The elasticity of wood is the ability to restore its original shape after the load is removed. This is a mechanical characteristic inherent in building materials, including wood. The characteristic is expressed mathematically by the modulus of elasticity - the relationship between normal stresses and relative deformations.

Despite the development of technology and the emergence of a wide variety of building materials, wood has been and remains the material preferred by many professional builders and customers. Wood has been used as a building material since time immemorial. Now the appearance and design of buildings made from it have changed significantly. The spans of wooden buildings can reach 120 m! When designing such structures, it is imperative to determine the internal forces from the action of external forces, including taking into account the deformed state. In programs for such calculations, one of the initial characteristics is the elastic modulus. By calculating this indicator, they determine what load the board or beam will experience without irreversible deformation, that is, without breaking. The higher the value of the characteristic, the stiffer the material.

Elasticity and plasticity of wood. Modulus of elasticity of wood

Author: Irina Zheleznyak |

Published: November 16, 2016 at 09:15 pm The elasticity of wood is one of the main characteristics of the mechanical properties of wood. Elasticity is the ability of a material, in this case wood, to resist deformation under mechanical stress.

The elasticity of wood depends on several wood parameters:

– humidity. The higher the humidity, the lower the elasticity

– straightness. Curly wood is less elastic than straight-grained wood

– volumetric weight. Light wood is not as elastic as heavy and dense wood

- age . Young wood is less elastic than mature wood

– dimensions of the medullary rays. For example, in coniferous wood the pith rays are single-row and very small, so this wood is highly elastic, despite its relatively low specific gravity.

– sapwood is less elastic than heartwood.

Appearance

Wood has the following external properties:

- Color. Visual perception of the reflected spectral composition of light. Important when choosing sawlogs as a finishing material.

- The color depends on the age and type of tree, as well as the climatic conditions where it grew.

- Shine. Ability to reflect light. The highest rates are observed in oak, ash, and acacia.

- Texture. The pattern formed by the growth rings of the trunk.

- Microstructure. Determined by the width of the rings and the content of late wood.

Channel PROGRAMMER'S DIARY The life of a programmer and interesting reviews of everything. Subscribe so you don't miss new videos.

The indicators are used for external assessment of the quality of logging. Visual inspection allows you to identify defects and the suitability of materials for subsequent use.

Modulus of elasticity of wood

Under short-term loads up to stresses that correspond to the limit of proportionality (in other words, until the moment when the deformation process is irreversible), the deformation of the material is proportional to its stress, and disappears after the load is removed. The elasticity of wood is also called wood stiffness or wood deformability.

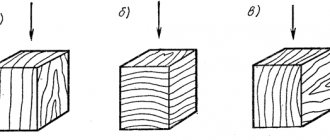

To determine the elasticity of wood, the concepts of wood elastic modulus, deformation coefficient and shear modulus . Moreover, all indicators will differ significantly depending on the direction in which the load is applied - along the wood fibers, tangentially across the wood fibers, radially across the wood fibers.

– The modulus of elasticity of wood E is the ratio between normal stresses and relative deformations. The following elastic moduli are distinguished: along the fibers Ea, across the fibers tangential Et, across the fibers radial Er, modulus of elasticity in bending Ebg;

– Wood shear modulus G is the relationship between shear stresses and relative shear

– The coefficient of transverse deformation of wood µ is the ratio of transverse deformation to longitudinal deformation that occurs when the rod is loaded.

Modulus of elasticity of basic wood species

| Wood type | Tensile modulus of elasticity of wood, MPa | Modulus of elasticity of wood in compression, MPa | Modulus of elasticity of wood for bending (static), MPa | ||||

| Ea | Еt | Er | Ea | Еt | Er | ||

| Birch | 18 300 | 490 | 670 | 16 100 | 520 | 670 | 15 400 |

| Spruce | 14 600 | 490 | 690 | 14 500 | 430 | 660 | 11 000 |

| Pine | 12 100 | 500 | 580 | 12 100 | 570 | 690 | 12 600 |

| Oak | 14 300 | 890 | 1 160 | 14 300 | 970 | 1 340 | 15 400 |

The modulus of elasticity of wood is calculated in MPa, or kgf/cm 2 (1 MPa = 10.19716213 kgf/cm 2))

