Today, it is rare to build one-story houses from wood. In general, preference is given to two-story spacious buildings, which have a lot of living space and can comfortably accommodate a large family. At the finishing stage, owners often face the question of how to insulate the second floor of a wooden house. And it is by no means idle, since the process of thermal insulation of the 2nd floor depends on many factors. In particular, this is influenced by the design features of a log house, for example, there may be a heated attic or an unheated attic above the top floor. Thermal insulation in these two cases will be carried out differently. And there can be many such nuances. Therefore, in this article we will analyze the main issues that arise when insulating this part of the house, and we will describe in detail the process itself.

Stages of work on insulating a pitched roof

The roof insulation scheme is quite simple. First of all, you need to measure the distance between the rafters. The slabs of cotton wool insulation should be cut according to the results obtained, adding 1 centimeter. This will allow you to fasten the heat insulator between the rafters. This stage of work is greatly simplified if the roofing system is initially designed and installed based on the use of slab insulation boards of a certain width.

If there is no waterproofing between the rafters and the already installed roofing, you should first secure a water barrier. The membrane should envelop the rafters; it is most convenient to fasten it with a construction stapler to the rafters themselves and to the roof sheathing in the openings between them. The waterproofing must be installed under the eaves at the bottom of the roof to ensure moisture drainage. It should be taken into account that with this method of fastening the hydrobarrier, the insulation must be installed without the necessary air gap. For this reason, it is recommended to use a superdiffusion membrane as a waterproofing material.

If there is a waterproofing layer under the roofing, nails are placed on the rafters in increments of about 10 cm. The nails should be located at a distance of 3-5 cm from the waterproofing layer. It is necessary to stretch a polyethylene thread or cord between the nails, tamping them to the end. This will help create an air gap between the hydrobarrier and the insulation. If the heat insulator is planned to be fixed with a cord, and not with lathing for internal cladding, nails must also be driven along the outer edge of the rafters.

If, when deciding how to insulate the roof of a house, you chose cotton slab insulation, then the prepared elements must be slightly compressed and inserted between the rafters

When using stiffer foam boards and similar materials, it is important to accurately size them so that the boards fit snugly into the opening. It is recommended to carry out insulation in two layers

If you have to mount not solid sheets into the opening, but narrower fragments, joining them along the length or width, you need to make sure that the joints of the second layer do not coincide with the joints of the first. The heat insulator should not protrude beyond the plane of the rafter legs. If the rafters are not wide enough to install two layers of insulation, additional timber is nailed to them.

The heat insulator is fixed between the rafters using a stretched cord secured to pre-filled nails. Or, as a fastening, a lathing made of slats is used, intended for mounting the interior lining of the room. The slats are nailed to the rafters in increments of 30-40 cm. In this case, the vapor barrier is stapled to the rafters before installing the sheathing: the thickness of the slats allows you to create the necessary air gap between the vapor barrier and the sheathing.

When installing a vapor barrier, special attention is paid to the tightness of the layer. The panel is laid with an overlap of at least 10 cm, the joints should be taped with adhesive tape in two layers

It is necessary to install the vapor barrier around the chimney and at the junction with the walls as efficiently as possible. At the final stage, the sheathing is installed using wood-based or plasterboard boards.

You can learn more about how to insulate the roof of a house from the video.

How to properly insulate a ceiling under a cold roof?

Currently, almost all residential buildings are heated using gas or electric heat-generating equipment. Even country houses and garden houses, which are used only in summer, are no exception. Most buildings that are not used year-round are equipped with inexpensive cold-type roofs, through which the main heat losses occur while maintaining a comfortable temperature regime. In this article we will tell you how to properly insulate a ceiling under a cold roof so that the house is always warm.

Exterior works

A prerequisite is that the house is insulated in warm and dry weather. It all starts with an inspection of the surface. Next, all wooden components need to be treated with an antiseptic, and metal ones with an anticorrosive agent. It is also necessary to thoroughly dry damp areas. If the tree is damaged by insects, it is replaced.

In a log house, the rafter system is made of wooden beams. So the waterproofing film is glued directly to these joists, after which the lathing is created and the roof is installed. Insulation from the inside occurs by laying the material between the rafters with its fixation on top of the vapor barrier, as well as finishing with plasterboard. There is no need to compact fiber-type insulation - you need to cut out pieces of material with a small allowance and insert them between the rafters. If a soft roof is to be installed, then OSB boards or moisture-resistant plywood are laid directly on the sheathing, after which the roof is created.

Thermal insulation methods

High-quality thermal insulation reduces heat loss and home heating costs by 30%, which is a good saving in terms of the family budget. The use of suitable insulation and the correct choice of installation method create a comfortable microclimate in the room.

The issue of thermal insulation of the ceiling under a cold roof is best decided at the stage of building a house, then you can choose the most effective and convenient option. Most often, insulation is installed in 2 ways:

- Insulation from the attic side . Builders consider insulation of the ceiling located under the cold roof on the attic side to be the most effective and correct. The fact is that the ceiling is most often made of wood, which in itself is a good peat-insulating material. In this case, the insulation is laid on the attic floor and covered with a subfloor. If insulation is carried out from the attic side, then materials in the form of slabs or backfill can be used.

Insulation from the first floor side . In cases where there is no access to the attic, when reconstruction of old houses with a finished attic floor is being carried out, thermal insulation is carried out from the side of the first floor. To do this, a frame made of metal profiles or wooden slats is mounted on the ceiling, insulation boards are laid there, and then covered with plasterboard. The disadvantage of this method is that it reduces the height of the ceiling. In addition, installation at the top is always much more difficult and longer. The effectiveness of this insulation method is less, so it is used when there is no other way to reduce heat loss without dismantling the floors.

Note! Any thermal insulation works comprehensively. Therefore, if you want to solve problems with heat loss in a house with a cold roof, do not forget about thermal insulation of the floor, door and window openings. A clear way to analyze where the heat goes is to look at the house with a thermal imager in winter. To improve the energy efficiency of your home, you need to pay attention to the areas painted red and yellow, as it is through them that heat escapes.

What to consider when insulating a roof

Whenever finishing work is carried out in a wooden house, you need to take into account the characteristics of this material. During the first year and a half after construction, the tree actively shrinks and the structure becomes deformed, so there can be no talk of any insulation during this period. We begin thermal insulation when shrinkage has ended.

If you plan to make the attic residential or place a storage room in it, then it is necessary to insulate the roof and the ceiling between it and the interior. If it will not be used as a residential building, it is allowed to insulate only the attic floor and the ceiling in the house.

