Installing a polycarbonate greenhouse on timber has a large number of advantages, not only from a technical point of view, but also from an economic one. The foundation for a polycarbonate greenhouse, made of lumber, has practically no competitors. This is due to the convenience of installation work, since there is no need to deal with formwork, reinforcement, prepare the mixture, and then wait for the poured solution to harden. Working with wood is very easy and simple. But if you do not understand how a polycarbonate greenhouse is installed on timber, the advantages of the building material are reduced to zero. Before starting installation work, it is recommended that you first familiarize yourself with all the available nuances that you will encounter.

Pros and cons of timber for a greenhouse

Installing a polycarbonate greenhouse on timber is used mainly in cases where the finished structure is light in weight. A special feature of a timber foundation is that, if necessary, it can be moved to any part of the summer cottage, which allows you to comply with agrotechnical standards and change the soil as necessary.

Before placing a polycarbonate greenhouse on a beam, it is recommended to first take into account all the available advantages:

- reasonable cost of building material;

- installation work is carried out quite quickly;

- easy dismantling process;

- foundation mobility;

- several types of connections can be used;

- if necessary, damaged elements can be replaced without much difficulty;

- all installation work can be done independently, without outside help;

- the material is completely safe and environmentally friendly.

Despite the large number of advantages, there are also some disadvantages - a short service life. As a result of the fact that a foundation made of timber is located underground, it is exposed to a high level of humidity, which leads to the process of rotting, the appearance of fungus and insects.

Terms of Use

The greenhouse must be installed on a frame, and if timber was chosen as the base material, then it is worth remembering several conditions for its use:

the weight that such a foundation can support is from 70 to 120 kg;- fastening of parts must be provided in such a way that in the future it can be disconnected and the greenhouse can be moved to another location;

- the greenhouse frame must ensure the rigidity of the entire structure;

- the timber must be treated appropriately to protect the soil inside from being washed away by rain;

- raw materials must be treated with antiseptics and impregnating materials to avoid rotting, attacks by rodents and insects;

- processing of the material should take place on a separate site to avoid chemicals getting into fertile soil;

- all cuts, places where beams and boards are fixed must be treated with antiseptics - this is done at the assembly site.

Important! To process the material, not only impregnations and antiseptics are used, but you cannot do without them. If you abandon the processing stage, then with constant rain and watering inside the greenhouse, the timber frame will become unusable very quickly.

Types of wooden bases for a greenhouse

Today, there are several types of bases for a greenhouse made of polycarbonate timber:

- tape;

- columnar.

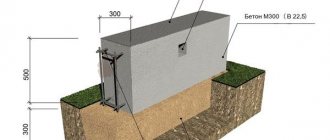

A strip foundation for a foundation is the most popular option. This type of foundation is used primarily for commercial buildings. The installation process does not take much effort and time, and in the end it is possible to get a strong and reliable foundation.

If a budget option is required, then in this case you can give preference to a columnar base for installing a greenhouse made of polycarbonate sheets on timber. The main stage during installation work is the installation of metal poles, which are intended for wooden beams as support.

Polycarbonate sheathing

The finished frame can be sheathed with polycarbonate. Since this material is quite expensive and does not always withstand shock loads well, it is better to cover the wall of the greenhouse up to the height of the beds with boards. This way you will definitely not damage the plastic with an accidental blow from a shovel or rake. The quality of the boards is not particularly important, the main thing is that they are impregnated with fire and bioprotection and, when connected, do not create large cracks (otherwise the earth will spill out through them).

When purchasing, pay attention to the thickness of the polycarbonate sheet: thin ones are easier to bend

Selection of timber

It is important not only to choose the right size of timber for the greenhouse, but also to decide on the species. Thus, there are several options: using hardwood or softwood. The second option is ready-made beams that have already been treated with special protective compounds.

It is worth considering that natural wood has a number of disadvantages, namely, the material is subject to deformation at high levels of humidity, which leads to the appearance of rot and fungus. But if the building material is processed in a timely and correct manner, then all these shortcomings disappear.

What will you need for the job?

To arrange the supporting structure, you need to prepare the following tools:

shovel;- roulette;

- level;

- hammer;

- drill;

- screwdriver;

- jigsaw or saw;

- screwdriver.

You also need to purchase screws or other fasteners that will secure the frame. The materials you will need are timber of the selected species; it should have a moisture content of about 22%.

There are also nuances when choosing the thickness of the boards. For example:

- For a lightweight greenhouse frame, 5x5 cm beams are suitable.

- For a medium-sized structure on metal rods, it is important to take a beam of 5x10 or 5x15 cm.

- If the greenhouse frame is created from profile pipes or thick wooden boards, then it is better to take raw materials with a cross-section of 10x10 or 15x15 cm.