Transverse deformation coefficients of main wood species

| Wood type | µra | µta | µar | µtr | µat | µrt |

| Birch | 0,58 | 0,45 | 0,043 | 0,81 | 0,04 | 0,49 |

| Spruce | 0,44 | 0,411 | 0,017 | 0,48 | 0,031 | 0,025 |

| Pine | 0,49 | 0,41 | 0,03 | 0,79 | 0,037 | 0,038 |

| Oak | 0,43 | 0,41 | 0,07 | 0,83 | 0,09 | 0,34 |

Shear modulus of basic wood species

| Breed | Gra (MPa) | Gta (MPa) | Grt (Mpa) |

| Birch | 1 510 | 870 | 230 |

| Spruce | – | – | 50 |

| Pine | 1 210 | 780 | – |

| Oak | 1 380 | 980 | 460 |

The modulus of elasticity of wood must be taken into account when constructing roofing and rafter systems, since determining the internal forces of wood under the influence of loads plays a very important role here. In addition, the elasticity of wood is important in the manufacture of gun stocks, handles for impact instruments, hammers and other cases where it is necessary to soften shocks.

Plasticity of wood

Speaking about the elasticity of wood, it is impossible not to mention its antipode - plasticity. The plasticity of wood is its ability to change shape when exposed to load and retain it even after exposure to load. This indicator depends on the same factors as elasticity, but their effect will be the opposite (the wetter the wood, the more plastic it is, the older it is, the less plastic, etc.).

The plasticity of wood can be increased by steaming or boiling with hot water.

Such methods are used in the production of bent furniture, sled runners and other places where the plasticity of wood plays a key role. Among the popular types of wood, beech, elm, ash and oak have the greatest ductility. In particular, beech has good ductility due to the many large medullary rays that bend the wood fibers. In elm, ash and oak, when bending, large vessels located in ring rows in the annual layers are significantly compressed by later, denser wood, which explains their high plasticity. Tatyana Kuzmenko, member of the editorial board of the online publication “AtmWood.

Wood-Industrial Bulletin” How useful was the information for you?

Density

Density directly depends on the moisture content of the fibers. Therefore, to obtain uniform measurement indicators, it is dried to a level of 12%. Increasing the density of wood leads to an increase in its mass and strength. Based on moisture content, timber is divided into several groups:

- Rocks with the lowest density (up to 510 kg/m3). These include fir, pine, spruce, poplar, cedar, willow and walnut.

- Rocks with medium density (in the range of 540-750 kg/m3). These include larch, yew, elm, birch, beech, pear, oak, ash, rowan, and apple.

- Rocks with high density (more than 750 kg/m3). This category includes birch and stock.

Below is a table of densities for different tree species.

| Breed name | Rock density, kg/m3 |

| Acacia | 830 |

| Birch | 540-700 |

| Karelian birch | 640-800 |

| Beech | 650-700 |

| Cherry | 490-670 |

| Elm | 670-710 |

| Pear | 690-800 |

| Oak | 600-930 |

| Spruce | 400-500 |

| Willow | 460 |

| Cedar | 580-770 |

| European maple | 530-650 |

| Canadian maple | 530-720 |

| field maple | 670 |

| Larch | 950-1020 |

| Alder | 380-640 |

| Walnut | 500-650 |

| Aspen | 360-560 |

| Fir | 350-450 |

| Rowan | 700-810 |

| Lilac | 800 |

| Plum | 800 |

| Pine | 400-500 |

| Poplar | 400-500 |

| Thuja | 340-390 |

| Bird cherry | 580-740 |

| Cherries | 630 |

| Apple tree | 690-720 |

Coniferous species have the lowest density, while deciduous species have the highest.

On the issue of standardization of the modulus of elasticity of pine wood

In recent decades, both in our country and abroad, buildings and structures with spans from 20 to 120 m have been erected using wooden laminated structures.

