What is veneer

Wood veneer production began in Europe back in the 19th century. They were the first to produce it in Germany .

Solid thin sheets were cut from large logs and logs on machines. Their surface retained all natural properties and a natural, unique pattern. The thickness of the resulting plates ranges from 1 to 12 mm, depending on the production method and the type of wood. Over time, machines were improved, which made it possible to produce different types of material. The German name was assigned to it: in translation “veneer” means “chips”.

Thin wood panels have become a godsend for cabinetmakers and musical instrument makers. They were used to sheathe blanks from cheap wood and create things that were indistinguishable in appearance from those cut from solid logs.

History of veneer

Back in ancient times, the first examples of modern veneer appeared. True, historians who are well acquainted with this topic cannot answer unequivocally where they first learned to make this material. It was found during excavations of settlements of Ancient Rome and Ancient Egypt. Scientists admired the beauty of the material made by the craftsmen of that time.

What especially amazed the experts was that at a time when there was no special equipment, people took a responsible approach to the production of veneer and valued the raw material - natural wood. The result was materials that were distinguished by the perfection of color and shape. For a long time, the manual method was used to produce this material. The process of its creation was quite lengthy and required a lot of labor. Using a regular saw, carpenters cut the logs in such a way as to produce sheets of minimal thickness.

A special saw designed for the production of veneer was invented only in 1562 . This happened in Germany, and the master who created such an instrument was called Georg Renner. Its use has significantly simplified the manufacturing process.

The manufacturing technology of this material was improved in 1806 by Marc Isambard Brunel. This master from Britain manufactured and patented a planing machine, which was equipped with a manual drive. Later, even more advanced equipment appeared - a peeling machine for the production of veneer, thanks to which the process of its production was noticeably simplified.

Mass production of the material began in 1843, when the first factory for its production was opened in Germany. It was equipped with primitive-looking machines. A serious breakthrough in the technology for its production was made only in the twentieth century, the credit for which belongs to the Italian Cremona family, which invented a horizontal planing machine. Today it is the basis of the production process of this material. True, modern models are seriously different in their design and functionality from the equipment used by the Italians.

Tangential sawing

This method of processing logs is considered one of the most popular. With a tangential cut, the plane of the cutter passes at a certain distance from the core of the trunk, tangentially to the growth rings. The result is practical and durable boards that are resistant to shrinkage and swelling. Such lumber has an attractive texture - the graceful wave-like pattern of annual rings is clearly visible on them. Boards obtained by tangential cutting can be used for exterior decoration of buildings and creating a cozy interior.

High-quality parquet is also produced in this way. When cut perpendicularly, a natural pattern is visible on the boards - rings, arches, waves, curls. If the parquet is made from Siberian larch, it can be used for laying floors in rooms with high humidity, since products made from this species not only do not collapse when in contact with water and steam, but also become stronger. A wooden floor covering created as a result of tangential sawing will last for many years without needing repair or renewal.

It is customary to call a radial cut of a log, carried out perpendicular to the annual layers. Lumber produced by this method has a uniform texture, they are characterized by increased strength and wear resistance, and are practically not subject to deformation. Radial cut boards have minimal shrinkage and swelling coefficients, so they do not collapse due to the negative influence of the environment and are excellent for external cladding of buildings. With this processing method, lumber has virtually no flaws. Defects may be caused by a violation of sawing technology (displaced core, incorrect size).

Radial sawing is used for the production of edged boards, a sought-after lumber used for finishing houses, summer houses and cottages. If the cladding is made of Siberian larch, it is ideal for decorating baths, saunas and bathrooms. Products made from this coniferous species do not require additional processing, have an attractive texture and have a long service life. Edged boards are widely used by interior designers; with its help, you can create a cozy atmosphere in a room. Lumber from Siberian larch contains resin, when released, it spreads a pleasant aroma.

Definition

Veneer is thin layers (sheets) of wood, their thickness ranges from 0.01 to 1 cm. They are used to glue the surfaces of furniture, room doors, panels, etc. for decoration using special adhesives that meet environmental requirements. As a result of veneer cladding, structures made of chipboard, fiberboard and other materials look beautiful and elegant.

Currently, many varieties of veneer are produced. For this purpose, valuable wood is used. It looks beautiful and gives furniture or other items the appearance of being made from real wood. The color of the veneer can be different - creamy white, dark chocolate, reddish, golden, etc. The pattern completely conveys the pattern of natural wood, which no technical means can recreate.

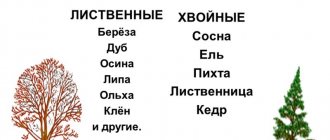

The type of veneer depends on the type of wood from which it is made. And this can be almost any wood used in industry. But more often than others, the following breeds are used for this.

- Nut. This material is of high quality. Therefore, walnut veneer is used in the production of musical instruments (grand pianos), furniture, and interior doors. The beauty of such products brings a special charm to the interior. The color of furniture walnut veneer varies from light beige to brownish brown.

- Cherry. Cherry wood veneer has interesting orange-brick tones. They are used to decorate luxury, expensive furniture.

- Oak. This type of veneer has increased strength and is used for carpentry work. Products finished with it will last a long time without being damaged. Oak veneer is expensive, but its high quality justifies the cost. Colors and shades range from yellowish-beige to dark brown.

- Maple. There are many varieties of maple used in the industry, and all of them can be used to produce veneers in the light shades characteristic of maple wood.

- Karelian birch. This veneer has an unusual, pleasant pattern and a beautiful pearlescent sheen. Its beauty will not leave even the most picky consumer indifferent.

- Pine. Light veneer is made from it, sometimes with a pinkish tint. Furniture with such a coating looks interesting and aesthetically pleasing.

Other types of wood are also used for the production of veneer. Veneer is made from larch, almost equal in strength and other properties to oak. It is not afraid of moisture and is resistant to rotting. The unusual pattern of annual rings gives it a decorative appearance. Beech, alder, ash, elm, aspen, poplar, fruit trees, etc. are also used. Sliced veneer is made from them in accordance with the requirements of GOST 2977-82.

Production technology

To obtain the plates, high-quality raw materials are selected. Timber should not contain a large number of knots, resin ducts, areas of deeply ingrown bark, or wide cracks. Curls are not a drawback, as they allow you to get a beautiful decorative pattern.

