A homemade wood waste crusher is an excellent solution that will help you save money and make a truly practical machine. Of course, you can purchase a ready-made version, but it will be very expensive. There are also used crushers on the market, but no one guarantees their quality.

You can make a tool yourself that will make housekeeping much easier. Shred wood for heating or even crush household waste in just a few minutes.

Purpose

A machine for chopping different types of wood is a useful machine. With its help, branches are processed into sawdust. In this process, chips are obtained from more or less large branches, which are used in the production of fuel briquettes, building materials, paper and cardboard. There is also more than one production facility where railroad sleepers and other “dirty” types of wood are processed.

Depending on the type of machine, both branches and large pieces of wood can be used for processing. Crushing turns all wood material into chips, which are then used on the farm.

Also, with the help of a crusher, household waste is recycled. Grinding will turn waste into fertilizer for the garden, or simply make it convenient for transportation.

The crusher provides:

- Recycling. Some materials, after grinding, can be used on the farm.

- Cleanliness. After cleaning and shredding all the debris, the yard will become much cleaner.

Another advantage of the crusher is that it can quickly pay for itself. Neighbors will be interested in shredding, so equipment can be borrowed or rented.

Hammer crushers in pellet line

In pellet and briquette production, compact hammer wood chippers are in great demand.

They have a number of significant advantages:

- High service life of working parts: 3-4 months can pass between replacing hammers.

- From a maintenance point of view, this is a simple and unpretentious equipment.

- Higher productivity compared to a pneumatic impact crusher (PIC) with the same engine power. Such mills are often installed in industrial lines with large production volumes.

- Thanks to the design features, the material does not stick to the hammers and does not clog the grates.

- Possibility of grinding wet wood chips.

Shredder device

This homemade shredder will help you get rid of small waste easily and quickly. Sawdust for igniting a wood heating system, grass and leaves for a compost pit. All this is good, but before you assemble the crusher yourself, you need to study its structure. The wood chipper consists of the following elements:

- Bunker;

- motor;

- grinding device;

- steel case with protective frame.

These are the main parts without which shredding wood waste is impossible. But to expand the functionality, the design is also equipped with the following elements:

- bin for recycled organics;

- pushing device;

- sieve for sorting the sawdust fraction.

If we talk about how it all works, then it’s worth giving an example of a regular meat grinder. When the machine is turned on, the engine starts, the shaft with the cutting device begins to grind wood or other waste. A funnel is located on top or on the side of the structure, into which a new batch of material is inserted for processing.

Design of the DM hammer crusher

The ALB company produces these devices for pellet granulation lines, mixed feed and other industries.

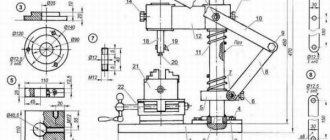

We will give you a drawing of a hammer crusher for wood produced by ALB Group.

The diagram shows the design of the DM-22 model.

Fig 1. Diagram of a hammer crusher

It consists of the following main elements:

- Frame (1);

- crushing chamber with crushing drum (2);

- 2-stage fan (3);

- intermediate pipeline system (4);

- sluice gate (5);

- precipitating cyclone (6);

- electric motor (7) drive (8);

- electric motor (9) of the sluice gate drive (10);

- magnetic separator (11);

- suction nozzle (12);

- suction hose (13);

- pressure hose (14).

Below is a diagram of the crushing chamber:

Fig 2. Diagram of the crushing chamber

1 – body; 2 – side cover; 3 – shaft; 4 – cover; 5 – disk; 6 – finger; 7 – hammer; 8 – spacer sleeve; 9 – sieve; 10 – clamp; 11 – deck; 12 – fan casing; 13 – rotors; 14 – front cover; 15 – rear cover; 16 – pipe; 17 – pipe; 18 – pipe; 19 – hose; 20 – pulley; 21 – double-row spherical roller bearing 3610 GOST5721-75; 22 – key 18x11x388; 23 – key 14x9x56; 24 – key 14x9x90; 25 – eccentric.

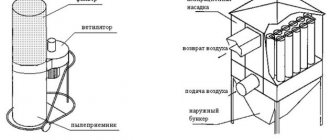

Crushing chamber housing

- This is a welded steel structure with inserted side covers. They are rigidly fastened with bolts and carry the main shaft bearing housings. At one end of the shaft there is a six-strand drive pulley, at the other there is a two-stage fan.

