The carpentry workshop begins with the appearance of a circular saw. Sawing is one of the main operations in a carpenter's work. Most circular saws allow you to perform longitudinal and transverse sawing, miter cuts, end trimming, and cutting quarters and grooves.

The most important characteristics of the machine for the home workshop:

- compactness,

- multifunctionality.

There is no point in purchasing separately a construction saw for longitudinal cutting with a fixed position of the saw blade and a machine with a carriage for cross cutting and cutting sheets. A large work table is convenient when working in a spacious workshop, but in a small room it is easier to get by with additional supports and removable extensions.

When choosing, you should focus on your budget and the amount of work to be done. To cut two or three boards every few months, it is not worth buying a professional machine. On the contrary, if there are prospects for growth and development of production, it is better to buy a circular saw with a power reserve, so that in the midst of work you do not have to stand idle due to breakdowns.

Home equipment

Machines in this category are united by: low cost, ease of maintenance and the need for modification. Moreover, one’s hands must be applied both to the design and to the mechanical and electronic “stuffing”. As a result, with some loss of time, but for a relatively small amount, you create equipment that allows you to qualitatively cut blanks from any wood.

Encore Corvette 11 – from 12,824 rubles

Portable circular saw with universal table and assembled stand.

Low price, space for a jigsaw and a router, the ability to cut an 80 mm thick board with a disk from the basic package - all this holds the attention of an inexperienced amateur until the machine is purchased.

The first troubles are weak hardware, the threads of which are dispensed with at the stage of assembling the stand. There is some play in the guide of the stop with the protractor - it will not be possible to repeat the angle at the ends of the decorative parts. Inconvenient setting of the rip fence - it takes a lot of time to move this bar. The disk is lowered arbitrarily - choosing a quarter or a long groove is possible only in several repeated approaches.

This Corvette does not initially have a soft start, but there is play between the gears in the gearbox. Because of this, after just a year of operation in a home workshop, you will have to rebuild the gearbox. From sudden impacts when switching on, the support bearings of the engine shaft are also destroyed. I recommend not using this machine without a soft starter.

Main technical characteristics of Encore Corvette 11

| Characteristic | Meaning |

| Cutting depth, 900/450, mm | 80 / 55 |

| Dimensions table/machine, (weight), mm (kg) | 700x465 / (27.5) |

| Equipment (disk) Ø external/Ø landing, mm | (cut) 255 / 30 |

| Drive: power/gear/speed, kW/rpm | 1.5 / gear / 4 500 |

| Ø nozzle for connecting a vacuum cleaner, mm | 30 |

Video review of the Enkor Corvette 11 circulation machine:

Ryobi RTS 1800 – from 14,890 rubles

Sawing machine on a folding scissor-type support.

The most powerful motor in the class of amateur equipment allows you to count on stable operation with any type of wood. Efficiency of adjustment is predetermined by a parallel stop, which is fixed with one clamp. Adjustment of the height and angle of the disk position is also assigned to one handle. The riving knife is adjusted without tools. There is a soft start and electronic protection; It is assumed that there is a retractable table. There is a place to store keys, a compartment for equipment and small items. Low price.

Models from some batches have defects on the table surface - this is a warranty case, but it is better to see this nuance immediately upon purchase. A flimsy angle stop, unreliable fastenings of the motor position adjustment posts - so you must always monitor the load applied to them. The machine was sold in its original configuration for no more than a year. Since 2016, the retractable table has disappeared from the official set - you can buy it in addition or make it yourself. The bearings quickly begin to knock, but this can be reliably treated by replacing them with similar SKF ones.

Keep in mind that Rayobi’s service network in the Russian Federation is not the most developed, and there are no identical sets of parts, except for bearings. Therefore, it is possible that the cost of repairs may exceed the price of new equipment.

