One of the main tools for working with various materials for a home craftsman is a hacksaw. It has several varieties, used depending on the type of surface being treated. It is important to know how to use each of them correctly.

What is a hacksaw?

In carpentry, a hacksaw is a special type of hand saw designed for cutting wood, metal, aerated concrete, plastic and other materials. Scientists find mention of the first such instruments in ancient times in the civilizations of Egypt, Greece and Rome. Over the course of its centuries-old history, the hacksaw has undergone significant changes, but has not lost its relevance and is always kept in a set of basic tools for a home craftsman.

Hacksaw device

Like any other carpentry tool, a hacksaw has a certain structure that affects its performance characteristics. It consists of:

- Working, hacksaw or saw blade. It is made of metal of various alloys, which, together with the size, affect the purpose of the tool. Another important parameter of the working blade is the number, shape and size of the teeth. Thanks to them, the surface is divided into parts using the reciprocating movements of the master.

- The working blade is attached and securely fixed to the handle or a special frame. It performs the functions of fixation, protection and ease of use. When selecting a saw, you must take into account its ergonomics.

What is a hacksaw for?

Having understood the definition of what a hacksaw is, it is worthwhile to dwell in more detail on the areas of its application:

- This tool is widely used in gardening for pruning trees and shrubs, cutting down knots and rough parts of wood.

- A hacksaw is used to saw wooden parts during construction and household repairs.

- It is used to cut out figures from plywood, make curved cuts or make through holes.

- There are special varieties for sawing metal sheets and pipes, aerated concrete blocks.

- Some modifications include cutting grooves, tenons and recessed holes.

How is a hacksaw different from a saw?

One of the main and frequently used types of saws is the hacksaw. It differs from other instruments in this group in that:

- This is an exclusively hand tool. The hacksaw saw is driven only by the reciprocating movements of the master’s hands. Whereas other saws can be electric or gasoline.

- When using a hacksaw, only return movements are used, while other saws can be circular.

- In the usual configuration, such a tool has one handle for the master to work alone.

- It has a mostly straight cutting blade, whereas analogues may have a chain, tape or disk.

- A hacksaw has only teeth on the working edge, while other varieties may contain abrasive.

Choose and purchase a quality hacksaw for the job?

We are pleased to offer a wide selection of construction tools at excellent prices. We always have popular product items in stock, so you can choose the necessary hacksaw and receive your goods in the shortest possible time.

Our experienced specialists are always ready to advise on the technical features of different types of hacksaws and will help you make the right choice based on the further scope of the tool. Contact the phone numbers listed on the website or fill out an application on the website to purchase a reliable hacksaw from a leading manufacturer at an excellent price.

Types of hacksaws

The whole variety of hacksaws can be divided into tools for:

- Works with wooden surfaces

. This includes both a universal saw and a garden hacksaw, and some other special varieties. - Treatment of metal surfaces

. This group also has its own modifications for masters of different classes. - Work with aerated concrete

.

The structure of the instrument is:

- Standard with one handle.

- There are modifications with a solid frame.

- A specialized tool is a folding hacksaw, which is an attribute of a traveler's tool kit.

Hacksaw for metal

Often, professional craftsmen use a special carpentry hacksaw for metal, which has the following varieties:

- Classic model with a special frame

. It is often equipped with a rubberized handle for ease of use. Using this model, you can make cuts in sheet metal at angles of 90º and 55º. - Hand hacksaw

. It consists of a special handle to which the equipment is attached only on one side. The special shape of the bracket allows for working in difficult conditions and creating internal cuts.

Wood hacksaw

The largest number of varieties of hacksaws are designed for working with wood. Among them, the popular ones are:

- A classic saw, also called a standard or regular saw. It is a standard tool with a wide cutting blade for straight longitudinal or cross cutting. The number and size of teeth may vary depending on the modification.

- Circular or narrow tool

. It differs from the classic model in that the hacksaw blade is much narrower. This saw is more maneuverable. It is more convenient to cut sheet material along a given contour. - A bow saw has a thin, curved shackle

. This tool is convenient for cutting tree branches and doing other work in the garden. Some varieties have a special connector for attaching a rod for working with high branches. - Passing saw

. It is also called spike or abutment. It is used by carpenters or joiners to remove protruding mortises or tenons, that is, to obtain an even cut.

