Any housing intended for permanent residence of a person needs to create thermal comfort, and a frame house in this regard is no exception. Stove heating is the traditional and most common method of heating rooms in a wooden house remote from the gas main. Find out which stove is best to choose and how to install it correctly and safely.

Design features of the installation

Typically, a fireplace appears to be a massive structure made of brick or stone. This design is distinguished by its heaviness, the weight of which we could not afford. Since the house is being built using energy-efficient frame technology, its distinctive feature is its relatively low weight, which does not require a heavy foundation. Since the entire structure stands on piles, each of them has its own load-bearing capacity, which cannot be exceeded. Therefore, the main criteria were:

- lightness of design, up to 500 kg;

- the ability to heat at least one floor out of two;

- aesthetic appeal.

During the design of the house, the option of installing a fireplace was discussed, so a separate pile with a load-bearing capacity of 2.5 tons was designed for it. But what a surprise we were when we found it not at the installation site, but on the same line as the wall stilts! It was no longer possible to correct this mistake.

Due to inexperience, when screwing in, we only checked the level, approximate location and quantity, but completely forgot about the base of the fireplace. While thinking, I contacted the designer, who suggested light fireplace systems. They can be installed without a special foundation, since the weight is relatively light. The answer to our doubts was the argument of ordinary wardrobes, the weight of which when filled reaches 700 kg.

Decorative finishing

The most creative aspect of making a fireplace is its decorative finish.

How to imitate fire

To create a picture of a fake flame, you can use 3D holograms with stereo effects, LCD technologies and digital panels.

Can be applied:

- an ordinary dummy painted on the back wall;

- LCD TV;

- Christmas tree garland with control of light transmission against the background of a 3D image;

- salt electric lamp;

- decorative firewood made of plastic or ceramics with or without internal lighting.

The listed materials are perfectly combined into a single composition and can both complement each other and create accents.

How to clad the roof

The cladding option depends on the material from which the portal is made. For strong structures made of brick, plywood, plasterboard or chipboard, you can use something heavier.

Such as:

- boards;

- artificial stone floor tiles;

- plywood scraps lined with laminate, porcelain stoneware or glass mosaic.

For more fragile structures, you can use the same material as for the false fireplace, painted in the same or contrasting color.

What to put in the firebox and how to decorate the back wall

If you need to decorate an electric fireplace, then the depth of the niche for it should be at least 40 cm, and it needs an outlet. In other options, a depth of 20 cm is sufficient.

A wide variety of elements can be placed in the firebox:

- candles with and without scent;

- real or artificial logs;

- large pebbles mixed with other colorful pebbles;

- diode tape along the contour of the bottom of the fireplace under transparent plexiglass, on which pebbles can be laid;

- cover the back wall with a photograph or draw the composition yourself;

- vases with flowers, figurines of different sizes and even soft toys.

Decorations for the back wall are selected depending on what will be in the firebox itself.

Finish options:

- continuation of the portal;

- cladding with plastic or gypsum “brick”;

- a painted or pasted picture;

- mirror tiles of different sizes or solid panels;

- mosaic tiles or small tiles with ornaments.

Even without a live flame, a false fireplace can bring a touch of calm and tranquility to an everyday evening.

Power calculation

A light fireplace stove for a country house consists of a firebox and a frame called a portal. Understanding that the installation process would take a lot of effort and money, we wanted to end up with not only a beautiful interior element, but also an element of the home heating system. Heating is planned for a while, but warmth on cool autumn evenings is always very welcome. It was clear that one firebox could not cope with heating the entire area, so the plan was to heat at least the first floor.

Having studied materials from construction portals, we realized that 1 kW of furnace power is designed to heat 10 square meters of area. And since our house has an area of 160 square meters, then, based on half, the firebox should be from 8 kW and above.

Stove heating in a frame house: pros and cons

Stove heating has many advantages:

- Independence. Residents of the house independently provide themselves with their preferred type of fuel and maintain a comfortable temperature, regardless of external factors.

- Relative simplicity and accessibility. If you have a diagram for laying out the rows and follow simple rules, you can lay out the oven with your own hands. Or simply purchase a factory-made oven.

- Low operating costs. This is due to the ability to use various types of fuel, including firewood.

- The variety of types of stoves gives scope for choosing the most suitable option, taking into account all the requirements for thermal comfort in the house.

But do not forget about the disadvantages of stove heating:

- Physical costs. The stove needs regular lighting, so it is necessary to add fuel quite often, as well as provide a place for its storage.

- The massiveness of the structure. Some types of furnaces may even require their own foundation . In addition, the large size of the heating stove entails a loss of room space.

