Plywood is one of the most popular and easy-to-work materials. It is used not only in construction and repair, but also in such work as furniture production. The popularity of the material is due to its flexibility, durability and lightness. For wall or ceiling cladding, smooth sheets of straight spatial shape are used. But when making furniture or to create crafts of various shapes, the sheets will need to be bent. There are various ways to bend plywood using increased temperature, moisture, scoring and other methods.

Bending plywood at home

Features of the material

Plywood is a multi-layer board-type material. To make it, veneer sheets are used, which are laid crosswise and coated with a resin-based adhesive. The strength and durability of the material is ensured by the cross arrangement of veneers. This guarantees additional resistance to mechanical damage.

However, when it becomes necessary to bend the material, its strength becomes a disadvantage. But there are effective ways to bend plywood at home without damaging the material.

Arches, portals

Various arches and generally complex-shaped openings are another typical application of bent plywood products.

Plywood arch in the opening leading to the loggia.

The main competitors of this material are drywall and plaster.

Why does plywood attract builders?

- Possibility of installation without a frame. For gypsum boards it is necessary, and assembling a frame for an arch of the correct shape sometimes turns out to be a very non-trivial task;

- Speed of installation against the background of plaster arches. Finishing the opening is possible immediately after installing the arch; if the opening is finished with plaster, you will have to pause for at least a week while the cement-sand mortar gains strength;

- Mechanical strength. It is relatively easy to damage both plaster and gypsum board, but not everyone can destroy the integrity of plywood 10–15 millimeters thick.

Advantages of using bent plywood

Bending plywood allows you to give it a smooth shape. Therefore, it can be used to decorate arches, furniture and create products with curved shapes. In this case, the products are not only visually beautiful, but also resistant to mechanical damage. Using bent plywood allows you to:

- reduce the number of fasteners used;

- minimize the number of angles, which reduces the risk of injury;

- gives the interior a sophisticated, stylish and modern look.

Plywood sheets are the optimal material for creating furniture and renovation work. Their use in a curved form opens up excellent design possibilities.

Furniture

A chair or armchair is usually a compromise between ergonomics (in other words, comfort) and practicality.

A simple wooden or plywood seat is practically not dirty and can be easily washed if necessary. There will never be untidy stains from sauce or fat on it; Your cat probably won’t even think of sharpening its claws on a wooden seat.

The price of practicality is convenience: a horizontal flat seat and an equally flat back are quite tiring during long work or during a feast.

On the other hand, all types of soft furniture upholstery constantly suffer from all of the above troubles. Light furniture fabric darkens within just six months of active use; The presence of animals or children at home aggravates the picture.

Furniture made from bent plywood has the advantages of both solutions:

- The shape of the seat and back evenly distributes body weight over the maximum area, reducing fatigue from a static posture and without impairing blood circulation;

- At the same time, caring for such furniture remains extremely simple. It does not require re-upholstery; Removal of dirt is reduced to simple wiping using mild cleaning agents.

Ergonomic plywood chair.

Let us clarify: over time, small scratches often appear on the varnish and polishing. A chair made of bent plywood can be easily polished with a felt wheel or defects can be removed by re-varnishing.

The most effective ways to bend plywood

For bending plywood, the most effective method is to use the method of increasing temperature and humidity. However, in some cases it is advisable to use the dry method of bending the material. When calculating the time and effort required to change the shape of the material, it should be taken into account that the thicker the sheet of plywood, the more difficult it will be to bend the sheet. Therefore, when choosing a bending method, you must first take into account the thickness of the sheet. There are several most effective methods for bending plywood yourself.

You can learn how to bend plywood correctly from the video:

Steaming

The steaming method is popular for changing the shape of plywood not only at home, but also in large-scale industries. In this case, a sheet of plywood is softened with steam, after which it is given the required shape. On a production scale, this method can be used for sheets of various thicknesses and sizes. You can bend only small sheets yourself using steam.

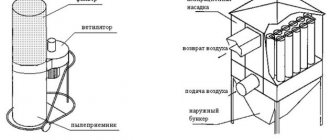

Steaming method

Technologically, the steaming process involves supplying steam directly to the sheet. In production, this process is performed using a special steam installation. At home, you just need to hold the leaf over a container of boiling water for some time. In case of high density of the material or low steaming efficiency, you can immerse the material in hot water.

Notching

If the plywood has a high density or large size, the steaming method at home will be difficult to use. In this case, you can use the cutting method. In those places where it is necessary to bend the sheet, cuts of a certain depth should be made. This indicator depends on the thickness of the sheet and should be no more than half of this value. If the cuts are too deep, the workpiece may simply break.

