Set of socks, Omsa socks

349 ₽ More details

Set of socks, Omsa socks

349 ₽ More details

Paper wallpaper on a paper basis

A log gazebo is a beautiful wooden structure that can decorate a summer cottage or a country house. This building looks very stylish and elegant.

Log gazebo: a multifunctional element of landscape design

Natural wood is an environmentally friendly, strong, reliable and durable material that will never lose its popularity and demand. Various structures, pieces of furniture, fencing and decorative elements can be erected from wood. One of these interesting buildings is a log gazebo . Such a massive and presentable element will become a real decoration of any country house or summer cottage.

A wooden gazebo will become the main decoration of the local area.

Wood processing

Since round timber is a natural tree, various insects can live in it.

To prevent this from happening, all building material must be coated with special means. They will help protect your gazebo from pests for a long time. If you bought already processed wood, then you won't have to do this.

Before you start coating the wood, it needs to be prepared. Remove all dust, debris, dirt and moldy areas (if any). They are additionally treated with a special antifungal solution.

What is special about a log gazebo: characteristics of the structure

A gazebo made of logs , which is often located on a suburban area, has a simple and cozy design. It can comfortably accommodate all family members and guests to spend time together. As a rule, the structure has a roof, which provides reliable protection of the internal space from precipitation and ultraviolet rays.

In a gazebo made of logs it will be convenient and cozy to spend time with friends or family.

Various materials can be used to make a gazebo.

It can be artistic forging, metal painted in any color or natural wood. The last option deserves special attention. The structure made from natural logs looks massive, original, distinctive, and fits harmoniously into the overall concept of the site, which is clearly shown in the photo of log gazebos. On a note! A log gazebo can be decorated with carved elements, thanks to which the structure turns into a unique, fairy-tale structure.

A gazebo made of logs (photo is a clear confirmation of this) can have any modification. The structure can be round, made in the shape of a rectangle, square, rhombus or polygon with obtuse angles, which is determined by the personal preferences of the owner. A log gazebo is characterized by strengths and weaknesses, which should be familiarized with in advance - before the construction of the structure.

To make such gazebos, in addition to logs, a variety of materials can be used, for example, metal or glass.

How to finish the structure from the inside?

Note! It is better to treat with antiseptics before installation begins. After all, when construction is completed, it is almost impossible to get close to individual elements. This applies not only to the lower crowns and joists, but also to the floorboards. What to process? Here are some options:

- Antiseptics. They are water-based compounds that protect wood from mold formation.

- Fire retardants. Special substances that protect logs from fire. They are extremely necessary when it is planned to place a barbecue inside the gazebo.

- Alkyd or oil paints. Will make the structure more durable.

Positive and negative sides of a chopped gazebo

A gazebo made of round timber has an attractive and distinctive appearance. This design is in harmony with the general atmosphere of the suburban area, demonstrating unity with nature. The structure can bring coziness and comfort, making the space more hospitable. This design will fit into any landscape design, as shown in the photo of chopped log gazebos.

A gazebo made of logs is an environmentally friendly structure that does not harm human health, since it does not emit harmful substances, but, on the contrary, has a beneficial effect on one’s well-being and mood. This is due to the fact that the logs have a pleasant natural aroma.

Structures made from natural logs can “breathe”. This feature helps maintain a sufficient level of ventilation. Pathogenic microorganisms, mold and mildew do not grow on the surface of the structure. A distinctive advantage of the structure is its good sound-absorbing characteristics.

Gazebos made from logs are environmentally friendly, in addition, they look beautiful and presentable.

Constructing a gazebo from a log is a simple process that takes a minimum amount of time. Even a novice home craftsman can easily handle it. Also, don't worry too much about finishing this design. The wood can remain in its original form.

Note! For long-term operation of the building, all wooden elements should be treated with antiseptic compounds to protect them from the adverse effects of external factors.

The use of such impregnations should not be neglected. They guarantee the protection of wood from rot and mold, and prevent cracking of the material and damage by insects.

Such gazebos are characterized by durability and strength.

