Plywood today is a high quality building material. It is characterized by a glued layered structure. To obtain such material, peeled birch and coniferous veneer are used during production. The structure of the material is a canvas consisting of several layers of veneer glued together in thickness. At the same time, in adjacent layers of veneer the fibers have a mutually perpendicular direction. Due to such characteristics as durability and attractive appearance, this material has become actively used in many areas of construction. It is distinguished by grades, of which there are only 4. Let's take a closer look at the material, grade 4 4, in order to understand what plywood is, you need to read the article below.

Characteristics of plywood grade

Let's start with the fact that plywood is widely used in such work as interior decoration of rooms, floor leveling, sound insulation, thermal insulation and furniture production. Since the type of plywood under consideration is 4 4, due to the presence of a large number of defects on its surface, it can only be used in the manufacture of containers and packaging. Despite its untidy appearance, it boasts high quality gluing layers.

Moisture-resistant plywood dimensions and prices are indicated in this article.

The main characteristics of the sheet include:

- thickness – 8 mm;

- canvas size – 1500x1500 mm;

- maximum deviation in width (length) – no more than 2 mm;

- grade – 4.

This article describes how to glue plywood to concrete.

4 4 is not subject to grinding; its surface may contain:

- knots in unlimited quantities;

- wormholes in unlimited quantities;

- edge defects.

The main advantage of this material remains its low price. But another quality that can be noted is the reliability of gluing. All sheets are securely glued during its production. The inner layers of plywood of any grade are the same. Their strength and geometric characteristics remain unchanged. Consequently, a logical question arises: what is 44 - an unsuitable material or high-quality plywood that is widely used in construction?

Moisture-resistant plywood technical characteristics and other data can be seen and read from this article.

This material is used when there is no need to use the decorative properties of plywood. It has excellent performance characteristics and is very popular among consumers due to its low cost. In addition to the production of containers and packaging, 4 4 is used in the arrangement of subfloors, and can also act as a base for carpet or other floor covering.

Based on the above, we can conclude that 4 4 is in great demand in the construction industry. It is used for rough finishing, temporary cladding and auxiliary roofing work.

Bakelite plywood price per sheet and other data are indicated in this article.

Application area

Let's take a look at some areas of application of the material in question:

- Leveling the floor. Most types of finished flooring require a reliable and solid base; wood-laminated board copes with this task perfectly, while also insulating the structure. In this case, the appearance of the flooring will still not be visible;

Plywood subfloor

Advice: for laying flooring in residential premises, try to purchase plywood from well-known manufacturers with markings indicating acceptable environmental friendliness of the product. Otherwise, you may come across products with a high content of toxins in the glue, which will subsequently negatively affect your health and your loved ones.

- Wall finishing for wallpapering;

- Production of packaging containers;

Example of plywood containers

- Manufacturing of trade or exhibition equipment, where the visual emphasis will be focused on completely different objects;

- Various types of repair work at home.

Comparisons and differences

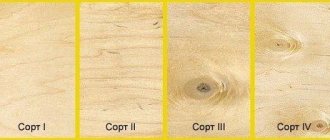

S nsh 34

It should be noted right away that all types of plywood have only one difference - their appearance. After all, the production process of each variety is carried out on the same equipment using the same technology. The physical and mechanical properties of the highest grade are no different from those of the lowest grade.

In the photo - grade 3 4 plywood

Classification by grade is carried out taking into account the quality of the veneer, which is used for the manufacture of the front and bottom parts of the product. The E value means the highest grades: 1 and 2. Low grades can be called 3 and 4. The marking of plywood also contains the grade of veneer on the outside and inside. For example, 3 4 is deciphered as follows: grade 3 veneer was used for the front side, and grade 4 veneer was used for the back side. It is the type of surface treatment of plywood that determines what the surface will be - sanded on both sides, unsanded or processed on one side.

Plywood FSF decoding of such building material is indicated in this article.

Plywood 3 4 is characterized by such characteristics as excellent appearance, excellent wear resistance and strength. Thanks to these advantages, such a product can be used for cladding inside the house, making furniture, in the field of automotive and carriage building.

The choice of variety should also be made taking into account such criteria as the glue used in the production process.