How to treat timber under a greenhouse against fungus

Processing timber for a greenhouse is a fairly important point, thanks to which it is possible not only to prevent the process of rotting, the appearance of fungus and mold, but also to significantly increase the service life of the building material used in the work. In order to impregnate timber under a greenhouse, there are a large number of special protective agents that can be easily found for sale on the market of goods and services. In specialized construction stores you can find impregnations for any type of building material. It is worth understanding that for greater reliability, it is best to apply several layers of the composition to the timber.

Material processing

Before using timber from the timber to lay the foundation, it is recommended that it be properly treated. It is worth considering several important nuances:

- the antiseptic must be intended for external use: compositions for internal use will be washed off at the first precipitation;

- the impregnation should be “friendly” with polycarbonate and not damage it during use;

- there should be no poison in the impregnation: it can penetrate the soil and infect the plants;

- the most optimal composition is water-based, which creates an invisible film on the surface of the raw material and protects it from rotting;

- Sometimes, instead of ready-made products, you can use a folk method: burning with a blowtorch, heated bit or machine oil works well.

You can also use copper sulfate - it is harmless to plants. For processing, each part is soaked in a solution and left to dry, but without exposure to sunlight. Drying usually takes about 3 weeks.

Site selection

Before you begin assembling a timber foundation for a greenhouse, you will need to select a plot of land. As a rule, such a site should be located in the sunniest place, protected from strong gusts of wind. Once you have decided on the location, you will need to remove all existing weeds and debris. If the area is uneven, it will need to be leveled. Where required, it is necessary to remove excess soil, and somewhere, on the contrary, add it. Once the area is prepared, you can begin marking. For these purposes, special pegs are used, which are installed in the corners of the future polycarbonate greenhouse, after which the thread is pulled.

Attention! It is not recommended to install the greenhouse on a beam on an uneven area.

Coatings for frame structures

The covering of a wooden greenhouse is often made from the following materials:

- Film. An economical and lightweight covering option, more suitable for greenhouses without a foundation. PVC film protects plants well from bad weather and sunburn, but it only lasts for one season. There is a thick reinforced film (it is used for swimming pools) that will last for 3-5 years, but it is significantly more expensive.

Wooden structure according to Mittlider for film Source pinimg.com

- Glass. The glass coating is aesthetically pleasing, easy to maintain, durable and resistant to chemicals. It creates comfortable conditions for plants, but it costs money, and installation is quite troublesome and difficult to complete without experience. In addition, the glass has to be replaced periodically - it cracks and breaks.

- Polycarbonate. Plastic is stronger than glass, transmits light well and at the same time traps heat inside. It is lightweight and flexible, which is used in arched models. Polycarbonate is destroyed by ultraviolet radiation, so for greenhouses they choose a material with a protective film coating. When heated, it expands, which has to be compensated for by thermal gaps with rubber gaskets.

Do-it-yourself timber foundation for a greenhouse

If necessary, it is possible to make a wooden foundation for a greenhouse with your own hands, without resorting to the help of third-party specialists. All that is required during the installation process is to adhere to the general rules, take into account the recommendations and advice of experienced specialists. It is thanks to such nuances that you can get a durable and reliable polycarbonate greenhouse.

The basic rules are as follows:

- a solution of uniform consistency must be used;

- the prepared cement surface for installing the timber must be flat;

- when using a reinforcing belt, the interval should be minimal.

After the solution has been poured, it is recommended to install the base for the greenhouse from polycarbonate sheets onto the timber as correctly as possible.

Important! The dimensions of the foundation for a greenhouse made of timber on pipes must be determined at the design stage of the structure.

About standard sizes

Strictly speaking, there are no standard sizes; it all depends on the needs of the owners, their financial and time capabilities. But most greenhouses tend to be 3x6 m in size, which fits optimally into the middle area. The greenhouse can accommodate a sufficient variety of crops, and daily care is not difficult.

Acceptable sizes are those that allow a person to use it comfortably. When creating a wooden greenhouse project, you can focus on the following parameters:

- Height. For a gable structure, the optimal height at the top point will be 2.5 m. You will be able to move around calmly and open the windows.

- Beds. The width ranges from one to one and a half meters. Beds are rarely made wider, as this makes maintenance difficult and forces you to organize not only the central, but also side aisles, which means irrational use of space.

- Central path. It stretches across the entire greenhouse, the width does not exceed 1 m. This is enough to carry buckets or roll a small garden wheelbarrow.

- Side passages. If plants are planted in several rows, side passages allow them to be inspected, fed and watered.

