – humidity – 0%.

There are special devices for measuring humidity - moisture meters . How do they work? Do you think it is possible to change the moisture content of wood? Is it possible to use freshly cut wood for production? Why? (Children's answers.)

When wood is dried, the strength of lumber increases significantly, and the possibility of rotting is reduced to zero. There are two types of drying: natural and artificial.

Natural drying is carried out outdoors under a canopy from rain and direct sunlight, as well as indoors. This process can last for weeks or even months, but as a result, the wood receives reliable protection from fungal attack.

Artificial drying takes place within a few days or hours and also makes the wood invulnerable to rot and fungi and ensures its high quality. The artificial drying process takes place in periodic and continuous drying chambers . The coolants are air, steam or flue gases heated to a temperature of 70-80o.

In addition, drying can be carried out in a high frequency electric field. The wood then dries evenly and 10–20 times faster than in a chamber. But this type of drying will be more expensive, since the cost of electricity is quite high.

How can boards change if they are not dried correctly? When dried in the sun, the outer surface of the wood quickly heats up, but the inner surface remains damp. Due to the difference in stress, cracks form and the wood quickly warps. As a result of drying, wood shrinks and warps in various directions. Wood shrinkage is taken into account when sawing logs into boards (shrinkage allowances), drying lumber, etc. Warping occurs due to shrinkage in different structural directions. There are transverse and longitudinal warping (along the edge, face, winging).

Moisture absorption is the ability of wood to absorb moisture (water vapor) from the surrounding air. To protect wood from the influence of moist air, the surface of wooden parts is covered with various paints and film materials.

Let's move on to mechanical properties. This is hardness, strength, elasticity.

- Hardness is the ability of wood to resist the penetration of other bodies into it. Hardwoods include pear, oak, maple; to soft ones - pine, poplar, linden. (write it down in a notebook)

- Strength is the ability of wood to withstand certain loads without breaking. (write it down in a notebook)

What loads can wood be subjected to?

The loads are:

· for tension;

· for compression;

· for bending.

Who can say what loads the legs of chairs (skis, chandelier pendants, etc.) experience?

- Elasticity is the ability of wood to restore its original shape after removing the load. (write it down in a notebook)

The teacher demonstrates the phenomenon of elasticity.

Who can name products whose operation is based on the property of elasticity? (Students' answers.)

- Laboratory work Determination of density and moisture content of wood.

- Number the wood samples provided.

- Calculate the volumes of the samples by multiplying the length by the width and thickness. Write the data in the table.

- Weigh the samples. Write the data in the table.

- Calculate the density using the formula

p=m/V

- Dip the samples into water and soak for 5-10 minutes. Take it out, dry it, weigh it. Write the data in the table.

- Calculate humidity using the formula

Write the data in the table.

- Draw and record your conclusion.

- Reinforcing the material learned

— Why know the properties of wood?

— By what characteristics can one distinguish, for example, aspen from other types of wood?

— What properties should be taken into account when choosing workpieces?

— what types of wood drying do you know?

7. Summing up the lesson

Grading.

Homework

Lesson on the topic: “Wood and its properties. Determination of wood hardness"

Ministry of Education of the Republic of Bashkortostan

MKU education department of the administration of the MR Ilishevsky district

MBOU secondary school No. 4

Lesson on:

“Wood and its properties. Determination of wood hardness"

(5th grade)

technology teacher

Sattarov Rustem Faritovich

With. Verkhneyarkeyevo. 2022

Topic:

“

Wood and its properties.

Determination of wood hardness ."

Class:

5th grade

Working hours:

90 minutes

Target

:

Give concepts of what wood and wood are, types of wood species, properties of wood.

Compare the hardness of wood of different species

Develop the ability to work with reference literature. Cultivate a cognitive interest in technology.

Formation of UUD:

- subject: learn to determine the names of wood and wood, types of wood species, properties of wood;

- meta-subject: regulatory - understand and be able to explain new material; - cognitive - to reveal in oneself the ability to see in a new way, in the ordinary, the unusual, the unexpected; — communicative – to be active in solving practical problems; — personal: goodwill and emotional and moral responsiveness to beauty; Equipment:

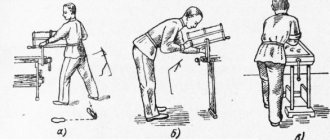

device for testing the mechanical properties of materials, samples of soft and hard wood (40x40x50 mm), ruler, textbook on technology.

Location:

training workshop

Lesson plan:

1. Motivation stage

. 2-5 min. Hello guys! Many materials used to produce material goods are obtained from nature by humans. Such materials are called natural.

Natural materials that have undergone pre-processing before being used in production and are subject to further processing are called industrial raw materials. For example, the raw materials for the timber processing industry are logs obtained from cut trees.

All extracted substances used by humans and retaining their primary natural properties and composition in the subject of labor are called natural raw materials.

