Articles

All photos from the article

In the process of performing various construction works, sometimes it becomes necessary to attach a wooden pole to concrete. As a rule, this operation raises many questions among novice masters. In this article we will look at how to attach wooden poles to a concrete base in several ways.

Wooden pole mounted on concrete

Tools and materials

To install the beam vertically on the foundation, you need to prepare the following tools and materials:

- building level;

- cement M500;

- sand cleared of impurities;

- antiseptic for treating wood against mold and mildew;

- roll of roofing felt for waterproofing;

- anchor studs;

- wooden beam.

Important! The timber is laid on a concrete foundation if it has stood for 7 days or more.

Preliminary preparation

To prepare the foundation you will need the following tools and materials:

- roulette;

- bayonet and picking shovels;

- rammer;

- crushed stone, gravel and sand;

- water.

Before you begin installing the supporting pillars, you need to remove the soil from the underground to a depth of about half a meter. The resulting pit is filled with crushed stone, sand or gravel. The backfill is filled with water several times and carefully compacted with special compactors; its level should be 15-20 centimeters higher than the outer soil level.

Preparing the base of the pillars

For the construction of retaining pillars, it is preferable to use red brick or wild stone. Less commonly, concrete support posts are installed. It is not recommended to use sand-lime brick or aerated concrete blocks. The best form of construction would be a truncated pyramid, the base of which should be wide enough.

The cross-section of the pillars depends on their planned height. The higher they are, the larger the cross section should be. For the best stability with a support height of up to 25 centimeters, the pillars are erected with one and a half bricks; at higher heights, the installation is done with two bricks. The dimensions of concrete support pillars must be no less than 40 by 40 centimeters and no more than 50 by 50 cm.

Scheme of laying brick supports

Important! The maximum height of the supports should not exceed 50 centimeters, as their stability is significantly reduced.

Requirements for wood

When choosing timber for building a wooden house, you should proceed from building codes and regulations, and specifically from GOST 2695-83. The first crown of timber must be laid on a foundation made of larch or oak. These materials have good strength and durability. To extend their service life, they must be treated with an antiseptic.

When choosing wood for building a frame house, the following points are taken into account:

- The cross-section of the timber is 20 × 20 centimeters; the lumber should not have any bending, falling knots or other defects.

- The maximum wood moisture content is 20%. It is best to take logs from winter felling, which took place from December to March. The tree should be aged under a canopy or in another room with natural ventilation. Decks are placed in piles in accordance with the rules of storage.

- Absence of defects allowed by state standards. These include damage to wood from bark beetles, mold or mildew.

- Absence of defects that may remain after processing the material on a sawmill.

The quality of the timber is assessed by a specialist based on the worst edge of the layer; inspection of flaws should be done at the ends, as well as along the entire length of the workpiece. After installing all the necessary cutouts and tongues, the product is impregnated with an antiseptic. If possible, store-bought solution is replaced with used machine oil. The quality of the log, the thoroughness of processing and the correct fastening of the strapping to the base affect the reliability and durability of the entire building structure.

Relevance of installing cabinets

Plank flooring is still considered one of the popular floor finishing options. According to the technology, the prepared boards are attached to a supporting lathing made of logs. This is a rectangular beam made of solid wood. This design allows you to create a ventilation gap so that the decorative coating can breathe freely and not become damp.

In fact, in a residential area, subject to technological requirements, this approach is sufficient to eliminate creaking and deformation of the plank sheet. However, over time, the load on the finish may change, which affects the overall condition of the floor. To ensure that the stationary position of the timber sheathing remains unchanged, support posts are additionally installed under it. They also allow you to create the most accurate base for the joists and not have to deal with continuous leveling of the subfloor.

Leveling the concrete base Source sense-life.com

There are often houses where cabinets were not originally installed. As a rule, the reason is that construction is carried out in winter. In this case, an additional installation option is possible. But the event will be labor-intensive, since the entire structure will have to be completely disassembled.

Schemes and technologies for fastening to the foundation

There are two ways to secure a wooden beam to the foundation. Let's take a closer look at them:

- Hard method - fastening of wooden products occurs using special clamps. The result of the work will be a stationary and reliable supporting structure.

- Overlay - the beams are laid along special cutouts; there are no fastening elements between the lumber and the base. The reliability of the structure is achieved due to the weight of the building, which presses on the lower crown.

Of the two indicated methods, the first is considered more reliable, the second method is easier to implement.

Columnar

Columnar-type structures are used for the construction of residential buildings on unstable soils. The service life of such a foundation is within 30–40 years. Here everything depends on the material used to make the columns (brickwork, concrete, asbestos-cement or metal pipes).