When thermally insulating the roof of an old log house, a thorough inspection of the structure must be carried out before work. If the roof was leaking, there is probably mold, mildew, or rotten areas on the beams; they will have to be replaced.

When arranging an attic, it is recommended to combine thermal insulation with a special foil film. The reflective layer is fixed on the outside, so it will effectively reflect UV rays during active sun, and the attic will not heat up too much.

What is dew point

This is the place in the structure where condensation forms due to the temperature difference between the street and the room. It appears because warm air from around the house accumulates in the form of steam under the roof, and steam, as you know, moves towards the cold air and settles on the under-roof structure in the form of condensation.

Therefore, insulating the attic from the outside is considered an ideal option. Thus, the dew point is moved outside the room. But most often, attic insulation occurs inside, which is why it is so important to follow the sequence of laying the layers of the insulating cake. With this technology, the insulation will not get wet, since the dew point is transferred to the gap between the roof and the insulation.

Insulation of the second floor in a private house

Features of the work on insulating the second floor in a private wooden house depend on the design of the building, whether the building has an attic or whether the upper tier is located directly under the roof.

Insulation of interfloor ceilings

We recommend starting with sealing the wooden floor between floors. First, you need to dismantle the floor, then lay a layer of vapor barrier material, after which the free area is filled with a heat insulator. For this purpose the following materials are used:

- Styrofoam,

- extruded polystyrene foam,

- foil polyethylene foam,

- mineral wool.

Then the vapor barrier layer is laid again and the floor covering is laid. The next stage will be thermal insulation of the walls of the first and second floors.

How to insulate the walls of a private wooden house

Wall finishing with insulation can be done on the outside or inside of the building. The most effective is external thermal insulation, the easiest way to do this is with foam or mineral wool.

Internal processing of the walls in the room is carried out in stages. First, all cracks are sealed, the walls are etched with an antiseptic solution in order to eliminate rotting and mold formation. Then thin glazing beads are attached horizontally to the surface to ensure ventilation, and a vapor barrier is tensioned to them. After this, the installation of vertical posts begins, between which mineral wool slabs are laid, and a layer of vapor barrier is attached on top of them. The top is covered with plasterboard or clapboard.

What to do for the attic floor and ceiling between the second and first levels?

Finishing the attic floor is done in the same way as sealing the interfloor partition. An important nuance: when laying a vapor barrier layer, it is necessary to do it with the rough surface facing outward in order to remove steam from the private house to the outside, but at the same time stop the penetration of moisture from the roof into the thermal insulation material.

To carry out thermal insulation work on the ceiling, the following building materials are used:

- mineral wool,

- foam concrete,

- expanded polystyrene,

- siopor slabs,

- ecowool.

A layer of insulation is attached directly to the ceiling, and the top is covered with plaster or other finishing materials. High-quality insulation of the ceiling between the second and first floors will keep the room warm.

Before starting construction work on insulating the second floor of a dacha or private house, it is necessary to carefully plan the procedure for carrying it out, calculate and purchase the required amount of raw materials. At the planning stage, we recommend using photos with instructions for each stage of work.

See how you can insulate a balcony with your own hands.

How to calculate the required insulation thickness yourself

The optimal thickness of the layer of insulation material depends on the climate zone, the area of the attic, and the thermal conductivity of the insulation. You can calculate it yourself using the formula.

δut=(R-0.16-δ1/λ1 -δ2/λ2 -δi/λi )×λut

Wherein:

- R-0 – coefficient of thermal resistance depending on the climatic zone;

- δth – insulation thickness;

- δ1,2..i – thickness of the attic structure in meters;

- λ1,2…i – thermal conductivity coefficient of construction materials;

- λth is the thermal conductivity coefficient of the insulating material.

If mathematical calculations are not your thing, you can determine the required thickness of the insulation layer based on its thermal conductivity coefficient.

| Insulation | Thermal conductivity coefficient W/(m °C) | Insulation layer thickness in mm |

| Styrofoam | 0,05 | 195 |

| Extruded polystyrene foam | 0,03 | 115 |

| Mineral wool | 0,04 | 155 |

| Glass wool | 0,047 | 185 |

| Stone wool | 0,044 | 170 |

| Ecowool | 0,04 | 155 |

| Polyurethane foam | 0,03 | 115 |

| Penofol | 0,045 | 175 |

[Table of recommended insulation layer thickness]

I had a sad experience when, in order to save money, I decided to insulate the top floor with a gable roof with 5 mm polystyrene foam in 2 layers. I realized my mistake when the temperature outside dropped to -15 °C. It was cool in the attic, and condensation appeared on the surface of the walls and ceiling. Soon dark spots appeared on the surfaces and fungus appeared.

Since the finish was plasterboard, I just had to remove it and throw it away. And in the spring, dismantle the entire insulation structure and bring the thickness of the insulation cake to the required thickness. Don't repeat my mistake, don't skimp on the thickness of the insulation.

Materials for thermal insulation of pitched roofs

Roof insulation technology involves the use of various materials. The most popular heat insulators include mineral wool and glass wool (in slabs or rolls), slab polymer materials - polyurethane foam, polystyrene foam. The principles of their installation are similar, but it is worth noting that installing slab material is much simpler and more convenient.

As waterproofing, roofing material or a waterproofing membrane is usually used, which is impermeable to water, but capable of removing moisture from the insulation. The vapor barrier layer can be made of

:

- roofing felt;

- polyethylene film;

- glassine;

- foil materials laid with foil towards the attic.

To create a roofing pie with high functional characteristics, it is recommended to use a special vapor barrier membrane to create a vapor barrier: it removes condensation outside from the insulation and does not allow steam and moisture to pass into the roofing pie.

Overview of thermal insulation for the attic

The slopes increase its area, so the thermal insulation of the attic is equivalent to high-quality protection from the cold of the roof. For this purpose, use thick insulation or lay it in several layers.

When choosing the best option, it is worth comparing the most popular types in relation to the attic space.

1. Mineral wool. It has a fairly low thermal conductivity (0.032-0.045 W/m2), does not contain toxic substances, does not burn, and is an excellent sound insulator. The vapor permeability of mineral wool is useful for roof insulation: thanks to this, condensation does not accumulate in wooden structures. The negative side is hygroscopicity, which in the absence of waterproofing leads to a loss of thermal characteristics. The advantage of inorganic species is their low specific gravity (10-15 kg/m3).

The Knauf company impregnates its products such as TEPLOroofing with hydrophobic compounds to increase resistance to moisture. Rocwool produces low-density mineral wool in rolls Domrock, Epirock, Megarock, as well as easy-to-use slab Rockmin, Superrock.