- Fire hazard. When planning to install a stove in a frame house, we must not forget about the increased risk of fire, because such buildings are made of wood. The risk is aggravated by the high temperature of the furnace elements and the possibility of burning coals and sparks entering the room.

- Uneven heating of rooms.

Selection of firebox and portal

It seems that knowing the technical characteristics, it is not difficult to make a choice via the Internet. A large number of manufacturers and intermediaries offer a huge selection for every taste. But, once you start studying the assortment, you realize that the color and size may differ significantly from the picture on the website. Therefore, it was decided to visit the exhibition “Stoves, fireplaces, barbecues” at Crocus Expo.

The assortment at such exhibitions is large and, as a rule, manufacturers, wanting to advertise themselves, show the best of their products for different price categories. After the agony of choice, preference was given to the assembled kit from one of the intermediary companies.

Firebox from the Hungarian manufacturer Technical, model PanTherm Optimum. The determining factors were:

- price in the middle range;

- Topi power 10 kW;

- cast iron, which should not be deformed;

- attractive appearance.

Having paid the full price, we ordered delivery to the site and began preparing for the start of work.

How to choose a stove for your home

Comfort and beauty must be combined with practicality and functionality. Therefore, when choosing stoves for your home, it is worth considering some important points.

The main purpose

If you plan to live permanently, you should opt for one of the types of stoves with good thermal inertia. Indeed, in this case it will be necessary to maintain constant heat, minimizing financial costs as much as possible. If we are talking about a country house, a fireplace will be enough. Or, as an alternative, a fireplace stove.

Choice of power and location

Typically, the required power is determined at the rate of 1 kW per 10 square meters of area; the average value of 2.5 m is taken as the height of the shelf. When purchasing a ready-made factory version of the furnace, the rated power is indicated in the technical data sheet of the device. Do-it-yourself options require more complex calculations.

Master's choice

Almost the future of the entire house depends on how competently the installation of the fireplace stove is carried out. It is necessary to know and strictly follow the technology to avoid deformation of the system, as well as the possibility of fire.

Considering that the majority of customers for fireplace system installation services do not want to deal with the intricacies of the technical side, a large number of companies greatly inflate prices, intimidating consumers with terms and the complexity of the process. At this point we were already seasoned customers. With the help of hired teams:

- they built a box of a house and covered it with a roof;

- made external cladding with log siding;

- We ordered the interior rough finishing with greenboard.

Performers for all these works were looked for on an Internet portal where specialists offer their services. We focused on the number of works, reviews and registration deadlines. If the contractor has been registered for a long time, has positive reviews and has completed many orders, then you can trust him.

As we understand, baking is shrouded in a veil of some strange mystery. During the period of consideration of candidates, many mysteriously did not name the final prices for the work, opaquely describing the strange schemes for constructing the chimney. One of these “specialists” spent about an hour trying to find out at least some prices to no avail. Later, the same person on a construction forum offered to break half of the house for us in order to remove the pipe, and we joyfully understood that refusing the services of such experts was a very right decision.

The choice was made on a man who did not ask for exorbitant fees; having understood the technology several years ago, he installed a fireplace in his home and now took orders for installation. We later learned that he was the deputy chief engineer of a large airline that had recently gone bankrupt, and we realized that the decision was the right one.

Classic fireplace design

The design of the fireplace consists of the following elements:

- The combustion chamber is the space in which fuel combustion occurs.

- Firebox - the lower part of the firebox made of fireproof material.

- Fireplace mouth (hailo) is a stove element that serves to remove combustion products directly into the chimney.

- The lintel and ceiling, the space from the ceiling of the firebox to the mantelpiece, serves to collect smoke, from which the smoke enters the chimney.

- A tooth or gas threshold, its purpose is to prevent soot from falling from the chimney into the firebox.

- Smoke exhaust - provides the removal of carbon monoxide and the supply of oxygen, which is needed to maintain combustion.

The grate is an element that distributes air as it moves into the fireplace firebox. When building a classic fireplace, you need to pay attention to the following important points:

- the thickness of the seams should not exceed 4 mm, as this can result in a poor-quality and fragile structure;

- the cross-section of the chimney is taken equal to 1/16 of the area of the portal window;

- the volume of the fireplace window should be 20 times less than the volume of the room, and the ratio of its height and width should be 2:3;

- in the case when the firebox is equipped with your own hands, it is better to make its internal corners rounded in order to better remove combustion residues and to avoid the accumulation of soot on the walls;

- you should take a responsible approach to choosing a mortar for masonry;

- A cap is installed at the end of the chimney to protect the structure from contamination.

