The basement is the coldest part of any private home, regardless of what material it is built from. Therefore, thermal insulation of the bottom of the house is a mandatory measure, which is carried out either at the construction stage or immediately after construction. For wooden houses, insulation of the subfloor is a vital necessity. The tree instantly absorbs moisture from the soil and atmosphere. To prevent rotting processes from developing in the wood, it is necessary to equip a high-quality insulation system, which, in addition to thermal protection, includes waterproofing, protection against vapor penetration and ventilation. In the article we publish instructions on how to insulate the underground in a wooden house; you will also learn the various nuances of this work.

We insulate the ceiling of the cellar

Before starting insulation work, we check the entire surface of the ceiling in the basement for cracks, potholes, etc. We carefully clean all these defects and seal them with a solution or carefully blow them out with foam. After this, we treat the entire surface of the ceiling with antifungal solutions (quicklime or copper sulfate).

There are a lot of options for insulating a basement ceiling in a garage - from polystyrene foam to reflective insulation.

The ceiling can be insulated with any of the materials described above; for insulation with mineral wool or glass wool, a special frame will be required, which is then sheathed with HA sheets, plastic, plywood, etc. Installation of polystyrene foam or expanded polystyrene can be carried out on parachutes with the preliminary application of a special solution, then the mesh is applied and plastered surface and painted, you can also use facing material (decorative tiles, panels, etc.). Decorative cladding material can also be used for reflective thermal insulation.

Microclimate of the underground room

Room thermometer

In order for the operation of a constructed building (residential building, barn, barn, etc.) to be successful for a long time, it is necessary to ensure a certain microclimate inside the basement (subfloor) located under such a building.

The microclimate inside any room depends on the combination of a number of parameters of the air environment in this room, such as temperature and humidity, as well as the frequency of air exchange carried out by the ventilation system.

Temperature

The subfloor in a wooden house can be cold or warm, which is determined by the nature of the use of the house.

If this is a country house that is used periodically, then the subfloor is made small and cold, without laying utility networks and installing equipment in it. Insulation in this case is done only on the floor covering, so that cold air from the underground does not enter the premises of the first floor.

In houses of permanent residence, the underground floor is made warm, for which the foundation, basement, underground floor and floor of the first floor are insulated.

Humidity and air exchange

Humidity in the underground and air exchange are two interrelated parameters.

In the cold version, there is no connection between the air inside residential premises and the underground air. Ventilation of the underground space is carried out through ventilation holes provided in the foundation (basement) of the building.

When the underground is warm, air circulates between the premises of the residential building and the basement. Ventilation is carried out through openings provided in the floor of the first floor.

To reduce heat losses, the foundation and other underground elements are insulated.

How to insulate the basement of a house with your own hands

Thermal insulation of a basement can be done in different ways. But the most successful option is when the thermal insulation materials are located outside. Thanks to the external placement of the insulation, the basement walls can be protected from freezing. There is no danger of condensation and mold development. At the same time, we must not forget that the basement walls must also be protected from moisture. It is better to use a material that is not afraid of contact with water. Well-known mineral wool and polystyrene foam can deteriorate if they get wet during use.

The most successful is considered to be such insulation, which is carried out during the construction of the building itself. At the initial stage of construction, it is possible to install waterproofing and arrange drainage without any particular difficulties. Be that as it may, it is necessary to decide on the materials used in advance. When choosing insulation, you need to take into account the practical characteristics it has, as well as the complexity of installation. Great importance is attached to the moisture resistance of the insulation and its flammability.

Preparatory work

In order to lay thermal insulation materials especially efficiently, it is necessary to first level the walls. They must also be properly waterproofed and, if necessary, coated with antiseptic substances. After insulation is carried out, the air humidity in the basement may increase. Therefore, it is also necessary to think about ventilation. Otherwise, mold cannot be avoided on the walls and ceilings.