Preparation of logs includes removing the bark, clearing the upper damaged layers, and cutting into large ridges . Depending on the type of subsequent processing, the logs are divided into smaller fragments.

To soften the structure or adjust the color, the workpieces are steamed for several days, or even weeks, then soaked in hot water. The exception is capricious species, for example, maple. There is a risk of losing the natural light color.

To obtain canvases, the prepared wood is run through machines. Fresh leaves are dried, sorted, put into bundles and cut.

When making fine line, peeled veneer is immersed in containers with dye or etched with glue already collected in piles. After some time it transforms into a layered conglomerate. The glued material is then placed under a high-pressure press, where it acquires the required density. Then sheets are planed from the finished mass.

Fine-line has high decorative qualities, is plastic, and is more resistant to moisture and temperature changes.

Semi-radial cut

With this type of processing, it is possible to reduce the angle of inclination of the growth rings to the level of 45⁰. Thus, the quantity of finished products increases several times. With lower raw material costs, the cost of the finished product will be lower than with radial cutting. But the quality of a semi-radial cut will also be inferior to a radial one, but not as much as a tangential one. The choice of material for facing work depends on the requirements for the facility, the purpose of construction and the budget. These parameters are the main ones when determining the type of products required. If you want a durable, beautiful and high-quality building, then it is better to achieve a high quality finish using radial sawing, because semi-radial lumber is not very suitable for implementing this idea. It is better to leave them for rough types of work.

As a result, in order to choose the right lumber, you should pay attention to the following characteristics of wood:

- type;

- variety;

- humidity level;

- natural properties;

- processing technology.

Low-quality lumber can also be among expensive products. Therefore, it is worth paying attention to the appearance of the blanks. It is also worth asking in what conditions they were stored. If any doubts arise, the buyer has every right to ask the distributor for documents and control cards that can inform about the origin of the tree, its species, age, type of processing, date of receipt at the warehouse, size, etc.

It is worth noting that it is not necessary to certify lumber and many people neglect this point. Although a conscientious manufacturer always requests a certificate of compliance of its products with the GOST standards system in order to convince the consumer of the quality and safety of the manufactured products. Mandatory certification of lumber is carried out if the product participates in a tender.

It is difficult to notice irregularities in processing, but if there are pronounced defects (rips, potholes, chips), then this is a clear sign of a manufacturing defect. This can happen due to outdated or poorly configured technical equipment, which during the sawing process affected the final result. Violation of drying technologies plays a big role in the wear resistance of wood, so you should purchase lumber from a trusted supplier.

Application of veneer

Veneer is a wonderful finishing material. It was mentioned above that it is used for finishing furniture as a decorative coating. Thanks to this, furniture made from cheap materials will look no worse than those for the production of which the most expensive and high-quality wood is used. Decorative veneer is used as a finishing for panels, railings and other indoor items.

Advantages and disadvantages

Thin plates of wood, processed using a special technology, make it possible to produce finishing materials, furniture and other objects that are externally indistinguishable from those carved from solid wood. The advantage of veneered surfaces is decorativeness . The fibers cut at different angles create many unique pattern combinations and intricate textures that a solid board does not have. This material can be used to finish various problematic surfaces: rounded or curved.

Veneer is a material that has already been processed and prepared for use. It is well dried, polished, coated with protective compounds, resistant to many adverse factors, non-hygroscopic, not prone to cracking, and does not mold. It can be restored after long-term use.

Furniture and doors finished with veneer are much cheaper than solid wood and are more practical. The material makes it possible to reduce the cost of goods. Two products, one of which is made of inexpensive chipboard, sheathed with thin sheets, and the other is machined from solid wood, can look equally noble, have comparable qualities and wear resistance. But the difference in the final price will be significantly different. At the same time, only one item can be made from one log, and so much veneer will be obtained from it that it will be enough to finish 5–10 similar ones made of composite.

Disadvantages - fragility and capriciousness of the coating . It is not resistant to scratches and other types of mechanical impact. In a house where there are animals, the environment will have to be protected from their claws and teeth.

In conditions of high humidity, some types of veneer may warp. They cannot be washed with water or aggressive household products.

Caring for veneered products

Compliance with the rules of care will help ensure long-term service for veneer trim.

Surfaces must not be cleaned with coarse abrasives, hard metal brushes, or solutions containing alkalis or acids. Veneered furniture should not be soaked with plenty of water, crushed with sharp objects, or cleaned off with a blade . Cups and plates with hot foods and drinks should not be placed on shelves or countertops. Protective pads must be used.

You need to remove dust and stains with a sponge, suede, napkins or soft brushes with bristles. For painted and varnished finishes, it is recommended to use special polishes. To remove greasy stains, you can use alcohol-based products. Traces of ink - with a regular school eraser.

Veneer that has lost its former shine can be renewed by covering it with a layer of paint or varnish that preserves its texture and pattern.

Features of natural veneer

This is a living material, which makes the presence of features inevitable: knots, waviness, stripes, sapwood, curls, eyes created by nature itself, which is not a defect, but only emphasizes the naturalness of the material. These features are especially clearly demonstrated by veneers made from old wood trunks, such as Retro oak veneer.

Features of working with natural veneer

The pattern of a wood cut is as individual as a person’s fingerprints. The uniqueness of the pattern and color of veneer, even of one type of wood, determines the peculiarities of working with this material:

- It is not possible to make a sample, because a product made from the veneer of another trunk will be different from it;

- It is not possible to create a warehouse program, because the veneer in different locks and knoles is different;

To emphasize the beauty of the pattern and create a harmonious piece of furniture or interior design consisting of individual parts lined with natural veneer, we offer to use the option of selecting a veneer pattern, which ensures a transition of the pattern across the entire surface of the product from part to part, from element to element. The pattern can be selected both horizontally and vertically.

When ordering products in natural veneer with or without a selection of patterns, you should take into account that additional ordering of parts is not possible, because newly manufactured veneered parts will differ in color, texture, and pattern. We will not be able to find veneer that exactly matches the main order.

Types of veneer

Veneer is a general concept that includes several types of wood finishing material. In industry, different types of this sheet lumber are used, depending on the purpose of the items and the characteristics of the raw materials. For their manufacture, different types of wood are used, as well as various technologies. When finishing furniture, panels, stairs, special bent elements are formed. There are several veneer production technologies.