Hacksaw for aerated concrete

A special type of tool is a hacksaw for foam blocks, specially designed for separating or removing excess parts of aerated concrete. This fragile material requires special tools with hard-melting tips on the teeth. Thanks to this technology it is possible to:

- Extend tool life. Special soldering prevents abrasion and wear of the teeth, making it possible to cut large quantities of aerated concrete.

- A hacksaw for drywall or wood is much sharper, but it cannot be used for foam blocks, since the materials have different densities and rigidities. Special equipment simplifies and speeds up the process of dividing blocks into parts.

- Eliminate the need to buy expensive electric or gas-powered devices for working with gas silicate.

How to choose the right hacksaw for concrete?

Hand hacksaws are actively used in modern construction, as they allow you to easily and quickly make additional elements from aerated concrete, gas silicate, foam concrete blocks, expanded clay, various types of bricks, and plasterboard.

This tool has many advantages in use:

- Versatility of use. Hacksaws can be used to cut almost any building concrete blocks, with the only exception being reinforced concrete structures.

- High quality of cutting, that is, the surface will not need to be processed a second time in another mechanical way, but the finished element will immediately be used when laying walls and other structures.

- Possibility of use in residential premises, since hacksaws do not emit any extraneous noise during operation.

- Good speed of work without extra effort.

- The ability to carry out repair work on construction sites that are deprived of electricity. And this is a very common problem for many suburban properties.

- The ability to work under unfavorable conditions, since such a tool is not at all afraid of high humidity or exposure to aggressive environments.

- You do not need any special skills to operate the tool.

- Minimum safety requirements.

Therefore, in the construction industry it is impossible to do without a hacksaw.

When choosing a cutting tool for working with concrete blocks, the following performance characteristics must be taken into account:

- Working blade length. The most commonly used standard blade length is from 35 to 50 cm.

- Thickness of the cutting part. If you have to work with a harder material, then it is better to choose a blade with a thicker thickness.

- The presence of soldering on the teeth. Such models are characterized by higher strength and reliability, and are durable in operation.

It is also worth paying attention to the material used to make the blade; there are 2 main types of hacksaws for concrete:

- made of high-strength steel, which are excellent for cutting hard concrete products;

- made of bimetallic alloys, this is the best option for cutting light porous cellular concrete.

It is also recommended to choose a tool with a large number of teeth, as it will provide a better and more accurate cut.

Types of hacksaw teeth

All the models described above differ not only in the shape of the blade for a hacksaw for metal or wood, but also in the size and sharpening angle of the teeth. According to shape and sharpening, all teeth are divided into:

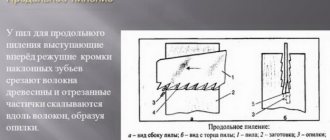

- Equipment for longitudinal sawing along the grain. It is equipped with large teeth sharpened at right angles.

- For cross-cutting layers of workpieces. The edges of the teeth are sharpened at an angle and slightly tilted back.

- The so-called Japanese teeth for cross cutting. They differ from the standard analogue by longer teeth and a double slope of the cutting edge.

- Universal teeth of symmetrical size, sharpened along the edges. Suitable for longitudinal and cross cutting.

The size of the teeth is:

- Small, about 2-2.5 mm long.

- Medium, the size of which is around 3-3.5 mm.

- Teeth with a length of 4-6 mm are considered large.

How to choose a hacksaw?

Before choosing in a store which hacksaw is best for wood or other materials, you should find out the basic criteria for purchasing a quality tool that will last a long time and function properly:

- Specialization of the model you like. It is worth carefully selecting what material you will work with. Tools for aerated concrete and gardening are significantly different.

- The grade of steel from which the cutting blade is made. High-speed and carbon alloys with a blade strength of 45 HRC and a cutting edge of at least 60 HRC perform best.

- Sharpening the teeth affects the quality of the cut in a certain direction or when working in hard-to-reach places. The universal sharpening is somewhat inferior in cutting quality to more specialized models.

- The length of the blade varies not only among different types of models, but also differs among tools of the same category.

- Comfortable handle. This parameter is especially important if the master will carry out a large amount of work with the tool. The more comfortable the hacksaw fits in the palm of your hand, the less your hand will get tired.