The housing also has an additional cover that is secured with bolts, which serves to replace grates that wear out during operation. Behind the sieve there is a specially shaped neck, which continues with a pipe - they form an ejection (discharge) chamber.

Inside, on the walls of the case, there are two relief cast-iron decks, on which sawdust is crushed.

The main shaft passes through the center of the chamber, on which 6 disks are mounted at regular intervals, forming a crushing drum

. The discs are pierced with steel pins on which sets of crushing hammers are hinged.

Mill electrical equipment

– this is a 22 kW electric motor (for the DM 22 model), an associated control box (with starting, monitoring and protection equipment) and a limit switch. The latter serves as a safety device against starting the device if the camera cover is open. The DM crusher is protected from short circuits, has thermal relays for thermal and zero protection, as well as fuses for control circuits.

Types of Shredders

First of all, a chipper for producing wood chips differs in the type of engine:

- Diesel.

- Gasoline shredder.

- Electric.

In the case of assembling the machine yourself, you need to take into account how much power is required, and what kind of motor is on the farm, or which one can be purchased inexpensively.

Another important characteristic is the type of construction. You can make a machine with your own hands:

- Stationary.

- Mobile

Stationary ones are usually powerful devices for processing fairly large waste. But a mobile wood chipper is suitable for a private home or cottage; it can always be moved to the place of work: in the garden, forest, or barn.

The main characteristic is the operating principle. Here you need to become more familiar with each type of wood chipper in order to decide which one is best suited in a particular situation.

Knife

A wood shredder of this type is an excellent option for working with thick branches and tree trimmings. The working mechanism is a base on which several knives are installed. The material is fed at a slight angle, and the knives crush it, creating a kind of sawdust mill. The size of the processed raw material (chips) will vary depending on the rotation speed of the shaft, the feed force and the dimensions of the feed material.

Drum

If you need a high-quality Russian-made wood chipper, then it is better to choose a drum type. It is suitable for working with large materials: stumps, logs, thick branches. The main grinding mechanism is a shaft with several knives mounted on the surface. Unlike the previous type, here the wood is laid in a straight line, and the blades cut the end part. The result is chips crushed across the fibers, so they are not suitable for wood concrete or OSB. But it is perfect as fuel for heating systems, smokehouses, and for landscaping.

Disk

The design of this type is also based on a shaft, but the cutting elements are not knives, but saw blades. When working with a disk wood crusher, large fractions of wood chips are obtained, which are suitable for heating, gardening, smoking and even for OSB. To adjust the thickness of wood chips, you only need to adjust the gap between the cutting discs and change the feed angle. In special stores there is even a disc-type washing crusher for sawdust, but it is difficult to make it yourself; it is better to refuse this option.

Hammer

Sawdust hammer crushers are a good option for all-purpose applications. Thanks to the knife device, they cut wood, and then also crush the material into a small fraction. This multifunctionality makes it possible to produce material for wood concrete, fuel briquettes, biofuels, and cardboard and paper sheets. Hammer crushers for small sawdust are equipped with special metal “fingers” that strike metal supports and crush the wood that gets there. The sawdust that did not fall under the fingers is sucked back into the air and crushed again.

Shredder

A specialized machine that is used in production for the production of dirty wood: scaffolding, sleepers, racks with nails. The recycled material, in addition to its poor pedigree, also has a poor-quality structure. Used for heating.

Varieties of engines for assembling homemade products

Electric and gasoline engines removed from unused equipment are used as a drive for homemade products. Each of these two options has its own advantages and disadvantages. Models with an internal combustion engine are more convenient in that their operation does not require a nearby power supply. But in general, they are more expensive and have a more complex design than their counterparts equipped with an electric motor. Therefore, it is easier to make electrical equipment, and also more compact.

The maximum thickness of cut branches that a branch chipper can grind depends on the power of the electric motor installed on it and the characteristics of the knives.

- Models with a motor up to 1.5 kW are capable of grinding sticks up to 20 mm in diameter. They are designed for low intensity work.

- If an electric motor of 3 to 4 kW is installed, then such units can chop branches up to 40 mm thick.

- More powerful electric motors (over 4 kW) are used to make a shredder for wood with a diameter of 7-15 cm.