The simplest method of arranging ventilation is considered to be one in which holes are prepared on opposite walls of the basement. It should be taken into account that as the air temperature decreases, these openings must be closed. To prevent atmospheric moisture and melt water from damaging the foundation of the house, a blind area needs to be built around the building. Thanks to it, rain moisture will be effectively removed.

Insulating the basement ceiling from the inside

In general, thermal insulation measures for the basement involve three related processes. So, the walls, floor and ceiling must be insulated. It's better to start with the last one. When insulating the ceiling in the basement, it is possible to reduce the heat loss of the room located above it.

First, the joints and all the cracks that are present in the floor are removed. Next, insulation is laid on the ceiling. As a result of such work, the floor in the house will be much warmer

But it is important that the thermal insulation material used can repel water. If such quality is not observed, the insulation should be covered with a vapor barrier

After this, finishing is carried out. For its implementation, PVC panels, plaster and other materials can be used.

Insulating the basement floor from the inside

Thermal insulation of the floor is also necessary. The fact is that moisture constantly gets into the basement from the ground, but heat, on the contrary, leaves. The most comfortable conditions in the basement will be if you install a “warm floor”

But before installing such communications, it is important to waterproof and level the base. To increase thermal insulation, penoplex is laid, which is filled with a concrete base

Roofing felt can be used as a waterproofing material. It is laid along the walls and partially extends onto them. Thanks to reliable waterproofing, you can protect yourself from high humidity. It is especially good to notice the advantages of the waterproofing layer in those periods when groundwater rises high.

Insulation of basement walls from the inside

The cheapest way to insulate basement walls is to use polystyrene foam. Its density should be about 25 g/m2. The first layer on the walls is waterproofing. The insulation can be secured using dowels in the form of mushrooms. The layer of thermal insulation coating can be sheathed with plastic panels, clapboard or covered with plaster.

The foam sheets are fastened with dowels. Each sheet requires 4-5 fasteners. When the foam is laid, all the remaining joints between the sheets are filled with polyurethane foam or mortar. Then cold bridges will not appear.

Thermal insulation of basement walls can also be done using mineral wool. But the owner must immediately take into account that such insulation cannot be left without waterproofing and protection from physical influences. To insulate walls with mineral wool, you must first lay vertical guides. They are placed in such a way that the mineral wool slabs fit tightly and are held by a similar frame.

Preliminary work before construction

The site is studied during engineering and geotechnical surveys. for which specialists from design organizations are involved. In order to save money, you can do it yourself and conduct research on the soils and hydrogeological conditions of the area yourself. A good result is obtained by interviewing neighbors and inspecting their cellars or basements.

When studying site conditions, you should pay attention to the following points:

- soil composition, depth of soil layers, tendency to accumulate moisture and heaving;

- groundwater level and the height of its rise during snow melting or intense precipitation;

- average depth of soil freezing.

This data will be necessary in the process of choosing the most optimal type of cellar for the given conditions and the method of its construction. Specialists use the obtained data in the process of design, calculation and estimate work. The best option for the homeowner is, without a doubt, a cellar under the house with an entrance from the interior. It is better to lay such a structure at the construction stage. The option of constructing a buried structure during the reconstruction process is also possible, but it is quite troublesome and time-consuming.

Is it necessary to insulate the basement under the house?

Very often, home owners consider the basement only as a room where they can store vegetables. But the basement can also play other roles. For example, it is well suited for placing a gym, a wine cellar, or a regular recreation room. True, if you want to arrange something like this, you cannot do without insulation.

The big advantage of the basement is that the air temperature in it is stable almost all year round. But this does not mean that the conditions are simply ideal. In fact, without high-quality thermal insulation it will not be possible to successfully use this part of a country house. But insulation can reduce heat loss by about 20%. If you also insulate the basement, the basement walls will not be exposed to moisture.

Without insulating the basement, you may encounter a problem such as condensation on the first floor ceiling. The floor in the house will remain cold, which will cause serious inconvenience to the owners. To insulate the basement floor, polystyrene foam, polystyrene foam, mineral wool and other materials can be used

It is only important to fully evaluate the capabilities of the insulation so that the results of its use are of the highest quality.