Insulation of the attic floor with mineral wool is carried out with protective glasses and gloves, since glass microparticles cause skin irritation and the development of silicosis in the lungs. To prevent the insulation from becoming dusty, it is securely covered with cladding.

Video text

Insulating the attic roof with mineral wool. How to insulate an attic roof Hello everyone! My brother and I started an interesting project: a children's playroom on the attic floor. In this video we will be insulating the attic roof with mineral wool, or rather the ceiling. Enjoy watching everyone. I bought the insulation here https://www.isover.ru

Playlist: Project “Children’s room on the attic floor” https://www.youtube.com/watch?v=7M337.

Financial assistance for the development of the channel: Yandex money: 410012884669167WebMoney: Z368854239077WebMoney: R166421536253

Diamond bits for tiles 6-50mm: https://ali.pub/2x2nziDiamond bits for tiles 6-90mm: https://ali.pub/2x2opdGuide for diamond bits: https://ali.pub/2x2parGuide for diamond bits: https://ali.pub/2x2pueDiamond cutting disc for an angle grinder: https://ali.pub/2x2uziDiamond cutting disc 125mm: https://ali.pub/2x2rhpCrowns for tiles for an angle grinder: https://ali.pub/2x2z5mCrowns for tiles on an angle grinder 2: https://ali.pub/2x2zey Square for marking: https://ali.pub/2x30ky Square for marking and more: https://ali.pub/2x322f Ruler-square for marking: https:/ /ali.pub/2x334xElectronic protractor: https://ali.pub/2x33odDevice for marking: https://ali.pub/2x33hdProtractor for marking: https://ali.pub/2×3462Dust removal housing for angle grinders: https: //ali.pub/2x3b4wMagnetic bracelet for self-tapping screws: https://ali.pub/2x3c6fMultitool: https://ali.pub/2x3cw3Multitool: https://ali.pub/2x3dhoDiamond cup for grinding: https://ali. pub/2x3dubCyclone for dust removal: https://ali.pub/2x3e84Cutter for milling drywall: https://ali.pub/267dk2Plaster wall ladle: https://ali.pub/203r04Magnetic bracelet: https://ali.pub/ 2x3ezq Spatula: https://ali.pub/267pxjConstruction stilts: https://ali.pub/f0ghvMulti-cutter: https://ali.pub/f87gaMini saw set: https://ali.pub/2x3gd4Screwdriver 12v: https:// ali.pub/2x3goeKnife for drywall: https://ali.pub/267nr6Marking lace: https://ali.pub/267mbgGrip for carrying gypsum board OSB plywood: https://ali.pub/267h31Cutter for profiles: https:// ali.pub/2040a6Saw for drywall: https://ali.pub/20421kSpatula for working with silicones: https://ali.pub/2x3hyhBits for self-tapping screws on drywall: https://ali.pub/267gfwDevice for carrying plywood, OSB : https://ali.pub/2x3j77Universal scissors: https://ali.pub/2x3kniUniversal scissors for electrical: https://ali.pub/2x3l2oBimetallic crowns 15-50mm: https://ali.pub/2x3lj03D green laser beam: https://ali.pub/2x3lq73D laser red beam: https://ali.pub/2x3m5rMiter box with clamps: https://ali.pub/2x3mpeDiamond blades for metal: https://ali.pub/2x3naeAdjustable wrench 70mm: https://ali.pub/2x3nt9 Pliers, Thin-nose pliers, Side cutters: https://ali.pub/2x3o7gJigsaw files: https://ali.pub/2x3ogz

Insulating an attic roof with mineral wool How to insulate a roof attic insulation, insulation, insulation, attic insulation, insulate the roof, insulate the roof with your own hands, insulate the roof, insulate the rafter system, insulate the house, install insulation, lay insulation, insulate, heat, keep warm, save on heating, how to properly insulate, insulation video, roofing, roof insulation, vapor barrier, installation of metal tiles, installation of siding, building a house, installation, review of how to install insulation and insulation how to make the attic comfortable

Basic requirements for thermal insulation material

How to choose insulation for a log house? To make the only right decision, you need to know the basic criteria. In particular, this group of materials must have the following properties:

Environmental Safety.

Obviously, if you choose toxic models, then one of the main advantages of wood (natural origin) will disappear. Therefore, it is necessary to use natural analogues, such as ecowool, penoplex, basalt wool, etc.

Thermal conductivity coefficient (the ability of a substance to pass warm air through itself).

This is a key characteristic of a thermal insulation material, on which its effectiveness directly depends (the lower it is, the better). However, all modern models meet the established requirements.

Unfortunately, most modern insulators are susceptible to combustion to one degree or another. Thus, penoplex, which is gaining great popularity, can smolder for several hours (along with it, the walls). The clear leader in this aspect is foam glass - it is a porous material sold in the form of slabs. However, it has two serious drawbacks - heavy weight and impressive cost. There are other solutions: before insulating a wooden house, treat all floors with protective compounds (they will prevent the wood from catching fire).

Resistance to organic influence.

If the house is old, then over time the walls will begin to become covered with fungus or mold. Therefore, it is necessary to choose insulators that are resistant to such consequences.

There is no ideal insulation that would more than meet all the requirements. For example, penoplex has better efficiency and lighter weight, but at the same time it burns well and releases toxic substances. Its counterparts, which are environmentally friendly and non-flammable, are characterized by less efficiency. Therefore, you will have to choose the “lesser of two evils” (safety or effectiveness).

Thermal insulation of flat roofs

How to make an insulated roof when installing a flat roof? It should be noted that a flat roof can be insulated both from the outside and from the inside.

The composition of the flat roof pie includes

:

- vapor barrier;

- heat insulator;

- waterproofing layer made of rolled material;

- bulk layer (drainage + cement-sand mixture).

External insulation is most conveniently performed using mineral basalt wool. You can also use polystyrene foam and other rigid insulation materials. It should be taken into account that polymer insulation cannot be used when installing roofing coverings with high fire safety requirements.

Material selection criteria

To avoid making a mistake when choosing an insulator, take into account a number of features:

- climate of the region;

- the main building material of the building and the specifics of the design;

- installation features;

- cost of coatings for all types of insulation and cladding;

- operational features of insulation materials.

The choice of materials depends on the construction material of the building and the specifics of the design.

Indicators of toxicity and durability are not ignored.

Roof insulation technologies

Experts recommend thermal insulation of roof slopes using mineral wool or extruded polystyrene foam

Both materials do not support combustion, which is very important for wooden structures. Below we will look at how to properly insulate a roof using different methods and materials.

