The main condition for any construction is simplicity and reliability of the structure, but in order to achieve this, correct calculations of the strength of the material must be made. Since a wooden frame is used to build wooden houses, an attic or an attic, its choice must be approached with all responsibility, because the durability, reliability and stability will directly depend on the load the timber can withstand (100x100, 50x50, 150x150, etc.) built house.

Calculate the load on the beam

To correctly calculate the load that a beam can withstand, you can use special programs or formulas, but in this case, additional loads that directly affect the strength of the structure will have to be included in the calculations. In order to correctly calculate the load on the beam, you will have to indicate the snow and wind influences present directly in the development region, as well as the characteristics of the materials used (thermal insulator, timber, etc.).

In this article we will look at what load a beam of size 50x50, 100x100, 150x150 will withstand in various structures, such as a log house, a wooden floor and a rafter system, and as an example we will analyze the latter, because this is the most important and complex work.

Table

In the photo you can see varieties of timber, which differ not only in shape, but also in the load they can withstand.

Wooden floor beams - dimensions and loads

We made a wooden floor in a timber house, but the floor shook, sagged, and a “trampoline” effect appeared; we want to make wooden floor beams 7 meters long; you need to cover a room 6.8 meters long so as not to rest the logs on intermediate supports; what should be the floor beam for a span of 6 meters, a house made of timber; what to do if you want to make an open plan - such questions are often asked by forum users.

Maxinova FORUMHOUSE user

My house is about 10x10 meters. I “threw” wooden logs onto the ceiling, their length is 5 meters, cross-section is 200x50. The distance between the joists is 60 cm. During the operation of the floor, it turned out that when children run around in one room and you stand in another, there is quite a strong vibration along the floor.

And such a case is far from the only one.

Elena555 FORUMHOUSE user

I can’t figure out what kind of beams are needed for the interfloor floors. I have a house 12x12 meters, 2 floors. The first floor is made of aerated concrete, the second floor is an attic, wooden, covered with timber 6000x150x200mm, laid every 80 cm. The logs are laid on an I-beam, which rests on a pillar installed in the middle of the first floor. When I walk on the second floor, I feel shaking.

Beams for long spans must withstand heavy loads, therefore, in order to build a strong and reliable wooden floor with a large span, they must be carefully calculated. First of all, it is necessary to understand what load a wooden log of a particular section can withstand. And then think about, having determined the load for the floor beam, what rough and finishing floor coverings will need to be made; what the ceiling will be hemmed with; whether the floor will be a full-fledged residential space or a non-residential attic above the garage.

Leo060147 FORUMHOUSE user

- The load from the own weight of all structural elements of the floor. This includes the weight of beams, insulation, fasteners, flooring, ceiling, etc.

- Operating load. The operating load can be permanent or temporary.

When calculating the operating load, the mass of people, furniture, household appliances, etc. is taken into account. The load temporarily increases when guests arrive, noisy celebrations, or furniture is rearranged if it is moved away from the walls to the center of the room.

Therefore, when calculating the operating load, it is necessary to think through everything - right down to what kind of furniture you plan to install, and whether there is a possibility in the future of installing a sports exercise machine, which also weighs more than one kilogram.

The following values are taken for the load acting on long wooden floor beams (for attic and interfloor floors):

- Attic floor – 150 kg/sq.m. Where (according to SNiP 2.01.07-85), taking into account the safety factor, 50 kg/sq.m is the load from the floor’s own weight, and 100 kg/sq.m is the standard load.

If you plan to store things, materials and other household items in the attic, then the load is assumed to be 250 kg/sq.m.

- For interfloor floors and attic floors, the total load is taken at the rate of 350-400 kg/sq.m.

How to calculate load-bearing capacity and deflection

It is worth recognizing that over many years of practice in the construction craft, a certain canon has been developed, which is most often used to calculate the load-bearing capacity:

Calculating the deflection of a wooden beam is part of the formula presented above. The letter M indicates this indicator. To find out the parameter, use the following formula:

M=(ql 2 )/8

There are only two variables in the deflection calculation formula, but they are the ones that most determine what the load-bearing capacity of a wooden beam will ultimately be:

How important is it to correctly calculate the deflection?

This parameter is extremely important for the strength of the entire structure. The fact is that the durability of the timber alone is not enough for a long and reliable service, because over time its deflection under load can increase.

Deflection does not just spoil the aesthetic appearance of the ceiling. If this parameter exceeds 1/250 of the total length of the floor element , then the likelihood of an emergency will increase tenfold.

Flooring with boards 200 by 50 and other common sizes

These are the types of beams on a span of 4 meters that are allowed by the standards.

Most often, in the construction of wooden floors, boards and timber of the so-called running sizes are used: 50x150, 50x200, 100x150, etc. Such beams meet the standards ( after calculation

), if you plan to cover the opening no more than four meters.

For floors 6 or more meters long, the dimensions 50x150, 50x200, 100x150 are no longer suitable.

Wooden beam over 6 meters

: subtleties

A beam for a span of 6 meters or more should not be made of timber and boards of standard sizes.

You should remember the rule: the strength and rigidity of the floor depend to a greater extent on the height of the beam and to a lesser extent on its width.