Technology and features of floor insulation from below in a wooden house

For each type of insulation, there are some specific features of use.

Mineral wool

The sizes of rolls and slabs are usually multiples of 60 cm, which makes this distance the optimal step between the logs. Mineral wool is cut to size with a cutter and placed in the space between the joists. For a tight fit, the size should be 1–2 cm larger than the distance between the joists. Cotton wool should not be pressed down forcefully as this may affect its characteristics.

The best option would be to lay two layers of insulation. The second layer is laid so that the joint of the lower layer falls on the center of the upper piece. This method of installation will prevent cold air from entering the room.

How to insulate a cellar foundation

Thermal insulation of the basement base. Click to enlarge.

Before you start insulating the cellar in the garage, you should work on the foundation. Concrete walls are in constant contact with the ground. Concrete only seems monolithic.

Small channels and cracks run through the thickness of the concrete base. Moisture can easily saturate a concrete slab.

In addition, concrete has high thermal conductivity. In winter it cools down and the cold penetrates into the basement through the concrete structures. Therefore, it is necessary to build a structure that will limit the concrete foundation from moisture.

The foundation walls are insulated from the outside. First you need to remove the soil at the base of the wall. Then the wall is plastered. A layer of plaster will protect the concrete structure from frozen ground.

It is also better to lay concrete slabs with sheets of roofing material. This material does not allow moisture to pass through and will protect the concrete base from getting wet. Now you can fill the structure with soil.

How to insulate a cellar floor

When drawing up a work plan for insulating a garage cellar, do not forget about the floors. To insulate them, you can build an effective structure:

- first we deepen the floor a little, remove about 30 centimeters of soil, level the space;

- pour a layer of crushed stone up to ten centimeters onto the floor;

- the next layer is a sand cushion up to five centimeters;

- carefully compact the insulating cake;

- pour a layer of hot bitumen on top of the structure;

- Now you can make a concrete screed.

How to insulate cellar walls

It is clear that the walls of the cellar will have to be insulated from the inside. We will need wooden blocks, insulation boards and polyurethane foam. Sequence of work:

- We screw the wooden logs to the walls using a drill;

- We insert insulation boards between the bars;

- polystyrene foam can simply be glued to the wall or screwed with plastic dowels;

- carefully seal all voids and cracks with tape, you can blow them out with construction foam;

- Before plastering, a mounting mesh is glued onto the insulating structure.

Which material to choose

Thermal conductivity coefficient of various insulation materials

The basement level is constantly exposed to lateral and vertical pressure, dampness, acids, insects and rodents. These factors must be taken into account when choosing insulation. There is a wide range of materials on sale, differing in price, performance characteristics and installation features. When making a choice, you should evaluate each product property.

Expanded clay

Expanded clay is balls or sharp porous granules obtained by vulcanization of natural clay. The material is more often used when constructing roofs in residential buildings and outbuildings.

Floor insulation scheme with expanded clay

The product has the following advantages:

- affordable price;

- low density;

- ease of use;

- environmental Safety;

- low thermal conductivity.

Styrofoam

Foam plastic is easy to process and is highly waterproof.

Foam plastic is a time-tested material that is used in private and industrial construction, in preparing country houses and garages for winter.

Expanded polystyrene has the following advantages:

- excellent insulating properties;

- waterproof;

- low specific gravity;

- ease of processing and installation;

- small price.

Disadvantages include fragility and toxicity when burning.

Penoplex

Thanks to the spongy structure, penoplex is easy to cut

The decision to insulate the basement from the inside with penoplex will create high-quality and reliable protection of the room from dampness, temperature changes, insects and rodents.

Polymer material has the following advantages:

- dense structure, eliminating crumbling and breaking during installation;

- low thermal conductivity;

- almost zero hygroscopicity;

- long service life;

- environmental cleanliness;

- repellent effect on living beings;

- wide temperature range;

- resistance to alkalis and acids.