Sliced veneer

Sliced veneer, which has a certain thickness, is made from the wood of coniferous trees, beech, birch, hornbeam, etc. It is preferable to use wood species with core rays for this purpose. They have an original texture. Its features determine several types of finished material.

The first of them is radial veneer. The annual layers of a tree trunk appear on it as parallel longitudinal lines. The core rays are in the form of strips of unequal width. The second type of sliced veneer is semi-radial. The annual layers are visible over most of the leaf surface; the medullary rays look like stripes located obliquely or longitudinally. The third is tangential veneer. On it, the annual layers are located in the form of inclined cones or curved lines, like the medullary rays. And the fourth is end-tangential veneer. On its surface, the annual layers are visible as curved lines forming closed figures; the medullary rays form strokes or uneven lines.

Sliced veneer is made by planing a piece of wood using a veneer planer. To increase plasticity, the wood is preheated to 30-60 °C. It also reduces the size and number of cracks.

Veneer obtained by planing is divided into 2 grades. The first grade includes products without flaws, or with minimal, barely noticeable cracks, stains, and scratches. The second grade allows the presence of such defects in small quantities, this is determined by the current standard. Certain roughness values are allowed for the surface. Products made from wood species such as ash, oak, larch, pine, and mahogany can have a roughness of 200 microns. Other rocks should have no more than 100 microns.

Peeled veneer

Peeling is a method of producing veneer by cutting a thin layer of wood from a wooden blank - block. It is installed on the peeling machine and rotates. From its surface, using a knife, the layer is removed in a spiral in the form of a tape. Peeled veneer is a material for the manufacture of plywood, cladding, panels, packaging, etc. It is often used to paste over wooden doors. Its main advantage is that the plates have a large area. This type of veneer is the thinnest: thickness ranges from 1 to 5 mm. Peeled veneer is the most budget-friendly type of such product. Inexpensive wood species are used for its production. This method of making veneer is the cheapest. Even when peeling more expensive wood - larch, cedar, oak, the cost of such veneer will be lower than planed or sawn veneer.

The appearance of peeled veneer is not particularly attractive, so it is not used for cladding furniture. If such a need arises, then various finishing methods are used: varnishing, hot printing, painting. An exception is veneer obtained by peeling wood with the presence of a defect - a random or tortuously uneven arrangement of fibers (kinkiness). This veneer looks impressive and beautiful.

Sawn veneer

The process of manufacturing sawn veneer, as the name implies, involves sawing boards using special equipment. Sawn veneer, or lamella, has a thickness of 0.2 to 1.2 cm. Such veneer is made from any wood, but more often raw materials from hardwood are used for this: ash, oak, beech. This material is the most expensive of all types of veneer. During its production, a large amount of waste remains, and it also requires a lot of labor.

Sawn veneer is most often used for finishing. But besides this, furniture, carpentry, panels, and floor coverings are made from it. It is used for finishing car interiors, as well as for the production of musical instruments, souvenirs: caskets, decorative boxes, etc. This type of veneer is suitable for products with curves and non-standard shapes. Such production from lamella is possible due to its elasticity. At the same time, the strength of the connection of wood fibers does not decrease. And the appearance of products made from lamellas is elegant and aesthetic. Virtually no additional finishing is required. All the beauty of the natural structure of wood is fully visible on such products. They look like they are made of natural wood.

Lamel has a number of advantages that make it popular; products made from it are in demand. In particular, we are talking about the following qualities:

- This material is environmentally friendly, and items made from it are safe for human health.

- The service life of such products is long; when used correctly, they are durable, not subject to deformation, do not crack or fade.

- Lamella coatings have high thermal insulation and sound insulation properties.

- Products made from sawn veneer are not afraid of temperature and humidity fluctuations and are resistant to mechanical stress.

- Such products look great and will decorate the interior of any room.

- The consumption of raw materials is low.

All these advantages are highly valued by consumers. As for the disadvantages, the main one is the high cost of the lamella.

Advantages of natural veneer

Originality

This is exactly the case when disadvantages are a continuation of advantages and vice versa. Originality, uniqueness, exclusivity - these are all the qualities for which we value natural veneer.

You have the opportunity to choose the pattern and color that best suits your furniture or interior, and you will get something unique!

Natural veneer is often compared to solid wood, especially with regard to price. But it is no less important that veneer patterns are much more diverse than solid wood due to the production technology of a tree trunk, which gives a variety of assortments.

And one more quality for which veneer is valued:

Environmental friendliness

This is not only an environmentally friendly material, safe for consumers, but optimal from the point of view of using natural resources.

With proper care and use, veneer products can last for many years, and there is the possibility of their restoration.

Wide range of applications

If previously veneer served mainly to decorate furniture or decorative items, now parts lined with natural veneer are used in many pieces of furniture and decoration of a wide variety of rooms:

- kitchen

- living room

- children's

- bathroom

Veneer can be used to veneer both flat and bent/radius products:

- furniture facades

- shelves,

- table tops

- furniture body parts,

- slats,

- beams

Description of species

Natural veneer can be flexible and rigid, which depends on the thickness of the material; for example, products with a thickness of 2 mm or 3 mm have greater ductility when gluing than a thick sheet whose cut is 5 mm. For ease of use, thin veneer is produced on an adhesive basis and is self-adhesive. The range of shades of the products repeats the colors of natural wood varieties, but it is also possible to dye the material to which a light cut of wood is exposed to produce colored veneer. It is cut into plates and also produced in a roll version. There is a glued type of product, where the edges of two plates are joined with a synthetic adhesive. Moreover, the plastic gluing element is absolutely not visible in a single sheet when the veneer is glued to the surface to be decorated.

On sale you can find cork veneer, which is made from exotic cork wood, and this coating looks unique. Production technologies make it possible to produce laminated veneer, which has improved durability and wear resistance characteristics. For the production of wood material, more than a hundred different types of wood are used, which allows you to obtain any color of the product - white, creamy brown, dark coffee, whitish cream, caramel, pink, red and other shades.

In addition, wood veneer is classified according to other criteria.