In modern fireplaces, increasing efficiency and maintaining the amount of air in the room is achieved by a certain organization of heat exchange. The air under the grate is not taken from the room, but comes from outside. To do this, holes are made in the floor of the room to supply air flow into the channels from the back wall of the firebox.

Thus, the heated air masses move to the heater just below the pass, then following into the room. As a result, the air takes heat from the combustion products and, transferring it to the room, reduces the temperature of the exiting gas.

This technological solution does not fully solve the problem of removing air from the room. For this reason, a fireplace stove in a frame house should not be installed in rooms with an area of less than 20 square meters. m.

Beginning of work

Before starting installation, it was necessary to decide on the chimney. The following varieties exist:

- brick;

- ceramic;

- sandwich

On the advice of the master, we took a sandwich type chimney, manufactured by the Research Institute of KM. Russian manufacturer, reliable, steel 1 mm thick. Having purchased the necessary elements in two steps, we took everything to the house.

The first unpleasant moment was that the diameter of the outlet from the firebox to the chimney was too small. This problem was solved with the help of an adapter. Still, it is better when the chimney has a larger diameter.

The second nuance was the lack of a stand for installing the firebox flush with the portal opening. Most likely they simply forgot to put it down during loading from the exhibition, but since a lot of time had passed, it was too late to look for it. Our master was not at a loss, and in a couple of hours he built a stand from metal profiles by welding and painted it with a special black paint.

Before the construction of the box began, a “fitting” was carried out, when, using a simple addition of elements, they looked at the finished portal with a firebox and chose the shape of the structure around the pipes.

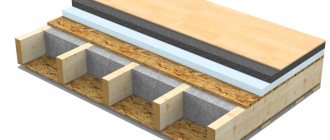

Required thermal insulation materials

Stone wool 50 mm thick serves as a fire shield between the chimney and other building elements. It is necessary to take this moment responsibly, especially when it comes to transition nodes in the areas of interfloor and attic floors.

The fireclay core and facing parts are sometimes separated by basalt cardboard, which has low thermal conductivity. Thanks to this thermal insulation layer, the temperature of the working core is maintained and the outer part of the fireplace does not overheat.

The tightness of the junction of metal elements to the brickwork is ensured using sealants that can withstand high temperatures. If this is not done, there will not be good draft in the chimney, which means the performance of the heating structure will decrease.

Assembly

The design of the box is a closed, sealed cabinet made of guides and special heat-resistant pink plasterboard. They didn’t find it for regular sale, so I had to order it and go pick it up at a large wholesale warehouse. A special heat-resistant insulation is placed inside the structure, we chose Rockwool Fire Batts, and everything is carefully sealed. For this we used steel heat-resistant foil tape from Izospan.

There is a misconception that stone wool gets into the air, but after we insulated the entire house with this material with our own hands, we could say for sure that it had nowhere to fly, since all possible leakage points were blocked.

Under the portal, tiles were laid, which, according to fire safety standards, formed a platform in front. Installation work was already underway on it. Between the greenboard-clad wall and the chimney, additional insulation and a mineralite sheet were laid.

Since no one in our family is a stove specialist, a topic was created on the construction portal in the appropriate section with the involvement of our master.

This was done with the expectation that nuances and shortcomings could be corrected online while work was underway. But, fortunately, apart from the incomprehensible phrases of the failed contractor who received a refusal from us, no one found any more errors in the installation.

The installation took eight days. During this time the following was done:

- a portal with a firebox on a stand was installed;

- chimney assembled;

- the box design is arranged according to all the rules;

- two hatches installed;

- a passage was made through the interfloor ceiling;

- pipes were brought to the roof;

- insulation has been installed in the attic;

- a protective fungus has been installed;

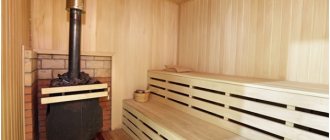

The first trip is unforgettable. When, after the chaos of building materials and discussions on the Internet, you light a fire and watch how it slowly flares up and then burns calmly - it’s unforgettable.

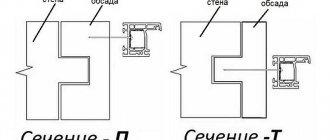

Bottom frame of frame structure

Before laying the timber, the heads are installed on the piles

Before starting work, you need to place the heads on the supports. If channel piping is chosen, the parts are attached directly to them. If beams are used, flanges must first be attached to the heads. This is done by welding. These parts have a width similar to that of the bars used. The joints must be lubricated with a composition that protects against corrosion.

The bars are often connected using the “claw” method. From the end parts, the element is sawed at an angle so that the width of the cut is identical to the thickness of the building material itself. Another option for tying is “half a tree”. Here the block is sawed lengthwise. In this case, the width will also be equal to the thickness of the element.

