When building a wooden house or during redevelopment, it is often necessary to erect interior partitions made of wood to zone the internal space. Such partitions have some advantages over heavy aerated concrete partitions. They are lightweight and do not require an additional foundation to be laid under them, which allows such structures to be erected anywhere in the house.

In general, wooden partitions can be installed in houses built from any building materials. Their advantage is that, if necessary, they can be easily dismantled and moved to a new location.

What are there

Based on the type of construction, wooden dividers are divided into two large groups: stationary and mobile.

The first category includes fixed structures, the elements of which are rigidly attached to the ceiling, floor and walls, and are also fixed to each other. These can be false walls and half-walls, vertical slats, patterned screens or shelving made from partitions. The main advantage of such systems is their neat appearance and stability; they are often used as an alternative to an entire wall. The second category includes any transformable models: screens, sliding and folding dividers. Such models are good because with their help you can easily change the structure of the room, separating zones or, conversely, forming a single open space.

Instagram @startdesign.spb

Instagram @evg.petrenko

Instagram @olgabondar_design

Instagram @design.karieva

Instagram @ma_gurova_design

Separation by appearance

- Solid sections have good heat and sound insulation and provide maximum privacy.

- Slatted - parallel vertical slats that also create privacy for the area, but at the same time allow air, light and sound to pass through.

- Openwork - carved continuous structures with patterns.

Instagram @startdesign.spb

Instagram @klimina.design

Instagram @st.ar.studio

- Small rooms

13 top design techniques for decorating a living room-bedroom (when you have to combine)

Types of wooden interior partitions

All structures made from wood materials can be divided into several main types:

- Frame-panel partitions. This is the most common type of partition. They consist of a wooden frame, for which, as a rule, 100x50 or 50x50 timber is used, wooden panels made of fiberboard, chipboard or OSB, with which this frame is sheathed on both sides, and a layer of insulation, which fills the space between the panels.

- Solid partitions. In wooden houses, these are structures made of timber or logs with a cross-section smaller than that of load-bearing walls. They do not require insulation, but they themselves are heavy, which imposes restrictions on the location of such structures.

- Carpentry partitions. Previously, such walls were made of long boards nailed together close to each other. To obtain good soundproofing properties of such a partition, it must be mounted from two rows of lumber and the gap between them must be filled with high-quality noise-absorbing material. A significant disadvantage of such an interior partition is the very high consumption of lumber and the heaviness of the resulting structure. Such walls have their roots in a time when there were no convenient slab materials on the market. Nowadays, carpentry partitions are used for decorative purposes and for zoning indoors.

The most modern option for zoning residential premises is the installation of frame partitions. If you have some skills, you can install them yourself.

Requirements for partitions

Internal partitions, unlike permanent load-bearing walls, are self-supporting structures. Therefore, they are made from lighter material.

They can be installed anywhere and have any direction. Therefore, they must be light, durable and resistant to various mechanical influences, fire-resistant, environmentally friendly, and soundproof.

Partitions in bathrooms, toilets, and kitchens must, in addition to the above requirements, comply with sanitary and hygienic standards, namely, be moisture resistant. To prevent the appearance of fungi and mold, they must be treated with special antiseptics.

To reduce the overall heat loss of the house, the partitions must have good thermal insulation. Their service life should be no less than that of the supporting structures of the house.

Pros and cons of wooden partitions

Wooden interior partitions are not load-bearing structures; they only divide the space between the main walls, allowing you to zone the internal area of the room as necessary.

Significant disadvantages of such walls include their strong dependence on atmospheric humidity. Wood, absorbing moisture, expands, deforming and bending the plane of the wall. To avoid this, special oil-based impregnations are often used, which clog the pores of the wood, preventing natural air exchange, but complete isolation from moisture is unlikely to be achieved.

If a house made of timber or logs has just been built, then you need to wait for it to completely shrink before proceeding with internal zoning. It takes 1 to 2 years for the house to completely shrink, which significantly delays the finishing time.

The advantages of wooden walls, obviously, include their low cost and environmental friendliness. In addition to the low cost of materials, the advantage is the ease of installation - you can carry out the installation work of installing a frame made of wooden beams and covering it with sheet material yourself, saving significant money. There is nothing particularly difficult in doing this work; you just need to have basic skills in working with wood and be able to use simple tools.

How to make an interior partition from wood

Before installing the partition, the best solution would be to create a project, even if it is just a simple hand drawing. This diagram will help you better understand how much material will be needed for construction, and in what order it is better to arrange the frame posts. All further work will be reduced to performing simple actions in accordance with the drawing.

Construction of a wooden partition frame

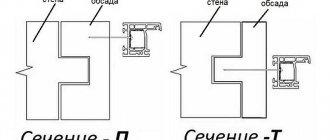

The frame is made in exactly the same way as when building a plasterboard wall. The only difference is that wooden beams and boards are used as the material for the frame, rather than a metal profile.

The main important point when constructing a frame interior wall is the impeccable alignment of the vertical, and with it the correct location of the upper and lower guide bars. To perform this procedure, on the side walls, with the possibility of changing their position, the starting bars of the structure are strengthened, which, after careful control and adjustment of verticality using a level, are fixed with reliable fasteners.

The next step is to attach bars of exactly the same size to the ceiling and floor, which will serve as the upper and lower guides of the frame. To maintain the correct geometry of the future partition, the guides must align exactly with the starting beams.

Nails are used to secure the starting and guide beams in a wooden house, but if the ceiling is covered with concrete slabs and there is a concrete screed on the floor, dowels and screws are used.

The cross-section of the timber used to construct the frame depends on how thick the partition needs to be. In most cases, a 100x50 beam is sufficient, which forms a frame 10 cm thick. A supporting frame made of such bars can easily withstand cladding made of any materials.

Sometimes, to improve soundproofing properties, interior partitions are made thicker, the structure becomes heavier, and then the diameter of the timber from which the frame is made must be increased.

Next, the frame is assembled by installing racks on the guide bars every 60 centimeters. Fastening is carried out using wood screws and metal corners. There is no need to achieve the ideal strength of the wooden frame lattice, because... double-sided cladding is a good strength element that imparts rigidity to the entire structure.

A distance of 60 cm is selected based on the standardized dimensions of sheet materials, so that the joints of the sheets fall on the wooden beam. This size is also convenient for laying soundproofing material into the frame.

After installing the vertical posts, proceed to the installation of the transverse beams, which give additional rigidity to the frame. 2-3 crossbars for the entire height, staggered in relation to adjacent openings, are sufficient.