When calculating such structures (determining internal forces from external loads and influences), their deformed state must be taken into account. As a rule, calculations are performed using software packages, where one of the many initial data is the value of the elastic modulus of wood. Depending on the value of the elastic modulus, it is possible to obtain different values of internal forces in compressed and compressed-bending elements of wooden structures and, as a consequence, the dimensions of the cross sections. A reasonable choice of the value of the modulus of elasticity of wood is one of the important tasks in the design of wooden structures, which is also aggravated by its properties such as anisotropy and creep.

In the standards [1], the value of the modulus of elasticity of wood along the fibers for structures protected from heating at a relative humidity of ambient air W ≤75% and under constant and temporary loads was taken equal to E k,0 = 10,000 MPa. This value was used in the calculations of wooden structures based on the limit states of the second group. As for the stability calculations, a dimensionless parameter was used here in the form of the ratio of the short-term elastic modulus to the temporary compressive strength.

In the standards [2], when calculating wooden structures according to the limit states of the second group, as in the previous standards [1], it was accepted that E k,0 = 10,000 MPa. In the calculations of elements for strength according to a deformed scheme and for stability, the assumption was made that the ratio E/fc,0 = 300 and does not depend on the type of wood, type and moisture content of the material, duration of the load, temperature, and cross-sectional dimensions of the elements [3]. That is, in calculations using a deformed scheme, the elastic modulus is determined from the expression

E 1 = 300 fc,0, d, (1)

where fc,0, d is the calculated compressive strength of wood along the fibers.

In this case, with the values of the design resistance of first grade pine and spruce wood fc,0, d = 14–16 MPa, the elastic modulus E 1 = 4200–4800 MPa.

The practice of operating wooden structures shows that the use of a short-term modulus of elasticity of wood equal to E k.0 = 10,000 MPa under long-term operation conditions leads to an underestimation of the calculated deflections of structures. Conversely, an underestimated value of the elastic modulus, determined by (1), in calculations using a deformed scheme leads to unjustifiably inflated sections of wooden elements. It was established in [4] that when determining the deflections of wooden structures, it is necessary to take into account the long-term modulus of elasticity.

As a result of theoretical studies, it was established that under the action of a constant load during a service life of 50 years and a wood moisture content of 12% E con / E k,0 = 0.76. Experimental studies of wooden samples under constant load along the fibers for up to 940 days made it possible to obtain the following values of duration coefficients: in tension E con /E k,0 = 0.77; during compression E con /E k,0 = 0.76 [5]. Consequently, the data from [3] confirmed the reliability of the conclusions from [4] regarding the ratio of the long-term to short-term elasticity modulus. Taking into account the combined action of constant and snow loads, in [4] it is proposed to determine the deflections of wooden structures using the formula

Normative documents

The elasticity of building materials, wood in particular, significantly affects the level of safety of buildings and structures for people, as well as the safety of the material assets located in them. Therefore, regulatory documents are being developed and approved that define the methodology for determining the elasticity parameter as well as calculations and design of structures made of laminated veneer lumber and solid wood.

SNiP II-25-80. Wooden structures. Building regulations

1 file 475.74 KB

SNiP II-25-80. Set of rules. Wooden structures. This document defines the methodology for calculating and designing buildings, structures and structures made of wood (solid and laminated veneer lumber). In particular, SNiP specifically states that wood structures must:

- meet the requirements of calculations for deformations and bearing capacity;

- designed taking into account operating, installation, and transportation conditions;

- be durable, which is ensured by design solutions and protective treatment.

GOST 16483.9-73 Wood. Methods for determining the modulus of elasticity during static bending

1 file 271.66 KB

GOST 16483.9-73. Interstate standard. Wood. Methods for determining the modulus of elasticity during static bending. In this GOST:

- methods for determining the modulus of elasticity during static bending have been established;

- the process of determining this indicator during static bending of conditioned and unconditioned samples is described;

- Sample protocols for determining elastic moduli are given.

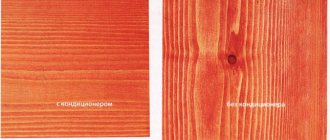

Pine and its characteristics

More than 50 species of pine naturally grow and are cultivated on the territory of the Russian Federation.