A distributed and concentrated load acts on the floor beam. Therefore, wooden beams for large spans are not designed “end-to-end”, but with a margin of strength and permissible deflection. This ensures normal and safe operation of the ceiling.

50x200 - overlap for an opening of 4 and 5 meters.

To calculate the load that the ceiling will withstand, you must have the appropriate knowledge. In order not to delve into the strength of strength formulas (and when building a garage this is definitely redundant), an ordinary developer just needs to use online calculators for calculating wooden single-span beams.

Leo060147 FORUMHOUSE user

A self-builder is most often not a professional designer. All he wants to know is what beams need to be mounted in the ceiling so that it meets the basic requirements for strength and reliability. This is what online calculators allow you to calculate.

These calculators are easy to use. To make calculations of the required values, it is enough to enter the dimensions of the logs and the length of the span that they must cover.

Also, to simplify the task, you can use ready-made tables presented by the guru of our forum with the nickname Roracotta

.

Roracotta FORUMHOUSE user

I spent several evenings to make tables that would be understandable even to a novice builder:

Table 1. It presents data that meets the minimum load requirements for the floors of the second floor - 147 kg/sq.m.

Note: since the tables are based on American standards, and the sizes of lumber overseas are somewhat different from the sections accepted in our country, you need to use the column highlighted in yellow in the calculations.

Table 2. Here is data on the average load for the floors of the first and second floors - 293 kg/sq.m.

Table 3. Here is the data for the calculated increased load of 365 kg/sq.m.

Build a house with your own hands

In order to build a reliable wooden floor, it is necessary to select the correct dimensions of the beams, and for this it is necessary to calculate them. Wooden floor beams have the following main dimensions: length and cross-section.

Their length is determined by the width of the span that needs to be covered, and the cross-section depends on the load that will act on them, on the length of the span and the installation pitch, that is, the distance between them.

In this article we will look at how to independently make such a calculation and select the correct beam sizes.

Self-production of laminated wood beams

One solution for spanning long spans is to use wooden beams in the floors. Let's consider a span of 6 meters - which beams can withstand a larger load.

According to the type of cross section, a long beam can be:

- rectangular;

- I-beam;

- box-shaped

There is no consensus among self-builders as to which section is better. If we do not take into account purchased products (factory-made I-beams), then the ease of production in “field conditions”, without the use of expensive equipment and accessories, comes first.

Just Grandfather FORUMHOUSE User

If you look at a cross section of any metal I-beam, you can see that from 85% to 90% of the metal mass is concentrated in the “shelves”. The connecting wall contains no more than 10-15% of the metal. This is done based on calculation.

Which board to use for beams

According to the strength of strength: the larger the cross-section of the “shelves” and the farther they are spaced apart in height, the greater the loads the I-beam will withstand. For a self-builder, the optimal I-beam manufacturing technology is a simple box-shaped structure, where the upper and lower “shelves” are made of boards laid flat. (50x150mm, and the side walls are made of plywood with a thickness of 8-12 mm and a height of 350 to 400 mm (determined by calculation), etc.).

Plywood is nailed to the shelves or screwed with self-tapping screws (not black ones, they do not work for cutting) and must be set with glue

.

If you install such an I-beam on a six-meter span with a step of 60 cm, then it will withstand a large load. Additionally, an I-beam for a 6-meter ceiling can be lined with insulation.

Also, using a similar principle, you can connect two long boards, collecting them in a “package”, and then put them on top of each other on an edge (take boards 150x50 or 200x50), as a result, the cross-section of the beam will be 300x100 or 400x100 mm. The boards are placed on glue and tied together with pins or placed on wood grouse/dowels. You can also screw or nail plywood to the side surfaces of such a beam, having previously lubricated it with glue.

Also interesting is the experience of a forum member under the nickname Taras174,

who decided to independently make a glued I-beam to span a span of 8 meters.

To do this, the forum member purchased 12 mm thick OSB sheets and cut them lengthwise into five equal parts. Then I bought a board 150x50 mm, 8 meters long. Using a dovetail cutter, I used a dovetail cutter to select a groove 12 mm deep and 14 mm wide in the middle of the board, so as to create a trapezoid with a downward expansion. OSB in grooves Taras174

glued it in using polyester resin (epoxy), having previously “shot” a strip of fiberglass 5 mm wide to the end of the slab with a stapler. This, according to the forum member, would strengthen the structure. To speed up drying, the glued area was heated with a heater.

Taras174 FORUMHOUSE user

On the first beam I practiced “pushing my hand.” The second one was done in 1 working day. In terms of cost, taking into account all materials, I include a solid board of 8 meters, the cost of the beam is 2000 rubles. for 1 piece

Despite the positive experience, such “squatter construction” did not escape several critical remarks expressed by our experts. Namely.

The main condition for any construction is simplicity and reliability of the structure, but in order to achieve this, correct calculations of the strength of the material must be made. Since a wooden frame is used to build wooden houses, an attic or an attic, its choice must be approached with all responsibility, because the durability, reliability and stability will directly depend on the load the timber can withstand (100x100, 50x50, 150x150, etc.) built house.

To correctly calculate the load that a beam can withstand, you can use special programs or formulas, but in this case, additional loads that directly affect the strength of the structure will have to be included in the calculations. In order to correctly calculate the load on the beam, you will have to indicate the snow and wind influences present directly in the development region, as well as the characteristics of the materials used (thermal insulator, timber, etc.).