Thermal insulation with slabs or mats

Roof insulation technology

The insulation pie diagram looks like this:

- The rafter system is covered with waterproofing material. For this, it is best to use high-density polyethylene (more than 200 microns), which will protect the roof from precipitation and wind. The canvases are laid overlapping each other and secured to the rafters with staples.

- A counter-batten is attached to each wooden element on top of the film, which serves to form a ventilation gap between the waterproofing and the roof covering.

- If the slopes are covered with soft material, sheets of plywood are laid on top of the counter slats. When using slate, a sheathing is installed. The pitch between the slats depends on the length of the sheets of roofing material.

- The roof covering is being laid.

Thermal insulation with slabs

All the described measures were carried out within the framework of external insulation. Next, you can begin to insulate the roof inside the house.

- Insulating material is placed in the space between the rafters, the thickness of which should match the width of the beams. It should fit tightly to the structural elements, leaving no gaps. Installation begins from the bottom, gradually moving towards the ridge.

- The insulation is covered with a vapor barrier film, which is attached to the rafters with slats.

- If you intend to equip a residential attic, the surface is sheathed with plasterboard or clapboard.

If necessary, for example in harsh climatic conditions, you can make a thicker insulation cake:

- The first layer of insulation, corresponding in thickness to the width of the rafters, is laid between the beams.

- Cross slats are placed on the beams in increments equal to the width of the next layer of insulation. You don't need thick material here; you can take thinner slabs.

- A vapor barrier layer is laid over the thermal insulation, the film is attached to the slats using a stapler.

- Decorative finishing material is mounted to the slats.

Insulation with sprayed polyurethane foam

This method can be used both when it is intended to organize a living room in the attic, and for an ordinary attic. In the first case, it is necessary to insulate both attic floors and roof slopes.

Before work, wooden elements must be moistened. This is done for better adhesion of the sprayed material to the surface.

Polyurethane foam is sprayed in a thin layer onto the damp surface between the beams. After the material has hardened, you can apply another layer if necessary. Spraying is carried out from the bottom up; the lower layers, when hardened, will serve as a support for the next levels.

Polyurethane foam insulation creates a completely sealed, moisture-resistant coating that has excellent thermal insulation characteristics. The service life of the material is about thirty years, during which the insulation remains unchanged and does not lose its original properties.

Insulating the roof of a log house is not an easy job; doing it yourself, without experience and special knowledge, is quite difficult. By deciding to do the insulation yourself, the home owner risks getting a poor-quality result, which will then have to be corrected by professionals. Therefore, it is better not to experiment, but to immediately contact specialists.

is ready to provide professional services in Moscow and the region for insulating the roofs of wooden houses. We use proven technologies and high-quality materials, which guarantees excellent results.

You can get additional information and call a specialist for free to take measurements on the “Contacts” page.

Calculate the cost of painting and insulating your home right now

How to insulate an attic

What insulation is suitable for the second floor and attic of a log house? Typically, in this case, standard materials are used, traditionally used for thermal insulation of the roof in a wooden house. This:

- mineral wool;

- expanded clay;

- ecowool;

- expanded polystyrene;

- polyurethane foam.

We talked in more detail about each material in the article about roof insulation in a wooden house.

If thermal insulation is carried out in the attic located above the bathhouse, then there are slightly different rules in choosing the material. Not every insulation can work effectively in conditions of high humidity and extreme temperatures.

For example, one of the best materials for insulation in a wooden house, mineral wool, will very quickly lose its consumer properties in a sauna. This material strongly absorbs moisture, which is abundant in the steam room. They can be used to decorate the walls, but it is best to insulate the attic floor of a bathhouse with moisture-resistant polystyrene foam.

A very important role in a bathhouse is played by vapor barrier, which prevents the process of moisture accumulation in the insulation. Therefore, special attention should be paid to the arrangement of the vapor barrier, especially in cases where the thermal insulation is done by hand.

invites residents of the Moscow region to take advantage of professional home insulation services. We guarantee high quality workmanship and quick results. To leave your request, go to the “Contacts” section. There you will find all our data.

Calculate the cost of painting and insulating your home right now

Select types of work:

Select materials:

Algorithm for insulating the 2nd floor floor

Above the second floor in a wooden house there is always an attic space

To prevent heat from the first level from penetrating upward, it is important to insulate the ceiling well. The thermal insulation layer will consist of several materials laid in a certain sequence

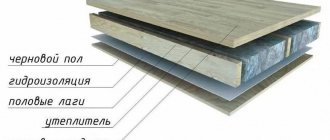

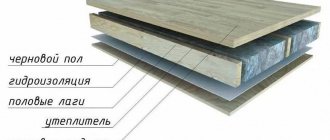

Traditionally, the “pie” for insulating the second floor of a wooden private house consists of the following elements:

- lower floor ceiling;

- a layer of construction paper;

- diagram of load-bearing beams made of high-quality timber;

- a layer of mineral wool placed in cells formed by beams;

- paper again;

- any flooring option.

The listed sequence should not be violated, otherwise the effectiveness of the hydro- and thermal insulation of the upper room may be greatly affected. If a teenage music lover lives on the second floor of the house or the house is located close to the roadway, you will have to take care of soundproofing the walls and floor of this room.

In addition to insulation, 2 layers of plywood are added to the multilayer “pie” to create a sound barrier. If expanded clay is used during the insulation process, a dry concrete screed is placed on top.

Portal about construction

12/24/2018 admin Comments No comments

Attic spaces are becoming a prestigious type of housing these days; they are appearing in private hotels and residential complexes. In a cottage or country house, insulating the attic from the inside allows you to equip an office, bedroom or bathroom under the roof. To create comfort under the roof, you should take a responsible approach to choosing and creating a thermal insulation “pie”.

There are several arguments in favor of carrying out work that requires additional costs:

- increasing the usable area of the house;

- reduction in heating costs - a large amount of heat evaporates through the attic as heated masses rise upward;

- protection from the inside of the attic room, as well as the lower floors from the summer heat;

- prevention of the formation of ice and icicles: the roof is protected from contact of warm and cold air, which causes the melting of the snow cap.

Video insulation of the second floor in a wooden house

Today, it is rare to build one-story houses from wood. In general, preference is given to two-story spacious buildings, which have a lot of living space and can comfortably accommodate a large family. At the finishing stage, owners often face the question of how to insulate the second floor of a wooden house. And it is by no means idle, since the process of thermal insulation of the 2nd floor depends on many factors. In particular, this is influenced by the design features of a log house, for example, there may be a heated attic or an unheated attic above the top floor. Thermal insulation in these two cases will be carried out differently. And there can be many such nuances. Therefore, in this article we will analyze the main issues that arise when insulating this part of the house, and we will describe in detail the process itself.