The following types of pine are mainly used in construction: common, flexible, resinous, swamp, Korean. In both northern and middle latitudes, the most common species is Scots pine (Pinus sylvestris L). However, the quality of Scots pine wood depends on where the tree grows. The best material for construction, which has excellent physical and mechanical properties, is pine that grows in the northern zone - Angara, Karelian, Arkhangelsk.

This is due to the fact that in the north winters are longer and colder, and summers are short and dry, which makes the distance between annual rings minimal (no more than 2 mm). And pine from the middle zone has wider rings (up to 10mm) due to warmer, wetter and longer summers and mild winters. Thicker annual rings in pine give the wood looseness, and therefore the log will have lower strength, heat capacity and higher cracking and a higher percentage of shrinkage

For example: the shrinkage percentage of Arkhangelsk log is 3-4%; Kirov, Vologda logs – 4-6%; Kostroma 6-7%; Tver, Smolensk, Yaroslavl - up to 10%. Therefore, when choosing material for building a house, it is necessary to take into account all these points.

Depending on the location and growing conditions of the tree, the pine core (the central part of the trunk) may have a different color. On higher, drier, and less fertile soils, pine produces fine-grained dense wood called kondovoy, which is especially valued in construction. Condo pine has a meat-red or yellow-red core. On fertile, well-moistened soils, coarse-grained, less dense, mandwood is formed with a core of pale yellowish color. Myanda pine is less valued and has worse mechanical properties.

Technical characteristics of pine

| Characteristic | Meaning |

| Density | 513kg/m3 |

| Density when freshly cut | 625 kg/m3 |

| Hardness in freshly cut state, kg/cm2 | 79 |

| Dry hardness, kg/cm2 | 109 |

| Specific gravity | 0,51 |

| Ultimate strength at static bending, MPa | 71,8 |

| Ultimate compressive strength along the fibers, MPa | 34,8 |

| Tensile strength along the fibers, MPa | 84,1 |

| Ultimate strength when shearing along the fibers, MPa: | |

| in the radial direction | 6,2 |

| in tangential direction | 6,4 |

| Hardness, N/kV.mm: | |

| Tortsovaya | 23,4 |

| Radial | 21,6 |

| Tangential | 20,7 |

| Modulus of elasticity at static bending, GPa | 8,8 |

| Specific work during impact bending, J/cm3 | 1,6 |

| Shrinkage,%: | |

| Longitudinal | 0,4 |

| In tangential direction | 6-8 |

| Radial direction | 3-4 |

Data at 12% humidity; 1 MPa = 1 N/mm2

Comparative characteristics of coniferous wood.

| Wood name | Rot resistance | Hardness, kg/cm2 | Density p15, kg/m3 | Density p conventional, kg/m3 |

| CEDAR (cedar pine) | 3-4: moderate to low | 200 | 440 | 350 |

| SPRUCE | 4: low | 235 | 450 | 360 |

| Siberian FIR | 4: low | 255 | 380 | 300 |

| PINE | 3-4: moderate to low | 260 | 520 | 400 |

| LARCH | 2-3: moderate | 395 | 670 | 520 |

Description of the main softwood species

PINE

The species and its main properties are wood of medium density, fairly high strength, resistant to rotting and fungal attack, and can be processed well. It is especially valued in construction due to the small number of knots and small changes in diameter along the length of the trunk.

External features: sound wood with resin ducts (concentrated mainly in late wood). The sapwood is wide, yellowish to pink. The annual layers are clearly visible in all sections with a clear boundary between early and late wood. The medullary rays are not visible.

SPRUCE

The species and its main properties - in terms of physical and mechanical properties (density, hardness, compressive strength along the fibers and static bending) are inferior to pine (by about 10%), but in terms of quality coefficient it is slightly superior to it by 3-4%. Wood is more difficult to process due to the abundance of knots and their increased hardness. Advantages: one-sided structure, long fibers, stable white color, low resin content, high ability to resonate.