Considering the positive aspects, one cannot fail to mention the negative nuances. In any case, a wooden structure will be a fire hazard. Therefore, it is not recommended to make fires near it.

How to achieve maximum aesthetics of the gazebo?

The building will look most advantageous on a site with a picturesque view, the very atmosphere of which sets you up for relaxation and rest. Therefore, before purchasing material and drawing up drawings for the construction of a gazebo, land owners need to decide on a place to build the frame. You need to choose it taking into account the size of the building and the layout of the site.

One more requirement cannot be ignored. It assumes that a wooden gazebo made of round timber will be protected from the sun and moisture by a reliable roof, the design of which will complement the structure. Therefore, in addition to wood, you need to prepare high-quality roofing materials and think about the roof format.

Structural types of log gazebos

Log gazebos can have different shapes, which are selected based on the dimensions and characteristics of the land where they are installed. For a compact area, the best solution would be a square building measuring 3x3 m. For such gazebos, a two- or four-pitched roof is made from logs for the dacha.

On a note! A structure adjacent to one wall of the house, which can be supplemented with a barbecue, looks convenient and practical.

Gazebos using logs can be open or closed.

To decorate square gazebos, various grilles or threaded elements are often used. To obtain a more expressive appearance of an angular structure, a combination of dark and light logs can be used when constructing a building.

No less popular are chopped gazebos made from rectangular logs. Such structures usually have dimensions of 3x4 or 3x6 m. The buildings are massive, so they are built in spacious areas. Gazebos made of wooden logs in the shape of a hexagon or octagon look impressive and original. Thanks to this configuration (a large number of sides), the buildings look very compact, while at the same time being characterized by good spaciousness. Therefore, this is a justified option for small areas.

Projects made from virgin natural materials

The designs of many log gazebos surprise with their uniqueness. If for rounded material there are traditional ways to build a log house, then for buildings made from unprocessed trees there are no architectural rules at all. In the latter, relying solely on the original imagination of the master.

Practice has shown that logs of the largest cross-section are used as the main supports of the frame, and all other heterogeneous elements are used as additional ties, decorations and to create a unique shape for the gazebo itself.

Structures made from untreated wood will require several large trunks and large branches. It’s not easy to find such material – you can’t buy it in a store. It will be useful to find one of the mature trees on the site. Cutting it down should not harm the appearance of the yard.

If this is not found, there is a way out to contact local lumberjacks or woodworking companies; they will certainly give away uneven sections of trunks for next to nothing.

The shape of a structure made from original logs may follow the configurations of conventional gazebos, but often has its own unique design. For example, such a masterpiece as a “mushroom” made of a log in the center and a round roof can hardly be included in the usual architectural projects.

It is difficult to give advice on assembling such ambiguous structures: this is a matter of individual construction technique. Several general laws in the construction of gazebos include achieving the following necessary qualities:

- strength of the building;

- its ability to withstand external climatic loads;

- the quality of fastening elements to each other to ensure safety during operation (heavy logs of non-standard parameters are the most dangerous if the mechanical balance of the structure is incorrectly calculated);

- safety precautions when installing heat sources (stoves, barbecues, etc.) inside the gazebo.

Interesting options for gazebos made of round logs

Very often, gazebos are erected in bizarre configurations that will appeal to creative, out-of-the-box people who want to get away from established standards. Such buildings can be made in the form of a trapezoid, an inverted cone, a carriage, a mushroom, or a hut, as demonstrated in the photo of log gazebos. With the help of such a structure it will be possible to give the site originality and uniqueness. However, non-format construction will require much more financial costs, which is associated with the labor intensity of the work.

Most often, log gazebos are made of square or rectangular shape.

On a note! In a limited space, you can build a compact structure in the form of a canopy and supports, where several people can sit.

According to numerous projects, log gazebos can be open, closed or semi-open. The first option is devoid of walls and windows. This design has fences of varying degrees of openness and height, which ensures free air circulation in it. These are unique summer wooden pavilions with canopies.

Closed gazebos look like compact houses with full walls, doors and windows. This building can be used as an outbuilding for receiving guests. Here you can also equip a summer kitchen. The semi-open version consists of 2-3 walls and a canopy. This gazebo is used seasonally.

