Floor finishing is carried out using different types of materials. Recently, consumers prefer a modern type of finishing, which is realized using laminate. It has many advantages: the original appearance of the floors, the ease of installation work and an affordable price. But there is still a fly in the ointment - this is a high degree of susceptibility to moisture. The question arises: is it necessary to protect the laminated coating? If so, what is the best varnish for laminate flooring?

To cover or not to cover?

The instructions for using laminate flooring indicate that exposure to moisture is detrimental to the laminate flooring. Therefore, consumers often ask the question: is it possible to varnish laminate flooring? Moreover, many complain about the rapid appearance of scratches on the laminated surface. Let's try to figure out how to avoid these problems.

Arguments against varnishing laminate flooring

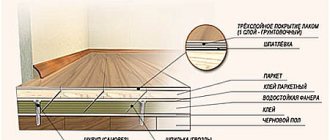

To better understand the inappropriateness of varnishing a laminate flooring, you must first become familiar with the structure of the board. It is this factor that will prompt the answer to the question whether it is possible to varnish laminate flooring:

- The laminate production process already includes the installation of a protective layer. It involves lamination, that is, applying a film that can protect the decorative layer.

- Unlike parquet boards, laminate has no pores. This is a shortcoming in ensuring adhesion of its surface with the paint composition that is planned to be used. After all, when opening the wood, the first layer of varnish penetrates into its pores. In the case of laminate, this process is absent.

- The next answer to the question of whether laminate flooring is varnished depends on the method of its installation. This is not a solid structure. It consists of separate strips that are connected to each other using a special lock. Experts call this type of installation floating. That is, during use, the coating can change its position. Therefore, a coating prepared in this way is not the best basis for applying varnish.

You can purchase laminate already varnished during the manufacturing process.

On video: why you don’t need to varnish laminate flooring.

Positive factors for varnishing

Let's look at the main factors why you still need to varnish this floor covering:

- The process of laying laminated floors begins with preparing the base, during which we try to create a perfectly level screed. This reduces floor movement.

- The next factor is to provide a decent ventilation system, which makes it possible to maintain optimal conditions for the good and durable functioning of the laminate and reduce the process of its vibration to zero.

- The last condition is the selection of high-quality varnish for protection, which forms a reliable coating against scratches.

Positive arguments for varnishing laminate flooring

Manufacturers of paints and varnishes present varnished laminate from the best side, arguing as follows:

- the problem with deformation of the varnish layer is eliminated by creating a high-quality screed that eliminates any movement of the floor covering;

- As for temperature changes in the room, they will also not be difficult to eliminate if you organize a high-quality heating system and install a reliable air conditioner;

- The varnish layer reliably protects the laminate from various minor mechanical damage: scratches from the claws of a pet, chips from falling heavy objects, etc.

Recommendations for choosing varnish

If we talk about what varnish to cover the laminate, then you should listen to the advice of the manufacturers:

- Initially, find out what composition the laminating protective coating was made of.

- Use acrylic-based varnish if the protective layer is acrylic, and polyurethane if the protection is made of polyurethane.

Related compositions interact very well with each other. If the solutions have a different base, this can lead to unpredictable results, even rendering the laminate board unusable.

Please note that the use of varnish for parquet is not recommended, since the process of coating a parquet board is significantly different from how laminate flooring should be varnished. It is necessary to coat the laminate with varnish, which has properties corresponding to the specific adhesion of the coloring solution to the surface of the laminate board.

We also pay attention to the color of the varnish coating. It should match the tone of the decorative layer of the laminate. You can also cover the floor with clear varnish.

Important! It is worth remembering that in any case, the laminate is opened immediately after installation.

How to achieve good results

To get the desired result, you need to do the following:

- choose the right varnish based on the composition of the laminate;

- select the desired color of the varnish solution used;

- carefully prepare the coating for painting;

- When working, do not deviate from the varnishing technology, otherwise the product may warp.

Laminate when properly varnished.

Before carrying out work, you must ensure that the floor covering is even.

