Brushing wood is one of the frequently used techniques for decorative finishing of wooden objects. It is based on different degrees of hardness of the layers of solid wood. The cross section clearly demonstrates the annual circles, which form fibers of different physical characteristics. Depending on the type of wood, the layers form a unique pattern that decorates any product or piece of furniture.

All the subtleties of brushing and painting the material

Artificial aging of wood. A trend that is gaining popularity very quickly. Already this year, January has not yet ended, and we have completed 4 orders with brushing elements. I’ll tell you how we do it and why it’s better to turn to professionals rather than try to do it yourself.

You can artificially age wood only with the help of a professional tool. Even if you rent a tool, you will have to buy new brushes, and they are quite expensive. Well, the most banal thing. You need a big room to work.

I’ll tell you how we do it: We work with a professional brushing machine “Festul”. When brushing, we perform three passes with different brushes.

- Passing with a wire brush. This way we scrape out the soft wood fibers. Thereby setting the basis for highlighting the wood texture.

- Pass with a plastic brush 80. Smooth out all the sharp points and irregularities left by a rough pass with a metal brush.

- Passing with a nylon brush. This way we polish the material.

- We apply 320-grit Brite tape to the board by hand. Thanks to its spongy material, we are able to achieve complete removal of even the smallest lint. This is very important before painting if you decide to set the color and protect the brushed board.

And in the case of this order, in addition to brushing, we also carried out painting according to the Elite scheme. This is the application of a primer - an antiseptic and two layers of Teknos colored varnish, with all intermediate sanding.

Particular attention should be paid to interlayer sanding when painting brushed boards.

The surface of the board is not smooth and it is impossible to clean all the brushing grooves with a regular block.

When painting, after drying, the small pile stands up, becomes glassy and seems sharp and rough to the touch. Using the method of trial and experimentation, we began to polish the brushed board with sponge tape Brite, and not with an abrasive stone.

The order was completed perfectly. The customer also received a January discount of 20%, which will be valid until the end of the month.

PROMO We will paint façade panels for your home, lining and imitation timber for interior decoration in the workshop. A large selection of colors will allow you to find the best solution for you. Let's protect the tree from negative factors. Let's add aesthetics. They say about us: “Lesobaza paints furniture of furniture quality!” And it is true! See for yourself!

Painting production Lesobaza.rf

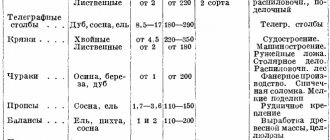

Dimensions and grades of brushed lining

Lining dimensions

You can buy both standard artificially aged lining and eurolining with a similar surface. These materials are manufactured in accordance with two standards: Russian and European. The latter regulates all the parameters of eurolining and is more demanding than the domestic one.

Dimensions of the lining Shtil

Lining diagrams with dimensions

An important characteristic for lining is its size. Precise material parameters verified by practice ensure its strength and durability. It is due to the optimal dimensions of the lining that it is not in danger of drying out and cracking. Therefore, when choosing these products, first of all, pay attention to the compliance of their dimensions with standards.

Lining size

Standard lining sizes.

| Product parameters | Standard | Eurolining |

| Thickness | 12-40 mm | 12.5 mm |

| Width | 76-200 mm | 80, 100, 110, 120, 140 mm |

| Length | 0.2-6 m | 0.4-6 m |

| Spike height | 5 mm | 8 mm |

There is a list of permissible deviations from the dimensions declared by the manufacturer:

- product thickness no more than 0.7 mm;

- width no more than 1 mm;

- length within 5 mm;

- the height of the spike is no more than 0.5 mm.

Of the brushed eurolinings, the variety that is most in demand is “Shtil”. Products of this brand are distinguished by the absence of a shelf on the front panel, which allows for a tight connection and a smooth surface of the cladding with barely noticeable recesses in the area of the seams.

How to choose the right wooden lining

Wood brushing

One of the methods of artificial aging of wood is brushing, the second name of the method is texturing. Using the brushing method, it is possible to give wooden objects a good aging effect. Brushing wood...

Brushing can age any wooden elements. From wooden floors to small decorative furniture details. After processing the wood by brushing, it acquires a seasoned, antique look, and its structure becomes clearer.

Any wood consists of soft and hard fibers. During the process of natural aging, soft fibers are destroyed, as a result of which the surface of the wood becomes embossed and textured.

To reproduce the same effect on fresh material, the wood brushing method is used.

For brushing, use a metal brush with stiff bristles. This is where the name of the method comes from. From the English word “brush”, which means “brush”.

Once you are fully familiar with the brushing process, you can easily do it yourself. This is a fairly simple method, but very effective.

Scope of use of brushing technology

The accessibility and stunning decorative effect of the brushing technique make it very popular in the manufacture of interior items and other details in the design of premises.