In this article we will look at what load a beam of size 50x50, 100x100, 150x150 will withstand in various structures, such as a log house, a wooden floor and a rafter system, and as an example we will analyze the latter, because this is the most important and complex work.

In the photo you can see varieties of timber, which differ not only in shape, but also in the load they can withstand.

What will we talk about:

Beam calculator - calculation for different types of structures

Beams in a house usually belong to the rafter system or floor, and in order to get a reliable structure that can be operated without any fear, you need to use a beam calculator .

What is the beam calculator based on?

When the walls have already been brought under the second floor or under the roof, it is necessary to make a ceiling, in the second case smoothly turning into rafters. In this case, the materials must be selected so that the load on the brick or log walls does not exceed the permissible value, and the strength of the structure is at the proper level. Therefore, if you are going to use wood, you need to choose the right beams from it and make calculations to determine the required thickness and sufficient length.

Beam calculator

The subsidence or partial destruction of the ceiling can be due to various reasons, for example, too large a step between the lags, deflection of the cross members, too small their cross-sectional area or defects in the structure. To eliminate possible excesses, you should find out the expected load on the floor, be it basement or interfloor, and then use a beam calculator, taking into account their own weight. The latter can change in concrete lintels, the weight of which depends on the density of the reinforcement; for wood and metal, with a certain geometry, the weight is constant. The exception is damp wood, which is not used in construction work without first drying it.

Beam systems in floors and rafter structures are loaded by forces acting on section bending, torsion, and lengthwise deflection . For rafters, it is also necessary to provide for snow and wind loads, which also create certain forces applied to the beams. You also need to accurately determine the required step between the jumpers, since too many crossbars will lead to excess weight of the floor (or roof), and too little, as mentioned above, will weaken the structure.

You may also be interested in an article about calculating the amount of unedged and edged boards in a cube: https://remoskop.ru/kolichestvo-dosok-v-kube.html

How to calculate the load on a floor beam

The distance between the walls is called a span, and there are two of them in the room, and one span will necessarily be smaller than the other if the shape of the room is not square. Interfloor or attic floor lintels should be laid along a shorter span, the optimal length of which is from 3 to 4 meters. Larger spacing may require non-standard sized beams, which will result in some unsteadiness of the deck. The best solution in this case would be to use metal crossbars.

How does the cross-section of a log house affect its reliability?

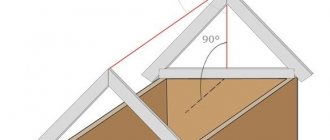

When creating a roof, a prerequisite for its reliability is the cross-section of the timber used and the type of wood, which affects durability.

When performing the calculation yourself, you will need to take into account such indicators as:

- what mass do all roofing building materials have;

- weight of attic or attic finishing;

- for rafter supports and beams, the calculated value is taken into account;

- The thermal and sedimentary effects of nature are taken into account.

In addition, you will need to indicate:

- distance between beams;

- length of the gap between the rafter supports;

- the principle of fastening the rafters and the configuration of its truss;

- the severity of precipitation and the impact of winds on the structure;

- other factors that may affect the reliability of the design.

All these calculations can be performed with your own hands using special formulas. But it will be simpler, both in terms of time and quality, to calculate the beam load using special programs, and even better, when these calculations are performed by a professional.

What requirements must the timber meet?

In order for the entire rafter system to be strong and reliable, the quality of building materials will have to be approached with all responsibility. For example, the timber should be free of defects (cracks, knots, etc.), and its humidity should not exceed 20%. In addition, a log house of any size (50x50, 100x100, 150x150, etc.) must be treated with protective agents against shashel and other insects, rotting and fire.

Also, when choosing a material, you will have to take into account that additional loads may be placed on the beam, such as:

- Continuous beam loads. These include the very weight of the entire rafter system, which includes: facing and roofing materials, insulation materials, etc. The data obtained for each material is summed up.

- Short-term loads can be of several types: especially rare, short-term and long-term exposure. The first type includes incidents that happen very rarely (earthquakes, floods, etc.). Short-term loads are wind and snow impacts, movement of people repairing the roof, etc. Long-term loads are all other impacts occurring within a certain period of time.

We determine the wind and snow load on the timber

To determine what load the beam can withstand (100x100, 150x150, 50x50, etc.) under wind and snow influence, you can use certain tables.

To determine the effect of snow on rafters of different sections, use the formula S=Sg*µ.

- Sg is the estimated weight of snow lying on the ground that affects 1 m².

Important! This value cannot be compared to the roof load.

- µ is the value of the load on the roof surface, which varies from horizontal to inclined. This coefficient can take on different values, it all depends on the slope of the roof.

When the surface slopes up to 25 degrees, µ takes the value 1.

When the roof slope is in the range of 25-60 degrees, µ is 0.7.

With a slope of 60 degrees or more, the coefficient µ is not taken into account as it has virtually no effect on the rafter system.

In addition to the snow load, before constructing a rafter system, the wind load on a wooden beam of 50 by 50, 100x100, etc. is calculated. If these indicators are not taken into account, as a result, everything can end in disaster. Table values and the formula W=Wo*k are used for calculation.