External characteristics: the breed is coreless, mature wood, and has a few resin tunnels. The wood is a uniform white color, sometimes with a faint yellowish or pink tint. The annual layers are clearly visible in all sections; Late wood is slightly different from early wood in that it is darker in color. The medullary rays are not visible. Unlike pine, it has larger knots arranged in whorls, between which there are single smaller knots.

Natural humidity

GOST 24452-80 concrete. methods for determining prismatic strength, elastic modulus and Poisson's ratio

The indicator is used to determine the amount of water inside the trunk immediately after cutting or during growth. It determines the quality of drying of wood materials. The natural moisture content of wood is considered the initial value, on the basis of which calculations for drying the material begin. If the indicator is determined incorrectly, there is a risk of under- or over-drying the lumber.

What percentage of water is contained in the trunk is determined by the following factors:

- wood structure;

- porosity;

- environment.

The natural moisture content of wood ranges from 30 to 80% and varies depending on the type of material. They are used as a starting point before determining the optimal drying mode to achieve the desired quality of the dry workpiece.

Deciduous wood has a lower natural moisture content than coniferous wood. This is due to the structure of wood. Spruce contains up to 90% moisture, fir contains up to 92%. For comparison, ash wood contains only 36%. In addition, the percentage of water in the material is influenced by the state of the environment. In winter, plants go into “dormant mode” and practically do not consume nutrients from the ground. Therefore, humidity in summer is much higher than in winter. Also, freshly cut wood has a much higher moisture percentage than older wood.

The task of those involved in lumber processing is to reduce moisture content to the lowest possible percentage. This is done so that the workpieces acquire the necessary hardness and strength. The wear and tear of products whose material has successfully undergone the drying process is significantly lower.

Humidity also affects the size of the workpieces. The more the material dries out, the smaller in size it becomes. Proper drying should be organized in such a way that moisture evaporates evenly. Then the weight and size of the workpiece will be standard, and the material itself will acquire the necessary properties. The latest methods of drying wood reduce the percentage of humidity to 6. This indicator also depends on the species, structure of the tree, and time of year.

Heavily dried wood is not used for construction, as it can crack. The amount of water in the material for these purposes is reduced in the following ways:

- Self-drying. A ready-made cut of natural moisture is purchased and laid out in stacks on the site. Gaps are made between the rows of boards using bars so that air can circulate freely. The supports must be placed at least 1.5 meters apart from each other, and the material will not bend. To prevent rain or other precipitation from spoiling the wood, the structure is covered with film or roofing felt on top. Natural drying is best done in the warm season. Materials are placed in the shade, under a canopy. Thin-width boards will dry out faster than thick ones. The structure is installed on pads made of pine branches or protective material.

- Purchase of finished material. In this case, the seller has already prepared the boards and dried them naturally on his own.

- If it is necessary to reduce the amount of moisture to 15% or lower, then chamber drying is used indoors. Such materials will be more expensive, since processing will require a large waste of resources. And it is better not to use such wood for construction, it can crack.

The ideal use of dry wood is furniture and interior items.

Modulus of elasticity of wood

Elastic moduli characterize the stiffness of the material and are very important calculated values. Elastic moduli can be determined for any case of action of the forces discussed above. The modulus of elasticity during tension and compression, as well as during static bending, is called the first kind modulus, and during shearing and torsion - the second kind modulus (shear modulus).

Due to the relative complexity of the determination, which requires very precise instruments for measuring deformations and is associated with a lot of time, the elastic moduli for wood have been poorly studied and there is little experimental data, and these data, due to differences in determination methods, are not always comparable.