Design features of the room

This indicator plays a decisive role in determining the work plan for thermal insulation of the second floor in a private house. Structurally, the room can be:

- A full second floor, above which there is an unheated attic or living room.

- The attic, which is located directly under the roof.

In each case, the principle of insulation will be different. The main difference between an attic and a full floor is the proximity of the roof, so the main task of insulation is to preserve heat in the room.

It should be emphasized that thermal insulation of the second floor must be done not only inside, but also outside the house. When insulating a full floor, you don’t have to install a vapor barrier layer; for the attic, vapor barrier is mandatory. Expanded polystyrene, mineral wool or expanded clay are most often used as insulation.

When insulating walls from the inside, it is important

Adhere to the following rules, which will reduce the disadvantages described above to almost zero:

- thorough preparation of the walls - filling the cracks with tow, treating surfaces with antiseptics;

- fastening horizontal slats to install a ventilation system that provides air access to the heat insulator;

- installation of a vapor barrier membrane;

- installation of vertical posts for subsequent fastening of mineral wool slabs;

- insulation is laid between racks made of timber or aluminum profile;

- Further on the technology is fastening the second layer of vapor barrier;

- final finishing with clapboard, plasterboard, chipboard or other building material of the choice of the home owner.

When using external wall insulation, the sequence of work is similar to that described above, the only exception is that the ventilation sheathing is not installed. These 2 methods of thermal insulation are performed “dry”, but in practice the “wet facade” method of insulation is often used.

Insulation of the facade of a house using the wet method is carried out as follows:

- preparing walls with antiseptic treatment;

- gluing mineral slabs to a special compound, additional fastening of the material with umbrella dowels;

- gluing reinforced mesh to the insulation, leveling the mixture using a wide spatula;

- applying a thin layer of glue, final leveling it on the walls;

- plastering the walls, if required - painting the facade.

Thermal insulation of the loggia and windows on the second floor

The “weak” point of any room and attic are glass surfaces, window and door openings. The lion's heat flows out of the rooms through them. Even if plastic double-glazed windows were initially installed in the window and doorway of the loggia, it is necessary to additionally insulate the slopes.

Any material can be chosen for insulating window and door slopes on the 2nd floor of a wooden building, but experts recommend using polystyrene foam, polystyrene foam or any other cellular product.

Thermal insulation of the loggia is carried out by analogy with the work aimed at insulating the pediment.

Self-insulation from the inside of the roof with foam plastic

The medium-density material PSB-S-25 (15-25 kg/m3) is best suited for insulation. The thickness of foam plastic for Russia is 200 mm, that is, two layers of 100 mm sheets are needed, laid with offset seams. This insulation installation scheme does not create “cold bridges”.

Thermal insulation work is carried out in a certain order.

1. Roof. The attic insulation scheme from the inside is carried out from top to bottom in the following sequence:

a waterproofing film or roofing felt is attached in the spaces between the rafters to the sheathing and on the rafters themselves; care is required not to damage the material when stuffing the slats; Styrofoam. Having sawed off along the markings, it is temporarily secured using nylon threads stretched over small nails driven into the rafters; vapor barrier protects against water vapor and is secured with staples; sheathing

Transverse slats are placed on the rafters in increments of 30-40 cm, fixing the insulation and vapor barrier; at the same time, it is a support for gypsum plasterboard or chipboard.

Thanks to the lathing, an air gap is created between the vapor barrier and the ceiling cladding for ventilation.

2. Floor insulation can be done using the following technology:

- flooring roll or sheet waterproofing on a bitumen or polymer base; the overlap on the walls and the sheets on top of each other is at least 15 cm, the strips are secured with a stapler;

- installation of a wooden frame around the perimeter, filling of logs in increments of 0.6 m;

- staggered arrangement of insulation material with a total thickness of 10-15 cm;

- installation of a vapor barrier layer (Penofol) with the foil side up so that it reflects heat into the room; the material is laid end-to-end with a slight sag and the strips are glued together with metallized tape;

- placement of moisture-resistant plywood or OSB.

3. Insulation of the attic gable.

To prevent condensation from collecting on the wall, slats or metal profiles are installed to create an air gap to remove moisture. In the upper part, the gap is connected to the general ventilation system. Foam plastic is installed between the sheathing elements (the thickness depends on whether there will be external insulation), and Penofol is laid on top. The frame is also the basis of plasterboard or plywood sheathing.

Additional insulation of the attic from the inside

It is optimal if the ceiling in the attic is insulated - then it is sheathed with plasterboard, which is sensitive to moisture. If it is not possible to reduce the height of the attic, then the insulation will have to be placed on top of the existing thermal insulation. But we have to dismantle the roof, sheathing, and create a supporting frame for a new roof. The task is quite difficult for a non-professional.

If the level of thermal insulation is insufficient, they decide to insulate the attic ceiling themselves. This is done if the height of the room allows. A frame of wooden beams is installed along the perimeter of the attic, and intermediate elements are nailed to them. Between them, foam boards are reinforced. The inside of the material is covered with a vapor barrier, then sheathed with plastic, plasterboard or plywood.

The third option for insulation is if there is already a ceiling. Then it is insulated on top of the previously installed thermal insulation, and the pitched surfaces are insulated on the bottom side. It is necessary to protect from the cold the part of the ceiling between the attic walls and the cornice adjacent to the outside of the house. Any vapor barrier is placed on the floor boards, insulation is placed on top, and then wind protection is placed.

Typical mistakes when insulating an attic

Thermal insulation ceases to fulfill its main function for several reasons.

1. Getting wet. This occurs due to the following processes:

- rainwater inflow - due to a small slope of the slope (for a metal roof - at least 10o), improper installation of roof windows, violations during the installation of roof aeroelements;

- steam penetration from inside. This is excluded if a vapor barrier is laid on the side of the room and its joints are taped with special tape; a vapor barrier is not needed only for polyurethane foam and Penoplex;

- the absence of a ventilation gap between the waterproofing and insulation - then condensation becomes the cause of getting wet.

2. Lack of wind protection. To prevent heat from blowing out on windy days, the roof is covered on the underside with a windproof membrane or fiberboard.

3. Insufficient insulation thickness. To determine it, a thermal engineering calculation is performed or guided by experimental data. For thin rafters, additional sheathing is installed to lay insulation material of the required size.