Main technical characteristics of Ryobi RTS 1800

| Characteristic | Meaning |

| Cutting depth, 900/450, mm | 80 / 55 |

| Dimensions table/machine, (weight), mm (kg) | 560x710 / (26.8) |

| Equipment (disk) Ø external/Ø landing, mm | (cut) 254 / 30 |

| Drive: power/gear/speed, kW/rpm | 1.8 / gear / 4 500 |

| Ø nozzle for connecting a vacuum cleaner, mm | 75 |

Video review of the Ryobi RTS 1800 circulation machine:

BISON ZPDS 255 1600S – from 16,783 rubles

Table saw with a pair of extendable tables and space for additional equipment.

The paradox of this machine is that, although it is the most expensive option among its household analogues, it still remains ill-conceived and also requires improvement. For example, there is a laser cut line indicator, but it is mounted on a flimsy riving device - the beam trembles when trying to align the workpiece with it. The parallel stop ideally holds onto the table on both sides, but its position must be adjusted not according to a ruler, but only relative to the disk. There are mounting spaces for a router and a jigsaw, but without additional preparation, not a single serial tool can be installed in them. The actual maximum for a raised saw blade is limited to 85 millimeters, but the 1.6-kilowatt engine does not always allow you to dissolve even the stated 80 millimeters in one pass - the thermal protection of the engine is triggered and you have to wait until it cools down. It is even stated that there is a lock from restarting, but there is no soft start.

I see that many hobbyists do not want to be left without warranty support, and refuse to purchase this machine in favor of more expensive equipment. Because it’s obvious that without modification there will be no precise work on the Zubr. But in a particular case, the manufacturer openly indicates that even new holes in the table are not a reason to refuse warranty obligations.

Main technical characteristics of ZUBR ZPDS 255 1600S

| Characteristic | Meaning |

| Cutting depth, 900/450, mm | 80 / 55 |

| Dimensions table/machine, (weight), mm (kg) | 725x499 / 980x740x1040 (20) |

| Equipment (disk) Ø external / Ø landing, mm | (cut) 255 / 30 |

| Drive: power/gear/speed, kW/rpm | 1.6 / gear / 4 500 |

| Ø nozzle for connecting a vacuum cleaner, mm | 40 |

Video review of the ZUBR ZPDS 255 1600S circulation machine:

Machines for professionals

Universal and narrow-profile, stationary and mobile, with V-belt or gear drive - all models from the category of professional machines are designed taking into account operation under heavy loads and over a long period of time.

BELMASH SDM-2000M – from 28,690 rubles

Multifunctional woodworking machine from a Belarusian manufacturer.

The advantages are the price and the fact that the machine: saws and mills with disk equipment; allows you to plan, joint and thickness planing parts on a planing table; can drill, select short blind and through grooves in the workpiece - on an additional table on the side of the quick-release chuck. When working with equipment on one table - sawing, planing or drilling and milling - contact with other moving elements is limited. Convenient reconfiguration - no manipulations with the elements of the poly-V-belt drive are required.

The downside is that there is no soft start and no automatic feed for the thicknesser nozzle. You have to push the workpiece manually, which, with a maximum permissible thickness of 65 mm, even at a workpiece width of 150 mm, is quite difficult for one person to do. And the design is flimsy for such loads.

I strongly recommend not to neglect the setup rules. Because, at my first attempt to work with an end mill, starting the engine led to the saw blade being thrown above the table level. And all because I was too lazy to tighten the wing nut, I just lowered the disk under the table and that’s it. I think that even a soft start could not prevent the problem here, because the engine is quite powerful.

Main technical characteristics of BELMASH SDM-2000M:

| Characteristic | Meaning |

| Cutting depth, 900/450, mm | 85/55 |

| Dimensions table/machine, (weight), mm (kg) | Sawing 732x456, planing 760x247, milling 410x190 / 806x793x445 (49) |

| Equipment (disc, disc cutter, end mill, planing shaft) Ø external/Ø seat, mm | 250 / 32; 125/32; 6-12; width 230 |

| Drive: power/gear/speed, kW/rpm | 2/V-belt/disc 2,850, end mill and planer shaft 7,700 |

| Ø of pipes for connecting a vacuum cleaner, mm | 28, 38, 63 |

Video review of the BELMASH SDM-2000M circulation machine:

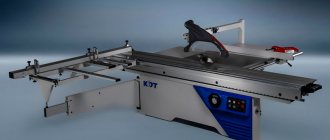

Bosch gts10 xc – from 59,900 rubles

Table circular saw with movable slide, table extender (+435mm) and table extension (+520mm).