Rice. 87. Sample with Guggenberger strain gauges mounted on it

To determine the modulus of elasticity in compression along the fibers, TsNIIMOD (N. L. Leontiev) recommends using a sample in the form of a rectangular prism with a cross section of 20 mm X 20 mm. The height of the sample is determined by the base of the strain gauge (a device for measuring deformations) and should be equal to the base with an addition of 20 mm in both directions. The total height of the sample at the indicated

In general cross-sectional dimensions cannot exceed 140 mm. The annual layers at the ends of the sample should be parallel to one pair of opposite faces and perpendicular to the other. The cross-sectional dimensions of the sample are measured with an accuracy of 0.1 mm (a and b in the middle of the height and at the points of attachment of the strain gauge legs) and the average for each size is calculated from the obtained values. The machine must be equipped with a ball joint. Loading speed 500 kg 20% per minute for the entire sample. Using two strain gauges mounted on opposite sides of the sample (Fig. 87), the deformation is measured with an accuracy of 0.001 mm with loads of 100 and 400 kg with a holding time of 10 seconds. before each reading using strain gauges. Then the sample is unloaded to 80-90 kg and the deformations are measured again with the same loads (100 and 400 kg); This operation is repeated for each sample 6 times (six times loading – unloading).

From the last three readings by strain gauge, meters, separately for the upper (400 kg) and lower (100 kg) loading limits, the arithmetic mean is calculated; the difference between these arithmetic averages gives the increment in deformation for the accepted loading interval (300 kg).

The elastic modulus value is calculated with an accuracy of 1000 kg/cm2 using the formula:

where: P – load in kg, equal to the difference between the upper and lower loading limits; l – strain gauge base in cm; delta l – deformation in cm corresponding to load P; n – gear ratio of the strain gauge; a and b are the cross-sectional dimensions of the sample in cm. Reduction to 15% humidity within the range of its change from 8 to 22% is carried out according to the straight line equation:

where a is the correction factor for humidity, equal to 2000 kg/cm2, regardless of the breed.

The tensile modulus of elasticity along the fibers is determined on samples of the same shape as in the tensile test, but to strengthen the strain gauge (Fig. 88) and eliminate the influence of the transition points of the working part of the sample into the heads, samples are taken of greater length by increasing the length of the working part ( Fig. 89).

The width a and thickness b of the working part of the sample are measured in three places: in the middle of the length of the sample and at the places where the legs of the strain gauges are attached; From the obtained values, the average is calculated for each size. The sample is secured between the grooved cheeks of a machine with a self-aligning head like this. so that the part of the heads bordering the working part remains free for 20-25 mm. The loading rate and all other operations for measuring deformations, processing the results and calculating the elastic modulus are quite similar to those described above for the compressive modulus of elasticity. The float coefficient for moisture is 2000 kg/cm 2 (the equation for recalculation is the same as for compression along the fibers).

Rice. 88. Sample with a MIL strain gauge mounted on it

Rice. 89. Shape and dimensions (in mm) of the sample to determine the tensile modulus of elasticity along the fibers

Rice. 90. Location and machine of the sample with a deflectometer mounted on it when determining the conditional modulus of elasticity

Strain gauges can be used to measure tensile and compressive strain. The simplest and most convenient to use is the strain gauge designed by Yu. M. Morozov and manufactured by the workshops of the Leningrad Institute of Agricultural Mechanization. This strain gauge, called "MIL", is particularly useful for measuring tensile strain; when compressed, its large base (100 mm) determines the large sample height (140 mm), which is the maximum height for a section of 20 mm X 20 mm, which must be considered a disadvantage of the strain gauge. The Guggenberger strain gauge is more useful

suitable for compression, since when stretched its small base (20 mm) is already a disadvantage. In addition, when using this strain gauge, it is necessary to make stickers on the sample from a solid material (celluloid, metal), on which the strain gauge mounted on the sample rests; Without such stickers, the strain gauge gives unacceptable errors. The modulus of elasticity during static bending (called conditional according to OST NKL 250) is determined on the same samples as in static bending tests. The shape of the knife and supports, the span, and the method of applying the load are the same. Measurement of deformations (sample deflections) with loads of 20, 40, 60, 80 and 100 kg is carried out with an accuracy of 0.005 mm using a deflectometer with an indicator mounted on the sample itself (Fig. 90). Loads are applied sequentially one after another without unloading the sample; Before each reading by the deflectometer, the sample is kept under a load for 30 seconds. From the deflection values for loads of 40 kg and above, the deflection for a load of 20 kg is subtracted with a simultaneous reduction of each load by 20 kg. the result is four deflection booms with loads of 20, 40, 60 and 80 kg. If the last load is out of proportionality, it is discarded. Based on each pair of readings (load - deformation), the conditional modulus of elasticity is calculated with an accuracy of 1000 kg/cm2 according to the formula:

Poisson's ratio

When a load is applied to the rod, in addition to the longitudinal deformation ε, a transverse deformation ε1 appears. The transverse strain ratio, or Poisson's ratio μ, is the ratio of ε1 to ε.