Features of cold roofs

The design of the roof depends on the nature of the use of the house and the space under the roof. It is these factors that determine the choice of shape, roofing material, rafter frame design and the presence or absence of a thermal insulation layer . In private housing construction, 2 types of roofs are used:

- Warm roof . This type of roofing design provides for complete insulation of the slopes. A warm roof is installed if the room located under the slopes is used as a living space. It is considered an excellent option for equipping a residential attic. It makes sense to build roofs of this type for houses that are used and heated all year round, as they eliminate heat loss through the slopes. The cost of materials and installation work for the construction of a warm roof is much higher than the cost of constructing a cold one.

Important! If the attic space is not heated, then the air in it serves as a kind of buffer zone, which serves as thermal insulation and reduces heat loss. The air rising from the heated rooms of the first floor, according to the law of convection, gradually cools and does not heat the surface of the slopes from the inside, due to which ice does not form on them.

To retain heat, as well as reduce fuel consumption to maintain an optimal temperature, the ceiling located under a cold roof is insulated using loose or fibrous thermal insulation materials. Since heated air always rises, this operation is an effective measure to reduce heat loss.

Interior work

Diagram of the structure of layered rafters. Click on photo to enlarge.

At the moment there are 3 most well-known methods.

The first is that thermal insulation is laid between the rafters. The material must fit fairly tightly to the chimney, windows and walls, and there must also be a 2-centimeter gap between the layers of hydro- and thermal insulation. It is also necessary to take into account the expansion of the material, which can reach 10-30 cm, like mineral wool, for which an appropriate gap must be left. If the width of the joists does not allow this, overlays are placed on them. The main thing is to prevent the insulation mats from sagging.

The second is complex work. They involve the use of materials that, in addition to the main property, have waterproofing properties. This necessitates a more careful installation of thermal insulation, as the question arises regarding air circulation. This approach will also “eat up” part of the room on the 2nd floor, because the heat insulator with other materials is mounted using seam connections either above or below the rafters.

The third is installing insulation above the rafters. It allows you to maintain the volume of the room and ensure reliable waterproofing.

Working with mineral wool

Insulation of the 2nd floor of any wooden house is possible using mineral wool.

First you need to purchase mineral wool, bring it to the work site and open the packaging – no comments. The material will take in air and noticeably increase in volume. Before work, you must put on protective clothing, and the room itself should be well ventilated.

Next, you need to check the location of the rafters of the 2nd floor with a long aluminum profile. You need to attach it to the outer ones and make sure that all the rafters touch the profile.

After this, the vapor barrier film is stretched with its obligatory alignment and fixation using a stapler. The overlap during installation should be 10 cm, and the joints must be taped with special adhesive tape (but not ordinary tape!).

To frame the window openings of the house, sheathing is installed in increments of 40-60 cm. The vertical bars are fixed with self-tapping screws, while a base beam is placed underneath them, where the joint between the drywall and the film will be. The entire frame is filled with a heat insulator.

The frame for filling plasterboard is created on the end side of the house in increments of 50 cm. The first slab of material is clamped with profiles. A vapor barrier film is glued on top of the thermal insulation. All joints and perimeter are taped with the same adhesive tape. Drywall is fixed with self-tapping screws. This is where the insulation ends.

Upon completion of this work, you can begin finishing the house and installing heating equipment.

Insulation from the attic

Insulating the floor from the cold attic side of a two-story house requires less labor than from a living room. All types of heat insulators are suitable for use:

- bulk;

- cotton mats;

- foam slabs;

- folk

Industrial ones benefit from ease and speed of installation. If soft raw materials were used, then ladders are made from boards in the attic for maintenance and inspection. Bulk and crushable materials are loosened as they compact.

Use of mineral wool

When working with mineral wool, use a respirator, gloves and goggles, and wear closed overalls.

Insulation from the attic side requires less labor.

The cotton wool is cut so that each cut is at least 2-3 cm wider than the cell size. The sections between the joists are covered with a vapor barrier, with an overlap made around the perimeter of the walls, as well as on the beams. A piece of cotton wool is slightly compressed and inserted into place. She will straighten up and hide all the bridges of cold.

Thermal insulation with polystyrene foam boards

To adjust to the required size, polystyrene foam boards are cut. Incorrectly cut parts can cause gaps and heat loss.

When using polystyrene foam, be sure to first create a layer of vapor barrier, since it absorbs water. The slabs are laid in 2 layers. If there are chamfers, then they are not treated with anything. Seams and joints on polystyrene foam are sealed with sealant or polyurethane foam.

On the slabs, paths are made of gypsum fiber sheets or a partial screed up to 4 cm thick with a reinforcing mesh. For the second option, before pouring the solution, lay waterproofing in order to protect the insulation.

Arrangement with expanded clay gravel

Expanded clay is the most popular backfill material, which is used both for insulation and to lighten mixtures and insulating compounds.

Expanded clay is a backfill material that is used for insulation.

Before backfilling, cover the floors with a vapor-proof film. In this case, the edges of the material extend onto the walls 10-15 cm above the expanded clay layer. It is periodically stirred with a rake to dry it. Moves for maintenance are made at will.

Bulk folk materials

Supporters of environmentally friendly materials use natural insulation materials. Before the development of the chemical industry, such raw materials easily coped with their task. Main advantages:

- There are no harmful components released. When replaced, they are disposed of or burned.

- It is extremely rare to provoke an allergic reaction in residents.

- Economically profitable and practical.

- Combination with natural building materials.

- Light weight.

There are also a number of disadvantages:

- Easy to flammable. Requires the use of fire retardants.

- Over time they cake, which leads to a reduction in thermal insulation properties.

- Attractive to rodents.

- If you don’t treat them with antiseptics and don’t stir them periodically, they will quickly rot.

Straw is a folk material.

Most of the natural raw materials are of the bulk type. They are laid over the ceiling and turned over as needed to dry. Folk materials include:

- Straw. The bundles are soaked in a 10% solution of copper sulfate and left until completely dry. Lay in a layer of at least 25 cm.

- Moss. It has antiseptic properties, perfectly absorbs moisture, and is durable. For insulation, a 10 cm layer is enough.

- Hay, dry leaves, pine needles. The raw materials are the most affordable; thermal insulation requires a thickness of 20 cm. The disadvantage is rapid saturation with moisture.

- Seaweed. Rarely used, mainly by residents of coastal areas. Laying layer up to 20 cm.

- Reed. Dry stems are tied with wire into mats 10-15 cm thick and filled with them in the spaces between the logs.

Materials with high environmental characteristics also include felt, coconut fiber, jute, flax, and clay.

Insulation of the second floor in a timber house

The work consists of three stages:

- Thermal insulation of interfloor ceilings.

- Thermal protection of walls.

- Insulating the attic of a house.

We insulate the ceiling between floors

It is more convenient to carry out the work from the upper floor; the material will be laid on boards, which are the ceiling of the first floor.