Minvata

Mineral wool is a good heat insulator.

The industry produces mineral wool from broken glass, steel slag and natural stone. The finished products are fibers randomly bonded in space. Mineral wool is produced in the form of mats and rolls, the thickness of which is 100-400 mm.

Advantages of the material:

- ease;

- low thermal conductivity;

- elasticity;

- flexibility;

- durability.

The disadvantage is its hygroscopicity and the release of many volatile particles harmful to health during installation.

Foam insulation

Insulation of the basement in a private house is often carried out with ordinary polystyrene foam. A more modern alternative is polystyrene foam. It has all the characteristics of foam, but is more durable. This material is often used in outdoor work. It is also used to insulate non-residential premises from the inside.

The popularity of foam thermal protection is due to the following advantages of the material:

- excellent thermal insulation properties;

- relatively light weight, due to which there is no additional load on the foundation and walls;

- affordable price;

- resistance to mold and rot;

- low hygroscopicity.

But this insulation also has certain disadvantages:

- when heated, it may emit an unpleasant odor, so it should not be used for interior decoration of residential premises;

- upon contact with fire, combustion occurs quite quickly;

- insufficient environmental friendliness.

To insulate a cellar with polystyrene foam, experts recommend using PSB-25 sheets 5 centimeters thick. Their installation does not involve the construction of sheathing, but is done by gluing insulation to brick or concrete walls using frost-resistant glue. Dowels with a wide head can be used to additionally secure the sheets at the joints.

To prevent the appearance of condensation when insulating the basement from the inside, a vapor barrier film is attached on top of the insulation. Its joints should be taped with reinforced masking tape.

Choosing insulation

We decided to insulate the cellar, but we don’t know how to do it, and most importantly, what material to use.

Let's look at how to insulate a cellar in a garage using modern materials that experts use to insulate basements:

- polystyrene foam or extruded polystyrene foam;

- mineral wool;

- “warm” plaster;

- glass wool;

- reflective thermal insulation.

Insulating a cellar in a garage with the materials described above allows you to achieve good thermal insulation properties and prevent the appearance of fungus in the room, but each material has its own advantages and disadvantages.

Extruded polystyrene foam or polystyrene foam

Advantages:

- simple installation;

- environmental friendliness;

- you can use extruded polystyrene foam for floor insulation;

- service life up to 40 years or more;

- excellent water resistance;

- low cost;

- perfectly tolerates sudden temperature changes.

Flaws:

- is flammable;

- does not allow air to pass through.

Helpful information! Extruded polystyrene foam differs from polystyrene foam in its increased density and strength. Thus, the thermal conductivity coefficient of extruded polystyrene foam will be higher than that of polystyrene foam with the same thickness of the material. In addition, only extruded polystyrene foam is used to insulate the floor covering.

Important! When using polystyrene foam or extruded polystyrene foam as thermal insulation, it will be necessary to treat all surfaces with a primer before starting work and, upon completion, additionally plaster the walls using reinforced plaster, and make a screed of cement and sand on the floor

Mineral wool

Advantages:

- allows air to pass through, allowing the room to “breathe”;

- excellent sound insulation;

- excellent thermal insulation;

- affordable price;

- long service life of 30 years or more.

Flaws:

- allows moisture to pass through;

- work is performed in special clothing and gloves.

Important! If mineral wool is chosen as insulation, then it will be necessary to additionally make a vapor barrier in the basement to prevent moisture absorption by the wool itself and deterioration of its thermal insulation properties

"Warm" plaster

Advantages:

- excellent thermal insulation;

- affordable price;

- excellent sound insulation.

Flaws:

- it is necessary to apply a thick layer for good thermal insulation;

- difficulty in installation.

Glass wool

Advantages:

- low cost;

- good thermal insulation properties;

- good sound insulation properties.