Wо – is a tabular value of wind load for each individual region.

k is the wind pressure, which has different values as the altitude changes. These indicators are also tabular.

Shown in the photo is a table of timber loads when exposed to the elements, easy to use, you just need to remember that the 1st column shows values for steppe, desert regions, rivers, lakes, forest-steppe, tundra, seashores and reservoirs. The next column contains data related to urban areas and areas with 10 meter obstacles.

Important! In calculations, it is advisable to use information on the direction of wind movement, because this can make an important amendment to the results.

Various timber

Note! A wooden beam is usually called a profile whose cross-section is at least 100×100 mm. If it is smaller, then the instructions recommend calling it a block, board or batten.

Payment methods

Storage for drying

The easiest way to find out how many pieces of timber are in a 100x100 mm cube is to use a table and each manufacturer always presents them to the wholesale buyer. Although the seller at the warehouse, most likely, will not be able to do this and will simply ask you to count the number of pieces in one knitting, which are made per cubic meter.

| Dimensions in mm | Volume of 1 piece in m3 | Number of pieces per m3 |

| 100x100x6000 | 0,06 | 16 |

| 100x150x6000 | 0,09 | 11 |

| 150x150x6000 | 0,135 | 7 |

| 100x180x6000 | 0,108 | 9 |

| 150x180x6000 | 0,162 | 6 |

| 180x180x6000 | 0,194 | 5 |

| 100x200x6000 | 0,12 | 8 |

| 150x200x6000 | 0,18 | 5,5 |

| 180x200x6000 | 0,216 | 4,5 |

| 200x200x6000 | 0,24 | 4 |

| 250x200x6000 | 0,3 | 3 |

| 150x150x4000 | 0,09 | 11 |

| 200x200x4000 | 0,16 | 6 |

Table of parameters for different sections

As you may have noticed from the table, the amount of timber in one cubic meter depends on two factors - its cross-section and length. Most manufacturers make the standard length, depending on the workpiece (log), these are 4, 5, and 6 m, although exceptions are possible.

A profile glued from lamellas is made somewhat differently - it can be cut depending on the building design, so the length there can be completely different.

Another parameter is the weight of the timber 100x100 mm, but it will depend on the humidity and type of wood. Below we offer you a table in which the weight of pine beams is calculated based on humidity.

| Beam dimensions (mm) | Freshly cut wood | Humidity 20% | Dry wood (kiln drying) |

| 100x100x1000 | 8.63 kg | 7.5 kg | 3.95 kg |

| 100x100x3000 | 25.9 kg | 22.5 kg | 11.85 kg |

| 100x100x4000 | 34.5 kg | 30.0 kg | 15.8 kg |

| 100x100x5000 | 43.13 kg | 37.5 kg | 19.75 kg |

| 100x100x6000 | 51.8 kg | 45.0 kg | 23.7 kg |

In the workshop at the sawmill

Now let's calculate on our own how much 100x100 timber is in one cube, and for this we will first need to find out the volume of one piece. For example, let’s take a six-meter, most common profile and find out its volume - then 0.1 * 0.1 * 6 = 0.06 m3. Now we divide the cube into the resulting volume 1/0.06 = 16.6 or 16 pieces in one cubic meter - everything coincides with the table.

Or, for example, you can use the same method to calculate the amount of 100x100 timber in a cube, the length of which is only 4 m. This requires similar actions, this is 0.1*0.1*4=0.04m3. Now we divide the cube by the resulting volume: 1/0.04 = 25 pieces.

Now let's see what load the beam can withstand on the floor, and again use the table below. It shows the calculated values for pine, spruce and larch at 12% humidity (SNiP P-25-80)

Calculated resistance values for softwood

Coefficients for other breeds (SNiP P-25-80)

Note. If the beams are made not from coniferous wood, but from other types of wood, then the value is multiplied by the coefficient indicated in the table above.

How to calculate the volume of walls for a building

If you wanted to build something with your own hands, for example, a bathhouse, as in the photo above, then you will need to calculate the volume of the walls. And if you draw up a draft of it in advance, then it will not be difficult at all.

There are two ways here and the first is to calculate the amount of timber for each wall and if you know how many pieces there are in a cube, then simply divide the total amount of material received by the number of pieces in a cube and get the required volume.

For example, for a bathhouse 4x4m and 2.6m high, you will need 2.6/0.1=26 pieces for one wall, which means the entire structure will require 26*4=104 pieces of 100x100 mm timber. Knowing that there are 25 such profiles in a cube, we carry out a simple calculation: 104/25 = 4.15 m3.

Also, the cubic capacity can be determined by the area of the walls - in this case we have 4 * 2.6 * 4 = 41.6 m2. Now all that remains is to multiply this by the thickness and we get 41.6 * 0.1 = 4.16 m3. The discrepancy of 0.01 m3 was due to the fact that the corners on the walls are included in the total volume, but we did not take this into account.

Advantages

Advantages of solid and laminated timber:

The beam can have different sizes.

What are the rules for calculating the required cross-section of timber?

The selection of the log section for the rafter system is influenced by several parameters:

- what is the length of the rafter construction;

- the distance between each subsequent beam;

- the obtained results of load calculations for the corresponding area.