The chopped arbors in the shape of a polyhedron look interesting.

Options and ideas for decorating a building

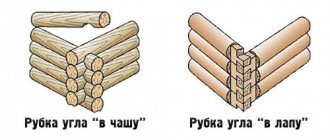

Rounded logs for a wooden gazebo are connected in two main ways: into a bowl and into a paw. They determine the appearance of the ends of the building:

- Into the bowl - in this case the ends protrude beyond the boundaries of the building, and the gazebo resembles a Russian hut;

- In the paw - the logs are cut at the ends on four sides and laid on top of each other, forming an angle without protruding parts.

Various variations of joining methods are possible (Canadian notch, dovetail), but they are all based on these classic types. Suitable for both logs and timber.

Connection options for logs

Ideas for gazebos with a large area

If large companies will gather at the dacha, you can build a gazebo with a long table and plenty of seating.

Long gazebo

A round table can be placed in a polygonal gazebo. But such a structure will require a fairly large area.

Polygonal gazebo

The structure with a barbecue or grill should be located away from the house and the fence. It is better to install equipment with a fire source away from the table.

Combined shaped gazebo with barbecue

Small gazebo ideas

To save resources, the walls can be made low and the roof high. This option resembles a hut; it can comfortably accommodate a company of 4-5 people.

Economical option for a gazebo

A budget-friendly and very compact design can be made from log seats and a roof without erecting a fence.

Open gazebo for a limited area

A small square gazebo is suitable for reading books or children's games.

Gazebo-log for children

Decorating ideas

Carved decor will highlight the natural beauty of wood. And it will give the building a national flavor.

Enclosed gazebo with wooden decorations

Wooden bars will elegantly replace windows and fences. They save material and provide ventilation to the building.

Rectangular seating area with bars

The natural style of the gazebo is emphasized by gnarled tree trunks, large branches, bark, climbing plants and flower beds.

Unusual decoration made from gnarled trunks

The ends painted in a contrasting color give the structure an interesting effect. This decor combines an aesthetic and protective function, since saw cuts are the most vulnerable areas to moisture and pests.

Square seating area with contrasting ends

Types of log house: gazebo made of rounded logs

There are five types of logs that can be used to construct various wooden structures. Each of them has its own distinctive features.

The first type is represented by rounded material. Such logs are processed on a woodworking machine for sizing, where the bark is removed from them and the top layer is sawed off. The result is even and smooth building products of strictly identical diameter, which ranges from 180-320 mm. A groove is cut at the bottom of each calibrated log. It is used to quickly erect a structure by stacking logs on top of each other. Different options for structures are shown in the photo of gazebos made of rounded logs.

This type of timber is often used specifically for the construction of gazebos. The log house is popular due to its attractive appearance. The products have the same shape and size, are characterized by increased air exchange, low level of thermal conductivity, which contributes to a comfortable microclimate inside the building even in the cold season, as well as durability.

When building a gazebo from a cylindrical log, it is necessary to create a reliable foundation, since such wooden elements are characterized by considerable weight. The laying of the wooden products themselves begins with the arrangement of the first crown. Next, the walls of the gazebo are installed. The process is quite simple and fast.

Thanks to processing on a sizing machine, the rounded logs have the same diameter.

To make rounded logs, pine, spruce, oak, linden or aspen can be used. Calibrated elements are distinguished by high quality processing, providing a smooth surface and precisely measured dimensions. Buildings made from such material look natural and attractive. They do not need finishing either outside or inside. To protect products from the negative effects of moisture, invasion of insects and other microorganisms, it is customary to treat logs with special antiseptic compounds. In addition, this type of logs is affordable.

Among the negative characteristics, one can highlight the possible shrinkage of the structure, which occurs after 2-3 years, as a result of which the wooden elements may become covered with cracks. However, this option is possible when using low-quality and unprocessed material. Also, after shrinkage, gaps may form between the logs.

Material selection

The logs seem the same only at first glance. In fact, the material differs in geometry, declared characteristics and consumer properties. It is important to study the main types of logs that the modern construction market can offer.