Cordless hacksaw

A special type of tool that has appeared relatively recently is the cordless reciprocating saw, which is also called an electric hacksaw. This device is useful when performing a large number of construction or gardening works. Its compact size allows you to use the electric hacksaw in confined spaces that would be difficult to handle with a conventional saw. Such a hacksaw should be selected based on its following characteristics:

- Battery capacity, which directly affects the operating time without recharging. Professional models can last about 5 hours before changing the battery.

- Voltage that affects the power and number of movements made by the saw per unit time.

- Possibility of connecting additional batteries to increase performance.

How to choose a saw?

The wood saw is available in different versions on the market. How products may differ:

- Tooth shape and size;

- Canvas size;

- The grade of steel from which the working part (blade) is made;

- Handle shape.

A hacksaw with a change in one of the specified parameters can radically change its characteristics. Also, sitting comfortably in the hand of one master, it will not suit another at all. These factors must be taken into account when choosing a tool for different purposes.

Teeth size

This parameter affects the quality and speed of work. For convenience in determining the size and number of teeth, the designation TPI was introduced, indicating the number of teeth in one inch . This parameter can be seen in the description of a hand saw for wood; the value is often written on the blade.

- A wood saw with a large tooth produces a rough cut at high speed. It is useful for cleaning the area from branches, cutting boards for firewood and other activities where you can get by with the rough ends of products and trunks. For such instruments, the tooth size TPI 3...6 is selected.

- For products that need to be cut neatly and evenly, a fine-tooth hacksaw with TPI 7...9 is suitable. This type is used for sawing fiberboard, chipboard, laminate, and in repair work. The productivity of such a tool is significantly lower than that of a coarse-toothed one.

A carpenter's saw is selected primarily based on the size of the tooth. So, for ordinary wood, small and large are suitable, but for “delicate” materials such as fiberboard, a fine-toothed saw is needed. In stores you can now find similar designations: “for wood”, “for drywall”, etc. Their main difference is the size of the teeth, which is optimal for sawing each of the materials indicated on the label.

The teeth are distinguished by shape, depending on this the tool acquires different purposes:

- The hacksaw for longitudinal sawing is equipped with triangular teeth with oblique angles. Their appearance resembles hooks that are sharpened on both sides. Because of this, the saw slides along the wood fibers and cuts the blade smoothly, almost without jagged edges.

- The crosscut tool is equipped with teeth in the shape of an isosceles triangle. A mechanical hacksaw of this type cuts as it passes back and forth, but it can only be used for processing dry wood.

- A manual hacksaw for mixed sawing is equipped with both types of teeth alternately located one after the other. Long curved saws the material in the forward direction; in the reverse movement, the triangles expand the channel for passage and catch shavings and sawdust behind them.

In modern models, teeth alternate with voids. This allows you to use the saw on dry and freshly cut wood; coarse unnecessary fibers are removed through the holes.

Steel selection

To make the tool last longer, you should choose high grades of steel for the production of the blade. It's better if it's stainless.

The teeth can be hardened or regular. Regular saws can be sharpened at home, saws with hardened teeth are disposable, and once worn out, nothing can be done with them. They are easy to recognize by their dark color as in the photo.

Blade length

This parameter is determined by the size and pitch of the saw tooth.

- A mini-hacksaw is always equipped with small, frequent teeth; the length of its blade does not exceed 350 mm;

- A universal hacksaw has an average tooth size and a length of no more than 550 mm;

- The wide hacksaw is equipped with large teeth with an increased pitch, the length of its blade is over 600 mm.

In addition to the length, the canvas can vary in shape. A traditional saw has the shape of a rectangle narrowed on one side. This is a universal type of tool that can be used to cut anything.

The rounded blade is adapted for working with branches and other objects at a distance: it is lightweight and easily glides along the wood without much effort.

Handle shape

This part of the saw determines the ease of work. The tool should fit perfectly into your hand and be comfortable. To make handles, various plastics that are pleasant to the body are used. An important note: the material should not slip if your hand suddenly becomes sweaty. For this purpose, the handle body has recesses and grooves and a rubberized lining.