Shelves, columns, ceiling beams, wall panels, fireplace trims, made of intentionally aged wood, add special charm and color to halls and living rooms, kitchens and restaurants.

Furniture made of wood with brushed elements looks very elegant.

Material touched by bark beetle is especially valuable, since such a texture cannot be reproduced by hand, but it is precisely this that creates the absolute impression of antiquity of a wooden product.

The brushing technique is an ideal and affordable way to create an impeccable interior with a colorful country or vintage style. Structured wood objects will fill the house with natural motifs, a special atmosphere of warmth and comfort, and will become a highlight in the overall design.

Material and tool

Please note that not all types of wood can be brushed. Species such as maple, pear, cherry, and beech are not suitable. Choose larch, pine, oak, ash, walnut, those species that have an easily processed structure.

As for the tool, a hand brush with stiff metal bristles is suitable for a small area. And to process a large area, as a rule, they use a drill with the same metal attachment.

Aged wood - a modern design trend

In modern interior design, brushed wood surfaces are used everywhere, in rooms with a wide variety of functionality. This is not a simple trend this season; it has been a popular way of creating design solutions for several years. Obviously, the fashion for artificially aged wood will not go away in the near future - you can safely use this technique to decorate your own home and be confident in the relevance of the created design.

Throwing is carried out by removing the soft layers of wood, after which the denser layers are exposed, presenting a beautiful natural pattern and relief surface. Usually, the removal of soft layers occurs naturally over time. Within a carpentry workshop, this process can be accelerated and the wood can be visually aged to produce a textured surface.

The process of accelerating the aging of wood can be done with both soft and hard wood. The only condition is the presence of clearly defined layers with a soft and hard composition, with a clear texture. The following types of wood have these properties:

- pine;

- oak;

- larch;

- ash;

- nut;

- wenge (a type of dark-colored African wood).

Those types of wood that it makes no sense to try to brush due to the lack of obvious “layering” (the difference between the soft and hard layer, the lack of a fine-fiber structure) include:

- cherry;

- birch;

- alder;

- maple;

- teak;

- beech.

Considering the fact that natural wood fits perfectly into almost any stylistic direction in interior design, scrap wood is actively used both for surface finishing and for the manufacture of furniture and decorative items. Flooring, wall and ceiling panels, frame furniture, facades of storage systems - it is difficult to list all the areas of application of artificially aged wood.

Wood brushing process

A metal brush is moved along the fibers with slight, light pressure on the tool. The movements should be as if you are scraping wood until you get the look you want. It's important not to overdo it. Otherwise, instead of a beautiful, aged look of wood, you will get a damaged piece of wood.

Experienced craftsmen often use firing before brushing, since under the influence of fire, wood fibers are destroyed and can be easily removed from the surface.

But without proper experience, it is difficult to fire wood correctly. If you get distracted for a second, you can irrevocably damage the wood. Because under the influence of fire, not only the necessary fibers are destroyed, but also deeper ones. And this then affects the endurance of the tree and its service life.

Secrets of decorative wood staining: techniques and tricks

City dwellers want to preserve the natural color of wood as much as possible. For those for whom wood in the house is a boring everyday thing, paint the interior lining in some unusual color. Modern paintwork materials allow you to achieve different effects. For example, textured or brushed lining, but in two colors. This technique is often used in loft style interiors.

Brushed lining in two colors is an excellent choice for decorating walls

The trick is to apply two layers of different colors. The first layer is a dark color, the second is a light or brighter color. After playing with colors and the order of their application, you can create your own version. Watch the video - how to get lining brushed in two colors.

Painting in two colors may not be the same. You can make the recesses a darker color, and only slightly tint the face (front part) or do everything exactly the opposite. The result is a striped wall made of clapboard - the effect of a slatted wall.

Sanding after brushing

After using the brush, the wood takes on a textured, very beautiful appearance. But its texture becomes very rough. It needs to be smoothed before treating with stains and varnishes.

For grinding, after brushing, sandpaper of varying degrees of hardness is used. You need to sand along the grain of the wood, starting with coarse-grain sandpaper, then fine-grain sandpaper.

What species are used for brushed boards?

To make brushed parquet boards, medium-soft and soft wood species are used, with a clearly visible texture and pattern of annual rings. The best breeds for this type of flooring:

- Jatoba;

- wenge;

- kempas;

- merbau;

- larch;

- nut;

- ash;

- oak.

Brushing is not used with breeds:

- teak;

- cherry;

- alder;

- alder;

- pear;

- maple;

- beech.

The reason is very simple - the wood of these species is either too soft, and it will not be possible to remove the soft layer, leaving only the hard one, or the pattern of the rings and the structure of the wood as a whole are too subtle and difficult to notice.

The best choice for brushed parquet boards is ash, and, of course, oak. Aged oak itself is a real work of art, and no other species, after brushing, gives such a striking, extraordinarily beautiful effect.