By cutting angle

The varieties of wood pattern on the cut of the workpiece depend on the processing technique, which is performed at a certain angle relative to the annual rings of the tree trunk:

- radial cutting angle - characterized by the presence of straight stripes on the blade located across the entire surface area;

- semi-radial cut - strips of growth rings are located parallel to each other and occupy no more than 70% of the surface area of the canvas;

- tangential cutting angle - layers of annual rings form a pattern consisting of curved lines and cones with increasing and decreasing;

- tangential-end cut - the surface of the canvas is covered with uneven circles or an elliptical pattern.

During the cutting process, the finished fabric has a front and back side. The side that came into contact with the blade of the cutting knife of the woodworking machine is the wrong side.

It may have small cracks that are barely visible to the eye; its structure is looser and not as smooth as compared to the front side, which has a perfectly smooth surface.

By manufacturing method

No artificial finishing material can convey the living texture of wood. Depending on the woodworking technique, not only the options for cutting log blanks differ, but also the method of making the cut. According to the manufacturing method, veneer is divided into 3 types.

- The sawn type is the most expensive option, which is obtained when woodworking round blocks or logs. For the work, a special type of saw is used, thanks to which thin planks are cut from solid wood - their thickness ranges from 5 mm to 12 mm. This manufacturing method involves leaving behind a large amount of waste, so sawn veneer is produced in small batches and made from inexpensive coniferous trees.

- Peeled type is the most affordable option, which is available in the range from 1 mm to 5 mm. For its production, log scraps are used, which are subjected to the action of a special cutter. Alder, beech, oak, birch and aspen are used for peeled veneer. Most often, this type of veneer is used to produce combined type finishing materials.

- Planed look - is in the middle price category and is available in the range from 4 mm to 10 mm. For its production, machines with cutting knives are used, where the workpiece can be fixed at different angles of inclination, which makes it possible to produce plates with a varied texture pattern. For sliced veneer, beech, pine, fir, cedar, and birch are used.

Among others, natural veneer can be produced in fine-line format. Often this product is mistakenly considered plastic, but in fact it is made from natural species of exotic trees. The technology involves peeling large-sized wood plates, which are subsequently cut into strips of the required parameters. In the production of this type of veneer, natural dyes and adhesives are used, which makes it possible to imitate precious wood species.

The material has excellent decorative properties - it is flexible, resistant to changes in humidity and temperature conditions.

Sawing hardwood

The sawing operation involves decisions about board thickness, turning the log, and compensating for the log's taper. This depends on many factors: the type of wood, the quality of the log, its size, the design of the machine and the grade of lumber that needs to be obtained. There are 3 standard cutting patterns:

Simple sawing

The log is sawed until its core is exposed, and then turned 180° and sawed to the end. This is the fastest and easiest sawing method; however, with this method, each piece of lumber must be cut on the sides. Lumber sawn in this way is somewhat wider and heavier, of lower quality and has a lot of waste. It is extremely susceptible to warping during drying. Therefore, simple sawing or sawing through is justified only in the case of very low quality logs, when all of the above disadvantages are no longer particularly important.

Circular sawing

When sawing in a circle, a cut is first made, and the log is turned over to a new edge, sawed, and turned over again until at least 5 turns have occurred. From a financial point of view, this is the best way for medium and high quality logs, although at the same time, at some sawmills, turning over the logs in this way is difficult, and the daily productivity will be low. Of course, a machine with hydraulics solves this problem.

Sawing timber

Jumbo sawing maximizes sawmill productivity (boards per day) and is typically used in industry for medium to large sized logs. In this case, the log is first sawn as in circular sawing, but the central part of the log, which can have dimensions of 18x23 or 25x25 and so on, is either transferred for processing to another machine along the production line, or sold as a large and heavy beam. Basically, logs of medium and low quality are sawn in this way, when it is impossible to obtain valuable lumber from the central part of the log. This saves time and effort in producing a product that is not of very high quality and therefore not of very high price.

Deciding which side of the log to start cutting on, which cut surface to open first, is the most important part of sawing. We divide the log into 4 sides, each of which extends along the entire length of the log and occupies a certain part of its circumference. The choice of the first face is determined by the position of all the others.

When sawing in a circle and sawing timber, two basic rules apply:

The worst edge of the log is sawn first without any consideration for the taper of the log. Counting the slope of a log means raising or tilting the log so that the saw cuts parallel to the bark. Since this is the worst part of the log, this means that it will produce short boards and a lot of slabs. Since we do not take into account the taper of the log, this gives us the opportunity to cut parallel to the bark from the opposite, better side of the log, without lifting or tilting the log. This means that from this best part of the log more boards of high quality will come out, which also match the length of the log.

Cut the best edge of the wood first, taking into account the taper of the log. This means that the log needs to be raised or tilted so that the first cut is made parallel to the bark.

The end result of both methods will be approximately the same, but the second method has one advantage. In this case, it is easier for the sawyer to rotate the log, because the open edge is the cleanest and has no defects. In the case of the first rule, the best part of the tree is the part opposite the open edge. It is not visible, and it is impossible to accurately rotate the log. Usually, if the wood is of good quality, then both rules work almost the same. But if you encounter a worse log, it is better to use the second rule.

Comparison with other materials

You can distinguish solid wood from veneered products by the weight of the product, since furniture made from veneer consists of blanks that are made from cheap woodworking products - MDF boards or chipboards, whose appearance looks much better when finished with natural wood plates. Despite the identical appearance, products made from solid wood and veneer differ from each other, and this difference lies in many aspects. Furniture made from a solid piece of wood is considered the most durable, high-quality and elite. These properties are reflected in a high price, since such products - furniture, doors, parquet boards - belong to an exclusive class of goods and emphasize the financial viability of their owner. In addition, luxury products never go out of style and are classics that live beyond time and competition.

If such furniture is decorated with fittings made according to ancient traditions, the result will be a unique work of art. But solid wood furniture requires careful and thorough care, which consists of treatment with wax-containing compounds. If such procedures are not followed, over time the products will lose their attractive appearance.

In addition, natural wood is sensitive to changes in temperature and humidity, so maintaining such products is not only a big responsibility, but also the associated costs.