A powerful engine, a cast aluminum table, a rigid rip fence with convenient one-sided control - thanks to this set, the machine allows you to work without focusing on the strength of different types of wood. A movable carriage, an extension, an expander and an angular stop - for precise processing of workpieces, from which not only decorative and applied crafts are made, but also large-sized furniture. Any moving element can be adjusted; All possible backlashes are selected using reliable standard fasteners. Protective casing, dense insert plate, overrun brake - for operator safety. Soft start, constant automation and overload protection - to reduce the load on the motor.

There are no objective disadvantages, other than the high cost.

I remember about 5 years ago a batch leaked to Moscow with crooked shields with which the vertical engine feed guides are attached to the table.

But then the issue was resolved at the manufacturer level, and everyone agreed that this was due to improper transportation of the machines. Main technical characteristics of Bosch gts10 xc

| Characteristic | Meaning |

| Cutting depth, 900/450, mm | 79/56 |

| Dimensions table with extensions / machine, (weight), mm (kg) | 1210x1288 / 775x768x343 (35) |

| Equipment (disk) Ø external/Ø landing, mm | 254/30 |

| Drive: power/gear/speed, kW/rpm | 2.1/ /3 200 |

| Ø nozzle for connecting a vacuum cleaner, mm | 30 |

Video review of the Bosch gts10 xc circulation machine:

Classification of compact circular saws

Externally, compact circular saws are similar and consist of:

- Desktop.

- Housings with a motor and a saw blade housed in it.

- Guides for longitudinal and cross cutting.

- Mechanism for adjusting the depth and angle of cutting.

The operating efficiency, service life and price of the machine depend on the design features of the working units, the materials from which they are made and the quality of the assembly.

According to these indicators, machines are divided into:

- household,

- semi-professional,

- professional.

Conclusion

I believe that among the many monotonous clones-copies-replicas of several successful European models, the Ryobi RTS 1800 . Power, a set of “adult” electronic functions and maintainability (if you have access to original spare parts) make it advisable to modify this machine to meet the needs of the home craftsman.

A professional attitude towards carpentry does not imply having free time to independently modernize inexpensive equipment. But the versatility of the Mogilev SDM 2000 M is worth it to introduce a soft start unit and understand the intricacies of the manipulations of setting up equipment and replacing equipment.

How to make your own circular saw for home

The easiest and fastest way is to tip a hand-held circular saw into the table, but this is only good for occasional one-time work. After all, to periodically adjust the position of the disk, the entire structure will have to be removed from the table, and this is not always convenient and always slow. And due to the thickness of the improvised tabletop, the nominal cutting height of the “parquet flooring” loses about 20 mm. The protective cover remains under the table, which is a direct violation of safety regulations. Any attempts to place a manual circular saw on a height-adjustable frame under the table will lead to the appearance of play in the disc relative to the tabletop. Which in no way contributes to the accuracy of the work.

Our option is a stationary machine with a rigidly fixed saw blade shaft and a belt drive from an electric motor.

bed

The material from which the base of the machine will be made is not of fundamental importance. The main thing is that the structure has sufficient strength and can without hesitation withstand the weight of the equipment and the workpiece with the force applied to it. The height of the bed depends on your height: working while bending over a low table or constantly raising your forearms over a high one is not much fun. The length and width of the future machine - taking into account the required space for placing the drive and the dimensions of the workpieces for the nearest project. Doing it with a reserve is not entirely correct, because the task of the frame is to compactly place the electromechanical “filling”, and additional tables can always be built as needed.

Drive unit

Structurally, everything is simple here - a pulley for a poly-V-belt (multi-ribbed) belt on the engine; a pulley with a similar texture on the saw blade shaft; a suitable belt that connects them; and the entire structure on the grooves of the inclined guide (the best option for inexpensive implementation of the function of adjusting the cutting height).