Rounded

One of the most common options. The construction of gazebos from rounded logs attracts attention with its relatively low price. In fact, this is a ready-made material; some manufacturers even cut special grooves, which simplifies the assembly of the structure.

Calibrated

Many novice builders believe that calibrated and rounded logs are different names for the same building material. This is not entirely true. A rounded log can be called any lumber of suitable shape. There is no reference to a specific diameter, and manufacturers attach importance only to the type of wood.

Calibrated logs are produced according to a single standard of length and diameter, taking into account permissible errors. This is a more precise lumber with longitudinal sampling. It should be clarified that logs are harvested from certain types of trees that have an initially straight trunk. In most cases, preference is given to pine. Logs made of cedar and larch are somewhat less common, but their cost is noticeably higher.

Taking these factors into account, garden gazebos made from calibrated logs always look standard: smooth geometry and the same diameter of individual crowns.

Chopped

A DIY log gazebo will cost less than the materials listed above, but the price point is a very relative concept. The fact is that chopped logs require manual processing of the harvested trunks. If you buy lumber that is ready for construction, the cost of logs increases many times: rounding and calibrating logs on machines is much easier and cheaper than cutting them.

You can simply purchase unprocessed round timber and process it yourself. The cost of the material is significantly reduced, but the process itself will be very long and energy-consuming.

Buildings of this type have one competitive advantage - originality. Chopped logs are not standardized in diameter, so everyone is different. The building will compare favorably with other buildings in its appearance and look like a real old hut.

Gazebo made of planed logs or carriage-type material

To construct structures for a summer house from a log house, planed logs are often used, the top layer of which is removed with an electric planer. This treatment helps remove a smaller layer of wood than in the case of a rounded product. Thanks to this, planed logs are more reliable, warm and protected. The products have a perfectly smooth surface.

Planed logs are obtained using an electric planer, which removes the top layer of wood.

When constructing buildings, logs should be adjusted to each other, ensuring a higher quality connection. However, as a result, the labor intensity and cost of work increases. Planed logs do not have an ideal round shape and identical product sizes, so the final structure will be less symmetrical and even.

Carriages are processed on both sides. The result is something between a beam and a log. This form of products allows you to create an even and symmetrical structure, which will be characterized by a low level of thermal conductivity, which also occurs due to the reliable connection of the log houses. A gazebo made of such material is less susceptible to cracks than buildings made of planed and rounded products. Gazebos made from gun carriages are characterized by a long period of operation. The disadvantage of the material is its high cost.

Distinctive advantages of scraped and solid logs

Another type of log is the scraped product. The bark is removed from the wood manually using a scraper. This treatment allows you to preserve all the performance properties of the material. How to build a gazebo correctly? Despite the fact that scraped logs are of high quality and reliability, it is necessary to carry out a number of additional measures in the form of adjusting the products to each other, processing small knots, additional fastening and other work.

Gazebos made from solid or scraped logs look the most original.

Scraped logs are characterized by a maximum service life. A structure made from such material can last up to 100 years. In addition, this type of log is characterized by low thermal conductivity and high resistance to mechanical damage. However, such material requires a large amount of additional manual work. In addition, scraped logs have a high cost.

Elite and expensive buildings are erected from debarked logs, as demonstrated by photos of do-it-yourself log gazebos. The material undergoes minimal processing, so these one-piece products have a rough appearance, but are extremely durable. The construction of structures is complex and labor-intensive, since uneven and asymmetrical elements must be adjusted to each other. Despite this, such a building will be characterized by reliability and durability. Solid logs have the highest cost.

Methods for installing wooden beams

A gazebo with a log frame is made using two technologies: “without residue” - smooth corners are obtained and “with residue”, where the logs extend beyond the walls.

Cutting "into the paw"

Installation of logs “without residue” allows for rational use of building material, but its implementation requires certain skills from the master. The complexity of the design lies in the uniform and tight connection without gaps:

- From the end part we outline a log with the minimum diameter of the log house, along which the rest of the material must be adjusted to within a millimeter.

- We process the beams using four edges. The through outer edge should correspond to the diameter of two logs, the remaining three should be slightly thicker than the diameter of the wood.