Hacksaw rating

Before purchasing a carpentry tool, you should pay attention to reviews from professionals and home craftsmen who have already assessed the quality of work with a particular hacksaw. The ranking of the most popular saws with excellent reviews includes:

- Gross Piranha 24101

is one of the best classic professional woodworking models with a comfortable handle from a German company with production in China. Cost – $20. - Vira 800240

is a high-quality domestic saw with three-sided teeth sharpening and additional hardening. High quality at a modest cost of about $7. - Stanley 1-15-122

– frame metal saw with a comfortable handle. Price – $8. - Stayer Max Cut

is a convenient folding type of woodworking tool that many hunters and tourists prefer to take with them. Price – $7. - Irwin 10505549

is a specialized tool for professional masons for working with aerated concrete blocks. Price – $24.

Manufacturers of hacksaws

Fiskars

The company produces functional and practical products. Clearly meets the advanced international standards. The company regularly improves its production so that the final product is as efficient and easy to use as possible.

Peculiarities:

- the panel is made only from hardened steel;

- the teeth remain sharp for a long time;

- fiberglass handles;

- handle with ledge for increased safety;

- very light - this simplifies the work;

- To clean, just rinse with water and wipe;

- The saws come with carrying and storage cases.

Fiskars Corporation manufactures not only saws, but also many other garden tools. The product range is very large: rakes, forks, pruning shears, shovels, axes, knives, scissors, kitchen utensils, dishes.

Gross

The company presents a large assortment of measuring, carpentry and other tools: tape measures, hammers, riveters, chisels, staplers, hacksaws, metal scissors, wrenches, bits, chisels, screwdrivers, core punches, side cutters, pliers.

Advantages of the Gross tool:

- Safety. When producing tools, the company's engineers carefully study operating conditions and implement the latest developments - this ensures safe operation.

- Wear resistance and durability. For production, only high-quality materials, durable anti-corrosion coatings, advanced equipment and modern technologies are used.

- Functionality and ease of use. Ergonomics.

- High quality. With proper use, the company guarantees impeccable results and durability of the tool.

IRWIN

Includes three brands:

- Lenox;

- Irwin;

- Rubbermaid.

IRWIN tools are used in the metalworking, woodworking and construction industries. They are used in plumbing, plumbing and plumbing work.

Not only hacksaws play an important role in the company’s production, but also power tool accessories:

- diamond cutting wheels;

- blades for jigsaws;

- saw blades;

- crowns (also bimetallic);

- blades for reciprocating saws;

- different drill options;

- drill.

JONNESWAY

The company's product range includes more than 2 thousand items and is divided into the following types:

- tools for diagnostic work;

- hand-held plumbing and assembly tools;

- tools for servicing;

- pneumatic tools: spray guns, jacks, screwdriver sets;

- body repair tools.

How to use a hacksaw?

The principles of working with basic plumbing tools, which include a hand saw, are simple, but failure to follow them can lead to a broken saw or a poor-quality cut. Main rules for handling the tool:

- The master takes a comfortable standing position with firm emphasis on his legs. Your elbows should bend at an angle of 90º.

- Reliable fixation of the sawn surface. If possible, it is better to secure the material in a vice.

- The hacksaw blade is firmly positioned strictly perpendicular to the surface. It is important to eliminate all vibrations of the instrument to prevent damage.

- Tools for metal are held with two hands, while tools for wood or aerated concrete are held with one.

Unusual hacksaw options

Of course, in general terms, a hacksaw is a metalworking tool that is used for cutting various materials. But there are also specialized hiking hacksaws, which are more compact in size and allow you to quickly prepare firewood for a fire and perform any necessary work on arranging a parking lot.

Most of these models fold easily and take up minimal space, so they are very convenient to carry with you and carry out all your planned tasks without any problems.

There are also miniature metal files that can also be used on hikes. But they should be handled very carefully, since the working cloth is very flexible and fragile.

How to sharpen a hacksaw?

After carrying out a certain amount of work with a hacksaw, the saw teeth simply become dull. The first signs of the need for sharpening include:

- Heavy and uneven cutting.

- Uneven cut.

- The blade often gets stuck.

- It is difficult to maintain a given trajectory.

When the above “symptoms” appear, every master should understand how to sharpen a hacksaw while maintaining the working profile of the teeth:

- Securely fix the tool in a vice or clamp.

- Set the teeth. This procedure involves alternately bending each tooth in different directions by the same amount, approximately 1.5-2 mm, with a special tool.

- A triangular file with a fine notch is selected.

- The sharpening angle of the teeth is determined by eye, which is approximately 15-30º.

- Carry out the same number of file movements in the selected direction on one side. Repeat the process for the other side.

- The teeth are aligned in height.