When building a wooden house, a project is drawn up, which determines the number and area of supports, as well as the distance between them. It is necessary to pay attention to the fastening of the timber to the pile foundation. Here you need to take into account the nuances of securing the first row of bars.

Before carrying out the main work, align all the columns in the same horizontal plane. For this, a water building level or level is used. The uniform shrinkage of the house and the durability of the building structure depend on the correctness of such actions.

Important! According to SNiPs, the wooden beam for laying the bottom row should be 5 centimeters larger than other products.

For piping, parts with a cross-section of 20 × 20 centimeters are taken; for the installation of load-bearing walls, square beams with a cross-section of 15 × 15 centimeters are used. The need to select a larger cross-section of wooden products for strapping is due to the fact that they bear the entire weight of the building and short-term loads (snow on the roof, etc.)

You should familiarize yourself with the nuances of attaching the beams to the columnar base. When building a bathhouse or wooden house, the lower crown is fixed through special embedded parts, pins with a diameter of 1.4 centimeters. These bolts are secured into the concrete posts as they are poured. After gaining sufficient strength, the first row of beams is fixed on the supports by clamping the nuts.

A similar situation occurs with brick columns. At the time of installation of the masonry, threaded rods of the same diameter are fixed in its structure. In this case, the upper part of the reinforcement must intercept the thickness of the wooden beam with a margin so that the lower crown can be intercepted. After fixing, the unnecessary part of the pin is cut off with a grinder. In cases where the posts are ready and the studs were not installed during the installation process, they can be replaced with anchor bolts.

Remember! Moisture condenses where metal touches wood, which can lead to corrosion of the steel and the appearance of mold or mildew on wooden structures. Problem areas must be treated with paint or antiseptic.

Tape or slab

When installing timber on a strip or slab base, preliminary preparation of the surface is carried out. Holes are drilled along the perimeter of the foundation at a distance of 50 centimeters from each other and anchor bolts with nuts are installed. The same holes are made in a wooden beam.

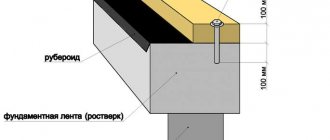

Before fixing the beam, it is necessary to check the horizontal plane of the base and lay a layer of roofing material that will be used as waterproofing. We place wooden blanks on the protruding bolts and secure them with nuts.

Let's look at the process of installing the bottom trim in more detail if the work is carried out along with pouring concrete:

- Bolts are installed into the newly poured concrete at a distance of 50 centimeters and left to harden. Fasteners must have curved ends.

- Drill holes in the timber at the required distance for the studs.

- Check the levelness of the base using a building level and level out any unevenness.

- Roofing felt is laid.

- In the corner parts, the beams are additionally fastened using metal squares and self-tapping screws.

- Place the beam on the bolts, install washers and secure its position by clamping the nuts.

Attaching the timber to a strip-type foundation occurs in the same way as a base made of blocks or slabs. In the latter case, it is necessary to assemble the crown frame in advance. Fixation is carried out using dowels.

Pile

Attaching wood material to piles is done as follows:

- U-shaped embedded parts are installed in the holes on the side of the supports;

- blanks are cut from timber;

- wooden products are installed in the head and fixed with fasteners;

- The bars are installed along one line, staples are stuck in and welded to metal piles.

Important! To prevent contact between wood and metal, pieces of roofing material are placed under the piles.

Screw

The construction of a residential wooden structure on a screw foundation occurs quite quickly. The timber is attached to this base quite simply. At the initial stage of work, it is necessary to measure the length and width of the building, after which we check the horizontalness of the surface using a level. We soak the timber with an antiseptic solution and leave it to dry.

Installation work is carried out in the following order:

- drill holes in wooden products for fasteners (their depth should be 2 millimeters greater than the fasteners);

- lay timber around the perimeter of the building;

- secure it to the screw foundation with bolts.

The harness is considered the easiest to install. In addition, it is reliable and durable.

General information

The need to install wooden poles on concrete can arise in a variety of situations, for example, when installing fences, building gazebos and other wooden structures on a strip foundation.

At first glance, it may seem that installing a wooden pole on concrete is very difficult, but in reality, professionals have some tricks that allow them to cope with this operation without any difficulties. Below you can see for yourself.

Double harness

This type of strapping involves the use of two rows of wooden beams of different sections. The structure can be fixed to a screw foundation in two ways:

Threaded connection

They place roofing felt under the supports, place a beam with a cross-section of 20 × 20 centimeters on the screws and tap it with a hammer. In the corner parts, wooden products are fastened using a metal corner and self-tapping screws. The second row of strapping is secured using through metal pins.