To protect the material from deterioration due to moisture, a waterproofing layer is used. Ruberoid or polyethylene is suitable for its organization. It must be laid in areas where wood and metal come into contact. If the timber is placed on a concrete grillage, the latter must be insulated with two layers of roofing material and bitumen mastic.

The piping begins at the corners, where the first adjacent elements are connected. A simple triangle is suitable for checking perpendicularity. Instead of ordinary nails, it is better to use self-tapping screws to fasten the strapping elements - they are easier to unscrew during repairs. One bar is connected to another with staples or metal plates.

Sometimes double tying is practiced. In this case, the first row of bars has a square cross-section with a side of 0.2 m, the second is rectangular, with dimensions of 0.1 by 0.15 m. The top row is placed on the smaller side.

Exploitation

During the first start, a chemical smell is felt. This is the burning of oils and lubricants. Then, everything went away. Heating was carried out regularly throughout the summer season. They burned with briquettes and wood. During all this time, it was overheated only once, after which the steel changed its color to bluish. After reading on the Internet, we concluded that this is a common option.

The structure has been standing quietly and working properly for a long time. Glass can be easily cleaned with wet newspaper soaked in ash, without any chemicals. The contractor was left with positive feedback and given the best recommendations. The cost of the entire installation with work and materials was as of September 2022. 74,000 rubles.

Since we are building a house for ourselves, trying not to attract borrowed funds, the process is not moving very quickly. Over the past period, other large-scale work has been completed, so the external finishing of the box is still in the plans.

Despite the fact that installing a fireplace is a difficult, slow and expensive process, the installation was worth all the costs. It's nice to sit near the fireplace, warm your feet and enjoy the cozy warmth, listening to the crackling of the firewood.

We thank Irina from the Moscow region for the material provided, who together with her family is building a warm and cozy frame house. You can read the story with a photo report about the cladding of this house here.

Follow new materials on the website GreenSector.ru so as not to miss interesting stories about country construction and site development!

Ardenfire (META, Russia)

GC Meta specializes in the manufacture of stoves, fireboxes, linings and accessories for stove equipment. This is a Russian manufacturer, 20 years on the market. The range of fireplace stoves we are interested in includes products made of steel and cast iron. The latter are produced in a separate Ardenfire line, in particular, models Marseille 7, 10 and 14. Despite the fact that the company is Russian, all components are supplied from abroad - only assembly and testing are carried out in the Russian Federation. Thus, cast iron parts come from France, sealing cords from Germany, glass for installation in doors from Japan. Among the features of the Marcel model: a large glass in the door with a “clean glass” system, firewood and brown coal can be used as fuel, and there is a secondary afterburning. Main characteristics of Ardenfire Marseille stoves from META

| Characteristic | Ardenfire Marseille 7 | Ardenfire Marseille 10 | Ardenfire Marseille 14 |

| power, kWt | 7 | 10 | 14 |

| Volume of heated room, m³ | 150 | 200 | 250 |

| Maximum log length, mm | 350 | 350 | 400 |

| Chimney diameter, mm | 150 | ||

| Size, mm | 364x410x800 | 415x513x977 | 439x550x1130 |

| Weight, kg | 80 | 103 | 130 |

| price, rub. | 41 250 | 60 000 | 64 000 |

Impressions from use. Powerful cast iron stoves that easily fit into the interior of a country house. Large firebox, suitable for standard size firewood. Heat from the body is transferred by radiation, so the room is not heated as quickly as in designs with convection elements. Long-term burning is not provided, but due to the massiveness of the stove, it cools down within 2-3 hours with an average burning time of 2 hours per stack. The design is simple, but the large glass area of the door gives it a special charm due to the mesmerizing view of burning logs.

View the Marcel 14 model in action:

Making a support platform

The supporting platform for the furnace on a pile foundation can be made in the form of a reinforced concrete slab or a thick metal sheet with an anti-corrosion coating.

The first option is more suitable for bored and driven reinforced concrete piles, while sheet metal will be the optimal and more economical solution for screw piles. In the latter case, the sheet is welded to the strapping channel. The optimal size of the support platform is chosen so that there is a margin of at least 5 cm on each side of the oven.

Advantages of screw rods

Screw piles are increasingly used in private construction to lay foundations for houses and separately for furnaces.

The demand for products is explained by their advantages:

- Lowest construction costs.

- Significant load capacity.

- Non-flammability.

- The ability to plunge into the ground with your own hands without renting equipment.

- Resistant to the buoyancy forces of frost heaving.

- Maintainability.

- Possibility of strengthening the foundation in case of reconstruction of the furnace.