You can find out how fk plywood differs from fsf by reading this article.

The most commonly used composition is based on the following resins:

- urea-casein;

- phenol-formaldehyde;

- melamine

This or that option must be indicated in the certificate. Therefore, when purchasing nsh 3 4 and 4 4 plywood, it is necessary to take this factor into account and ask the seller for documents for the purchased product. If you buy FK 4 4 plywood, this means that the process of gluing the veneer layers was carried out using carmabide glue. This composition does not pose a danger to human health, has average moisture resistance and high strength. For this reason, 4 4 can be used for interior work, namely when arranging a subfloor, roofing and structural work along with OSBI boards.

Plywood under laminate on a wooden floor, how to do it correctly can be done by reading this article.

If you need to carry out some external work, then plywood 3 4 can help here. It is characterized by higher moisture resistance. For gluing layers of veneer, formaldehyde resins are used, which do not have a specific odor. But compared to 4 4 plywood, this material has a higher price.

How to get plywood

Plywood is one of the oldest artificial materials used by people. Items made from plywood, similar to modern ones, were found in the tombs of Egyptian pharaohs.

The maximum thickness of the outer (finishing) layer can be no more than 3.5 mm, and the inner one - up to 4 mm. Layers of plywood or veneer are made by sharpening cylindrical logs rotating in a special machine. The resulting semi-finished product is sent to the places of collection and gluing, that is, to where the plywood is made.

The perpendicular direction of laying veneer fibers gives the material increased tensile and bending strength. The grade of plywood primarily depends on the quality and decorative appearance. Therefore, the top layers are used with wood veneer with fewer defects. Sometimes it can be veneer made from valuable and exotic wood species. Then the external surfaces are subjected to additional processing - grinding, varnishing, polishing, lamination (pasting with paper or polymer film with a printed wood grain pattern of a particular required species).

At the same time, veneer made from low-quality wood that has a greater number of defects is used on the inner layers - mainly coniferous (pine, larch), birch.

The number of veneer layers in plywood ranges from 3 to 21.

In accordance with this, the thickness of plywood produced by domestic enterprises, regardless of its type and what its grade is, is standard - 3, 6, 9, 12, 21, 15, 18, 27, 24, 30, 35, 40 mm .

During the manufacturing process, the sheets are dried and cut into slabs or panels with dimensions accepted by the relevant GOST.

C 2 4

What does grade 2 4 mean? If we consider grade 2 4, then such a product is characterized by flaws on the front side, which are typical for grade 2. On the back side of the plywood there are defects characteristic of a grade 4 product. Unlike 4 4 plywood, this material has a better appearance, so it can be used for interior decoration. Another difference between them is the cost; the first option has a higher price.

What is plywood grade 2 4 can be found out in this article.

Separation of plywood according to surface treatment method

A number of manufacturers, in addition to the grade, additionally indicate the method of processing the surface layer when marking plywood. Plywood is divided into 4 categories based on surface type:

- Laminated. The sheet is covered with a special film for additional protection and increased strength.

- Ш2. Plywood, sanded on both sides.

- Ш1. Plywood, sanded on one side.

- NS. Plywood that has not been sanded.

Price

The price of this material is not too high, which is why it is in great demand among consumers. The average price for 4 4 plywood is 560 – 690 rubles per sheet.

To find out what is better to mount plywood or OSB on walls, you need to read this article.

Plywood 4 4 is not the highest quality material, since there are a large number of flaws on its surface. But this does not prevent such a product from being used in various fields of construction. Such plywood, despite its unattractive appearance, has high strength indicators, which is why it is used in the construction of structures for which the important criterion is not beauty, but reliability.

Dividing plywood by type of wood

The properties of the material greatly depend on the type of wood, but for plywood only the veneer composition of the outer layers of the sheet is taken into account.

Based on the type of wood, plywood is divided into 3 categories:

- Birch. 90% consists of birch shavings and sawdust. It has a pleasant light shade with a uniform soft texture and high tensile strength.

- Coniferous. Consists of coniferous wood. It is characterized by increased resistance to moisture and insects due to the resins in the fiber structure, while the resin is often found in the texture in the form of noticeable resin pockets.