As for furniture and other products made using wood veneer, they are less capricious and easy to use, so the popularity of affordable models is steadily growing. The appearance of veneer products will look no worse than their natural massive counterparts. Production technologies make it possible to prevent the possibility of cracking of veneer on the surface it decorates. In addition, such furniture and other products are resistant to changes in temperature and humidity, and they can withstand exposure to ultraviolet rays. Such strength is possible due to the treatment of the natural cut with a special protective coating in the form of a layer of polyurethane varnish. Veneered furniture does not have as much weight as solid furniture, so it is easy to move. If part of the veneer is damaged, this area can be restored to extend the life of the product.

In addition to regular veneer, there is also the so-called eco-veneer, which also first appeared in Germany. The production technology of this product was based on the recycling of waste that remains during the production of conventional veneer. Enterprising Germans decided to create a new type of material, which is a mixture consisting of wood fibers and a polymer component. This type of facing product made it possible to switch to waste-free production, resulting in the emergence of a qualitatively new decorative material that combines the properties of natural wood and the strength of polymer. Compared to conventional veneer, eco-veneer has a lower cost and different color options. Thanks to this material, it has become possible for the average buyer to purchase furniture made from the most valuable types of wood.

In addition, eco-veneer is particularly resistant to environmental influences and has a long service life. Thanks to the polymer component included in the material, it is resistant to scratches and mechanical stress. Eco-veneer does not delaminate, does not corrode due to changes in temperature and humidity, it can be washed using synthetic detergents, since the fibers connected to the polymer are absolutely resistant to moisture. Eco-veneer can imitate any species of valuable trees, while remaining an environmentally friendly material for human health.

Summarizing the comparison of different materials, we can conclude that ideal products do not exist, since each of them has its own advantages and disadvantages. Natural wood is an expensive material that requires certain conditions for operation. At low humidity, wood dries out and cracks, and at high moisture levels it swells and becomes deformed. As for veneer, it is cheaper than solid wood, but more expensive than eco-veneer. Possessing resistance to changes in air humidity, this material does not react well to scratches and impacts. The damaged area must be completely replaced, since there is no other way to restore it. Eco-veneer is the cheapest option, but in appearance it differs significantly from natural solid wood and veneer, although its performance qualities are high.

Tangential cutting of wood - ordinary parquet boards

When producing a regular board, the cutting plane runs at a distance from the center tangentially to the growth rings. This way you get more boards from one log, but the pattern will be unpredictable, with a lot of curls, lines, spots and rings. Wood looks more natural. Unlike radial cut boards, in this case the wood is more porous and less resistant to wear. Therefore, tangential cut parquet belongs to the economy class.

Thanks to modern production technologies, as well as special compounds for impregnating parquet, the durability of tangentially cut wood increases.

Wood defects

- These are natural deficiencies of individual sections of wood, reducing its quality and limiting its use.

Defects

are the defects of wood of mechanical origin that arise in it during the process of harvesting, transportation, sorting, stacking and mechanical processing.

One of the defects of wood is the slope of the grain.

- used to be called cross-layer. As is already clear from the name, this defect consists in the deviation of the fibers from the longitudinal axis of the trunk. The inclination of the fibers can be either tangential or radial.

Traction wood

characterized by a change in structure in the extended zone of trunks and branches, manifested in a sharp increase in the width of the annual layers. When exposed to light, such areas of wood turn brown. As a rule, traction wood is characteristic of deciduous trees.

Curlyness

- tortuous or random arrangement of wood fibers. It is found in all tree species, more often in deciduous trees.

Curl

- local curvature of annual layers near knots or shoots. It can be one-sided or through, reducing the strength of wood. The same “side effects” are also produced by the eyes - traces of dormant buds that have not developed into shoots. Their diameter does not exceed 5mm. The eyes can be scattered or grouped, light or dark.

- density inside or between annual layers, filled with resin or gums.

Core

- a narrow central part of the trunk, consisting of loose tissue of brown or lighter color than the surrounding wood. At the ends of the assortment there are spots of about 5 mm of various shapes, on the radial surface - in the form of a narrow strip.

Displaced core

- eccentric location of the core, accompanied by curliness.

Double core

— the presence in the assortment of 2 or more cores with independent systems of annual layers, surrounded on the periphery by one common system.

Dry-sidedness

- a section of the trunk surface that has become dead during the growth of the tree as a result of damage.

Sprouting

- a healing or overgrown wound.

Cancer

- a depression or swelling on the surface of a growing tree as a result of the activity of fungi or bacteria.

False core

- a dark, unevenly colored zone, the border of which does not coincide with the annual layers, separated from the sapwood by a dark border.

Wood spotting

- coloring of sapwood of deciduous trees in the form of spots and stripes, close in color to the color of the core.

Internal sapwood

— adjacent annual layers located in the core zone, their color and properties are close to the color and properties of sapwood.

Water layer

are called areas of core or mature wood with a high water content.

The hardness of wood primarily depends on the type of wood, and also to a large extent on the growth conditions of the tree, humidity, etc. Within one type, the spread of values can be quite significant. Usually the average relative Brinell hardness values are indicated as a percentage relative to oak, the relative hardness of oak is taken as 100%.

Strength is the ability of wood to resist destruction under mechanical loads. It depends on the direction of the acting load, the type of wood, density, humidity, the presence of defects and is characterized by its tensile strength - the stress at which the sample is destroyed. There are main types of forces: tension, compression, bending, shearing.

Thus, when choosing materials and wood products, you should take into account the above characteristics and not purchase products with defects and defects in wood. As a rule, low-quality wood is not used for the production of products, but only your vigilance will help you avoid purchasing low-quality products that do not meet norms and standards.

Sawing lumber

- a fundamental process in wood processing. First, we need to recall a few terms that are used in the woodworking industry and which are defined by GOST 18288-87 sawmill terms and definitions:

Lumber. Materials that have one or more straight sides. Depending on the ratio of length to width and the number of parallel sides, timber, beams, boards, obapol and sleepers are distinguished.

- Bars

- thickness less than 100 mm, width does not exceed double thickness. Slats also fall into this category, only their linear dimensions are much smaller. - Timber

- thickness more than 100 mm, width does not exceed double thickness. - Boards

- the width exceeds two thicknesses, can be edged (all four sides are trimmed) or unedged (the sides are not trimmed). - Sleepers

are timber with strictly defined dimensions, used during the construction of railways, but are now rarely used. - Obapol

- the more common name is “croaker”, the outer side of the whip has only one flat surface. Most often used for further processing into wood chips.