- We cut grooves in the logs.

- We connect the logs outside the foundation. If the structure is sealed, mount them directly on the foundation.

A year after construction, the constructed pavilion requires maintenance. Remove excess cracks from the structure through which heat escapes.

Cutting "into the bowl"

Installing wood in this way determines the following sequence of actions:

- We lay the bars crosswise.

- Using a carpenter's line, we cut out the legs so that the first rests on the first log, and the second on the second.

- To excavate the lower log, place the tip of the line at half the diameter of the upper log, and vice versa.

- First we place the bowl, then the longitudinal groove.

- We lay the log we are working with on top of the others so that the beams create a gap. Before marking the lower groove, we spread the edges of the line to the distance of the gap and increase it by 2 cm.

- We place the wood on the frame and determine the contour of the ledge.

- After processing the logs, we lay them on top of each other and eliminate the gaps using wedges and a sealant (moss or tow).

The strength characteristics of both methods are identical, and which one to choose depends on your wishes, skills and capabilities.

The process of building a gazebo from logs with your own hands

Work on the construction of a building begins with the creation of a project for a gazebo made of logs, which displays detailed drawings of structural elements indicating dimensions. At this stage, the exact amount of materials for constructing the foundation, erecting walls, floors and ceilings of the building is determined.

Before making a gazebo, you should choose a suitable foundation. The base must be strong and reliable, since logs, regardless of their type, are characterized by significant weight.

Project of a simple gazebo made of logs measuring 3x3x3.5 meters.

A monolithic foundation is installed for large closed or semi-open gazebos, which are built from large-section logs. A pit is dug for it, the depth of which should be above the freezing level of the soil. On average, this value is 45-50 cm. A cushion of sand and crushed stone is placed at the bottom. Next, the formwork is installed, into which a frame made of reinforcement is inserted, and concrete is poured.

Projects for gazebos made of rounded logs involve the arrangement of a strip foundation, which is ideal for lighter buildings of simple geometric shape. To do this, a trench is dug along the perimeter of the planned gazebo with an indentation of 10 cm. The formwork is installed in it. A sand cushion is placed on the bottom and compacted. A reinforcement frame is inserted into the formwork, which is filled with concrete mortar.

If you want to raise the gazebo to a certain height, you can build a columnar foundation. This foundation is characterized by strength. The pillars are formed from a square brick structure, under which there is a cushion of non-bulk materials. After setting, the pillars are covered with a layer of roofing felt waterproofing. For this, you can also use bored piles, which are characterized by high load-bearing capacity. When there is a significant slope of the terrain or for an area with access to water, screw piles are used.

To create a gazebo, you need to purchase high-quality logs.

More about foundation and assembly

Let's take a closer look at how to properly lay the foundation for a log gazebo:

- Marking, preparing holes. They are filled with gravel, which will need to be compacted well. Then the formwork is installed and concrete is poured.

- Output to one level. For these purposes, you can use cement blocks.

- Laying the first crown. To prevent wood from rotting, waterproofing must be placed under the lower crowns. Ruberoid will come in handy.

The assembly of the log house is carried out according to the drawing. The logs are laid out in advance on the sides according to the markings. To achieve good strength, don't just limit yourself to corner joints. It is customary to connect the crowns with wooden dowels. To do this, holes are drilled in the logs through two or three crowns.

The roofing system consists of rafters and sheathing. We assemble it step by step and lay the roof.

How to properly build a gazebo with your own hands: laying logs

You can build a gazebo yourself, which will save you a lot of money. If you do not have the appropriate carpenter skills, it is better to entrust the work to specialists. This is especially true for complex structures. The price of a log gazebo depends on the type of structure, complexity of execution, type of roof and roofing covering. The average cost of a small building measuring 3x3 m will be 100-160 thousand rubles. The price of a gazebo made of galvanized logs of complex design starts from 250 thousand rubles.

The final cost of the structure is influenced by the need for additional processing of the log house, finishing the structure with decorative elements, creating furniture from wood, and connecting utility lines.