- In order for the insulation to be high-quality and effective, it is necessary to dismantle the floor of the second floor.

- The next stage is laying a vapor barrier layer. We wrote above that you don’t have to do a vapor barrier on the second floor, but to prevent the accumulation of condensation in the insulation and prolong its service, it is best to lay a vapor barrier film on the boards and beams.

- Next, the space between the beams is filled with thermal insulation, the material is laid very tightly so that there are no cracks or gaps between the slabs and the ceiling. If expanded clay is used, then all cavities are filled with granules, and then they are well leveled.

- Then the insulation is covered with a waterproof film, on which a wooden floor is laid.

If thermal insulation cannot be done from the second floor, then work is carried out from below in the following sequence:

- The ceiling of the first floor is being dismantled.

- Waterproofing is stapled to the ceilings.

- Insulation mats are laid between the beams and secured with wooden slats.

- The structure is covered with a vapor barrier film, which is secured with a stapler.

- The ceiling covering is mounted, it can be plasterboard, chipboard, plywood sheets, etc.

Thermal protection of walls

Usually the walls are insulated from the outside. Internal insulation is done in cases where, for some reason, work cannot be done outside.

It is necessary to note the disadvantages of insulation from inside the house:

- the usable area of the room decreases;

- the facade remains cold, which causes some cooling of the house;

- Condensation may appear between the wall and the insulation and, as a result, mold may form.

By strictly following the work technology, negative consequences can be minimized.

- First, the cracks are caulked with natural materials, and then the wood is treated with antiseptic impregnations.

- Horizontal slats with a thickness of 20 mm are mounted.

- A waterproofing film is laid. It needs to be tensioned on the slats.

- Vertical counter-lattice posts are installed. The distance between the slats should be slightly less than the width of the insulation boards.

- Thermal insulation is placed in the space between the vertical slats.

- A vapor barrier layer is laid on top of the insulating material.

- Installation of decorative finishing.

Insulation of the attic floor of a log house

Thermal insulation is carried out in the following sequence:

- Before insulating the attic, you need to make a vapor barrier for the floor in the attic, which will become an additional barrier to heat escaping from the house and prevent condensation from getting on the insulation. To do this, the surface is covered with a vapor barrier membrane. The film should completely cover the entire floor area. The canvases are placed on top of each other with a small margin and glued together with tape. After this, they are secured to the floor boards with a construction stapler.

- The insulation is installed, the method is selected depending on the selected material. If slab insulation is used (mineral wool, polystyrene foam or polyurethane foam), it is laid in dense layers between the floor beams. Ecowool is applied by spraying with a high-pressure apparatus; all cavities must be well filled. Expanded clay is poured in a thick layer onto the floor and leveled.

- Floor beams can become cold bridges into the house, so they also need to be insulated. To do this, thin insulating material is laid on them.

- The thermal insulation is again covered with a vapor barrier film on top, which, like the first time, is laid overlapping. The membrane is secured to the beams with counter-battens.

- The final stage is laying the covering from boards or plywood.

Types of insulation

Insulation is designed to prevent the heat emanating from the building from mixing with external cold, and also protects against overheating in hot weather. Depending on the raw materials used for production, they are organic, inorganic and mixed. Based on their operating principle, they are divided into:

- Reflective - redirect warm air back into the room. To do this, they are equipped with a foil or metallized element.

- Preventative - contain most of the thermal energy within the protected surface.

Styrofoam

Polystyrene foam has a number of disadvantages, due to which it is not always recommended for use in residential premises, bathhouses or cottages. Minuses:

- flammability;

- when heated above 30°C, it releases toxic substances;

- frequent habitat for rodents;

- contributes to the formation of the “greenhouse effect”.

Foam plastic refers to foamed cellular materials.

Mount the foam on the frame or put it on glue.

Fiberboard

Fiberboards are resistant to temperature changes, have high sound insulation, and are excellent for insulating roofs and floors. They weigh little, can be easily processed with hand tools, are convenient and quick to install, and are not damaged by insects.

They have 2 sides - a smooth front side for finishing, a rough back side for better adhesion when gluing.

Glass wool

One of the cheapest insulation materials with high fire resistance. The material is elastic and easy to install. Due to its softness, it is susceptible to deformation; for a dense texture, several layers are made. When working, glass chips fall off, which forces the use of personal protective equipment.

Glass wool is one of the cheapest insulation materials.

Minvata

The best option for insulating wooden structures. Mineral wool (stone wool) is environmentally friendly, does not deform, is resistant to weather conditions, vapor transmission is at an acceptable level.

Expanded clay

Safe raw materials that are not subject to rotting. It is an oval or round granule with a diameter of 5 to 40 mm. Pros:

- easy to use;

- does not burn;

- resistant to chemicals;

- unsuitable for rodents and insects;

- high thermal resistance;

- durable.

Expanded clay is a lightweight porous building material.

Expanded clay has a relatively large weight, which will depend on the thickness of the embankment. It is used for strong ceilings with support beams.

Polyurethane

Polyurethane is used on attic floors and in the basement. Using special equipment, it is applied to the surface and it turns into foam. Penetrating into all irregularities and crevices, it creates seamless protection against water, wind and heat loss. Easily adheres to various materials, elastic and durable, high fire resistance.

Sawdust

Used to fill the space between floor beams. To avoid rotting, they are treated with antiseptic compounds and mixed with lime.

Sawdust fills the space between the beams.

Expanded polystyrene foam

Sheets of different thicknesses are resistant to mechanical stress and weather factors, and are leaders in the thermal materials market. Advantages:

- easy;

- frost-resistant;

- sound insulation is above average;

- low thermal conductivity and flammability;

- non-toxic;

- low moisture absorption.

Expanded polystyrene is susceptible to destruction by rodents and reacts with various types of solvents.

Liquid penoizol

Modified foam plastic in the form of foam insulation with a high degree of adhesion to other materials. Penetrates into voids of horizontal and vertical surfaces. It has a low density, forms a monolithic layer, and allows water vapor to pass through.

Liquid penoizol is a thermal insulation material.

Ecowool

80% consists of cellulose, the remaining 20% includes fire retardants and other additives. It is a liquid mixture that is supplied from a hose under pressure or applied by hand. Sometimes they just pour it in, but it produces a lot of dust. Due to high hygroscopicity, during installation it is necessary to create a ventilated gap so that moisture escapes into the atmosphere.

Penofol

Reflective insulation with a foil top layer and a PVC foam base. Advantages:

- environmentally friendly;

- thickness is less than that of other heat-saving materials;

- does not absorb or allow moisture to pass through;

- flame retardant;

- Easy to install with any fasteners.