You will learn: what are the mechanical, physical and technological properties of materials;

You will learn: determine the hardness of wood 2. Stage of updating knowledge

. 3-4 min Goal setting and task setting. A conversation to clarify and concretize knowledge from personal life experience. Tell me, what will we talk about today?

-What work do we have to do? What to learn?

3. Studying new material.

Wood and timber

A tree is a perennial plant consisting of roots, a trunk and a crown [branches].

Wood is dense plant tissue that makes up the roots, trunk and branches of trees. Most wood is found in the trunk of a tree. The structure of the trunk is shown in Fig.

In longitudinal sections of the trunk, the pattern formed by the wood fibers is clearly visible - the texture.

Texture (from the Latin “fabric”, “structure”) is a natural pattern obtained on the surface of wood when cutting wood fibers. The nature of the pattern depends on the direction of the cut, as well as the type of tree.

ABOUT

- What parts does a tree consist of?

- How is a tree different from herbaceous plants?

- How is wood different from wood?

- Where is the beauty of wood texture used?

The peculiarity of the structure of trees and their fixation in the ground was used by the Russian designer N.V. Nikitin when designing the Ostankino TV tower in Moscow.§

:

3. Types of tree species

Coniferous and deciduous trees grow in the forests. There are much more deciduous tree species than coniferous trees.

Coniferous species. Coniferous species include pine, spruce, larch, cedar, fir, juniper, cypress, and thuja.

Pine has white wood with a yellowish tint. The wood has a well-defined texture and few knots. Pine is resinous and therefore resistant to decay. Pine wood is widely used in construction and carpentry and furniture production.

Spruce has yellowish-white wood, less resinous than pine. The wood is not hard, but has many small, very hard knots. The texture is clearly visible and resembles that of pine. This wood retains its natural color for a long time. It is used along with pine. In addition, spruce is used to make musical instruments. Larch has white wood with a brown tint. She's hard. Very resistant to rotting. Due to its beautiful texture, it is widely used in the production of furniture, etc. Hardwood. In the forests of Central and Southern Russia, the most common trees are oak, beech, birch, aspen, alder, and linden. They are divided into hard and soft rocks.

Hardwood

Oak has light wood with a beautiful texture. This wood is durable and resistant to decay even in water. Therefore, Peter I ordered that houses be built in the marshy areas of St. Petersburg on stilts from oak trunks. Nowadays, during excavation work in this city, petrified oak trunks are often found.

Oak is a valuable wood species. Specially processed bog oak is highly valued. This wood is used in the production of furniture, parquet, and arts and crafts.

Beech wood is white with a pink tint. Its texture is beautiful, with specks on the longitudinal section. The wood is quite durable, but not resistant to decay. Used in the production of furniture and musical instruments.

Birch has white wood, sometimes with a reddish tint. The texture is pronounced, viscous, but quickly rots. Birch wood is used to make furniture, sports equipment, tool handles, and in the production of plywood.

Softwoods

Aspen has white wood with a greenish tint. The texture is poorly expressed. Under the influence of atmospheric phenomena it acquires a silvery tint. The wood is soft, can be processed well, but is not resistant to decay. It is used for the manufacture of dishes, art products, toys and in the production of matches.

Alder. The wood has a homogeneous structure. The white color of this wood becomes reddish over time. The material is soft. Used for plywood production and furniture making.

L

Linden

Ipa. The wood is white-pinkish in color, the texture is weakly expressed. This is a very soft, non-fragile wood that can be easily cut with various tools. Used for products with artistic carvings, such as furniture decorations. In the old days, toys were made from linden, but now very few of them are made.

Deciduous softwood trees (linden, alder)

Alder

Wood from acacia, apple, pear, cherry, ash, maple, as well as wood from a number of African trees is also used in furniture production.

Coniferous species: pine, spruce, larch, cedar, fir; deciduous

Species: oak, beech, birch, aspen, alder, linden.

List coniferous and deciduous species. Where are they used?

List the tree species that grow in your area.

What types of wood are best used for artistic carving?

Why does birch find little use in building houses?

Lesson #2

Properties that determine the appearance of wood

The properties of wood include color, texture, shine and smell.

The color depends on the species, age and growing conditions of the tree. Wood can have different shades. Walnut, for example, can have up to 40 shades, and oak - up to 20. The color of wood is taken into account when making furniture and art products.

Texture, or grain pattern, is considered in beautiful furniture and artwork.

Shine occurs in smoothly processed wood. Oak, beech, maple and other species have a beautiful shine after processing. Wood decay leads to loss of shine. Gloss is taken into account when making furniture and products without tinting.

The smell of wood depends on the presence of resinous substances and essential oils in it. The strongest odor is possessed by conifers (cedar, pine, spruce, especially juniper), which contain resin. Among hardwoods, oak and aspen have a strong odor. The smell of wood is taken into account when making containers for food products.

Color, shine, smell.