Today, for each specific area, there are special tables with already entered data on load values for rafter systems. As an example, we can cite the Moscow region:

- to install the Mauerlat, you can use timber with a cross section of at least 100x100, 150x100 and 150x150;

- timber 200x100 can be used for diagonal valleys and rafter supports (legs);\

- purlins can be created from wood 100x100, 150x100 or 200x100;

- a log house 150x50 will be the optimal solution for tightening;

- It is best to use a log frame 150x150 or 100x100 as racks;

- rafter 150x50 is suitable for a cornice, struts or filly;

- It is best to install crossbars from rafters 150x100 or 200x100;

- A board of at least 22x100 can be used as cladding or fronting.

The above data are optimal, that is, less than this value the material cannot be used. Also, all dimensions are indicated in millimeters.

Summarize

To create a reliable and durable wooden structure, you need to carefully calculate all possible loads, and then just purchase timber. If you have doubts about the correctness of the calculations, it is best to use the services of a professional or use a special program that will calculate the permissible load on the beam (150x150, 100x100, etc.).

Floor beams or ceiling joists are the supporting structure of the house, therefore, before you begin to independently install floor joists in a log house or bathhouse, we strongly recommend that you be especially careful in choosing the material

and

correctly calculate

the design of the floors.

For the manufacture of floor joists, it is best to use dry, first-grade material impregnated with a fire-bioprotective composition.

Beams are most often embedded:

How to ensure the strength of floors and convenient installation

Having previously marked the places where the beams will be inserted, cuts are made in the log and tightly

beams are inserted into them at a distance of about 600 mm from each other. This distance between the beams provides the necessary strength of the floors. Most types of insulation are produced exactly 600 mm wide, which ensures convenient installation of heat and noise insulation. With this method of installing logs, there is no need to attach them additionally to the wall.

Floor joists can also be mounted after the frame has been assembled, securing them to the wall using special brackets and self-tapping screws. There is now a huge variety of fastening devices on the construction market. But more correct and reliable

installation method - first!

Necessary explanations for calculations

- Height and width determine the cross-sectional area and mechanical strength of the beam.

- Wood material: pine, spruce or larch - characterizes the strength of the beams, their resistance to deflection and fracture, and other special performance properties. Usually preference is given to pine beams. Larch products are used for rooms with a humid environment (baths, saunas, etc.), and spruce beams are used in the construction of inexpensive country houses.

- The type of wood affects the quality of the beams (as the grade increases, the quality deteriorates). 1st grade. On each one-meter section of timber, on any side there can be healthy knots measuring 1/4 of the width (face and edge), and 1/3 of the width (edge). There may also be rotten branches, but their number should not exceed half of the healthy ones. It should also be taken into account that the total dimensions of all knots in an area of 0.2 m must be less than the maximum width size. The latter applies to all grades when it comes to load-bearing beam structures. There may be plate cracks measuring 1/4 of the width (1/6 if they extend to the end). The length of through cracks is limited to 150 mm; first grade timber can have end cracks up to 1/4 of the width. The following wood defects are allowed: tilting of the fibers, tilt (no more than 1/5 of the side area of the beam), no more than 2 pockets, one-sided growth (no more than 1/30 in length or 1/10 in thickness or width). Grade 1 timber may be affected by fungus, but no more than 10% of the lumber area; rot is not allowed. There may be a shallow wormhole on the wane parts. To summarize the above: the appearance of such timber should not cause any suspicion.

- 2nd grade. Such a beam can have healthy knots measuring 1/3 of the width (face and edge), and 1/2 of the width (edge). For rotten knots, the requirements are the same as for grade 1. The material may have deep cracks up to 1/3 the length of the timber. The maximum length of through cracks should not exceed 200 mm; there may be cracks at the ends up to 1/3 of the width. Allowed: inclination of fibers, heel, 4 pockets per 1 m., sprouting (no more than 1/10 in length or 1/5 in thickness or width), cancer (extending up to 1/5 of the length, but not more than 1 m) . Wood can be affected by fungus, but not more than 20% of the area of the material. Rot is not allowed, but there can be up to two wormholes in a 1 m area. To summarize: grade 2 has borderline properties between 1 and 3, and generally leaves a positive impression upon visual inspection.

- 3rd grade. Here the tolerances for defects are greater: the timber can have knots measuring 1/2 the width. Face cracks can reach 1/2 the length of the lumber; end cracks measuring 1/2 the width are allowed. For grade 3, it is allowed to bend the fibers, tilt, pockets, core and double core, sprouting (no more than 1/10 in length or 1/4 in thickness or width), 1/3 of the length may be affected by cancer, fungus, but not rot are allowed. The maximum number of wormholes is 3 pcs. per meter To summarize: grade 3, even to the naked eye, does not stand out as the best quality. But this does not make it unsuitable for the manufacture of floors on beams. For more information about the varieties, read GOST 8486-86 Softwood lumber. Technical specifications;

Issues arising during the construction process

When building a log house, log baths

Questions naturally arise: What section should I embed the floor beams (floor, ceiling)? What load can wooden joists (beams) withstand? What is the maximum beam length possible for what section of board, beam, or log?

Based on the table below, it is easy to calculate the cross-section of the log, depending on its length. The data is given for standard spans with a width of 2 to 6 meters, with a frequency of lags every 600 mm (distance between lags 600 mm) Design load 300 kg per 1 sq. meter. The table shows the breaking loads for these joists in kg per square meter.