The drive of the last category is equipped with equipment if it is necessary to constantly perform large volumes of work associated with the processing of waste of various thicknesses.

To create a homemade shredder, you can use electric motors from an angle grinder, washing machine, or trimmer. They must be adapted to work from a stationary network with a voltage of 220 V. In order to grind material as thick as possible at home, it is recommended to equip the shredder with an electric motor of 1500 rpm with a power of about 3.5 kW. This parameter for internal combustion engines corresponds to 5-6 horsepower.

Motor from an old washing machine

DIY making

A homemade version of the machine is often a simple design, with a low power of kW and a simple way of working. The work must be performed in several stages:

- Scheme selection. As you know, each sawdust crusher differs in design and operating principle. You need to decide in advance which option to assemble, what will be the main cutting mechanism - a saw or knives. Make a drawing.

- Preparation of tools and materials. If everything is not prepared, the assembly can take many weeks or even years. It's better to have everything at hand right away.

- Assembly. This stage is the most important; it consists of two parts: assembling the body and assembling the working part. Assembling and installing the shaft, making the structure convenient and safe are the main tasks of the third stage.

Each stage of work should be studied in more detail in order to avoid mistakes that will damage the structure for cutting sawdust.

Classification of hammer crushers

These units differ in the following parameters:

- By number of rotors

: with one or two rotors;

- By shaft location

: with horizontal or vertical shaft;

- WITH reverse mode

or without it.

Shredders with reverse mode can rotate their shaft in both directions. If one side of the hammers is worn down, you can reverse the stroke of the shaft to use the impact elements on the other side.

These devices also differ:

- Dimensions of the chamber and rotor;

- Shape of hammers;

- Electric motor power.

Selecting a device circuit

A wood chipper is a technique that requires precision to manufacture. First you need to choose a mechanism option. After this, a drawing must be drawn; this can be done either with a regular pencil on paper or on computer equipment.

Choosing a design is not an easy task, because there are many options and schemes on the Internet. Based on your needs, you need to choose an option so that it is effective and the design is simple.

The preparation and assembly process is shown using the example of wood chippers with a circular saw as a cutting element. This device has a simple design:

- Steel frame.

- Circular saws.

- Engine.

- Belts.

- Pulleys.

- Protective cover.

These are the main elements that ensure the functionality of the device: the engine, using belts, transmits torque to the shaft with knives; it easily copes with wood materials. You can also install additional parts, for example, dividers between saws.

Preparation of tools and materials

To assemble a wood chipper, you will need the following materials:

- Electric or gasoline engine;

- steel sheets for the casing, hopper and body;

- discs or knives for the cutting element;

- metal pipes for the machine frame;

- metal shaft;

- bearings;

- pulleys, belt;

- fastening elements (nuts, bolts).

If an electric motor is used, then experts advise using 3000 W units. Such devices are suitable for a home machine for monitoring the site, processing branches and other wood waste.

Cutting tools - knives or discs. You can make knives with your own hands, for example from springs. It is better to buy discs; they are inexpensive and will cope with crushing small materials.

To make a good machine out of all this, you need the following tools:

- Bulgarian;

- welding machine;

- electric drill or specialized machine;

- a set of screwdrivers or a screwdriver;

- a set of keys.

In addition, you need to prepare a brush and paint. This will improve the appearance of the machine and protect it from rust and other troubles.

The nuances of operating homemade equipment

A self-made shredder is essentially three in one: a chopper for branches, a straw cutter, and a mechanism for cutting grass. It helps to significantly facilitate household work associated with the disposal of plant waste, as well as feeding poultry and livestock.

If you have to process grass in small quantities, for example, for chickens, geese, ducks, then very simple devices that operate on human muscle power, for example, a hand pruner, are sufficient.

For homemade electrical equipment, it is recommended to install a separate differential circuit breaker to provide reliable protection against electric shock in case of unforeseen circumstances. In any case, when making a garden shredder yourself, you must follow safety regulations. It is also worth adhering to them during operation of the mechanism. Before working with equipment, it is recommended to wear goggles, suitable protective clothing and check that the structural elements are securely fastened. When creating a home-made unit, you should take into account the upcoming amount of work, as well as the nature of the vegetation being processed, in order to select an engine of the required power and the desired design of knives. This will allow the completed device to cope with the assigned tasks without any problems.