- Combined. It consists of wood of different species, partly made from especially valuable wood species. It is characterized by increased strength, but due to the technological complexity of production and the partial content of valuable species in the composition, it has a high price.

Nuances of marking, or what other letters mean

But if it were all that simple, remember 2-3 letters and go buy plywood. Yes, there are other letters and numbers on the sheets of this material. This is already a designation of grade, as you can read about in this article.

Moreover, please note that if the grade of plywood is written through a fraction, say, I/II, this means that the first grade corresponds to the front side, and the second, accordingly, the back.

Wood type veneer

The wood used to produce solid veneer divides plywood into the following types:

- E – material made from coniferous wood (it is quite soft, but very resistant to rotting);

- Ex – plywood made from deciduous trees (usually birch). This material is strong and hard, but is more susceptible to rotting.

Emission classes

Based on formaldehyde content, plywood is divided into classes:

- E1 – 100 g of plywood contains less than 10 mg of formaldehyde;

- E2 - 10-30 mg in a similar amount;

- E3 – the formaldehyde content in 100 g of plywood ranges from 30 to 60 mg.

Type of material processing

The plywood is divided into the one that was processed and the one that was produced without it. The absence or presence of processing divides such material into:

- NSh (unpolished veneer) . This type is used for rough work; for example, it is quite suitable as plywood for the floor. The cost of NS is low, and if desired, it can be sanded and thereby save on building materials.

- Ш1 . The plywood is processed only on the front side.

- Ш2 . Sanding was carried out on both sides of the plywood sheet (front and back).

- DF-1 . The plates are lined with a film containing melamine-formaldehyde resins.

- DF-2 . This plywood is double-sided with decorative paper containing melamine-formaldehyde resins. The plates have increased hydrophobicity.

- FOF . The surface is laminated, which increases the moisture resistance of the material and adds aesthetics.

Sheet thickness

Since the scope of application of first-grade sheets is very wide, one or another material thickness is better suited for each type of work. There are three types of products according to thickness - it can be thick, medium or thin. With a material thickness of 18 mm or more, it is classified as a thick product; if the sheets are 8-15 mm, then the thickness is average; thin types include products up to 6 mm.

Thin sheets, called aviation or Finnish, are highly durable and flexible. This material has a thickness of 0.4-6 mm. The scope of application of these products is determined by its name. This is the design of aircraft, amateur aircraft modeling. This material is used to make souvenirs, devices and musical instruments.

Let's consider where material with a thickness of 3 mm to 6 mm is used (grades FSF and FK). Plywood 3 mm grade 1 is used for the manufacture of souvenirs and decorative items. Such products are characterized by a high level of flexibility and strength, this is due to the high quality of the products. At the same time, products with a thickness of 3 mm are used somewhat less frequently than 4 mm sheets. This fact is determined by the lower price of the latter.

The thin 3mm material has a high cost, which is offset by the small quantities needed to make each item. In addition, due to high quality, labor productivity increases.

Sanded plywood of medium thickness with the designation 1/1, 1/2 and 1/3 is distinguished by a beautiful texture of the front side and an aesthetic appearance. The products are used for interior decoration, front sides of floors and walls.

Thick, first-class sheets are used less frequently; they can be used in the construction of playgrounds, wall cladding, partitions, in mechanical engineering and furniture production, and in construction for the manufacture of formwork.

Selection rules

The main rule of choice is that you should delve into all the existing parameters of plywood in as much detail as possible, know the various markings, and clearly understand what they mean. Considering that this is not only a finishing material, but sometimes also a building material, which is also not always 100% environmentally friendly, you need to be sure that no potentially dangerous properties of plywood are left behind. Avoid choosing plywood that differs from what you need “in just one or two points” and is cheaper.

Before purchasing, think carefully about what the ideal plywood should be like to solve the task at hand, and do not deviate one step from the requirements. Agree, it would be strange to use theoretically toxic plywood in a nursery simply because such material costs a little less. Savings are also inappropriate if the moisture resistance class of the material is lower than required, or if the product turns out to be so rough that it loses its aesthetics and can become a source of splinters.