Internal structure of a greenhouse made of wood Source na-dache.pro

Installing a greenhouse on a timber foundation

Most of the questions related to how to properly install a greenhouse on a beam with your own hands ultimately come down to one point - which option for attaching the frame to a wooden frame to choose. Today, there are several popular installation options, so everyone can choose the best method for themselves based on financial costs and effort. If some difficulties arise, then it is worth watching exactly how the installation of a polycarbonate greenhouse on timber is carried out in the video, which is presented below in the article.

Screwing

Since there are currently no polycarbonate greenhouses made of polymer pipes on sale, it is worth taking into account that metal is used to produce the frame, and metal piping is used for the lower part.

The process of installing a timber foundation for a greenhouse made of polycarbonate using screwing technology has its own characteristics. The first step is to make a foundation from timber. The lower part of the greenhouse made of polycarbonate sheets is fixed to the wooden base using bolts. According to the attached instructions, assemble the frame.

It is recommended to install the bolts or screws used for fixation in the corners of the polycarbonate frame. The number of attachment points around the perimeter directly depends on the size of the greenhouse and individual preferences. The minimum step is 50 cm, and the maximum is 100 cm. Many experts recommend carefully ensuring that all fasteners are installed at the same distance.

Reinforcing bars

You can make a foundation for a greenhouse from timber using reinforcing bars. Reinforcing bars are very popular in the construction market, as they are capable of performing several functions simultaneously. The lower part is used as an anchor, thanks to which it is possible to achieve a strong fixation of the polycarbonate greenhouse, the upper part is a pin and is used for installing wooden bars or polymer arcs.

The reinforcement is cut into rods 75 to 80 cm long. After the foundation box is completely ready, the rods are driven into the ground so that the reinforcement is located on the outside or inside of the wood base. All installation work must be carried out in stages, this is the only way to achieve the desired result.

Steel corners

In addition, the greenhouse can be fastened to a timber foundation using steel angles. Galvanized corners are made from fairly durable steel alloys, as a result of which they can be used not only for wooden, but also for metal greenhouse structures made of polycarbonate. It is important to understand that such fasteners are not a budget option, but they are the most reliable. In order to save money, it is allowed to use steel corners only in those places that are the most important; in other cases, nails, screws, and bolts are suitable.

Attention! In the process of assembling and installing a polycarbonate greenhouse on timber, you must adhere to the advice and recommendations of experienced specialists.

Nails

Fastening a greenhouse to a beam with nails is chosen mainly by those people who do not have skills in carpentry and carpentry. It is recommended to drive nails through the base of corner and row posts; the angle should be 45 degrees. Nails should be driven in from the outside and inside of the polycarbonate greenhouse frame. Sections of timber are ideal as additional support for vertical posts. After the work on installing the racks has been completed, you will need to secure the greenhouse to the beam using cross-shaped spacers. In this case, corner posts serve as additional support for the end braces, the first row of rafters and the top frame of the greenhouse frame.

Preparatory stages

Since the wooden frame will be recessed into the ground, special attention is paid to the choice of material. The timber must be of high quality, without cracks, splits or other defects. In this case, you can count on 8-10 years of operation. The ideal would be to purchase coniferous wood for the foundation, and larch to create the frame.

All wooden parts used for the foundation and frame of the greenhouse must be processed. To do this, the timber is thoroughly dried and impregnated with a special store-bought antiseptic and improvised materials - hot bitumen, used motor oil, etc.

Before using the timber, it should first be treated

Also, to carry out all the work, the master will need the following tools:

- building level;

- hacksaw and saw;

- ax and hammer;

- drill and screwdriver;

- set of keys and screwdrivers.

To work with timber, the master will need a set of screwdrivers and wrenches

An open area is suitable for construction. Nearby buildings, trees and tall bushes should not cast shadows on it, but can provide protection from the wind. The area is leveled, the top layer of turf is removed, and sprinkled with gravel. Then a base is prepared for the wooden foundation:

- A trench is dug the width of the beam and the depth of half its thickness plus 10 cm for the “cushion”.

- The trench is leveled, then a cushion of sand, gravel or broken brick is formed. The pillow is carefully compacted.

- It is recommended to wet the sand, let it harden and compact it again.

- The pillow is covered with roofing felt or polyethylene to improve waterproofing.

Installation errors

Putting a greenhouse on a beam is not as difficult as it might seem at first glance, however, many people make quite serious mistakes during installation work, which later leads to disastrous consequences:

- the timber does not undergo the processing process, as a result of which, with constant contact with moisture, it begins to rot;

- An uneven area was chosen for installing a polycarbonate greenhouse;

- the installation of fasteners is installed in large increments, as a result of which the greenhouse loses a high level of reliability.

These mistakes are the main ones today, which is why they should be taken into account and not made.

Attention! If necessary, you can watch exactly how to correctly install a polycarbonate greenhouse on a beam in the video, which will eliminate the consequences and many questions in the future.