Simply put, the numbers on a colored background are the load in kilograms per 1 m2, at which the ceiling will simply break. But in order to prevent the floor from “springing”, there is also an indicator of the bending of the beam. Blue background - the floor will not “spring”, yellow - the maximum permissible, and red background the floor will sag under a load of 300 kg more than the permissible norm.

Table for calculating the destructive load (kg/m2) on the joists (beams) of the floors of a log house.

| log length m | 2,0 | 2,5 | 3,0 | 3,5 | 4,0 | 4,5 | 5,0 | 5,5 | 6,0 |

| log section mm | |||||||||

| Board 100x50 | 733 | 587 | 489 | 419 | 367 | 326 | 293 | 267 | 244 |

| Board 150x50 | 1650 | 1320 | 1100 | 943 | 825 | 733 | 660 | 600 | 500 |

| Board 200x50 | 2933 | 2347 | 1956 | 1676 | 1467 | 1304 | 1173 | 1067 | 978 |

| Beam 200x100 | 5867 | 4693 | 3911 | 3352 | 2933 | 2607 | 2347 | 2133 | 1956 |

| Beam 200x200 | 11733 | 9387 | 7822 | 6705 | 5867 | 5215 | 4693 | 4267 | 3911 |

| Log 200 | 6912 | 5529 | 4608 | 3949 | 3456 | 3072 | 2765 | 2513 | 2304 |

| Log 220 | 9199 | 7359 | 6133 | 5257 | 4600 | 4089 | 3680 | 3345 | 3066 |

Blue

in the table,

values with a safety margin

in Yellow

the table highlights the

maximum permissible

deflection values of beams for these conditions

In red

values

that are unacceptable for deflection

(more than twice the permissible norm) of beams for these conditions are highlighted.

Note: additional rigidity can also be given to the beam by splicing two or more boards in thickness.

Today, a variety of materials are used for construction, but wooden beams are most often in demand. They are used for the construction of rafter systems, for organizing the ceilings of attics, basements and between floors. It is wooden structures that are used to construct floors using joists. This material is durable, able to withstand numerous loads, environmentally friendly and relatively low cost. If a wooden beam is used, it is necessary to first carry out calculations regarding their length. If you have no experience, then it is better to entrust the work to specialists.