To carry out the work yourself, you will need to prepare a shovel, electric saw, axe, drill, screwdriver, hammers, knives, level, plumb line, concrete mixture for arranging the foundation, reinforcement, logs, wooden beams for creating the frame of the gazebo and roof, boards, roofing material, fastening elements , individual protection means.

After the construction of the selected type of foundation, the lower piping is performed. For this purpose, timber with a cross-section of at least 150x150 mm is used, which has increased resistance to rotting. The walls of the log gazebo will be laid on it. Installation of the bottom frame allows you to tightly and securely fix the gazebo at the base, supplementing it with logs on which the floor will be laid.

The process of laying logs is quite simple and quick.

The first log of the log house should be laid on a waterproofed base. For this, bitumen mixtures are used to cover the upper surface of the foundation. This coating will prevent the penetration of moisture from concrete into the wood. As a result, the service life of the structure will increase.

Laying of logs is carried out without the use of nails and screws. Wooden elements for wall installation are laid using the “butt to top” technology. The timber is a truncated cone-shaped material. The butt is the end of the log with the largest diameter, and the top is the smallest. This arrangement of the log frame elements will allow you to achieve a uniform height of the sides of the gazebo.

The logs are installed horizontally. Each new row should be checked with a building level. Vertical connections are made using dowels.

Roof construction

The roof of the building should not be heavy; it is characterized by lightness and rigidity. Strength is assessed taking into account external loads - wind and precipitation. The gazebo rafter system does not differ in construction approach from conventional roofs - the elements are the same:

- Mauerlat - the last row of log framing is used.

- Rafters are smaller section logs or beams.

- Ridge purlin is a vein at the intersection of rafters. It is recommended to use timber.

- The pediment of the gazebo, if there is one, is made from a pyramidal row of logs of the same section as the log house. The connection is made with the outer rafters.

- The sheathing for the roofing of the gazebo is attached across the rafters. Usually these are thin slats or boards of small cross-section.

The roofing covering is selected taking into account the design. Bright colored shades and variegation are not suitable for chopped arbors. Stylistically, moderate tones matching the color of wood or paintwork are more combined. Projects where a log frame and a wooden roof (with waterproofing) are combined are considered pristine and unified in execution.

How to quickly build a gazebo with your own hands: further algorithm of actions

Fastening logs at the corners when constructing a gazebo from calibrated logs or other types of timber can be done in one of two ways. The first involves fixation “in the paw”. This is a connection of wooden elements without any residue. It is carried out using cut paws made in the shape of a regular trapezoid. This technology ensures tight and reliable fixation of the elements among themselves, which further strengthens the future construction.

To fasten the log house, two methods are used: “in the paw” and “in the bowl”.

Note! Fastening logs “into the paw” requires certain skills and abilities, since it is quite difficult to correctly cut out the elements for joining.

Another technology for installing logs for a gazebo from a rounded log or another version of a log house is called “in a bowl.” The elements are stacked on top of each other using a moon-shaped recess. This method requires a lot of material consumption, since the edges of the logs will protrude beyond its area in all corners. This option, compared to the previous one, is characterized by simpler technology, and therefore is very popular among builders. This method allows you to get a real gazebo in the Russian style.

Some time after the structure shrinks, the structure is caulked. Next, the roof is installed. For this purpose, the rafter base of a single, double or hipped roof is used. The rafters are covered with sheathing, on top of which the roofing material is laid. For this, slate, corrugated sheets, metal tiles or wood can be used.

The floor is laid using joists. They are attached using metal corners to the bottom trim made of timber. Boards are mounted on top. If the gazebo is an open structure, it is necessary to leave a gap between the elements to allow excess moisture to escape.

The final point in constructing a gazebo is treating the wood with an antiseptic.

At the final stage, surfaces are treated with antiseptic impregnations and a fire-resistant mixture, followed by finishing with decorative elements. For this you can use forged or carved products. Often a weather vane is installed on the roof. Near the gazebo you can place an outdoor fountain, garden sculptures or flower beds. The path to the building is laid out with pebbles or stones. Many people create a gazebo from logs with a barbecue.