Please note: Wood deck paints

Varnishing process

To ensure the quality of the varnish coating, we will consider the technology of applying varnish to a laminate coating. It consists of several stages:

- We carefully prepare the floor in advance. To do this, clean the surface well. There should be no debris or dust left. Under no circumstances should you scrape or putty a laminate board. Sanding with sandpaper is also excluded.

- If there are any defects, the damaged areas must be masked using a paste that has a shade similar to the decor of the board. The work should be carried out carefully, and excess paste should be removed.

- If there is significant damage to the surface, then it should be repaired using PVA glue. To do this, apply glue to deep chips and wait until it dries completely.

- Then they begin to apply varnish to the surface. This process uses a paint brush or roller. The first layer of varnish begins to be applied from the far corner of the room and moves towards the exit.

- After the first applied layer has dried completely, begin to re-apply the paint and varnish substance. To ensure good quality, 3-4 coats should be applied.

Laminate flooring must be treated with a varnishing compound once every 3–4 years. When performing work, it is necessary to ensure the room is ventilated so that varnish vapors do not harm human health.

General information

Naturally, if the lamellas were glued to the base, then there will be no deformations or deflections, and in general, the laminate coating will look very stable and durable. Is it a different matter if the laminate is laid on a fresh substrate, and for at least another 2 months the coating will settle and also adapt to the base.

As a rule, the floor is varnished for the following reasons:

There is a desire to tighten and bind the panels with a varnish film, and a fixing varnish composition for laminate can make the coating more durable and monolithic.- Protect the laminate flooring from moisture - if you properly cover the surface and joints with a varnish composition, then even inexpensive and non-waterproof laminate panels can withstand short-term flooding with water.

- Trying to restore a decorative laminate coating with a varnish compound is a classic method of floor restoration. If you cover the slats with a tinted varnish composition and also polish the layer, then it is quite likely that you will be able to hide floor abrasions and scratches under the film.

- In certain cases, they try to cover the laminate with some kind of decorative varnish composition, and this is required to reduce wear, which helps to increase its service life.

According to reviews, 5 out of 10 cases of using varnish are due to the fact that the owners did not like the previously chosen shade of the material. Such cases happen quite often, and it is not the buyer’s fault. Certain models of laminate flooring look much worse on the floor than in an advertising video or on a stand in a hardware store. In this case, there is no choice but to begin to develop the texture of the coating, just as they do with parquet flooring. It is enough to cover the materials with mastic or a high-quality varnish composition to make the pattern and texture brighter and more saturated. This will give the varnished laminate a more interesting appearance.

Please note that it is technically possible to cover a laminate floor with paint and varnish, but most manufacturers of laminate flooring materials are categorically against this amateur activity.

The varnish film that gets into the locking joints can lead to deformation of the lamellas and even swelling of the substrate due to moisture blocking on the surface of the substrate. Naturally, you can varnish the floor, but only if you have chosen the right varnish composition for the laminate.

Additional coating properties

Despite all the doubts and disagreements about whether it is possible to paint laminate flooring with varnishes, there are significant advantages to this procedure. Many of them are noted by consumers who have already completed this procedure. These include:

- Applying several layers of a protective substance reliably protects the surface for several years.

- If you choose the right varnish, you can almost completely get rid of scratches and other minor damage.

- During cleaning, you don’t have to worry about the harmful effects of moisture on the laminate board.

- Varnish gives the floor surface an original look, which compares favorably with the natural coating by giving it shine.

So, this article provides significant arguments as to whether laminate flooring can be opened with varnish, and how to do it correctly. But the decision remains only with the owners, depending on personal preferences, room conditions and the quality of the laminate board.

Tips for caring for laminate flooring (1 video)

Lacquered laminate in the interior (30 photos)

Waterproof laminate in the kitchen advantages and disadvantages

When starting to arrange the floor in the kitchen, keep in mind that housewives regularly prepare food here. It will be affected by temperature changes, high humidity, and in the kitchen liquid is often spilled, cutlery falls, and grease stains appear.

When choosing laminate flooring for your kitchen, be sure to choose a moisture-resistant material. Since ordinary panels will quickly become unusable under the influence of the above negative factors.