Wood sawing methods

This is a very important factor; the overall yield of lumber and its quality largely depend on the chosen method. Depending on the direction of cutting to the annual rings, there are two methods:

- Radial.

The highest quality lumber has an excellent structure and high levels of physical strength. The saw moves perpendicular to the annual rings. - Tangential.

It produces a significantly higher yield of lumber, but its quality is somewhat lower. The saw moves parallel to the annual rings or in a tangential direction.

The choice of a specific cutting method depends on the end use of the lumber and the condition of the log. On the Internet you can find “strange articles” about circular sawing and so on. In fact, the vast majority of the logs are in one position during sawing; as a result, some of the lumber has a tangential cut (about 2/3 of the total), and the rest of the lumber has a radial cut. The top and bottom of the log are sawn tangentially, only its middle is sawn radially.

At the request of the customer or taking into account our own production, the pole can be sawed from the sides, then turned 90°, and sawing is done again. As a result, some of the boards are unedged, tangentially cut, and the rest of the boards will be edged with a radial cut. Let us repeat once again that cutting methods are selected in each specific case separately, taking into account the above factors. Currently, there are three types of sawmills, each of them has its own advantages and disadvantages. Let's talk about them in more detail.

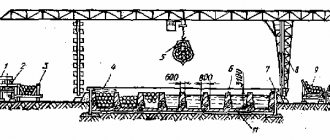

Frame sawmills

These were the first mechanisms that began to be used for mechanical sawing of wood. Today, in our opinion, they have undeservedly gone out of fashion. Let's take an objective look at their advantages and disadvantages.

To make it clearer, you need to learn about the principles of operation. On a frame sawmill, several saws are fixed in a vertical position (from ten or more, it all depends on the size of the frame), the distance between the saws is set once, sawing is carried out by the vertical movement of all saws with the simultaneous feeding of the blade.

pros

.

- The entire process can be completely mechanized

- The sawmill is easy to set up and maintain

- Performance is at a very acceptable level

- Cuts the entire length of wood in one pass

- All resulting unedged boards can be edged simultaneously and also in one pass

- The edged board is of high quality

- Save time

Minuses

- It is believed that these sawmills convert large quantities of wood into sawdust. But this is only true for older models. Previously, saws were made from low-quality steel, the thickness of each saw was up to 3 mm, plus the spread of the teeth, the cut increased to 5 mm. Today, by reducing the thickness of the saw and the angle of the teeth, the thickness of the cut is significantly reduced. We will compare the thickness of the cut with the band sawmill below, you will find out what their manufacturers are silent about.

Band sawmills

They are considered the most advanced equipment, the most productive, the amount of sawdust is minimal. We will discuss this later, but first we will briefly describe their structure and principle of operation. The cutting is done with closed high-speed saws, the thickness of the saws is small, the width of the cut is reduced. The cutting occurs due to the forward/reverse movement of one saw along the blade. To be honest, we don’t notice any particular advantages (for the buyer), but there are disadvantages. In order not to be unfounded, we will talk about the intricacies of the cutting process.

Sawmills require a very careful attitude. Incorrect sharpening of the teeth, incorrect tension or selection of cutting speed (all of these parameters are selected taking into account the type of wood) lead to the fact that the lumber gets a wavy surface. The height of the waves can reach several centimeters. And such waviness of even one board negates all the “advantages of thin cutting.” A wave on lumber is a visible processing defect and reduces the grade of lumber. The classification of wood defects is described in detail in the article of the same name.

These sawmills have rather low productivity and require a lot of physical labor. For example, if your log has a diameter of 100 cm, then calculate how many passes back and forth you need to make to cut it into boards 2 cm thick, and the frame sawmill will cut it in one pass. In addition, each sawn board must be manually removed from the sawmill and stored in a separate place. In this case, after each cut you have to set the saw level again. Very high degree of danger during operation. The risk of injury while working at such a sawmill increases exponentially - this includes the breakage of the saw at high speeds, and the presence of metal objects in the body of the tree (and this does not happen so rarely). Problems with sawdust removal. They scatter along the entire length of the sawmill, removing them is long and difficult.

Of course, manufacturers of band saws are “bashfully” silent about such “subtleties”. We advise you to take into account the maximum number of factors when choosing a sawmill: the required volume of lumber, the availability of qualified personnel, the characteristics of lumber and requirements for their quality. After all, professional workers at a band sawmill produce grade 1 lumber in accordance with GOST.

pros

.

- Relatively inexpensive

- Sawing in both horizontal and vertical directions

- Large whip thickness, up to 400 mm

- Low waste percentage

- Clean saw

Minuses

- Poor performance

- Increased danger

- Complex setup

- Highly qualified personnel

- Mandatory “rest time” of 8 to 10 hours

- Cleaning

Disc sawmills

Circular saws differ from band and frame (multi-saw) sawmills in the quality of edges and parallelism of the face. Lumber produced on a circular sawmill is rightfully considered the best, but only from the consumer’s point of view. The main fact that makes lumber produced on a circular sawmill unavailable for consumption is its high price. The high price does not allow us to compete in the building materials market, despite the excellent quality of boards and timber produced by this method. This circumstance is connected with three facts that influence the increase in the cost of lumber from a circular sawmill:

Summarize:

When choosing edged lumber, you need to take into account not only the method of sawing the lumber, but also the qualifications of the personnel servicing this equipment. You can buy good quality lumber from a trusted supplier by looking at the products using the photos offered on the manufacturer’s website or by visiting the finished product warehouse. The Elka-Palka company is ready to offer its services in accordance with the price lists listed on our website. We sell only high-quality products of our own production or purchased from trusted suppliers. Mandatory quality control.

Lumber

- wood materials (beams, boards and whetstones) obtained by sawmilling. There are lumber of radial, tangential and mixed sawing. Lumber with sawn edges is called edged, while lumber with unsawed edges is called unedged.

Large, high-quality logs (these are logs from the bottom, butt part of the tree) provide the most valuable lumber. When sawing such logs, you need to decide on the thickness of the resulting boards in order to maximize the volume and cost of the resulting material. Since lumber prices depend on its thickness, and because cutting into thick timber produces less sawdust, this decision has a serious impact on income. However, if the quality of the thick material is lower, even if the best edge is almost pure, then it will not be easy to sell it for a good price. The sawyer should try to reduce the size of the material being cut when he sees that the quality of the wood begins to decline.