The Poisson's ratio of wood is determined by compressing rectangular prismatic samples with a cross-section of 40x40 mm and a height of 150 mm. To measure the deformation, six strain gauges with a base of 20 mm and a gear ratio of about 1000 are installed on the sample. Of these strain gauges, two record longitudinal strain (deformation in the direction of the compression force), the other four measure transverse strains in two mutually perpendicular directions. Each of the samples is loaded six times up to 400 and 1600 kg when compressed along the fibers, up to 40 and 160 kg when compressed across the fibers.

For pine and spruce wood, Poisson's ratio with a force directed along the fibers v0=0.5.

Modulus of elasticity of wood

| Wood processing, drying and classification of wood, properties of wood) |

| Breed | Modulus of elasticity of the 1st kind in 1000 kg/cm2 | Modulus of elasticity of the 11th kind (at torsion) in kg/cm 3 | ||||

| in tension | when compressed | limits of fluctuations | average | |||

| along the grain | ||||||

| limits of fluctuations | average | limits of fluctuations | average | |||

| Scots pine | 116 – 166 | 150 | 116 – 176 | 139 | 4200 – 8300 | 6100 |

| Siberian larch | 119 – 181 | 149 | 118 – 168 | 145 | 5200 – 9800 | 7300 |

| Norway spruce | 118 – 191 | 146 | 119 – 185 | 142 | – | – |

| Caucasian fir | 90 – 173 | 126 | 96 – 181 | 125 | 4800 – 7000 | 5700 |

| Common ash | 127 – 181 | 150 | 143 – 178 | 155 | 6700 – 11100 | 8700 |

| Summer oak | 111 – 174 | 138 | 102 – 163 | 135 | 5200 – 9700 | 7700 |

I. L. Leontiev determined the modulus of elasticity of the second type directly when shearing along the fibers. The values he obtained show that between the modulus of elasticity of type II, found by testing for torsion and shearing along the fibers, the same relationship is observed as between the limits of strength during torsion and shearing: the modulus of elasticity of type II during torsion is on average approximately 1. 5 times higher than the modulus of elasticity found by shear testing along the fibers.

Differences from other conifers

How can you distinguish pine wood from other conifers, in particular from spruce? Pine contains significantly fewer knots. It has a striped texture. The annual rings are clearly visible in the sections. The medullary rays are invisible. It is characterized by high density and strength. However, it is quite soft and light wood. It is distinguished by its increased resin content, making it resistant to decay and the effects of fungi, parasites, as well as precipitation and other atmospheric phenomena.

Pine wood has high-tech properties and is easy to process. Due to this, it is used in production more often than other coniferous species. It is used to make furniture, musical instruments, containers, and is used in construction and finishing work.

Chemical composition

99% of the wood mass contains organic matter. The composition of elementary particles is the same for all rocks: nitrogen, oxygen, carbon and hydrogen. They form long chains of more complex molecules. Wood consists of:

- Cellulose is a natural polymer with a high degree of polymerization of chain molecules. A very stable substance, insoluble in water, alcohol, or ether.

- Lignin is an aromatic polymer with a complex molecular structure. Contains a large amount of carbon. Thanks to it, lignification of tree trunks appears.

- Hemicelluloses are an analogue of ordinary cellulose, but with a lower degree of polymerization of chain molecules.

- Extractive substances - resins, gums, fats and pectins.

The high content of resins in coniferous trees preserves the material and allows it to maintain its original properties for a long time, helping to resist external influences. Low-grade timber with a large number of defects is used mainly in the wood chemical industry as raw material for the production of paper, laminated wood or the extraction of chemical elements such as tannins used in leather production.