What is shingles

Shingles are the same as shingle roofing, which is the oldest method of creating a roof using thin pieces of wood that are layered on top of each other to improve the waterproofing performance of the roof.

The material is made from pine or aspen wood, which during production is cut into plates of identical size. This design has a minimum slope of 15°.

Main characteristics

Shingle roofing is one of the oldest methods of roofing and uses thin pieces of wood laid in multiple layers overlapping to create an airtight waterproofing layer. It is made from aspen or pine wood, which is cut into plates of the same size during the production process. A wooden roof is laid with a minimum slope of 15 degrees; compared to metal and polymer analogues, it has the following advantages:

- A light weight. The shingle covering is lightweight due to the qualities of the wood and the small thickness of the plates. This quality allows you to reduce the load on the rafter frame and foundation of the building.

- Low thermal conductivity. A wooden shingle roof retains heat well inside a building in winter, and also prevents the room from heating up during high solar activity.

- High noise absorption capacity. The shingle covering does not resonate when drops fall during rain or hail, so it is considered virtually silent.

- Affordable price. The technology for laying shingles is quite simple, so you can do such a roof yourself without spending money on hiring a professional team.

Note! The disadvantages of shingle roofing are its relatively short service life compared to more modern analogues. In addition, it is a fire hazard; therefore, it is not used to cover buildings with a high risk of fire without mandatory treatment with a fire retardant.

Advantages and disadvantages of a shingle roof

Compared to metal and other roofs, wood roofing has the following advantages:

- Environmental friendliness. Almost all manufacturing companies claim that the products they sell are environmentally friendly, and in this case this is true. Do not forget that when creating such a roof, practically no chemical methods are used.

- Additional oxygen. This coating allows the structure to breathe, because wood is not a completely sealed material.

- Appearance. Nowadays it is rare to find such a roof, since people always prefer corrugated sheeting and other materials. That is why a shingle roof will look unusual and original.

Despite this, there are also disadvantages to a shingle roof:

- Fragility. You will have to constantly monitor the condition of the shingles, since wood is extremely unstable to temperature changes and precipitation.

- Difficulty of creation. Because of this, you will have to attract a large number of craftsmen, and since this is not the most popular type of roof, you will have to look among a narrow circle of specialists.

- Price. This is due to both the price of the material itself and the installation work. The fact is that each of the roof boards is made almost entirely by hand, and manual labor is valued higher than machine labor.

Features of manufacturing roofing shingles

The material is produced in two ways: manually and mechanically. For production, coniferous wood species (spruce, pine, larch) or aspen are selected. Thanks to the resin produced by trees, the material has natural antiseptic protection and is able to withstand temperature fluctuations. Summer, spring and autumn are the most suitable seasons for harvesting raw materials. The diameter of the trunk can be any, the main thing is that it is free from knots and defects, and its surface is as smooth as possible.

You can make shingles yourself

Sawn logs of the required size are manually processed by removing the core and bark. A distinctive feature of the industrial production of shingles is the cutting of logs into long logs and the subsequent production of timber, the width of which is equal to shingles. The wooden planks themselves are obtained by unraveling the timber.

The size of a hand-made chindel reaches 40–45 cm, parts that have undergone mechanical processing are 2 times longer, that is, 80–90 cm. The first option is used for standard roofing structures, the second is perfect for both roofs with long slopes and and for ordinary roofs, but it will be necessary to cut the shingles in half.

Instructions for preparing roofing shingles with your own hands

You can prepare the material for laying the roof yourself, following the sequence of work.

- Selecting a tree trunk that is smooth and free of cracks.

- Cutting logs 40–45 cm long.

- Preparation of thin log plates using the following technology:

- the log is cut in half or into four quarters,

- the bark is removed,

- the core is removed

- the remaining material is cut into thin plates - shingles 3-8 cm thick and the required width - from 8 to 18 cm.

For work you need to use only a sharp tool

The process can be simplified by using already machined wood and then sawing long planks into short elements. In this case, the material will last a shorter period, since the raw material was not split into fibers - it was simply cut. In a word, to preserve the quality of shingles, it is recommended to use the peeling method, which, although very time-consuming, is the most practical when harvesting the material manually.

Shingles can also be produced mechanically

Video: how to make shingles with your own hands

How to choose wood for shingles

You can make a good wooden roof only by using quality materials. To protect yourself from wind, snow and rain, you will have to use hardwood with increased density.

Such wood can be, for example, larch: the fact is that it contains many phytoncides that slow down the process of wood decay.

In any case, when choosing a material, experts rely on the following criteria:

- Round timber diameter. High-quality shingles can be made from round timber, whose diameter varies between 30 and 60 centimeters.

- Density of annual rings. Only wood with thin but dense rings can provide good waterproofing.

- Presence of knots. In this case, they should practically not exist. Therefore, roofing boards are made from the butt part of the trunk, because there are almost no small knots on it.

- Rock hardness. High-quality shingles with good waterproofing properties are made from hardwood, the distance between the fibers of which is minimal. High-quality tiles that will last for decades can be made from larch. The peculiarity here is the increased cost: to save money, some people resort to making shingles themselves and installing shingle structures.