Flaws:

- work is performed in special clothing and gloves;

- an additional frame for installation is required;

- allows moisture to pass through;

- If exposed to moisture, it may emit an unpleasant odor.

Important! If mineral wool is chosen as insulation, then it will be necessary to additionally make a vapor barrier in the basement to prevent moisture absorption by the wool itself and deterioration of its thermal insulation properties. In addition to the vapor barrier material, it is necessary to use film or foil to insulate glass wool

Reflective Thermal Insulation

Advantages:

- high thermal insulation properties;

- material thickness is only from 2 to 5 mm;

- simple installation;

- possibility to use facing material.

Flaws:

- price;

- possible heat loss

Important! Reflective thermal insulation is quite thin and, like a mirror, will reflect infrared heat when reflected. As a result, it is not efficient enough at convection or induction of reflected heat, which leads to heat loss

Moisture-repellent mastics

Treatment of the rough base will not provide guaranteed protection from moisture if the process steps of applying the selected material or composition were not followed. It is best to entrust the work of laying heat, hydro and vapor barrier layers to professionals. Naturally, you can carry out such work yourself. Then, after high-quality processing, you can apply a moisture-repellent mastic.

The main advantages of such compositions:

- possibility of application even on areas of floors that are not completely dry;

- increased flexibility and strength of the applied layer after drying;

- service life from 10 years;

- Possibility of applying mastic in the form of paint or aerosol.

Also, liquid mastic can be used in combination with a rough base leveled with a screed. The resistance of such compositions to temperature changes makes it possible to protect such floors even at very low temperatures.

How to insulate a ceiling correctly

Knowing how to insulate a cellar with maximum efficiency means understanding the principle of carrying out work, starting from the ceiling. It is its surface that is isolated first. Foamed polyurethane foam, resistant to mold and mildew, is suitable for the ceiling. Insulation with this insulation will prevent heat loss through the ceiling and prevent the penetration of cold from the outside.

The ceiling can be insulated from two sides: from above - from the side of the living space of a private house and from below - in the basement itself. The essence of the work practically does not depend on the choice of insulation method. They begin with preparing the surface, after which they install thermal insulation with an additional layer of hydro- and vapor barrier for insulation materials that exhibit insufficient resistance to moisture. The final stage is rough or decorative finishing.

They work in this sequence, insulating the ceiling both from the side of the living space of a private house and from the basement.

How to drain and drain water

Eliminating water penetration into the basement from the ground is either difficult or impossible. More often it is necessary to install a drainage system around the house or repair the existing one.

In this case, it is necessary to tear off the foundation from the outside. In this case, talking about internal insulation loses all meaning, since the foundation walls become free for external insulation and for additional waterproofing.

There may be other drying options. Sometimes the issue is resolved comprehensively for a group of houses or an entire village, by opening a drainage ditch.

Sometimes the basement can only be drained by installing a well with a pump. Although pumping out a spring under a house is an extremely thankless task, what should you do? This source of water can serve the purpose of water supply to the house, so not all the work of the pump will be “wasted”.

Thus, for a wet basement there is only one method of insulation left - external with preliminary drying of the soil.

Types of basements

There are several types of underground: warm and cold. Cold is used for houses that are not heated during cold weather; for this purpose, the floor is additionally insulated.

In such a subfield, the temperature depends on the temperature outside, and not in the house. The ventilation system in the underground of a private building is carried out through the foundation vents of the house; air is not exchanged with the internal home premises.

Floors with a warm underground are used in houses with regular residence and heat supply. Temperature in the underground

depends on the temperature in the house, because it is connected to the interior with vents for ventilation in the floor.

To reduce heat loss, foundation insulation is done.

Very often, the depth of the warm underground floor is 15-25 cm. With a depth of more than 25 cm, heat loss becomes greater, with less, the ventilation system will deteriorate.

Materials for basement insulation

First, the home owner must decide how to insulate the basement. There are many types of thermal insulation materials with very different characteristics on the construction market.