Penofol has a foil layer.

Penofol is not used outside the building, otherwise the accumulation of condensation will lead to dampness and fungus on the wall.

What to choose - second floor or attic

Many people, wanting to build a house with more than one floor, are tormented by the question of what to actually build - a full second floor or an attic. In the case of the second option, construction is faster and easier and costs much less. But the attic, behind the walls of which, as a rule, the roof is immediately located, needs additional insulation. Moreover, if in the case of the walls of a full second floor, vapor barrier may not be carried out at all, then when creating an attic, this insulation itself is simply necessary.

Correct floor design

Interfloor wooden floors are arranged on beams. They are usually used as timber. The size of the section depends on the size of the span that needs to be covered, as well as on the size of the expected load on the floor and the types of wood used. Most often, timber with a section width of 100 mm and a section height of 150-200 mm is used.

Next, the ceiling itself is formed by installing the floor boards of the upper floor and hemming the ceiling materials of the lower floor. You can often see that floor boards are laid directly on beams, but it is more correct to first install logs on the beams, and then make flooring from the boards over them. The second option is the most preferable, as it will allow for proper interfloor insulation along wooden beams.

The fact is that in the pie, which the filling of the interfloor ceiling is so similar to, there must be layers of vapor barrier.

They are made of a special membrane with a certain coefficient of vapor permeability, and the top layer of the membrane allows steam to pass in only one direction - from the insulation into the air. Therefore, an air gap is needed between the membrane and the plank floorboard, which will remove steam from under the boards. Otherwise, the latter will simply begin to rot.

In this case, the membrane is laid on the interfloor floor beams, and the air gap is formed due to the thickness of the logs laid perpendicular to the beams.

Steam is removed from under the boards through specially cut holes in the floor or slotted skirting boards used to edge the perimeter of the room.

Note! The bottom layer of the membrane must be made of a material with a very low vapor permeability coefficient.

This is necessary so that moisture from the lower rooms does not seep upward through the interfloor ceilings, and also does not linger in the layers of insulation. All air from the floor should be vented into the atmosphere only through ventilation ducts or windows for ventilation.

How to choose a filler

The best insulation for floors is considered to be mineral wool, polyester, steel shavings, etc. They are easy to install, use, environmentally friendly and fireproof. However, they have increased requirements for vapor barrier and waterproofing.

You can also use materials such as:

- Polystyrene is lightweight, resistant to adverse influences and has a long service life. It can be regular (less durable, fireproof) and extruded - it has low thermal conductivity and moisture absorption.

Installing this type of insulation is simple: the sheets are placed end to end, and an edge strip is installed along the entire perimeter of the floor.

- Expanded clay and slag - has low thermal conductivity and is light in weight.

- Penofol is an insulating foil that is rarely used as an independent insulation material.

- Edge tape - This is used to edge the entire perimeter of the house before the insulation is installed.

How is insulation done?

In order to ultimately get a warm frame house, its walls must be insulated from the inside and outside. The work process is almost the same, with a few exceptions.

Insulation from outside

To insulate walls from the outside, it is best to choose the cross method.

The insulation is always laid with the seams staggered to avoid the appearance of blown cracks.

- The frame of the building is covered with OSB boards, which should have gaps of 2-3 mm. Subsequently, they need to be foamed.

This is what OSB boards look like

- Next, waterproofing is stretched, which protects both the walls of the house and the insulation from moisture and other adverse environmental influences. Usually the waterproofing has self-adhesive strips, if there are none, the knocks between them should be sealed with tape.

Connecting insulation joints

- Each layer of insulation should be laid in such a way as to overlap the previous one by 15-20 cm.

- The thickness of the insulation is approximately 15 cm.

- After laying the insulation, all voids are filled with polyurethane foam.

Insulation of walls inside the house

After the frame house is fully insulated for winter living, you can begin interior decoration. For this:

- The first layer of thermal insulation is laid, the thickness of which is 5 cm.

- Then the insulation is laid in the frame house, the thickness of which is 10 cm. The entire frame between the posts is filled with it.

- Then a vapor barrier is attached, which prevents steam from entering the insulation. They are laid with the rough side outward and the smooth side facing the thermal insulation.

- The bars are installed on top of it.

Important! The insulation cannot be pushed in by force or compacted, since the heat in the room depends on the voids inside it.

Insulation is also installed in the partitions between rooms. For the most part, it is required for sound insulation. To do this, slabs are installed with a layer of 10 mm. There is no need for vapor barrier here, since the temperature in the separated rooms will be the same.

Features of work related to insulation of the second floor ceiling

When the second floor is under the attic, the floors are insulated on both sides. The attic in most cases does not contain a heating system. The film is laid on the living room side.

This is done in order to eliminate the possibility of warm steam from entering the unheated attic. In this case, it is also possible to insulate the second floor using mineral wool.

Of course, in this case you will have to fork out a lot, but you won’t have to use additional insulation.

Where does the heat go?

A warm house is a house that retains heat inside. Heating the street means not respecting your Galaxy. In recent years, people have been trying to make any buildings energy efficient so as not to pay extra money to suppliers of gas, electricity or other fuel, and the effectiveness of these insulation measures is visible to the naked eye.

qazwer1973FORUMHOUSE Member

I have a log house 150x150, everything is caulked, but without insulation - the house cools down in winter in 4 hours. A 150x150 timber extension with an insulated ceiling and floor takes much longer to cool down. Now I’ve insulated the walls of the extension with 50mm mineral wool, I’ll see how it goes in winter.

How does heat escape into uninsulated house structures?

But these numbers in the diagram are conditional; it all depends on the material of the structures and compliance with construction standards.

Cat-EdgeFORUMHOUSE user

This is very conditional and individual. Heat loss through the walls can be 5%, or even 80%.

Dimastik25FORUMHOUSE user

What's the point of insulating the walls if you plan to install windows with a 50-gauge profile and a single-chamber double-glazed window?

There is a simple and old-fashioned method that allows you to detect heat leaks in wooden walls without a thermal imager. You need to wet your hand with water and move it along the walls, at a distance of 15-20 centimeters from them. You can’t help but feel a stream of cold air from a wall or window; you need to mark with chalk the place where it comes from.

Insulation of attic gables

Sequence of work:

- beams are installed along the walls of the pediment;

- between the beams a distance must be maintained equal to the thickness of the sheet of heat-insulating material +/- 0.5-1 cm;

- vapor barrier material is laid;

- mineral wool slabs are installed;

- a layer of vapor barrier is laid;

- cladding is done with finishing material.

We wrote in detail about attic insulation here