Arrangement of the gazebo

Some site owners do not modify the timber gazebo in any way, since such buildings are attractive even without additional decoration. But if you wish, you can make the building more beautiful. To do this you can:

- Decorate it with forged elements. A weather vane is also often installed on the roof.

- If the gazebo is created without a barbecue, it can be placed next to the building by making a separate canopy.

- Also, to decorate the gazebo, you can lay out a path to it using stone. This will not only decorate the area, but also make the path more comfortable, since it will not get wet during rain. Moreover, during heavy rainfall, puddles do not form on such a path.

- Often a platform is created next to the gazebo for setting up a table. It is used to set up the table in good weather.

- In addition, to decorate the space near the gazebo, it is worth installing decorative garden sculptures or placing flower beds.

- Decorative gates are often installed on gazebos.

- To make rest more comfortable, it is worth installing street lights near the gazebo, illuminating the surrounding space and the approach to the building (which can be seen in many photos).

Lighting can be installed inside the gazebo. Thanks to this, you can rest even at night, weather permitting. It is worth noting that lighting is almost always installed in closed gazebos.

Furniture is also often installed inside the building. This allows you to make the environment more comfortable. If there is free space, it is worth placing a rocking chair in the building. You can also place a chaise lounge instead of a chair.

If desired, you can place a grill or barbecue inside the gazebo. Thanks to this, you can fry meat in any weather. To make the gazebo more cozy, you should hang curtains and lay out pillows. The table should be covered with a tablecloth.

You can also decorate the inside of the building with fresh flowers in pots. They can be either arranged or hung around the gazebo. Some site owners who want to be closer to nature plant climbing plants or roses next to the gazebo.

Common mistakes when building a log gazebo with your own hands

Many home craftsmen often make standard mistakes when creating a gazebo from logs with their own hands. To avoid irreversible problems, you should familiarize yourself with them.

When choosing a location for a building, it is necessary to focus on the terrain features. The gazebo should be located on a flat area, preferably on some hill. The structure should not be erected in a lowland, since this area is characterized by high humidity. In such a place, water often stagnates, which drains from other areas after precipitation. These climatic features will significantly shorten the service life of the gazebo.

When choosing a roof type, you should focus on an option with a sufficient angle of inclination, which will eliminate the possibility of precipitation remaining on it. The most appropriate solutions are shown in the photo of gazebos made of rounded logs. When arranging the floor, it is necessary to use moisture-resistant wood. Logs must be treated with antiseptic impregnation. It is imperative to install a waterproofing layer between the foundation and the first crown.

Before you start building a gazebo, you need to choose the right place for it.

The construction of a gazebo from logs should begin in warm sunny weather, since during periods of high humidity or under the influence of light precipitation the wood will swell. After it dries, the products become deformed, which can lead to cracking of the wooden elements.

If you plan to organize utilities to the gazebo, you should take care of this in advance by drawing up the appropriate drawing. For a closed design option, it is necessary to design a ventilation system. When building a gazebo from old logs, each element should be treated with moisture-repellent and antiseptic impregnations.

A log gazebo will become a real decoration of any garden plot, where all family members can sit comfortably or spend time in a friendly company. From the many existing options, it’s easy to choose the project you like, adding to it as you wish. To create a reliable, durable and aesthetic structure, it is important to choose the right quality logs with high performance characteristics.

Project

When creating a construction project, it is necessary to draw design drawings in different sections, taking into account the following points:

- features of working with the material;

- combination of gazebo design with the main structure;

- the intended purpose of the future design;

- what time of year the building will be used - an open structure is suitable for the warm season, glazed ones will be an excellent place to relax in autumn and winter.

All projects must begin with preliminary site marking. In the drawings it is necessary to display the structure in three main projections:

- sectional design;

- main facade;

- structural components of a wooden structure.

Creating a gazebo is a labor-intensive process, but you can do it yourself.

A closed wooden structure must be equipped with a ventilation system. Its average height is usually 5.20 m with a roof slope of 30°. The project should reflect the diagrams of all structural units: the location and dimensions of window openings, doors, rafter system, foundation plan, load-bearing floors, roofing.