It is somewhat more difficult to organize 3000-4000 revolutions per minute for the idle speed of the disk, but this can be solved - you need to measure the speed and diameter of the pulley on the electric motor. Pulleys are measured at the bottom of the groove. Let's take, for example, 1500 rpm and 10 cm. In order to get the desired 3000, the drive ratio must be 1:2. What can be done if you install a driven pulley with a diameter of 5 cm.

I propose the following principle for constructing a shaft with a driven pulley: because in this form the greatest rigidity of fixation of the unit is ensured.

Table

There is only one requirement for the machine table top – an exceptionally flat surface. The cut for the disk should be made so long that a riving knife with a protective casing fits into it, with a 5-mm gap from the disk in the upper position. When working with workpieces longer than a meter, these elements will provide you with the proper level of safety.

Of the simplest, easiest to use and reliable versions of the parallel stop, I like the model with parallel guides that are clamped on screws that are rigidly positioned in the table top. Because in this case it is easiest to align and tighten the screws with one hand.

The best option for a carriage with an angle stop is an overhead structure that moves along the table, resting on its end. This version eliminates the need to constantly blow through the grooves and deal with backlash.

Even taking into account the fact that you need to pay for the material, pulleys, shafts and engine, the proposed design will cost more than half as much as the most inexpensive ready-made machine, which initially needs serious modification.

Choosing a sawing machine: what to look for

Type. Sawing machines can be made in tabletop, floor-standing or stationary format. The first option is the simplest, easiest and most convenient. These machines are best suited for home workshops. Floor-standing machines are installed on legs - this is also very convenient, but when purchasing it is important to ensure that the legs are of high quality: thick and stable. Stationary machines are not found in the domestic sphere; they are used in sawmills: they are powerful, productive and extremely expensive.

Purpose. Many experts and some manufacturers divide wood sawing machines into household, semi-professional and professional. Models for home use are cheaper, but are inferior in performance to competitors for professional use - these can cut for many hours in a row every day for many years, but they also cost much more than household devices. Semi-professional machines are somewhere in the middle of this scale.

Nutrition. Sawing machines can operate from a 220 or 380 volt power supply, as well as from a battery. The last option is rare; after all, a machine is a thing that is not particularly mobile, but it still occurs and in some situations can be irreplaceable.

Power . Typically, manufacturers indicate power consumption, which allows us to only indirectly judge the performance of the sawing machine and its main parameters. In general, we can say that the higher the power, the better. As a rule, it is 1000-2000 watts.

Saw rotation speed. High spindle speed means high productivity and accurate cutting. At the same time, some capricious materials, for example, certain types of plastic, require a low disk rotation speed, since they can warp from heat caused by friction at high speeds.

Number of speeds. It is normal if the sawing machine has only one speed - for most tasks this is quite enough. However, the presence of several speeds or smooth adjustment of speed allows you to select the operating parameters of the machine for a specific material.

Depth of cut. As a rule, it does not exceed 40% of the saw blade diameter and is about 80-140 mm.

Width of cut. This parameter is important when working with valuable wood species: the thinner the cut, the less material will go into waste.

Angle of cut. Typically, machines can cut at an angle of up to 45 degrees, but on sale you can find models whose maximum cutting angle is up to 60 degrees - this seriously increases flexibility when working with the tool.

Additional functionality. The further we go, the more additional functions appear even in such seemingly simple devices as sawing machines. When choosing, you should pay attention to such options as laser marking, accidental start blocking, smooth engine start, sawdust collection, vibration protection and rotation stabilization. All this greatly simplifies working with the tool.

Manufacturer. Among the manufacturers of power tools, there are several brands that have long and firmly established themselves: these are the Japanese Makita, the German Bosch and Metabo, and the American DeWalt. However, even from lesser-known companies, for example the Russian Zubr, Vikhr or Interskol, you can find quite decent sawing machines at affordable prices. Our independent Top 4 includes tools from some of these manufacturers. Let's take a closer look at them.