Of course, even moisture-resistant slats cannot be filled with water; it is recommended to wash them not with a wet, but with a slightly damp cloth.

Listing the main advantages of this coating we can note:

- attractive appearance;

- hygiene, hygroscopicity;

- simple installation, ease of further maintenance;

- excellent heat and sound insulation qualities.

It is pleasant to walk on this floor in slippers, barefoot. It is warm and pleasant to the touch. Laying laminate flooring will cost you much less than linoleum or ceramic tiles. A special laying technology allows it to be laid throughout the home with a smooth and beautiful transition between rooms.

It is best to choose a waterproof laminate for the kitchen

What you will need to carry out the work: review of materials and tools

To paint laminate flooring, you need to stock up on a certain set of tools and materials. First of all, you should think about what you will use to remove the top protective layer. It is better not to use a sander, as it can remove too much. Sandpaper of varying degrees of abrasiveness and a block are suitable for cleaning. The latter is necessary only for convenience, because sanding the floor with paper will take a long time.

What else is needed:

- brushes and roller (the latter is needed for applying primer);

- masking tape;

- respirator or protective mask;

- gloves;

- paint and primer;

- composition for filling defects (ideal option - wood putty);

- vacuum cleaner or other dust removal tool.

Installation

According to the technology for performing the work, installing a plastic (PVC) laminate is no different from laying a regular one. Interlocking connections allow you to create a durable monolithic canvas without cracks. Before starting work, we recommend that you read the coating instructions in full and strictly follow the manufacturer’s recommendations. This will ensure the guaranteed service life of the floor.

Preparing the base

The base is leveled so that the difference does not exceed 2 mm per 1 linear meter. Depending on its condition, leveling is carried out by pouring a cement-sand screed; small defects are eliminated by sealing them with a leveling mixture. After this, remove debris and dust with an industrial or household vacuum cleaner.

Wooden floors are leveled with chipboard or OSB slabs, the joints of the slabs are puttied and cleaned.

Tools

Installing plastic is no different from installing conventional laminate. The work will require the same tools:

- level 2 m long;

- measuring tape or metal ruler 1 m long;

- pencil or marker;

- mallet;

- metal clamp;

- a flat wooden block measuring 2x4x50–100 cm for padding the laminate;

- limiter wedges 1.0–1.5 cm thick to fix the gap between the walls and the covering (you can

- purchase ready-made ones or use pieces of wooden planks of this thickness);

- jigsaw with metal file;

- masking tape.

Laying plastic laminate

PVC laminate can be laid in various ways, but the most commonly used is straight or diagonal. They influence the perception of space in different ways. In small rooms, diagonal laying is recommended.

To cut strips, use a jigsaw with a metal file. To ensure an absolutely even cut without chips, apply masking tape to the cut site and place the lamella face up. Once cutting is complete, the tape strips are removed.

A polyethylene film is laid on the prepared base with an overlap of 15–20 cm, and the overlaps are taped with masking or plastic tape. The film should extend onto the walls to a height of 10–15 cm. At the end of the work, its excess is removed before installing the floor skirting boards.

Backing strips of foamed polyethylene or polypropylene 2 mm thick are laid end-to-end on the film. The joints of the substrate strips are glued with tape. You will get a very smooth surface without folds or creases.

Depending on the type of installation (straight or diagonal), work begins from the wall or from the corner of the room. If two people are working, it is convenient to start from the center in both directions to the walls or corners, respectively.

Plastic (PVC) laminate is not subject to thermal expansion to the same extent as regular laminate, so a gap of 1.0–1.5 cm is sufficient between the wall and the laminate. The same gaps are left in places where heating or water supply pipes pass.

Laying the next row begins with the remainder of the canvas of the previous row, if its length is at least 50 cm, so that the joints of the canvases are staggered.

A wooden block is used to seal the lock joints. It is pressed against the canvas and tapped with a mallet along its entire length. The last row is tapped using a clamp.

At the end of the work, remove excess waterproofing strips, cutting them off at a level of 1–2 cm above the floor, then install floor skirting boards.

>Plastic laminate video