Mechanical properties of wood

In addition to appearance, wood is characterized by mechanical properties. These include:

Humidity. It characterizes the moisture content in wood. Its presence is associated with the growth of the tree. Moisture in wood causes it to rot. Depending on the degree of humidity, wood is divided into: wet - kept in water for a long time (humidity 100%); freshly cut (humidity from 50 to 100%); air-dry (humidity 15-20%); room-dry (humidity 8-12%); absolutely dry (humidity 0%).

Wet wood is poorly processed; products made from it can warp, change in size and shape, and crack. Therefore, it is dried before processing. You will get acquainted with methods of drying wood later.

Strength is the ability of wood to withstand loads without breaking. The strength of wood depends on the species. Wet wood is less durable than dry wood. Defects, especially knots and cracks, reduce strength. Strength also depends on the direction of the fibers.

T

Rice..

Instrument for measuring wood hardness:

1

- base,

2

- graduated scale,

3

- handle,

4

- tip,

5 - wood sample, 6 —

shaft,

7

- spring,

D

- diameter of the tip,

d

- diameter of the resulting depression in the sample

. Hardness is the ability of wood to resist the penetration of other, harder bodies into it.

Hardness depends on the type of wood, the direction of the fibers and humidity. As humidity increases, the hardness of wood decreases. The hardness of wood is determined with a special device.

Using a handle, a steel tip is pressed into the wood sample. The hole formed in this case on the surface of the sample under the action of the same force has a different diameter depending on the hardness of the sample. The harder the wood, the smaller the diameter of the hole. To obtain wells of the same diameter in different samples, different forces must be applied to the instrument handle. The hardness of the wood is determined by the readings of the instrument needle.

Impact strength is the property of wood to absorb work upon impact without breaking. The viscosity of hardwood wood is higher than that of coniferous wood. This property is used in the manufacture of handles for percussion instruments (hammers, mallets, etc.).

Elasticity is the property of wood to restore its original shape and size after the load is removed. The elasticity of wood depends on its species and humidity. As humidity increases, the elasticity of wood decreases.

4. Practical work

Exercise:

Draw table 1.

Check out the appearance of the samples. Determine their breed.

Mount the device on a workbench or table. Press the tip into one of the samples. Record the device readings in the table.

Repeat the experiment with other samples.

Measure the diameters of the prints.

Compare the hardness of different samples and draw a conclusion.

Table 1

| Number sample | Wood type | Instrument needle indication | Diameter fingerprint |

| 1, 2 Etc. |

6.Reflection

What is wood moisture content?

How does the hardness of wood affect its processing?

What determines the strength of wood?

Which is easier to drive a nail in: along or across the grain?

Why is oak, beech, and hornbeam wood often used to make parquet?

In the manufacture of which products are the elastic properties of wood used?

7.Homework

Repeat the terms moisture, strength, hardness, impact strength, elasticity.

Lesson plan for 6th grade “Wood species”

Technical characteristics of spruce: spruce wood is soft, light, splits well and sticks together. Less resinous than the rocks discussed above. Very hard small numerous knots. Retains natural color for a long time.

It is used along with pine wood, as well as in the manufacture of musical instruments.

Technical characteristics of fir: the wood has many hard, small knots, does not contain resin, and has no odor. It has low resistance to rotting. Fir is used to make musical instruments and in construction. Yew

has a brownish-red core, which makes it sharply different from the narrow yellowish-white sapwood. The sinuous annual layers are clearly visible.

Technical characteristics: the wood is beautiful in texture and color, and is well processed.

Used for interior decoration, production of small art products and in furniture production. Currently, yew is listed in the Red Book. Hardwood.

The structure of trees of such species is characterized by the presence of vessels that have a tubular shape and are clearly visible in the cross section of the trunk in the form of small holes. According to the location of the vessels in the annual layer, they are divided into ring-vascular

(a ring of large vessels is located in the early zone of the annual layers) and

scattered vascular

(vessels of various sizes are distributed throughout the annual layer more or less evenly, and therefore the boundary between early and late wood is not clearly expressed).

Hardwood

trees are also divided into

hard and soft

, with all

ring-vascular trees being hard, and scatter-vascular trees being hard and soft.

To trees with ring-vascular wood

include

oak, ash and velvet tree (Amur velvet).

All listed breeds

are sound.

Oak

has a core from dark brown to yellowish brown. The light yellow sapwood is clearly defined and has 8-10 layers. The annual layers are clearly visible in all sections. In a cross section, due to the sharp difference between early and late wood, they are clearly visible. The medullary rays are highly developed and vary in all sections; vessels are small.

Technical characteristics: oak wood has a beautiful texture and color, high strength against rotting, and good bending ability.

Oak wood is used in carpentry and furniture, parquet and plywood production, in carriage and shipbuilding. (In the time of Peter I, it was necessary to use about 1,600 oak trunks for one sixty-gun ship.)

I am the canopy

has a light brown core. The sapwood is wide, yellowish-white, gradually turning into the core. The annual layers are clearly visible in all sections. The medullary rays are narrow and difficult to distinguish. The cross section shows large vessels in the annual layers.