Let's consider the most popular insulation materials from the point of view of the feasibility of using them for thermal insulation of a basement:

expanded polystyrene. A more modern analogue of polystyrene foam. It has all the properties inherent in polystyrene foam, but is distinguished by a higher density (and therefore stronger), and the presence of a tongue-and-groove system. At the same time, expanded polystyrene is characterized by ease of mechanical processing (the sheet does not crumble when cut), resistance to stress and a higher price. Basement insulation with polystyrene foam is actively practiced because... this material is best suited for insulating the basement from the outside and inside;

polyurethane foam. Sprayed thermal insulation material. The peculiarity of polyurethane foam is its ability to fill the smallest cracks. Polyurethane foam does not allow moisture to pass through, does not rot, does not burn, and ensures complete tightness of the room. Insulating the basement with polyurethane foam allows you to create a durable outer layer of insulation. Disadvantages include high cost and the inability to do the work yourself;

mineral wool. Insulating the basement from the inside allows the use of soft insulation materials and only in the absence of moisture. Mineral wool is hygroscopic and, when wet, loses its thermal insulation properties;

expanded clay Despite the fact that this is a bulk insulation, it has good thermal insulation properties. However, insulating a basement with expanded clay is only justified to insulate the floor in the basement and to protect the foundation from the outside, since expanded clay gravel (crushed stone) provides good drainage.

The insulation, its type and thickness, is selected individually for each specific case. The choice of thermal insulation material can be entrusted to a professional who will calculate the required thickness taking into account many factors. Or you can do the calculation yourself. To do this, you can use the recommendations that contain:

- SNiP II-3-79 “Construction heating engineering”

- reference book on heat and sound insulation designs. Basement walls and foundations;

- SNiP “Thermal protection of buildings”

And:

Thermal requirements for basement insulation

Studying the above documents makes it possible to highlight the main thermal technical requirements:

heat transfer resistance (SNiP). For Moscow – Ro = 4.15 m2•°C/W.

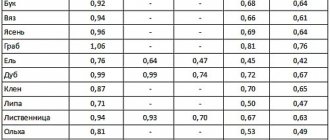

Dependence of the thermal conductivity coefficient of insulation and its thickness for internal basement insulation (table)

Dependence of the thermal conductivity coefficient of insulation and its thickness for external basement insulation (table)

- load perception (SNiP -85);

- heat resistance of the enclosing structure. Calculation of the amplitude of temperature fluctuations is based on the provisions of SNiP;

- vapor permeability of the enclosing structure (SNiP).

- fire safety requirements (SNiP, GOST 30247, GOST 30403).

The selected material leaves a significant impact on the choice of technology and determines what and how to properly insulate the basement in a private house.

This is interesting: Summer kitchen (video)

Why do you need to insulate a cellar?

Insulating the cellar will help prevent food from freezing in winter.

The storage facility is built at a distance from buildings equipped with heating appliances and communications. This means that the internal space is less influenced from the outside and is relatively stable. However, temperature differences in winter and summer reach serious values, which cannot but affect the microclimate of the underground warehouse. Sometimes construction is done under sheds and garages in co-ops. These buildings do not have any impact on the underground premises, but protect them from precipitation.

Basement insulation is carried out for the following reasons:

- In the summer heat, the earth becomes so hot that the heat penetrates deep underground, heating the walls of the cellar and its contents. This causes vegetables to sprout, preserves to explode, and pickles to become moldy.

- In cold, snowless winters, the soil freezes heavily. This also affects the microclimate in the underground storage facility. Vegetables and fruits spoil, jars crack, and smoked products quickly disappear after thawing.

- When temperature changes, condensation forms. Dampness promotes the development of pathogenic microorganisms, metal corrosion and the destruction of wooden products.

- Contact with the ground causes gradual destruction of the walls of the structure. Insulating the cellar from the outside protects it from the effects of an acidic environment and the depletion of freezing-thawing material.