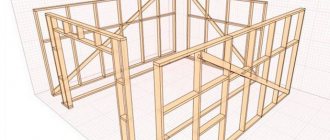

Lathing requirements

Finished wooden roofing is a multi-layer waterproofing coating consisting of individual elements that overlap each other. Although shingle flooring is very lightweight, its installation requires a strong and secure base. There are two types of lathing for decking a wooden roof:

- Solid. Continuous sheathing consists of individual slats or square-section wooden blocks laid without gaps.

- Sparse. Sparse lathing is also made from slats, boards or wooden blocks, however, they are fixed in increments of 5-10 cm, which makes the structure lighter and saves materials.

Experienced craftsmen argue that it is necessary to lay vapor-permeable waterproofing on top of the rafters to protect the roof frame from water penetration, but at the same time not to make it impossible for the structure to “breathe.”

Sheathing for shingle roofing

Preparation of shingles

To create a high-quality, long-lasting wooden roof, you need to either purchase or hand-make thin planks, also known as chocks.

Thin wooden blocks, from which shingle roofing is made, are made from wood separated from the bark.

There are two ways:

- Handwritten. To make a block of wood, you need to purchase a flat piece of wood, for example, a log. Then you need to split it in two, cutting out the central part. After the core is removed, it is necessary to split the remains into thin identical plates.

- Industrial. This method differs in that during production the log is divided into large logs, and this allows the planks to be lengthened - thus making it easier to overlap the slopes on a large roof.

Remember that the cost of industrial shingles, although not high, is recommended to make the plates yourself.

The fact is that when you make lumps with your own hands, the plates are created by splitting, while the industrial method involves cutting wood: in this case, the material is deformed and the integrity of the fibers is broken.

Calculation of lumber and estimate for wooden roofing

Of course, you should make sure in advance that the material so carefully prepared for installation is enough for the intended area of the wooden roof. It is advisable to calculate the required number of logs in advance. For such calculations, special tables have been developed that can be used.

With their help, it is easy to calculate the number of planks required for laying in a given number of rows with a known slope. The material should be taken with a margin of at least five percent. What if some amount of material is spoiled by unsuccessful attempts?

The home roofer also focuses on the slope, size and area of the roof. But first of all, they find out how many plates are required per square meter of coating.

A thick log four meters long, prepared for shingles, is divided into an average of ten logs. Each of them will make three or four fifteen-centimeter boards.

Precise calibration is not needed here. Approximately seven plates are laid per meter of roofing along the longitudinal line. Further calculations are made based on the number of proposed coating layers. For example, with a three-layer installation used in housing construction, only a third of the element appears on the daytime surface.

Over verandas, bathhouses and gazebos, wooden tiles are often laid in two layers. That is, the number of prepared plates doubles, resulting in fourteen of them. With an overlap of each previous row of ten centimeters, in the case of a two-layer laying, about thirty cm of the board will be visible from under the next row.

This makes approximately three rows vertically . If you round and multiply the resulting data, you get about 42 pieces. It is better to round this number to 50: in any case, the remainder will not be lost. The façade and pediment are finished with shingles, and the interior cladding is made from it.

Important note! A roof with tiles can have a reasonable slope from 55 to 71 degrees. Experienced roofers consider slope indicators to be the main determinants of the service life of such a coating. The critical limit is the slope of the slopes with an angle of 14-18 degrees. The steeper the slope, the more material it will require.

Shingled roof installation technology

Installing a dense wood shingle roof requires a lot of time and effort. In total, the structure can consist of two to five layers of chocks. Two layers are enough if your building is commercial or non-living.

But if you plan to classify the building as residential, then you will need up to five layers.

The creation of chocks was already mentioned earlier, but now it’s time to lay the structure. For installation it is recommended to follow the following instructions:

- Place planks on the sagging rafter structure, then carefully attach it to the base with a construction stapler.

- At right angles to the rafters above the waterproofing, fix the sparse or solid sheathing. The first is made from boards or slats, but they are fastened at a distance of 50-100 mm, while the slats in the second sheathing are placed without a distance between them.

- Start laying the roof from the bottom. Attach the chocks using special nails 6-8 cm long. Please note - the nails must be boiled in drying oil to avoid splitting the wood.

- Lay the second row, while overlapping the lowest one so that water does not flow into the structure.

Advantages of a wooden roof

It can be assumed that laying wooden shingles consists of carefully fixing individual elements.

Anyone who prefers a more budget-friendly option will have to prepare the necessary material themselves. But for their considerable efforts, the owners will be generously rewarded: they will not be disturbed by the sound of rain or cats jumping on the roof.

The method of applying wooden plates will create a unique effect. Almost all types of roofing coverings that come under the name shingles are constructed according to the simple principle of a fir cone.

When their constituent elements get wet, they swell, increase in size, and seem to close with each other, creating an insurmountable barrier to moisture.

When it gets dry outside, the wood dries out and shrinks, leaving free space for air circulation between its constituent elements.

Nothing prevents the air flow from circulating freely in the under-roof space, as well as in the gaps of the roof itself. In other words, this type of natural organic matter is capable of independently ventilating and waterproofing the roof.

An additional bonus is that if the slopes of the slopes are not less than those specified in DIN 68119, such a roof does not require water- and vapor-proof films and layers.