If the log is good, producing large lumber and railroad ties from the central part of the log is, to say the least, unwise. Because the price of timber is always less than the price of boards.

For high grade logs, circular sawing is recommended. In fact, cutting to the taper of the log and angling the log so that the cut is parallel to the bark is recommended for all "good" edges. The result will be clean wood along the entire length, more valuable pieces of lumber, and this will avoid the need to saw the clean wood later into short pieces. When you reach the low-grade part of the log, move on to the shape of the beam and minimize the operation of cutting the beam on the sides.

Durable but low-quality logs should be cut as quickly as possible. These logs are of little use - the profit is very small, or none at all, which means that these logs need to be removed from the machine the faster the better. Any sawing method is suitable here. Most often they are sawed onto timber, or simply sawed right through. In this case, it is generally better to reduce log overturns to absolute zero.

Fragile logs provide such an insignificant profit and such a huge risk of breaking the product that it is better not to deal with them at all.

Logs of average quality can produce a significant amount of good lumber, and here a lot depends on the sawyer, on how he will turn the log. Here the decision to rotate the log is critical to profit.

First, you need to select the worst part of the log and cut it without taking into account the runoff. But you can't cut too much on this side. For small logs, you generally need to cut one layer, that is, cut once along the entire length of the log, or a layer and a short board, and then turn the log over to the opposite side.

Another way is to choose the best side of the log and start cutting taking into account the taper of the log. Then this particular part is sawed for a long time before the log is turned over.

Lumber is sawed from one side until the sawyer expects that the next board on that side of the log will be at least as good as the boards that can be obtained from the other side. There is an exception: if you start sawing from the worst edge of the log, you must saw until you get a completely smooth cut surface in order to turn the log over onto it. In other words, the good side of the log needs to be cut deeply, and the bad side is simply removed with a layer or layer and one board.

If we take a log with a diameter of 60 cm, although this is true for all logs of any size, when sawing with a 180° turn, we get 8 boards that need to be additionally trimmed on the sides, and using a less efficient method, always turning to the adjacent edge, we get 13 such boards This circumstance alone can already be a significant argument in favor of turning the log 180°, especially for small enterprises. In addition, this method of sawing produces more wide boards, which are usually more valuable. When flipped over to the adjacent edge, you get 8 tangentially cut boards, which are subject to severe warping when drying. Further, if it is walnut or red oak with a narrow sapwood part, then with a 180-degree turn of the log we will get 10 boards with sapwood, with another turning method - 13 boards. Sapwood causes problems during drying. And when the log is turned 180 degrees, the internal tension of the wood is relieved, which results in the avoidance of cracks and cracks.

Turning over to an adjacent edge may be easier, but from an economic and cutting safety point of view, rotating the log 180° is more beneficial.

After two opposite edges of the log have been sawn, you need to move on to the third and fourth. As usual, the worst of these edges is cut first, without taking into account the taper of the log. However, a good quality edge should always be sawn parallel to the bark to increase the yield of good lumber from the log.

The width of the first layer when sawing from all four sides of the log is critical.

If the edge is of good quality, that is, the first sawn board can be classified as a good grade, then the minimum width of the sawn timber should be 15-1 cm. Of course, this depends on the size of the log itself. To take into account further processing of the board, planing or even cutting on the sides, 15-1 cm is recommended, and not 15 cm.

If the edge is of poor quality, then it makes sense to cut boards with a width of at least 10-1 cm. The length of such boards should be at least 1.2 m. In general, you need to produce boards of no less length at your sawmill.

When it comes to logs of frankly poor quality, it makes sense to cut them from the “belly” or from the “ears”, rather than looking for a good edge. The "ears" are usually removed with 1 or 2 passes of the saw, revealing a smooth surface inside the log. Cutting from the belly requires more manipulation, and as a result you get several short, but clean boards.

Timber has a number of advantages compared to thin boards. The timber often has a beautiful wood pattern that buyers love. When dried, it dries out half as much as boards (3% versus 6% for boards). Less cracking during drying. When the ambient humidity changes, the timber is more stable. When the floor is covered with it, it hardly wears out.

Also, when sawing timber, the yield of useful product from the log is 20% lower. Its production speed is much lower. It requires 15% more drying time. The timber dries out in thickness 2 times more than narrow boards. Sharp branches that remain in the timber, in contrast to round branches in the boards, greatly reduce the strength of the material.

Radial

called a cut, in which the plane of the cut passes through the core of the trunk. The wood of such boards is quite uniform in color and texture, the inter-ring dimensions are minimal. Radial cut boards are resistant to external influences, are practically not subject to deformation and have high wear resistance. The radial cut board has a shrinkage coefficient = 0.19% and a swelling coefficient = 0.2%. These indicators for radially cut lumber are twice as good as for tangentially cut boards. For a radial cut board, the process of shrinkage and swelling occurs along the width of the fibers - the thickness of the board, and for a tangential cut along the width of the board because the fibers of the “tangent” are located along the width. Accordingly, floor boards, parquet boards, imitation timber, block houses, and radially cut linings have virtually no cracks compared to similar tangentially cut products. Since the yield of radial cut boards is 10 - 15% of the total volume, their cost is quite high.

Radial cutting of wood is a method of cutting a log in which all the fibers in the board run along the direction of the annual rings. When radially cut, lumber has the best physical and mechanical properties. The strength and hardness of wood with radial cutting is higher than with tangential cutting.

The yield of radial cut boards is usually small (does not exceed 30%). On the UP-700 longitudinal sawing machines, the yield of radial cut boards reaches 60%. This high rate is achieved thanks to the cutting optimization system. By choosing among the optimization criteria the maximum output of a radial cut board, the conditions of radial and semi-radial cutting, the technologist determines the percentage of output of the radial board.