Notching plywood

The width of the cut is determined depending on the angle that should be obtained when bending the material. After making the necessary cuts, the sheet should be placed on a pre-made template, and a sheet of veneer should be glued onto it. After which it is recommended to leave the workpiece for at least a day so that it dries completely.

Gluing

A great way to bend plywood. It consists of cutting it completely and then gluing it together. In this case, it is also necessary to leave the workpiece for a day to dry completely. The advantage of this method is the ability to create clear geometric shapes. However, it is not possible to achieve perfect smoothness using gluing.

For this method, it is recommended to use synthetic or protein glue. At the same time, various types of glue can be used to glue sheets that will not be used for cladding. During gluing, the material must be strengthened using a channel.

Drying items takes at least a day

Necessary equipment

The required fixtures and tools largely depend on which bending method has been chosen. In some cases you need:

- A template by which a form is given. How to level plywood? For straightening, a regular board with the required rigidity is often used.

- Device for clamping a workpiece.

When choosing a moistening method, you need a bath in which the workpiece will be soaked. In case of steaming, an airtight container is required. An electric tool, such as a grinder, is used to create grooves.

Step-by-step instructions and required materials

The most popular and reliable way to bend plywood is by steaming it. Its peculiarity is the possibility of application in industrial and home conditions. Therefore, this particular method is worth considering in more detail. However, it is necessary to use the bending method only if the sheet thickness does not exceed 4 mm.

For bending you will need the following materials and tools:

- plate;

- large diameter saucepan;

- rope, which has a high resistance to humidity and high temperatures;

- potholder;

- plywood.

After preparing the necessary tools, you should proceed directly to steaming the material for bending. To do this you need:

- Fill the pan with water so that it occupies half the volume and put on fire.

- It is necessary to lay plywood on top of the pan so that the area that is to be bent is in the very center of the pan above the water.

- It is necessary to place a lid on top of the sheet so that it covers the pan as much as possible.

- When the water boils, let it sit for 15 minutes, then remove the plywood from the pan.

- Bend the steamed plywood so that an angle of the required radius is formed.

- The ends of the sheet should be tied with a rope so as to maintain the resulting shape.

- If the first time it was not possible to give the sheet the required shape, you should place the plywood in a tightened form on the pan again and heat for the same time. Then continue bending and tightening the rope. Repeat the procedure until the desired bend angle is achieved.

- Leave the product taut until it is completely dry.

To ensure the bend area has the required roundness, it is additionally recommended to apply a round roller to the bend area. You can use a tin can or any other cylindrical object at hand as a roller.

Differences in metal thickness

The thicker the metal being bent, the higher the structural load on the beams and moving parts. The pull on machines for metal up to 2 mm is usually manual, but the design of the rotary joints and the drive lever can be different.

In repair and construction, metal with a thickness of more than 0.6–0.8 mm is rarely bent on machines; usually, tin for air ducts and roofing iron fit into these frames. With such insignificant loads, there is no need to provide a safety margin; almost any breakdown appears as a consequence of defects or technical imperfections of the faulty unit.

The beams of the machine for bending thicker rolled products have a reinforced structure. They are usually cast and wide; on the back side you can see longitudinal and transverse stiffeners. This also applies to most portable machines, where the greater thickness of the beams has a negative impact on weight. And yet, the greatest load falls on the hinge-lever mechanisms, especially at the points of attachment to the beams.

Welding is rarely used in such areas, but is usually a bolted connection on intermediate brackets, much like a handrail system on public transport. In low-grade equipment, these parts are made by powder casting, which is passed off as a heavy-duty alloy. After a couple of years of active use, the parts become covered with cracks due to the load, and over time they finally break. The price of a sheet bending machine is often proportional to the quality of its workmanship.

Features of bending large sheets

To bend large sheets, using the steaming method is quite difficult and ineffective at home. Therefore, it is recommended to make construction cuts in the shape of cones. To perform this work, you can use a milling machine. In this case, it is recommended to make parts to the opposite layer in order to reduce the likelihood of material fracture at the bend. When bending plywood with a thickness of 4 mm, it is necessary to make cuts of 2 mm.

It is recommended to make as many cuts as possible to make the bend as smooth as possible. After making the cuts, the sheet must be attached to the template, and then a layer of veneer must be glued to it. Leave for at least a day for the glue to dry completely.

Gluing

Gluing plywood

To give plywood a curved look, a “pattern” piece is cut out of a thin sheet of plywood. It is laid on the sheet in such a way that the direction of the veneer alternates. As a result, the structure will have the necessary ductility and rigidity. Each layer of plywood is glued together with epoxy glue. To give the shape, the workpiece is clamped with clamps for one day. After drying, all irregularities and any exposed glue are removed from the part. Once completed, the workpiece is sanded.

Photo gallery

Original bent plywood parts for furniture, see a small photo gallery