Rack made of boards or timber of the 1st grade

The table is compiled for scheme B

| Lumber GOST 24454-80 | Stand height, m | ||||||

| Width, cm | Thickness, cm | 1 | 2 | 3 | 4 | 5 | 6 |

| Safe permissible load on rack P, kg | |||||||

| Ultimate flexibility λmax ≤ 120 (columns) | |||||||

| 3,2 | 3,2 | 366* | |||||

| 4 | 3,2 | 458* | |||||

| 4 | 895* | ||||||

| 4,4 | 3,2 | 504* | |||||

| 4 | 985* | ||||||

| 4,4 | 1311* | ||||||

| 5 | 3,2 | 573* | |||||

| 4 | 1119* | ||||||

| 4,4 | 1490* | ||||||

| 5 | 2155* | ||||||

| 6 | 3,2 | 687* | |||||

| 4 | 1343* | ||||||

| 4,4 | 1788* | ||||||

| 5 | 2586* | ||||||

| 6 | 3694 | 1130* | |||||

| 7,5 | 3,2 | 859* | |||||

| 4 | 1678* | ||||||

| 4,4 | 2234* | ||||||

| 5 | 3232* | ||||||

| 6 | 4618 | 1413* | |||||

| 7,5 | 6528 | 2763* | |||||

| 10 | 3,2 | 1145* | |||||

| 4 | 2238* | ||||||

| 4,4 | 2979* | ||||||

| 5 | 4309* | ||||||

| 6 | 6157 | 1884* | |||||

| 7,5 | 8704 | 3684* | |||||

| 10 | 12651 | 8614 | 3874* | ||||

| 12,5 | 3,2 | 1432* | |||||

| 4 | 2797* | ||||||

| 4,4 | 3724* | ||||||

| 5 | 5387* | ||||||

| 6 | 7696 | 2355* | |||||

| 7,5 | 10880 | 4605* | |||||

| 10 | 15814 | 10767 | 4842* | ||||

| 12,5 | 20523 | 16483 | 9470 | 5309* | |||

| 15 | 3,2 | 1718* | |||||

| 4 | 3357* | ||||||

| 4,4 | 4469* | ||||||

| 5 | 6464* | ||||||

| 6 | 9235 | 2826* | |||||

| 7,5 | 13056 | 5526* | |||||

| 10 | 18976 | 12921 | 5810* | ||||

| 12,5 | 24628 | 19780 | 11365 | 6370* | |||

| 15 | 30145 | 26101 | 19370 | 11028 | 7030* | ||

| 17,5 | 3,2 | 2004* | |||||

| 4 | 3916* | ||||||

| 4,4 | 5214* | ||||||

| 5 | 7542* | ||||||

| 6 | 10775 | 3297* | |||||

| 7,5 | 15232 | 6447* | |||||

| 10 | 22139 | 15074 | 6779* | ||||

| 12,5 | 28732 | 23076 | 13259 | 7432* | |||

| 15 | 35169 | 30451 | 22598 | 12866 | 8202* | ||

| 17,5 | 41515 | 37468 | 30732 | 20454 | 13052 | 9025 | |

| 20 | 3,2 | 2290* | |||||

| 4 | 4476* | ||||||

| 4,4 | 5958* | ||||||

| 5 | 8619* | ||||||

| 6 | 12314 | 3768* | |||||

| 7,5 | 17408 | 7368* | |||||

| 10 | 25302 | 17228 | 7747* | ||||

| 12,5 | 32837 | 26373 | 15153 | 8494* | |||

| 15 | 40193 | 34801 | 25826 | 14704 | 9374* | ||

| 17,5 | 47446 | 42820 | 35122 | 23376 | 14917 | 10314 | |

| 20 | 54636 | 50583 | 43843 | 34414 | 22298 | 15433 | |

| 22,5 | 3,2 | 2577* | |||||

| 4 | 5035* | ||||||

| 4,4 | 6703* | ||||||

| 5 | 9696* | ||||||

| 6 | 13853 | 4239* | |||||

| 7,5 | 19584 | 8288* | |||||

| 10 | 28465 | 19381 | 8716* | ||||

| 12,5 | 36941 | 29670 | 17047 | 9556* | |||

| 15 | 45217 | 39152 | 29054 | 16542 | 10545* | ||

| 17,5 | 53377 | 48173 | 39513 | 26298 | 16782 | 11603 | |

| 20 | 61465 | 56906 | 49323 | 38716 | 25085 | 17362 | |

| 25 | 3,2 | 2863* | |||||

| 4 | 5595* | ||||||

| 4,4 | 7448* | ||||||

| 5 | 10774* | ||||||

| 6 | 15392 | 4710* | |||||

| 7,5 | 21760 | 9209* | |||||

| 10 | 31627 | 21535 | 9684* | ||||

| 12,5 | 41046 | 32966 | 18941 | 10617* | |||

| 15 | 50241 | 43502 | 32283 | 18381 | 11717* | ||

| 17,5 | 59308 | 53525 | 43903 | 29220 | 18646 | 12892 | |

| 20 | 68295 | 63229 | 54804 | 43018 | 27873 | 19291 | |

| 25 | 86124 | 82060 | 75308 | 65869 | 53741 | 37786 | |

| 27,5 | 3,2 | 3149* | |||||

| 4 | 6154* | ||||||

| 4,4 | 8193* | ||||||

| 5 | 11851* | ||||||

| 6 | 16932 | 5181* | |||||

| 7,5 | 23936 | 10130* | |||||

| 10 | 34790 | 23688 | 10652* | ||||

| Ultimate flexibility λmax ≤ 150 (uprights, attachments, support braces) | |||||||