And although it is difficult to call oak a softwood, and brushing oak parquet boards is one of the most labor-intensive, the result of such processing is really worth the effort. For this reason, the price of oak parquet boards with this treatment is one of the highest.

Finishing

After sanding, the wood can be coated with stain to give the desired shade. If you don’t need this, you can immediately coat the wood with varnish. The varnish is applied in several layers. The first layer is applied, allowed to dry, then sanded and cleaned of dust. The first, rough layer is necessary to raise the wood pile.

Next, apply a second layer of varnish and allow to dry completely. After complete drying, if necessary, add additional shine to the surface by polishing it.

Mistakes when installing lining that should not be made

1. No gaps between panels

The facade is constantly exposed to aggressive environmental influences. Therefore, the geometric dimensions of the panels will constantly change: increase when wet and decrease when dry. In order to compensate for these movements, gaps of 1-2 mm are required. Therefore, when installing the lining, they are matched to each other, taking into account this requirement.

Video - Installation of lining with an error

2. Lack of moisture and bioprotection

The panels must be prepared for installation on the facade: covered with an antiseptic and moisture-proof composition.

Antiseptic for wood

3. Panel distortion

In order to avoid this trouble, the correct installation of each panel is checked with a level. The lining must lie strictly horizontal.

If you follow all the rules and know the nuances of the work, covering the facade with brushed clapboard will not cause any difficulties, and the quality of installation will be impeccable.

What is wood brushing

Among modern finishing materials, natural wood remains a relevant decorative element. Popular interior styles Provence, loft, colonial require that wooden furniture elements look as if our grandmothers used them. The paradox is that the older the tree looks, the more successful and noble the owner of such an office or living room appears.

What does the term wood brushing mean?

In the natural environment, wood is gradually subject to mechanical wear, the surface texture changes unevenly, loose layers are washed away, while dense layers remain. The result is an aesthetic picture created by nature and time. But try to find naturally aged wooden furniture now.

Artificially aged wood

Craftsmen resort to technologies for artificial aging of wooden surfaces. There is a word in the English language “brush” - brush, bristles. It gave its name to the term brushing as one of the methods of aging furniture, parquet, and interior items.

The essence of the technique is to enhance the texture of the natural grain of wood by combing out loose fibers and then treating them with special antiseptics.

Brushing wood is one of the aging technologies that emphasizes the natural beauty and noble texture of the material.

How does the brushing procedure work?

The essence of the technique is quite simple: the surface is moistened with a chemical composition. Soft fibers absorb liquid. At the next stage, loose parts are selected with a stiff brush. Solid fibers remain, which form a unique pattern. To enhance the effect, the surface is additionally treated with dye.

The result is an interesting stylized texture, with a slight touch of aristocracy and charm.

What tools and materials are needed for the job?

If you decide to age a buffet, chair or mantel yourself, then first prepare a set of tools. To use the brushing technique you will need:

- sandpaper of different grits (coarse-grained is suitable for roughing, fine-grained for finishing polishing of surfaces);

- two or three metal brushes of varying degrees of hardness;

- stain (to give individual elements additional decorativeness);

- paints for tinting;

- matte or glossy varnish for finishing.

Varnish coating

For large volumes of work, a stripping milling machine is used, which automates most of the aging processes. Replaceable attachments allow you to perform grinding, polishing, and brushing in stages.

Using a power tool speeds up the brushing process

When made by hand, the product looks more aesthetically pleasing, it looks like a piece product.

How to age wood yourself

Brushing wood with your own hands is done in several stages. Typically the sequence of actions is as follows:

- The workpiece is slightly moistened with water; in the further process of work there will be less dust.

- Using a stiff metal brush, begin the initial surface treatment. Make sure that the bristles scrape out only the soft layers without damaging the dense ones. They work in the direction of the fibers.

- To make it more decorative, go over some areas with a chisel and select recesses of arbitrary shape. After rough sanding with softer brushes, they are shaped into the old cracks that have gradually formed in the wood.

- Next, the parts are sanded with coarse sandpaper. Having removed everything unnecessary, they evaluate how well the structuring was carried out. Make sure that the treated surface has a natural appearance and that traces of treatment are not noticeable. If necessary, additional cleaning is carried out.

- Final polishing with fine-grained sandpaper.

- Depending on the design, parts are painted, tinted, patinated or gilded.

When tinted with ordinary stain, an interesting two-color texture is obtained. The composition is applied in a thick layer, the excess is quickly removed. Areas with soft fibers have time to dye, but hard layers do not have time to absorb the pigment and remain light.

7. After drying, the finishing stage begins: the workpiece is varnished.

This easy-to-use technique allows you to transform an ordinary interior into an elite, expensive, stylish one.

Chalet style interior

A mantelpiece, ceiling beams, headboards, and a sideboard made of aged wood will emphasize the taste of the owners.