Radial cutting can also be done using other equipment. But the percentage yield of a radial cutting board on other equipment depends on how the operator cut the log. Typically this figure is significantly less than 50%. Due to the microprocessor control system and optimization system on the UP-700, you can obtain the maximum possible number of radial cut boards.

| Cut texture: 1 - tangential cut; 2 - radial cut; 3 - semi-radial cut. |

Tangential

called a cut, in which the plane of the cut passes at a distance from the core, tangentially to the annual layer of the trunk. Such boards have a pronounced texture and a rich wave-like pattern of annual rings. Tangential cut boards have higher shrinkage and swelling rates, but are more affordable.

Where is it used?

Wood veneer is used for decorative purposes in the furniture and woodworking industries. It is used to finish surfaces made of cheap materials. Veneer coating creates the effect of natural wood at a low cost of the finished product. Thin veneer is used in the manufacture of door panels, as well as finishing wall panels. This material is used to make matchboxes, produce fruit boxes, and is also used in the technology of producing multilayer plywood sheets.

The base for veneering can be a sheet of chipboard, MDF, or plasterboard. Wood cut sheets are suitable for restoration work when repairing used furniture. Sliced veneer is used in the manufacture of sports equipment, designer souvenirs, household items and much more. Sawn veneer is used in the creation of musical instrument cases, doorways and arched structures, exclusive furniture models, boxes, panels, and gift products. The colored veneer of noble wood species is a subject for creativity.

With its help, craftsmen create objects of art using the techniques of marquetry, intarsia, and mosaic, where pieces of material are selected according to color and shape, making up the canvas of a picture or ornament.

Modern production technologies

In addition to traditional methods, many enterprises have introduced and are successfully using new approaches to the production of veneer products.

Variegated, multi-character multi-veneer is popular, the surface of which may have light or dark brown shades, gray tones with different textures. There are design works that create a strictly defined or chaotic pattern, unlike natural colors, but with the texture of wood. The products are in demand among connoisseurs of non-standard solutions in interior design.

Fine-line features

Products with a unique name, understandable to anyone who studied English at school, indeed have beautiful lines on the surface. The material is made from wood waste, as a result of which its cost is more affordable than that of first-class natural veneer. This type of veneer is also called reconstructed. Fine-line products are presented in an assortment, have a wide range of colors, and can easily undergo further processing.

The technological cycle for the production of reconstructed veneer includes the following stages:

- removal of plates on peeling machines;

- drying and sorting;

- impregnation with dye in containers;

- treatment with adhesives;

- pressing;

- formatting by planing.

Thus, the products are peeled and at the same time planed. The moisture content of the material should be in the range from 8 to 12%. The types of reconstructed fine-line plates with a thickness of 0.35...5 mm and a density of 450 to 600 kg/m3 are in greatest demand. The final product contains up to 94% natural wood, approximately 6% adhesive, and no more than 2% color pigments.

Fine-line coatings can imitate the texture of any wood species and create textile patterns, such as a satin surface pattern. Fine-line veneer has great plasticity and heat resistance, does not react to humid air conditions, and is easily varnished.

What types of wood are used

Lamels and veneer sheets are used in various fields, the choice of which depends on the characteristics of the raw material.

There are many types of oak, from the main parts and growths of which veneer is made. The products are characterized by strength, high aesthetic characteristics, and durability. Oak veneer is used to decorate furniture, parquet boards, and doors.

Birch plates from Karelian species stand out from the general range with their non-standard, beautiful texture. They are suitable for any work with budgets that allow for the acquisition of exquisite finishes.

Walnut veneer is characterized by increased plasticity, which is useful for the production of railings, handrails, and other curved parts of buildings or furniture.

To decorate luxury furniture, veneer plates from European or American cherry are often chosen, the wood of which has light or reddish shades of brown and a noble texture.

Beech veneer, obtained both by steaming wood and without it, is characterized by increased strength, necessary for everyday use. The plates have a peculiar shade of brown, are well polished, ground, and take curved shapes.

The existing assortment allows you to choose any type of natural or reconstructed material that meets the requirements for appearance, strength, prices and customer wishes.

Rustic cut

The cut is made in any direction at an acute angle to the wood fibers: boards are obtained with a wide variety of textures. That is why the rustic cutting method is extremely rarely used in the production of parquet: it is almost impossible to select uniform dies that are comparable in color.

The cutting method and selection of parquet based on external characteristics determine the texture and color of each block, and also directly affect the stability and strength of the floor covering.

We invite you to the Polov salons in Moscow and Odintsovo: see samples of parquet boards and solid parquet of various selections, study quality certificates, ask related questions to managers and order inexpensive delivery at a time convenient for you!

What is better – eco-veneer or natural material?

In addition to traditional thin wood sheets and a material called fine line, which is still considered natural, there is their analogue, the so-called eco-veneer, which, unlike the first two types, costs much less and has a number of unique properties.

There are several options for such finishing, but the most common are polypropylene film and nano-flex. These are materials of artificial origin, but nevertheless, they are distinguished by a high degree of identity of natural ones, strength and durability.

Polypropylene coating is produced by pressing waste wood chips with the addition of appropriate artificial ingredients. Its appearance is practically no different from natural material.

The nano-flex coating contains Japanese parchment as a base, covered with several layers of polymer and varnish. In addition to the formation of a velvety surface that feels reminiscent of natural wood, this material produces the effect of three-dimensional visualization due to the fact that this eco-veneer consists of sections of different textures - matte and glossy.

Artificial turf has a number of advantages compared to natural wood materials:

- Low cost

- Resistance to mechanical stress, temperature changes, high humidity

- Wide range of colors and textures

- Absence of chemically active harmful substances - phenol, chlorine and formaldehyde

Among the shortcomings, low maintainability can be noted. And of course, its artificial origin, no matter how safe it may be.

Now watch this amazing video on how to make a veneer countertop:

We've told you everything we know about veneer, but it's up to you to decide how to use it. You can buy it in many building materials stores if you decide to veneer some household items with your own hands.

Equipment for sawing logs

The most famous type of equipment for dissolving logs into lumber is a sawmill. As the name implies, a sawing machine of this type has frames on which the cutting parts are fixed. By moving the frames along the log, it is cut.

The operation of a band sawmill, a video of which can be found on the Internet, will give an idea of the operation of this equipment . This machine allows you to process logs with a diameter of up to 80 cm and a length of up to 7 meters. The design of band sawmills comes in two types: vertical and horizontal. In both types of such equipment, the blade is responsible for cutting the wood.