| 3,2 | 3,2 | 366* | |||||

| 4 | 3,2 | 458* | |||||

| 4 | 895* | ||||||

| 4,4 | 3,2 | 504* | |||||

| 4 | 985* | ||||||

| 4,4 | 1311* | ||||||

| 5 | 3,2 | 573* | |||||

| 4 | 1119* | ||||||

| 4,4 | 1490* | ||||||

| 5 | 2155* | ||||||

| 6 | 3,2 | 687* | |||||

| 4 | 1343* | ||||||

| 4,4 | 1788* | ||||||

| 5 | 2586* | ||||||

| 6 | 3694 | 1130* | |||||

| 7,5 | 3,2 | 859* | |||||

| 4 | 1678* | ||||||

| 4,4 | 2234* | ||||||

| 5 | 3232* | ||||||

| 6 | 4618 | 1413* | |||||

| 7,5 | 6528 | 2763* | |||||

| 10 | 3,2 | 1145* | |||||

| 4 | 2238* | ||||||

| 4,4 | 2979* | ||||||

| 5 | 4309* | ||||||

| 6 | 6157 | 1884* | |||||

| 7,5 | 8704 | 3684* | |||||

| 10 | 12651 | 8614 | 3874* | ||||

| 12,5 | 3,2 | 1432* | |||||

| 4 | 2797* | ||||||

| 4,4 | 3724* | ||||||

| 5 | 5387* | ||||||

| 6 | 7696 | 2355* | |||||

| 7,5 | 10880 | 4605* | |||||

| 10 | 15814 | 10767 | 4842* | ||||

| 12,5 | 20523 | 16483 | 9470 | 5309* | |||

| 15 | 3,2 | 1718* | |||||

| 4 | 3357* | ||||||

| 4,4 | 4469* | ||||||

| 5 | 6464* | ||||||

| 6 | 9235 | 2826* | |||||

| 7,5 | 13056 | 5526* | |||||

| 10 | 18976 | 12921 | 5810* | ||||

| 12,5 | 24628 | 19780 | 11365 | 6370* | |||

| 15 | 30145 | 26101 | 19370 | 11028 | 7030* | ||

| 17,5 | 3,2 | 2004* | |||||

| 4 | 3916* | ||||||

| 4,4 | 5214* | ||||||

| 5 | 7542* | ||||||

| 6 | 10775 | 3297* | |||||

| 7,5 | 15232 | 6447* | |||||

| 10 | 22139 | 15074 | 6779* | ||||

| 12,5 | 28732 | 23076 | 13259 | 7432* | |||

| 15 | 35169 | 30451 | 22598 | 12866 | 8202* | ||

| 17,5 | 41515 | 37468 | 30732 | 20454 | 13052 | 9025 | |

| 20 | 3,2 | 2290* | |||||

| 4 | 4476* | ||||||

| 4,4 | 5958* | ||||||

| 5 | 8619* | ||||||

| 6 | 12314 | 3768* | |||||

| 7,5 | 17408 | 7368* | |||||

| 10 | 25302 | 17228 | 7747* | ||||

| 12,5 | 32837 | 26373 | 15153 | 8494* | |||

| 15 | 40193 | 34801 | 25826 | 14704 | 9374* | ||

| 17,5 | 47446 | 42820 | 35122 | 23376 | 14917 | 10314 | |

| 20 | 54636 | 50583 | 43843 | 34414 | 22298 | 15433 | |

| 22,5 | 3,2 | 2577* | |||||

| 4 | 5035* | ||||||

| 4,4 | 6703* | ||||||

| 5 | 9696* | ||||||

| 6 | 13853 | 4239* | |||||

| 7,5 | 19584 | 8288* | |||||

| 10 | 28465 | 19381 | 8716* | ||||

| 12,5 | 36941 | 29670 | 17047 | 9556* | |||

| 15 | 45217 | 39152 | 29054 | 16542 | 10545* | ||

| 17,5 | 53377 | 48173 | 39513 | 26298 | 16782 | 11603 | |

| 20 | 61465 | 56906 | 49323 | 38716 | 25085 | 17362 | |

| 25 | 3,2 | 2863* | |||||

| 4 | 5595* | ||||||

| 4,4 | 7448* | ||||||

| 5 | 10774* | ||||||

| 6 | 15392 | 4710* | |||||

| 7,5 | 21760 | 9209* | |||||

| 10 | 31627 | 21535 | 9684* | ||||

| 12,5 | 41046 | 32966 | 18941 | 10617* | |||

| 15 | 50241 | 43502 | 32283 | 18381 | 11717* | ||

| 17,5 | 59308 | 53525 | 43903 | 29220 | 18646 | 12892 | |

| 20 | 68295 | 63229 | 54804 | 43018 | 27873 | 19291 | |

| 25 | 86124 | 82060 | 75308 | 65869 | 53741 | 37786 | |

| 27,5 | 3,2 | 3149* | |||||

| 4 | 6154* | ||||||

| 4,4 | 8193* | ||||||

| 5 | 11851* | ||||||

| 6 | 16932 | 5181* | |||||

| 7,5 | 23936 | 10130* | |||||

| 10 | 34790 | 23688 | 10652* | ||||

| *— When you hover over a table cell with a number marked with an asterisk, a tooltip appears showing the maximum height of a rack of a given section and the maximum load at which the flexibility of the rack does not exceed the limit value for this type of structure. If the load or height of the rack exceeds the specified values, the rack will lose stability (bend more than the normalized limit). | |||||||

A post in Diagram B can support a load four times greater than a post in Diagram A. A post in Diagram B can support 8 times the load of Post A and twice that of rack B. The rack, fixed according to scheme D, can withstand a load 16 times greater than rack A, 4 times greater than rack B, and 2 times greater than rack B. (“Strengthening material for a carpenter”).

A post in Diagram B can support a load four times greater than a post in Diagram A. A post in Diagram B can support 8 times the load of Post A and twice that of rack B. The rack, fixed according to scheme D, can withstand a load 16 times greater than rack A, 4 times greater than rack B, and 2 times greater than rack B. (“Strengthening material for a carpenter”).

Recalculation of the table values for any other values of the calculated resistance R should be done by subtracting the beam’s own weight (volume, m³ × 0.51 kg/m³) from the values given in the table (white and beige cells) and multiplying the resulting number by the transition coefficient. The transition coefficient is calculated by dividing the required and available design resistance.

Source

Loads on wooden structures

If floor beams are used, you should consider what load will be applied overall. This takes into account:

- own weight of a wooden beam;

- weight from inter-beam filling, i.e. insulation, waterproofing, etc.;

- sheathing

The calculation is carried out taking into account what kind of insulation is used, what pitch of beams is taken (the amount of material depends on this). The issue of insulation should be taken seriously. A cold attic will lead to higher heating costs, this is approximately 15% additional costs

. To insulate the attic, you can purchase fiberglass or basalt slabs. They are relatively lightweight and can be installed quickly.

The weight of furniture, equipment and people is taken into account. Usually the value is taken on average at 50 kg/m² for hemming and inter-beam filler. The operational load according to SNiP 2.01.07-85 for the floor in this case will be equal to:

70 * 1.3 = 90 kg/m², while

“70” is the standard, and 1.3 is the so-called safety factor.

The total value is:

50 + 90 = 130 kg/m².

The value should be rounded up, resulting in a figure of 150. If heavy material is purchased for insulation, the overall value will be different. It will be 245 or 250 kg/m².

50 + 1.3*150, where 150 kg/m² is the standard value.

If the attic is used as living space, then the calculated load level increases to 350 kg/m².

This should not be forgotten, otherwise the structure will not be as strong as necessary. For ordinary interfloor structures, a standard value of 350-400 kg/m² is used.