Features of installation on logs

Insulation with stone wool on joists

When a strip foundation is used as a base, a structure consisting of joists, rough and finishing flooring is used. Flooring material is selected based on the type of interior and the maximum values of ground temperature in summer and winter.

In such cases, beams are used as a frame for placing thermal insulation

In this case, special attention is paid to the processing of the lower boards, which are exposed to dampness coming from the ground. The best option is to cover them with waterproofing, but this is not always possible, especially when a shallow tape is made

When insulation is laid between the joists, polyethylene or other similar material is first placed there. And only then the insulation is installed. After this, a membrane film is applied, then a final or pre-coat. To ensure high-quality ventilation, grilles with mesh are installed in the corners of the room.

Ventilation and waterproofing layer

Insulating the basement of a private house requires the provision of high-quality waterproofing and ventilation. They help prevent premature wear of almost any insulation.

Waterproofing

There are many methods and materials for waterproofing a basement from the inside. The simplest and most reliable is surface treatment with liquid rubber. This is a water-based polymer-bitumen mass. The material is quite easily applied to the surface in any way: brush, roller or spatula.

Before starting work, it is necessary to ensure good ventilation of the room. Then a primer is applied to the entire surface, which is usually sold complete with bitumen paste. The mastic is mixed with a construction mixer and applied to the walls, floor and ceiling in any convenient way.

After drying, a homogeneous rubber layer is obtained. Despite the fact that the adhesion of waterproofing to the surface is very strong, it is necessary to additionally press it against the walls and floor so that even after several years, leaking water cannot tear off the rubber layer. To do this, a screed is made on the floor, and the walls are plastered, lined with brick or tile.

Ventilation

One of the simplest ways to ensure cellar ventilation is to install special vents in the foundation or two supply and exhaust ducts made of PVC pipes with a diameter of 1 to 5 centimeters. The operation of such a system is based on the temperature difference between the air coming from the street and the basement air.

Drainage

Additional protection is provided by drainage channels dug around the foundation, forming a single system. A drainage ditch is dug outside the building, and its depth is 0.2–0.3 meters. Next, geofabric is laid and crushed stone is backfilled. After laying the drainage pipe, cover it with geotextiles and fill it with sand or carefully compacted soil. The arrangement of a drainage system is necessary when the groundwater level is high.

A mandatory attribute of the cellar foundation is a blind area, which allows you to protect the cellar from rain and melted snow.

Setting up a glacier to preserve food

On the site, in addition to stationary basements, you can build a storage facility that is a little simpler, for example, a pit, a pile or a glacier. Let's take a closer look at how to properly build a glacier.

The glacier serves to preserve food and is a room buried in the ground, which has an ice chamber, a compartment for storing food and a vestibule. Glaciers can be divided into three types, which are determined by the method of filling the ice: bottom, side, top filling. The simplest option is a glacier with a top filling of ice, but at the same time, the arrangement of a water drainage system becomes more complicated. The glacier is loaded once a year.

The location of the glacier on the site should be selected taking into account its distance from the garbage pit, yard latrine and other sanitary facilities. A pit for arranging a glacier is dug in a rectangular shape with the most acceptable dimensions: length - from 1.5 m to 2.2 m, width - 2 m, and depth of the pit - from 2.2 m to 2.5 m. Wall cladding should be done with brickwork , which must be treated in advance with an antiseptic or rubble stone. The floor is laid with bricks or cobblestones.

Above the ground, the glacier is erected up to 3 m high and covered with a continuous plank sheathing. On the outside, the covering and walls should be covered with a layer of a mixture of crumpled clay and straw, and then covered with a layer of dry earth at least 30 cm thick. The outer layer of earth should again be coated with clay up to 3 cm thick and the entire surface should be covered with turf.

To increase the shelf life of ice in the glacier, it can be covered with matting, a layer of shavings or sawdust. To enter the glacier, you need to equip a vestibule with good wall insulation.